EP0808946B1 - Schienenbefestigung - Google Patents

Schienenbefestigung Download PDFInfo

- Publication number

- EP0808946B1 EP0808946B1 EP96108053A EP96108053A EP0808946B1 EP 0808946 B1 EP0808946 B1 EP 0808946B1 EP 96108053 A EP96108053 A EP 96108053A EP 96108053 A EP96108053 A EP 96108053A EP 0808946 B1 EP0808946 B1 EP 0808946B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fact

- rail

- rail fastening

- anchor element

- fastening according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B9/00—Fastening rails on sleepers, or the like

- E01B9/02—Fastening rails, tie-plates, or chairs directly on sleepers or foundations; Means therefor

- E01B9/28—Fastening on wooden or concrete sleepers or on masonry with clamp members

- E01B9/30—Fastening on wooden or concrete sleepers or on masonry with clamp members by resilient steel clips

- E01B9/303—Fastening on wooden or concrete sleepers or on masonry with clamp members by resilient steel clips the clip being a shaped bar

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B9/00—Fastening rails on sleepers, or the like

- E01B9/02—Fastening rails, tie-plates, or chairs directly on sleepers or foundations; Means therefor

- E01B9/04—Fastening on wooden or concrete sleepers or on masonry without clamp members

- E01B9/10—Screws or bolts for sleepers

Definitions

- the present invention relates to a Concrete sleepers or the like pre-assembled Rail fastening, which is on both sides of the rail on the Rail attachment point is arranged and each an elastic clamp spring and an angular one Has guide plate, the guide plate with one side on the rail foot and on that of the rail opposite side with an inclined surface on one corresponding support surface of a recess Concrete sleeper or the like is applied and the Guide plate and the clamping spring by means of a in the Anchored concrete sleeper or the like Fasteners held in their pre-assembly position be and the clamping spring in the final assembly position presses the rail foot.

- Such a rail attachment is from the DE 39 18 091 A1 known.

- the tension clamps from the pre-assembly position as far as Moved towards the rail until it was on the Side facing away from the rail in a in the angle guide plate engage trained guide groove and press their free ends onto the rail foot.

- the position is then dismantled by the Threshold screws using a torque wrench be tightened until a desired clamping force is reached, the middle part of the tension clamp in one comes to a small distance above the rail foot.

- This known rail fastening is characterized by a easy pre-assembly as well as a simple transition from the Pre-assembly in the final assembly position after inserting the Rail off.

- the angle guide plates sure that horizontal forces are directly on the concrete sleepers are transmitted and thus only pure tensile forces on the Threshold screws act so that they do not can solve automatically.

- Screwless rail fastening systems require special Anchoring in the sleepers.

- Systems are known where springs, for example, parallel to the rail or be threaded perpendicular to the rail. Also exist in the prior art systems in which a spring end in one opening is inserted, after which the second Spring end by lever into a second half-open bracket use.

- EP 0 373 099 A1 describes one on concrete sleepers pre-assembled rail fastener known, the one elastic clamping spring and an angular guide plate having.

- the clamping spring is in one piece with it trained fasteners in the form of a Anchor element provided in a concrete sleeper cast sleeve is anchored. For this is the sleeve at one end with a radial extension provided, in the radial at the end of the anchor element protruding paragraph can be screwed.

- the tension the clamping spring takes place in that this with a cooperates on the guide plate arranged ramp.

- the guide plate is relatively flat. Accordingly, it is due to its facing away from the rail Side on a relatively small, essentially vertical support surface of a recess in the concrete sleeper on. This guide plate can therefore only be used relatively Introduce low horizontal forces into the concrete sleeper.

- the present invention is based on the object a rail fastening of the type mentioned above improve that besides the benefits of screwed Rail fastening systems, such as the direct derivation of Horizontal forces in the concrete body, an even faster and easier rail mounting.

- the fastener is an anchor element attached to one within the Threshold mounted cam plate attacks when Twisting the anchor element tensioning the clamping spring causes.

