EP0828980B1 - Wärmetauscher - Google Patents

Wärmetauscher Download PDFInfo

- Publication number

- EP0828980B1 EP0828980B1 EP96909112A EP96909112A EP0828980B1 EP 0828980 B1 EP0828980 B1 EP 0828980B1 EP 96909112 A EP96909112 A EP 96909112A EP 96909112 A EP96909112 A EP 96909112A EP 0828980 B1 EP0828980 B1 EP 0828980B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heat exchanger

- medium

- plate

- heat

- cooled

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Revoked

Links

- 239000002826 coolant Substances 0.000 claims description 10

- 229910000679 solder Inorganic materials 0.000 claims description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 2

- 229910052782 aluminium Inorganic materials 0.000 claims description 2

- 238000002485 combustion reaction Methods 0.000 claims description 2

- 239000012530 fluid Substances 0.000 claims 2

- 239000004411 aluminium Substances 0.000 claims 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 12

- 238000010276 construction Methods 0.000 description 4

- 239000000498 cooling water Substances 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 239000007788 liquid Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F9/00—Casings; Header boxes; Auxiliary supports for elements; Auxiliary members within casings

- F28F9/02—Header boxes; End plates

- F28F9/0246—Arrangements for connecting header boxes with flow lines

- F28F9/0251—Massive connectors, e.g. blocks; Plate-like connectors

- F28F9/0253—Massive connectors, e.g. blocks; Plate-like connectors with multiple channels, e.g. with combined inflow and outflow channels

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D9/00—Heat-exchange apparatus having stationary plate-like or laminated conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D9/00—Heat-exchange apparatus having stationary plate-like or laminated conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall

- F28D9/0031—Heat-exchange apparatus having stationary plate-like or laminated conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall the conduits for one heat-exchange medium being formed by paired plates touching each other

- F28D9/0043—Heat-exchange apparatus having stationary plate-like or laminated conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall the conduits for one heat-exchange medium being formed by paired plates touching each other the plates having openings therein for circulation of at least one heat-exchange medium from one conduit to another

- F28D9/005—Heat-exchange apparatus having stationary plate-like or laminated conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall the conduits for one heat-exchange medium being formed by paired plates touching each other the plates having openings therein for circulation of at least one heat-exchange medium from one conduit to another the plates having openings therein for both heat-exchange media

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F9/00—Casings; Header boxes; Auxiliary supports for elements; Auxiliary members within casings

- F28F9/02—Header boxes; End plates

- F28F9/0246—Arrangements for connecting header boxes with flow lines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D21/00—Heat-exchange apparatus not covered by any of the groups F28D1/00 - F28D20/00

- F28D2021/0019—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for

- F28D2021/008—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for for vehicles

- F28D2021/0089—Oil coolers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F2280/00—Mounting arrangements; Arrangements for facilitating assembling or disassembling of heat exchanger parts

- F28F2280/06—Adapter frames, e.g. for mounting heat exchanger cores on other structure and for allowing fluidic connections

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S165/00—Heat exchange

- Y10S165/906—Reinforcement

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S165/00—Heat exchange

- Y10S165/916—Oil cooler

Definitions

- the invention relates to a heat exchanger, in particular an oil cooler for internal combustion engines, according to the preamble of claim 1.

- a heat exchanger is known from WO-A-95/00 810.

- DE-OS 32 10 114 is a heat exchanger, in particular a Radiator known for motor vehicles.

- This heat exchanger is there of several tubes arranged in parallel to each other for guidance of the heat exchange medium. These pipes open into an upper and a lower water tank.

- the heat exchanger also consists of arranged lamellar and perpendicular to the pipes plate-shaped heat exchange fins fixed to the pipes are connected.

- heat exchange fins are bent at their front edges Provide end parts, which are superimposed like a scale and thus form side parts on which fastening devices for Angle can be arranged.

- the well-known heat exchanger is built with relatively simple elements and a good one Has heat transfer has the disadvantage that for attachment of the heat exchanger on a support additional angles required are.

- the connections for the Heat exchangers in the upper and lower water tanks fixed and not variable.

- a heat exchanger is also known from DE-GM 93 09 741, in which on one side of the heat exchanger element Outlet for the medium to be cooled and on the other side Inlet and outlet for the cooling medium, i.e. the heat exchange medium is provided.

- This arrangement is characterized by a simple structure. In many cases, however, it is desirable arrange all inflows and outflows on a single page.