- the solution according to the invention represents a kind Quick release represents an almost foolproof Rail assembly guaranteed. By maintaining the for taken known angular guide plate this in turn ensures that only tensile forces, however, no shear forces act on the anchor element.

- Clamping springs can e.g. Tension clamps, so-called fast clips or the like are used.

- a preferred embodiment of the invention Rail fastening is characterized in that the Cam is stepped and at least has a ramp-shaped section over which the Clamping spring is tensioned when the anchor element is rotated.

- the anchor element is preferably lockable. to The anchor element can be locked in the cam disc one or more rest stages are formed, which different degrees of tension assigned to the clamping spring are.

- the cam disc a first rising has ramp-shaped section, which in a first Resting stage passes, to which an in turn increases second ramp-shaped section that connects into a second rest stage passes, the first rest stage one Pre-assembly position and the second locking step one Final assembly position corresponds.

- the ramped sections can be different Have slopes, preferably the slope of the first section is larger than that of the second Section. In this way, the torque increase be reduced when tensioning the clamping spring, so that turning the anchor element into the final assembly position is relieved accordingly.

- Anchor claws should be formed.

- the anchor element To attach a wrench or another suitable tool, the anchor element have standardized railroad screw head. Alternatively, it can also be useful if the Head of the anchor element is designed so that only a special one, but not a commercially available one Wrench can be attached. In this way unauthorized persons prevent the anchoring from being loosened or at least difficult. For example, that Anchoring element an internal key approach have and / or with an opening or holding part be provided for the attachment of a crossbar.

- the cam in one in the Concrete sleeper arranged housing is held that preferably consists of plastic. That way it is possible to put the cam with the housing directly in to integrate the concrete sleeper in its manufacture.

- the housing serves as a placeholder and the electrical track insulation, provided it is made of plastic or another electrically insulating material is made.

- the anchor element can also be in a sleeve made of plastic or another electrical insulating material.

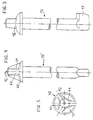

- 1 and 2 is the rail fastening according to the invention on the left half of the picture in the Final assembly position and on the right half of the picture in the Pre-assembled position shown, namely in Fig. 1 in a central longitudinal section through a concrete sleeper 1 and in Fig. 2 in a plan view, but the Concrete sleeper omitted and the rail 2 outside the Epsilon-shaped clamping springs 3 is cut off.

- the left side shows the track exterior and the right side the track interior, with the rail 2 in the track exterior in the assembled state and in the track interior in pre-assembled state is shown.

- the rail 2 the here using the example of the well-known UIC 60 rail profile is shown using a vibration damping Liner 4 on the concrete sleeper 1 between two angular guide plates 5, the Rail axis in a known manner in a fixed Ratio of e.g. 1:40 compared to the vertical to Track interior is inclined.

- the angular ones Guide plates 5 each have a longitudinal rib 6, with which they rest on the rail foot 7.

- the guide plates 5 each have an inclined surface 8 with which they the side facing away from the rail 2 on one corresponding support surface 9 of a recess 10 in the Apply concrete sleeper 1.

- Anchor elements 15, each having a clamping spring 3 holding head 16 and an angled end 17th have, which on a within the concrete sleeper 1st stored cam 18 attacks.

- the cams 18 are each inserted in a plastic housing 19, with which they are used in the manufacture of the concrete sleeper 1 poured into the concrete mass.

- the housing 19 can be aligned obliquely so that the central axis of the anchor element 15 used therein Intersects the rail axis below the rail (see Fig. 1).

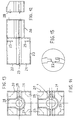

- the housing 19 is composed of two parts 20, 21 together, with a slight press fit through a tongue and groove connection 22 can be positively connected to one another are (see Figs. 14 and 15).

- the housing 19 forms a chamber-like section 23, which has a rectangular cross section.

- the Cam 18 is accordingly with an im provided substantially rectangular shaped paragraph 24, such as can be seen particularly well in FIG. 9.