- a plate heat exchanger is known from WO 95/00810. This has a stack of heat exchanger plates on. An end plate is provided with the appropriate connections for two heat transfer media.

- a disadvantage of this device is that the connections are due to the construction of the heat exchanger are predefined. An adaptation to different connection structures is due to the structure of these Device not possible.

- the invention is therefore based on the object To create heat exchangers that can be used universally and without Enlargement of the building volume can also be connected where all inflows and outflows are arranged on one side.

- a major advantage of the invention is that it by means of the distributor plate, also the inlet and outlet to integrate for the cooling medium. Are in the distributor plate the corresponding inlet and outlet openings are provided for this.

- Distribution plate arranged a mounting plate.

- a distributor plate and form the mounting plate as a one-piece element.

- the two-piece configuration is preferred Distribution plate and mounting plate soldered together.

- Another embodiment of the invention provides that To build the distribution plate out of individual plate elements are sandwiched on top of each other. This has the advantage that Flow channels of different types or with crossings in the individual plate elements can be provided. In order to can also be complicated flow patterns in the Realize distribution plate.

- Another embodiment of the invention provides for the individual Parts of the heat exchanger made of solder-plated aluminum to manufacture. This can be soldered in a continuous furnace

- the distributor plate is also advantageously in its sandwich-like construction in the last heat exchanger element integrated. By integrating this plate, the overall height of the entire heat exchanger element is not enlarged. At the same time but are all connections in this distribution plate contain.

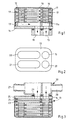

- a heat exchanger which consists of several arranged parallel to each other and by a heat exchange medium flows through, plate-shaped heat exchange elements 10.

- These heat exchange elements are on the circumferential outer edges 11 bent and lamellar to a heat exchanger package stacked on top of each other.

- the top end of the heat exchanger package forms a cover plate 12.

- the lower end forms a Distribution plate 13 in combination with a mounting plate 14.

- Distribution plate 13 and mounting plate 14 can also be made be made in one piece. But there is also Possibility to form this in two parts from two stamped parts.

- the connection of the individual heat exchanger elements 10 to one another and with the cover plate 12 and the distributor plate 13 by soldering. For this purpose, the individual components with a Coated solder material.

- the medium to be cooled for example oil, flows through the bore 15 into the mounting plate 14 and Distributor plate 13 and then into the heat exchanger, is distributed over the individual levels according to arrows 16 and leaves the heat exchanger through the bore 18th

- FIG. 2 shows a top view of the distributor plate 13 shown.

- the opening 21 is in the distributor plate 13 for the cooling water inlet and the opening 22 for the Cooling water outlet provided. It is from this illustration can be seen that both the feed holes for the cooling oil as well as channels for transmission to any Positions are positionable.

- the distributor plate enables one Connection of the heat exchanger to any connection form. Of course there is also the possibility of Distribution plate with shoulders, recesses or the like to design and thus to a variety of different Adapting fastening structures.

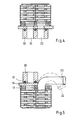

- FIG. 3 shows a variant of a heat exchanger with a Distribution plate 13 which is designed in a sandwich construction.

- This Distribution plate 13 consists of the individual parts 23, 24, 25. Due to the sandwich structure, there is the possibility of Liquid flows in the individual levels differ too distribute so that they can cross each other.

- connection for the cooling medium are also that Cooling water shown.

- the connecting pieces 27 are on the housing 30 for the water inlet and connecting piece 28 for the Water return arranged.

- the housing 30 is with the Attachment plate 14 connected. Between mounting plate and There is a profile seal 29 in the housing.

- FIG. 4 A variant in which a sandwich-like structure is also used

- the adapter plate is shown in FIG. 4. In this figure is the water outlet 22 and the oil inlet 15 can be seen.

- Figure 5 shows a variant in which both the water outlet as well as the water inlet as connecting pieces 32, 33 pulled out and deflected by 90 ° or by more than 90 °.

- the Connection pieces are preferably with the distributor plate attached via a solder joint while the oil inlet and the Oil leakage - as shown in FIG. 4 - via a housing 30 he follows. Again, the seal between the Mounting plate 14 and the housing therein a groove 31st cast in which a sealing ring or sealing element is inserted is. This seal is a processing of the cast Part 30 not required. So that is less Manufacturing effort a tight connection between the oil cooler and the outer structure of a housing.

- Figure 6a shows the base plate 14 with the oil inlet 15 and diagonally arranged oil outlet 20, and the Water inlet 21 and water outlet 22.