- Paragraph 24 is in the upper area of the chamber-like Housing section 23 by four lying in one plane Support ribs 25 held so that the cam 18 in the axial direction of the anchor element 15 is fixed.

- On the chamber-shaped section 23 closes in the direction a tubular housing section of the threshold top 26 with a keyhole-shaped cross section one round and one essentially rectangular Has partial area 27 or 28.

- the rectangular one Partial area 28 is bevelled on the upper side, so that the Housing 19 in concrete just below each Recess 10 arranged for the angle guide plate 5 can be.

- the housing 19 is on the underside an opening 29 provided with a recess 30 in the underside of the threshold meets (see FIG. 1).

- the anchor element 15 can with its angled End section 17 from the top of the concrete sleeper 1 through an elongated hole-like opening 31 within the Guide plate 5 through the channel-shaped Section 26 in the chamber-like housing section 23 be introduced.

- the Cam 18 on a U-shaped opening 32 with the channel-shaped housing section 26 meets, so that the angled end 17 of the anchor element 15th easily pass cam 18 and on it can attack on the underside.

- the cam disc 18 has a first ramp-shaped Section 33 with a relatively large slope on the passes into a first trough-shaped locking step 34. On this first locking step 34 closes a second ramped section 35, which is a smaller Has slope and into a second trough-shaped Locking step 36 passes (see. Fig. 9 to 11).

- the first Locking step 34 serves to lock the anchor element 15 in the pre-assembly position.

- the epsilon-shaped Clamping springs 3 After the rail 2 between the angle guide plates 5 using the liner 4 on the Concrete sleeper 1 is placed, the epsilon-shaped Clamping springs 3 from the pre-assembly position in Pushed towards the rail 2 so that their free Press leg ends 12 onto the rail foot 7 and the leg 37 facing away from rail 2 in the longitudinal groove 38 engage the guide plate 5.

- the angled end section 17 becomes the final assembly position of the anchor element 15 then from the first latching step 34 via the second ramp-shaped section 35 into the second locking step 36 rotated and finally there again locked.

- the shaft of the anchor element 15 looping middle part 39 of the clamping spring 3 comes at a slight distance above the rail foot 7 lie. In this way, the rail 1 with a certain tension force pressed onto the concrete sleeper 1 (see right and left half of Fig. 1).

- the rod-shaped anchor element 15 can be released instead a railroad sleeper screw head 16 preferably a specially designed head 40 exhibit.

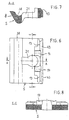

- 4 and 5 is an example of one such special anchor element 15 'shown.

- the head 40 this anchor element 15 ' has three at about 120 ° offset polygonal attachment surfaces 41 for one appropriately trained special keys.

- At the The top of the head 40 is also a bore 42 arranged in the one on the special key (not shown) provided guide pin can be inserted.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Railway Tracks (AREA)

- Clamps And Clips (AREA)

- Connection Of Plates (AREA)

- Fuel-Injection Apparatus (AREA)

Description

- Fig. 1

- einen Querschnitt durch ein Schienenprofil mit einer erfindungsgemäßen Schienenbefestigung, bei welchem die linke Seite die Endmontagestellung im Gleisaußenraum und die rechte Seite die Vormontagestellung im Gleisinnenraum im Schnitt darstellt;

- Fig. 2

- eine Draufsicht auf das Schienenprofil und die Schienenbefestigung gemäß Fig. 1;

- Fig. 3

- in Seitenansicht ein stangenförmiges Ankerelement mit einem Vierkantkopf und einem abgewinkelten Endabschnitt;

- Fig. 4

- in Seitenansicht ein anderes Ausführungsbeispiel eines stangenförmigen Ankerelements mit einem besonders ausgestalteten Kopfabschnitt;

- Fig. 5

- eine Draufsicht auf den Kopfabschnitt gemäß Fig. 4;

- Fig. 6

- eine Draufsicht auf eine Winkelführungsplatte für die erfindungsgemäße Schienenbefestigung;

- Fig. 7

- einen Querschnitt durch die Winkelführungsplatte gemäß Fig. 6 entlang der Linie A-A;

- Fig. 8

- einen Querschnitt durch die Winkelführungsplatte gemäß Fig. 6 entlang der Linie E-E;

- Fig. 9

- eine Draufsicht auf eine Kurvenscheibe für die erfindungsgemäße Schienenbefestigung;

- Fig. 10

- einen Querschnitt durch die Kurvenscheibe gemäß Fig. 9 entlang der Linie A-A;

- Fig. 11

- den abgewickelten Außendurchmesser der Kurvenscheibe gemäß Fig. 9;

- Fig. 12

- eine Seitenansicht eines zweiteiligen, in Längsrichtung geteilten Gehäuses zur Aufnahme der Kurvenscheibe;

- Fig. 13

- eine Draufsicht auf das Gehäuse gemäß Fig. 12 in zusammengesetztem Zustand;

- Fig. 14

- eine Draufsicht auf das Gehäuse gemäß Fig. 12 in geöffnetem Zustand; und

- Fig. 15

- eine vergrößerte schematische Darstellung des Details Z der Fig. 14.

- 1

- Betonschwelle

- 2

- Schiene

- 3

- Klemmfeder (Spannklemme)

- 4

- Zwischenlage

- 5

- Winkelführungsplatte

- 6

- Längsrippe an der Winkelführungsplatte 5

- 7

- Schienenfuß

- 8

- Schrägfläche an der Winkelführungsplatte 5

- 9

- Stützfläche an der Betonschwelle 1

- 10

- Aussparung in der Betonschwelle 1

- 11

- Innenschenkel der Federklemme 3

- 12

- freie Schenkelenden der Federklemme 3

- 13

- Anschläge an der Winkelführungsplatte 5

- 14

- innere Führungsrinnen der Winkelführungsplatte 5

- 15

- Ankerelement

- 16

- Vierkantschraubenkopf

- 17

- abgewinkelter Endabschnitt des Ankerelements 15

- 18

- Kurvenscheibe

- 19

- Gehäuse

- 20

- erstes Gehäuseteil

- 21

- zweites Gehäuseteil

- 22

- Feder-Nut-Verbindung

- 23

- kammerartiger Gehäuseabschnitt

- 24

- Absatz an der Kurvenscheibe 18

- 25

- Stützrippen

- 26

- rohrförmiger Gehäuseabschnitt

- 27

- runder Teilbereich des rohrförmigen Abschnittes 26

- 28

- rechteckiger Teilbereich des rohrförmigen Abschnittes 26

- 29

- unterseitige Gehäuseöffnung

- 30

- Ausnehmung in der Betonschwelle 1

- 31

- Öffnung in der Winkelführungsplatte 5

- 32

- U-förmige Öffnung der Kurvenscheibe 18

- 33

- erster rampenförmiger Abschnitt der Kurvenscheibe 18

- 34

- erste Raststufe der Kurvenscheibe 18

- 35

- zweiter rampenförmiger Abschnitt der Kurvenscheibe 18

- 36

- zweite Raststufe der Kurvenscheibe 18

- 37

- von der Schiene 2 abgewandte Schenkel der Klemmfeder 3

- 38

- Führungsrille in der Winkelführungsplatte 5

- 39

- Mittelteil der Klemmfeder (Spannklemme) 3

- 40

- Ankerkopf

- 41

- Ansatzflächen für Spezialwerkzeug

- 42

- Bohrung im Ankerkopf 40

Claims (18)