- this is Plate member 25 shown.

- In this is for water entry 22 a longitudinal slot 34 is arranged.

- Plate element 24 shown. This is as a cordon Plate element designed.

- Figure 6d shows for the Water outlet 21 a cross connection 35 and a Cross connection 36 for the oil outlet 20.

- Figure 6e is the first tub 11a shown with its connection openings for Water entry and exit and for oil entry and exit.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19519740A DE19519740B4 (de) | 1995-06-02 | 1995-06-02 | Wärmetauscher |

| DE19519740 | 1995-06-02 | ||

| PCT/EP1996/001252 WO1996038699A1 (de) | 1995-06-02 | 1996-03-22 | Wärmetauscher |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0828980A1 EP0828980A1 (de) | 1998-03-18 |

| EP0828980B1 true EP0828980B1 (de) | 2000-11-15 |

Family

ID=7763187

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96909112A Revoked EP0828980B1 (de) | 1995-06-02 | 1996-03-22 | Wärmetauscher |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US5964283A (ja) |

| EP (1) | EP0828980B1 (ja) |

| JP (1) | JP3878671B2 (ja) |

| KR (1) | KR100390235B1 (ja) |

| BR (1) | BR9608420A (ja) |

| DE (2) | DE19519740B4 (ja) |

| ES (1) | ES2153956T3 (ja) |

| WO (1) | WO1996038699A1 (ja) |

| ZA (1) | ZA964398B (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1522811A2 (de) | 2003-10-10 | 2005-04-13 | Modine Manufacturing Company | Wärmetauscher, insbesondere Ölkühler |

| KR20170097156A (ko) * | 2014-12-19 | 2017-08-25 | 말레 인터내셔널 게엠베하 | 자동차의 오일 필터 모듈을 위한 오일 냉각기 |

Families Citing this family (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19628560C1 (de) * | 1996-07-16 | 1997-08-28 | Laengerer & Reich Gmbh & Co | Anschlußadapter, insbesondere für Plattenwärmetauscher |

| DE19654362B4 (de) * | 1996-12-24 | 2007-12-06 | Behr Gmbh & Co. Kg | Wärmeübertrageranordnung |

| DE19711258C2 (de) * | 1997-03-18 | 1999-09-02 | Behr Gmbh & Co | Stapelscheiben-Ölkühler |

| DE19716200A1 (de) * | 1997-04-18 | 1998-10-22 | Funke Waerme Apparate Kg | Plattenwärmeaustauscher |

| DE69936546T2 (de) * | 1998-04-20 | 2008-03-13 | Sundsvall Energi Ab | Verfahren zur Regelung einer Wärmetauscher-Einrichtung |

| DE20010816U1 (de) * | 2000-06-17 | 2001-11-15 | Behr Gmbh & Co, 70469 Stuttgart | Stapelscheiben-Wärmeübertrager |

| US6591807B1 (en) * | 2000-08-25 | 2003-07-15 | Walter Hengst Gmbh & Co Kg | Combination comprising a main unit and at least one add-on functional unit |

| JP4077610B2 (ja) | 2001-03-16 | 2008-04-16 | カルソニックカンセイ株式会社 | ハウジングレス式オイルクーラ |

| FR2832791B1 (fr) * | 2001-11-28 | 2004-07-09 | Valeo Thermique Moteur Sa | Echangeur de chaleur pour un circuit de fluide de refroidissement, notamment pour vehicule automobile |

| DE10260030A1 (de) | 2001-12-21 | 2003-07-03 | Behr Gmbh & Co | Wärmeübertrager, insbesondere für ein Kraftfahrzeug |

| FR2850740B1 (fr) * | 2003-01-31 | 2006-11-24 | Valeo Thermique Moteur Sa | Echangeur de chaleur a plaques a haute tenue a la pression, en particulier pour circuit de climation de vehicule automobile |

| DE10304733A1 (de) * | 2003-02-06 | 2004-08-19 | Modine Manufacturing Co., Racine | Plattenwärmetauscher |

| DE10336030A1 (de) * | 2003-08-01 | 2005-02-24 | Behr Gmbh & Co. Kg | Wärmeübertrager sowie Platte für einen Wärmeübertrager |

| DE102004003790A1 (de) * | 2004-01-23 | 2005-08-11 | Behr Gmbh & Co. Kg | Wärmetauscher, insbesondere Öl-/Kühlmittel-Kühler |