- Auf Betonschwellen (1) oder dergleichen vormontierbare Schienenbefestigung, die beidseitig der Schiene (2) an der Schienenbefestigungsstelle angeordnet ist und jeweils eine elastische Klemmfeder (3) und eine winkelförmige Führungsplatte (5) aufweist, wobei die Führungsplatte (5) mit einer Seite am Schienenfuß (7) und auf der der Schiene (2) abgewandten Seite mit einer Schrägfläche (8) an einer entsprechenden Stützfläche einer Aussparung der Betonschwelle (1) oder dergleichen anliegt und wobei die Führungsplatte (5) und die Klemmfeder (3) mittels eines in der Betonschwelle (1) oder dergleichen verankerten Befestigungsmittels in ihrer Vormontagestellung gehalten werden und die Klemmfeder (3) in der Endmontagestellung auf den Schienenfuß (7) drückt,

dadurch gekennzeichnet, daß das Befestigungsmittel ein Ankerelement (15) ist, das an einer innerhalb der Schwelle (1) gelagerten Kurvenscheibe (18) angreift, die beim Verdrehen des Ankerelements (15) ein Spannen der Klemmfeder (3) bewirkt. - Schienenbefestigung nach Anspruch 1,

dadurch gekennzeichnet, daß die Kurvenscheibe (18) stufenförmig ausgebildet ist und mindestens einen rampenförmigen Abschnitt (33; 35) aufweist. - Schienenbefestigung nach Anspruch 1 oder 2,

dadurch gekennzeichnet, daß die Kurvenscheibe (18) eine oder mehrere Raststufen (34; 36) aufweist. - Schienenbefestigung nach Anspruch 2 oder 3,

dadurch gekennzeichnet, daß die Kurvenscheibe (18) einen ersten ansteigenden rampenförmigen Abschnitt (33) aufweist, der in eine erste Raststufe (34) übergeht, an die sich ein wiederum ansteigender zweiter rampenförmiger Abschnitt (35) anschließt, der in eine zweite Raststufe (36) übergeht, wobei die erste Raststufe (34) einer Vormontagestellung und die zweite Raststufe (35) einer Endmontagestellung entspricht. - Schienenbefestigung nach Anspruch 4,

dadurch gekennzeichnet, daß die rampenförmigen Abschnitte (33; 35) unterschiedliche Steigungen aufweisen. - Schienenbefestigung nach einem der vorangehenden Ansprüche,

dadurch gekennzeichnet, daß das Ankerelement (15) einen abgewinkelten, an der Kurvenscheibe (18) angreifenden Endabschnitt (17) aufweist. - Schienenbefestigung nach einem der vorangehenden Ansprüche,

dadurch gekennzeichnet, daß das Ankerelement (15) einen genormten Schraubenkopf (16) aufweist. - Schienenbefestigung nach einem der Ansprüche 1 bis 6,

dadurch gekennzeichnet, daß das Ankerelement (15) einen Kopf (40) aufweist, an den ein spezieller Schraubenschlüssel, jedoch kein im Handel erhältlicher Schraubenschlüssel formschlüssig angesetzt werden kann, so daß ein Lösen des Ankerelements (15) durch Unbefugte verhindert wird. - Schienenbefestigung nach einem der vorangehenden Ansprüche,

dadurch gekennzeichnet, daß die Kurvenscheibe (18) in einem in der Betonschwelle (1) angeordneten Gehäuse (19) gehalten ist. - Schienenbefestigung nach Anspruch 9,

dadurch gekennzeichnet, daß das Gehäuse (19) aus Kunststoff besteht. - Schienenbefestigung nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, daß das Ankerelement (15) mit einem Kunststoffmantel versehen ist.

- Schienenbefestigung nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, daß das Ankerelement (15) in einer Hülse aus Kunststoff oder einem anderen elektrisch isolierenden Material angeordnet ist.

- Schienenbefestigung nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, daß die Klemmfeder (3) aus der Vormontagestellung in die Endmontagestellung verschiebbar ist.

- Schienenbefestigung nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, daß die Führungsplatte (5) eine Führungsrille (38) aufweist, in welche die Klemmfeder (3) in der Endmontagestellung eingreift.