| DE102004004975B4 (de) * | 2004-01-31 | 2015-04-23 | Modine Manufacturing Co. | Plattenwärmeübertrager |

| DE102004031567A1 (de) * | 2004-06-29 | 2006-02-02 | Behr Gmbh & Co. Kg | Wärmeübertrager |

| EP3276291B1 (en) | 2005-10-05 | 2019-07-24 | Dana Canada Corporation | Dish plate heat exchanger with reinforcement element |

| KR100762297B1 (ko) | 2005-11-14 | 2007-10-01 | 한희선 | 알루미늄 라디에이터 주수구 접합구조 및 접합방법 |

| DE102006031608A1 (de) * | 2006-07-06 | 2008-01-17 | Behr Gmbh & Co. Kg | Wärmetauscher-Filter-Anordnung, insbesondere für ein Kraftfahrzeug |

| KR100837655B1 (ko) * | 2008-03-17 | 2008-06-13 | 주식회사 엘에치이 | 판형 열교환기 |

| DE102008032816A1 (de) * | 2008-07-11 | 2010-01-14 | Mahle International Gmbh | Konditioniermodul zum Konditionieren von an sich ruhenden Flüssigkeiten |

| SE533067C2 (sv) * | 2008-10-03 | 2010-06-22 | Alfa Laval Corp Ab | Plattvärmeväxlare |

| DE102009007186A1 (de) | 2009-02-03 | 2010-08-05 | Modine Manufacturing Co., Racine | Plattenwärmetauscher |

| DE102009050016A1 (de) * | 2009-05-27 | 2011-05-05 | Modine Manufacturing Co., Racine | Wärmeübertragereinheit |

| US8375917B1 (en) | 2009-07-23 | 2013-02-19 | Gene Neal | Engine oil cooler |

| FR2950682B1 (fr) | 2009-09-30 | 2012-06-01 | Valeo Systemes Thermiques | Condenseur pour vehicule automobile a integration amelioree |

| DE102011009647A1 (de) * | 2010-01-27 | 2012-05-10 | Behr Gmbh & Co. Kg | Wärmeübertrager |

| DE102010027923A1 (de) * | 2010-04-19 | 2011-10-20 | Behr Gmbh & Co. Kg | Stapelscheibenkühler |

| EP2413045B1 (de) * | 2010-07-30 | 2014-02-26 | Grundfos Management A/S | Wärmetauschereinheit |

| FR2967248B1 (fr) * | 2010-11-10 | 2015-01-23 | Valeo Systemes Thermiques | Echangeur de chaleur fluide/fluide |

| WO2013159172A1 (en) | 2012-04-26 | 2013-10-31 | Dana Canada Corporation | Heat exchanger with adapter module |

| JP6420140B2 (ja) * | 2014-12-26 | 2018-11-07 | 株式会社マーレ フィルターシステムズ | オイルクーラ |

| EP3124907B1 (en) * | 2015-07-29 | 2019-04-10 | Zhejiang Sanhua Automotive Components Co., Ltd. | Heat exchange device |

| JP6616115B2 (ja) * | 2015-07-30 | 2019-12-04 | 株式会社マーレ フィルターシステムズ | 熱交換器 |

| DE102015221528A1 (de) * | 2015-11-03 | 2017-05-04 | Mahle International Gmbh | Wärmeübertragermodul |

| JP6671170B2 (ja) | 2015-12-28 | 2020-03-25 | 株式会社マーレ フィルターシステムズ | 熱交換器 |

| JP2018044710A (ja) * | 2016-09-14 | 2018-03-22 | カルソニックカンセイ株式会社 | 熱交換器 |

| KR20190074362A (ko) * | 2017-12-20 | 2019-06-28 | 주식회사 경동나비엔 | 열교환기 |

| US11274884B2 (en) | 2019-03-29 | 2022-03-15 | Dana Canada Corporation | Heat exchanger module with an adapter module for direct mounting to a vehicle component |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH604208A5 (ja) * | 1974-06-11 | 1978-08-31 | Ciba Geigy Ag | |

| DE2840522A1 (de) * | 1977-10-05 | 1979-04-19 | Alfa Laval Ab | Plattenwaermetauscher |

| DE3210114A1 (de) * | 1982-03-19 | 1983-09-22 | Süddeutsche Kühlerfabrik Julius Fr. Behr GmbH & Co KG, 7000 Stuttgart | Waermetauscher, insbesondere kuehler fuer kraftfahrzeuge |

| US4561494A (en) * | 1983-04-29 | 1985-12-31 | Modine Manufacturing Company | Heat exchanger with back to back turbulators and flow directing embossments |

| DE3341263A1 (de) * | 1983-11-15 | 1985-05-23 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Waermetauscher |

| US4708199A (en) * | 1985-02-28 | 1987-11-24 | Kabushiki Kaisha Tsuchiya Seisakusho | Heat exchanger |

| FR2656412B1 (fr) * | 1989-12-21 | 1995-02-17 | Valeo Thermique Moteur Sa | Echangeur de chaleur a lames, en particulier pour le refroidissement de l'huile de lubrification d'un vehicule automobile. |

| SE9000712L (sv) * | 1990-02-28 | 1991-08-29 | Alfa Laval Thermal | Permanent sammanfogad plattvaermevaexlare |

| SE467275B (sv) * | 1990-05-02 | 1992-06-22 | Alfa Laval Thermal Ab | Loedd dubbelvaeggig plattvaermevaexlare med bockade kanter |

| US5099912A (en) * | 1990-07-30 | 1992-03-31 | Calsonic Corporation | Housingless oil cooler |

| JP2823139B2 (ja) * | 1990-07-30 | 1998-11-11 | カルソニック株式会社 | ハウジングレス式オイルクーラのコア部 |

| JP2521328Y2 (ja) * | 1990-08-06 | 1996-12-25 | カルソニック株式会社 | 自動変速機用オイルクーラ |

| DE4037969A1 (de) * | 1990-11-29 | 1992-06-04 | Schmidt Bretten W Gmbh | Plattenwaermeaustauscher |

| SE502254C2 (sv) * | 1990-12-17 | 1995-09-25 | Alfa Laval Thermal Ab | Plattvärmeväxlare och förfarande för framställning av en plattvärmeväxlare |

| JP2558019Y2 (ja) * | 1992-09-24 | 1997-12-17 | カルソニック株式会社 | オイルクーラ |

| FR2697621B1 (fr) * | 1992-11-03 | 1995-01-13 | Ciat Sa | Echangeur de chaleur à plaques. |

| DE4313506A1 (de) * | 1993-04-24 | 1994-10-27 | Knecht Filterwerke Gmbh | Ölkühler in Scheibenbauweise |

| DE4314808C2 (de) * | 1993-05-05 | 2003-10-30 | Behr Gmbh & Co | Plattenwärmetauscher, insbesondere Öl/Kühlmittel-Kühler |

| DE9309741U1 (de) * | 1993-06-30 | 1993-08-26 | Filterwerk Mann & Hummel Gmbh, 71638 Ludwigsburg | Wärmetauscher |

| SE502984C2 (sv) * | 1993-06-17 | 1996-03-04 | Alfa Laval Thermal Ab | Plattvärmeväxlare med speciellt utformade portpartier |

| DE9309805U1 (de) * | 1993-07-01 | 1993-08-26 | Filterwerk Mann & Hummel Gmbh, 71638 Ludwigsburg | Wärmetauscher in Scheibenbauweise |

| DE19511991C2 (de) * | 1995-03-31 | 2002-06-13 | Behr Gmbh & Co | Plattenwärmetauscher |

| US6075678A (en) * | 1998-03-24 | 2000-06-13 | Quantum Corporation | Pivoting lever cam guide tape head positioner |

-

1995

- 1995-06-02 DE DE19519740A patent/DE19519740B4/de not_active Expired - Lifetime

-

1996

- 1996-03-22 ES ES96909112T patent/ES2153956T3/es not_active Expired - Lifetime

- 1996-03-22 KR KR1019970708725A patent/KR100390235B1/ko not_active IP Right Cessation

- 1996-03-22 DE DE59606144T patent/DE59606144D1/de not_active Revoked

- 1996-03-22 US US08/952,691 patent/US5964283A/en not_active Expired - Lifetime

- 1996-03-22 BR BR9608420A patent/BR9608420A/pt not_active IP Right Cessation

- 1996-03-22 EP EP96909112A patent/EP0828980B1/de not_active Revoked

- 1996-03-22 WO PCT/EP1996/001252 patent/WO1996038699A1/de active IP Right Grant

- 1996-03-22 JP JP53612596A patent/JP3878671B2/ja not_active Expired - Lifetime

- 1996-05-29 ZA ZA964398A patent/ZA964398B/xx unknown

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1522811A2 (de) | 2003-10-10 | 2005-04-13 | Modine Manufacturing Company | Wärmetauscher, insbesondere Ölkühler |