- Schienenbefestigung nach Anspruch 14,

dadurch gekennzeichnet, daß die Führungsplatte (5) eine langlochartige Öffnung (31) aufweist, durch die der abgewinkelte Endabschnitt (17) des Ankerelements (15) hindurchgesteckt werden kann. - Schienenbefestigung nach Anspruch 14 oder 15,

dadurch gekennzeichnet, daß die Klemmfeder (3) eine derart gebogen ausgebildete Spannklemme ist, daß deren Innenschenkel (11) das Ankerelement (15) umschlingen und durch das Ankerelement (15) übergriffen werden. - Schienenbefestigung nach Anspruch 16,

dadurch gekennzeichnet, daß die Führungsplatte (5) mit Anschlägen (13) versehen ist, an denen die freien Enden (12) der Spannklemme (3) in der Vormontagestellung anliegen. - Schienenbefestigung nach Anspruch 16,

dadurch gekennzeichnet, daß die Klemmfeder (3) eine epsilonförmig ausgebildete Spannklemme ist.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT96108053T ATE215150T1 (de) | 1996-05-21 | 1996-05-21 | Schienenbefestigung |

| DE59608964T DE59608964D1 (de) | 1996-05-21 | 1996-05-21 | Schienenbefestigung |

| EP96108053A EP0808946B1 (de) | 1996-05-21 | 1996-05-21 | Schienenbefestigung |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP96108053A EP0808946B1 (de) | 1996-05-21 | 1996-05-21 | Schienenbefestigung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0808946A1 EP0808946A1 (de) | 1997-11-26 |

| EP0808946B1 true EP0808946B1 (de) | 2002-03-27 |

Family

ID=8222803

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96108053A Expired - Lifetime EP0808946B1 (de) | 1996-05-21 | 1996-05-21 | Schienenbefestigung |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0808946B1 (de) |

| AT (1) | ATE215150T1 (de) |

| DE (1) | DE59608964D1 (de) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19807627A1 (de) * | 1998-02-23 | 1999-08-26 | Ortwein | Unterbau für ein aus Schienen gebildetes Gleis für Schienenfahrzeuge |

| RU2300600C2 (ru) * | 2005-01-17 | 2007-06-10 | Общество с ограниченной ответственностью Совместное российско-американское предприятие "Технология XXI века" | Рельсовое скрепление |

| DE102005058465A1 (de) * | 2005-12-07 | 2007-06-28 | Db Netz Ag | Befestigungsmittel zur Befestigung von Bahnschienen auf Gleisschwellen oder Gleisfahrwegen |

| ITTV20060051A1 (it) | 2006-03-30 | 2007-09-30 | Emmetechnic Srl | Elemento elastico |

| ES2283235B1 (es) | 2007-04-04 | 2009-03-01 | Mondragon Soluciones, S.L.U. | Vaina para sujeciones de railes ferroviarios, procedimiento para reemplazar dicha vaina en una traviesa y utiles para ejecutar dicho procedimiento. |

| PL2410090T3 (pl) | 2010-07-19 | 2015-08-31 | Schwihag Ag | System mocowania szyn |

| DE102010060745A1 (de) * | 2010-11-23 | 2012-05-24 | Vossloh-Werke Gmbh | Führungsplatte zum seitlichen Führen einer Schiene und System zum Befestigen einer Schiene |

| DE102012003989B4 (de) | 2012-02-28 | 2022-06-09 | Elisabeth Ortwein | Unterbau für ein aus Schienen gebildetes Gleis für Schienenfahrzeuge |

| CN109910165A (zh) * | 2019-03-21 | 2019-06-21 | 北京好运达智创科技有限公司 | 用于安装高铁轨枕预埋套管的涨紧式定位轴 |

| CN110359325A (zh) * | 2019-08-02 | 2019-10-22 | 太仓中博铁路紧固件有限公司 | 一种钢轨的扣件组装结构及对应的钢轨安装方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8505959U1 (de) * | 1985-03-01 | 1985-06-27 | Vossloh-Werke Gmbh, 5980 Werdohl | Bausatz zur Befestigung von Schienen |

| FR2639971B1 (fr) * | 1988-12-02 | 1991-02-08 | Vape Sa Ets | Bride de fixation rapide d'un rail de chemin de fer et traverse munie d'une telle bride |

| DE8906790U1 (de) * | 1989-06-02 | 1989-08-31 | Vossloh-Werke GmbH, 58791 Werdohl | Schienenbefestigung auf Betonschwellen od.dgl. mittels elastischer Spannklemmen |

-

1996

- 1996-05-21 AT AT96108053T patent/ATE215150T1/de not_active IP Right Cessation

- 1996-05-21 EP EP96108053A patent/EP0808946B1/de not_active Expired - Lifetime

- 1996-05-21 DE DE59608964T patent/DE59608964D1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| ATE215150T1 (de) | 2002-04-15 |

| DE59608964D1 (de) | 2002-05-02 |

| EP0808946A1 (de) | 1997-11-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102008003744B3 (de) | Abstützung für ein System zum Befestigen einer Schiene und System zum Befestigen einer Schiene | |

| DE2314168C3 (de) | Einstückiges Ankerelement für Stehbolzen | |

| DD291593A5 (de) | Schienenbefestigung auf betonschwellen od. dgl. mittels elastischer spannklemmen | |

| DE202007018602U1 (de) | System zum Befestigen einer Schiene | |

| EP0808946B1 (de) | Schienenbefestigung | |

| EP1899613B1 (de) | Schraubanker | |

| EP0194550B1 (de) | Befestigungsklammer und Befestigungsanordnung für Eisenbahnschienen | |

| EP2246577A1 (de) | Befestigungselement | |

| DE102005000129A1 (de) | Befestigungsvorrichtung für die Befestigung von Solarpaneelen an einer Montageschiene | |

| EP1222406B1 (de) | Halter für kopfschrauben | |

| DE4406105A1 (de) | Befestigungsanordnung für eine Schiene | |

| EP0794289A1 (de) | Federnde Schienenbefestigung | |

| DE19642971C2 (de) | Federnde Schienenbefestigung | |

| DE2916003A1 (de) | Befestigungsvorrichtung, insbesondere fuer die verbindung von zwei bauteilen von bauwerken | |

| EP2609255B1 (de) | Schienenbefestigungssystem | |

| EP2039834A1 (de) | Befestigungselement zum Verbinden von öffentlichen Gegenständen wie Poller mit und ohne Beleuchtung, Strassenmobiliar, Strassenschilder, Spielplatzgeräte u. dgl. mit einer im Boden eingesetzten Einbetthülse | |

| DE19604174A1 (de) | Verfahren und Vorrichtung zur Befestigung von Geländerpfosten an einer Betonplatte | |

| DE3620573A1 (de) | Vorrichtung zum befestigen eines gegenstandes an einer wand oder dgl. | |

| EP4332300B1 (de) | Schienenbefestigung mit spannfeder zum niederhalten eines gleiskörperelements | |

| DE4303731A1 (de) | Montageelement und Verfahren zu seiner Befestigung an Profilträgern | |

| DE3509473C2 (de) | ||

| EP1860334A1 (de) | Federsenkmutter sowie elektrische Verschienung mit einer solchen Federsenkmutter | |

| DE10156222C1 (de) | Vorrichtung zur Verankerung von Hohlprofilelementen | |

| DE4418710C2 (de) | Verbindung für mit Zugankern versehene Hausschornsteinelemente | |

| EP1141486A1 (de) | Verankerungsschraube für schwellen und dgl. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19980108 |

|

| 17Q | First examination report despatched |

Effective date: 20000217 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020327 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 20020327 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020327 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020327 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020327 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020327 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020327 |

|

| REF | Corresponds to: |

Ref document number: 215150 Country of ref document: AT Date of ref document: 20020415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59608964 Country of ref document: DE Date of ref document: 20020502 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020521 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020521 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020531 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020627 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020627 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020627 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20020327 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020925 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| EN | Fr: translation not filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20021230 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150520 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59608964 Country of ref document: DE |