| US7533717B2 (en) | 2003-10-10 | 2009-05-19 | Modine Manufacturing Company | Heat exchanger, especially oil cooler |

| KR20170097156A (ko) * | 2014-12-19 | 2017-08-25 | 말레 인터내셔널 게엠베하 | 자동차의 오일 필터 모듈을 위한 오일 냉각기 |

| KR101868306B1 (ko) * | 2014-12-19 | 2018-06-15 | 말레 인터내셔널 게엠베하 | 자동차의 오일 필터 모듈을 위한 오일 냉각기 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0828980A1 (de) | 1998-03-18 |

| US5964283A (en) | 1999-10-12 |

| JPH11506532A (ja) | 1999-06-08 |

| ZA964398B (en) | 1996-12-09 |

| WO1996038699A1 (de) | 1996-12-05 |

| KR100390235B1 (ko) | 2003-10-23 |

| BR9608420A (pt) | 1998-12-29 |

| ES2153956T3 (es) | 2001-03-16 |

| DE59606144D1 (de) | 2000-12-21 |

| JP3878671B2 (ja) | 2007-02-07 |

| DE19519740B4 (de) | 2005-04-21 |

| KR19990022246A (ko) | 1999-03-25 |

| DE19519740A1 (de) | 1996-12-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0828980B1 (de) | Wärmetauscher | |

| EP0653043B1 (de) | Wärmetauscher | |

| DE69626295T2 (de) | Plattenwärmetauscher | |

| DE19549801B4 (de) | Plattenwärmetauscher | |

| DE112014004486B4 (de) | Wärmetauscher mit integriertem koaxialen Einlass-/Auslassrohr | |

| DE60130274T2 (de) | Wärmetauscher mit paralleler Fluidströmung | |

| DE10393221B4 (de) | Anordnung für einen Plattenwärmetauscher | |

| DE102004036951A1 (de) | Wärmeübertrager sowie Verfahren zu dessen Herstellung | |

| EP0623798A2 (de) | Plattenwärmetauscher, insbesondere Öl/Kühlmittel-Kühler | |

| DE112018004787T5 (de) | Multi-fluid wärmetauscher | |

| EP0928405A2 (de) | Plattenwärmetauscher, insbesondere öl/kühlmittel-kühler für kraftfahrzeuge | |

| DE112009000888T5 (de) | Kalibrierte Umgehungsstruktur für einen Wärmetauscher | |

| DE20307881U1 (de) | Wärmeaustauscher, insbesondere Ladeluftkühler | |

| EP2863157B1 (de) | Wärmeübertrager | |

| DE102017219433B4 (de) | Wärmeübertrager für einen Verbrennungsmotor | |

| DE19709601A1 (de) | Plattenwärmeübertrager | |

| DE69500676T2 (de) | Wärmetauscher | |

| DE102017119119A1 (de) | Wärmeaustauscher | |

| DE102004002252B4 (de) | Wärmeübertrager für Fahrzeuge | |

| DE20121112U1 (de) | Sammelkasten für einen Wärmeaustauscher, insbesondere an Kraftfahrzeugen | |

| DE69613918T2 (de) | Wärmetauscher mit Adapter | |

| DE69311789T2 (de) | Wärmetauscher | |

| DE102005059920B4 (de) | Wärmetauscher, insbesondere Verdampfer | |

| DE4327213C2 (de) | Rekuperativer Wärmetauscher, insbesondere Kühler für Kraftfahrzeuge | |

| EP0819906B1 (de) | Anschlussadapter für Plattenwärmetauscher |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19971127 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE ES FR GB IT SE |

|

| 17Q | First examination report despatched |

Effective date: 19990208 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT SE |

|

| REF | Corresponds to: |

Ref document number: 59606144 Country of ref document: DE Date of ref document: 20001221 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20010209 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2153956 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: MODINE EUROPE GMBH Effective date: 20010707 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| RDAH | Patent revoked |

Free format text: ORIGINAL CODE: EPIDOS REVO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030226 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20030304 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20030311 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030314 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20030321 Year of fee payment: 8 |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| 27W | Patent revoked |

Effective date: 20030407 |

|

| GBPR | Gb: patent revoked under art. 102 of the ep convention designating the uk as contracting state |

Free format text: 20030407 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: ECNC |

|

| APAA | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOS REFN |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |