EP0615917B1 - Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique - Google Patents

Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique Download PDFInfo

- Publication number

- EP0615917B1 EP0615917B1 EP94107235A EP94107235A EP0615917B1 EP 0615917 B1 EP0615917 B1 EP 0615917B1 EP 94107235 A EP94107235 A EP 94107235A EP 94107235 A EP94107235 A EP 94107235A EP 0615917 B1 EP0615917 B1 EP 0615917B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- turning

- lid

- cylindrical surface

- opening

- turning lid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/20—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge

- B65D47/26—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge with slide valves, i.e. valves that open and close a passageway by sliding over a port, e.g. formed with slidable spouts

- B65D47/261—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge with slide valves, i.e. valves that open and close a passageway by sliding over a port, e.g. formed with slidable spouts having a rotational or helicoidal movement

- B65D47/263—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge with slide valves, i.e. valves that open and close a passageway by sliding over a port, e.g. formed with slidable spouts having a rotational or helicoidal movement between tubular parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/046—Closures with swivelling dispensing devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/20—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge

- B65D47/24—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge with poppet valves or lift valves, i.e. valves opening or closing a passageway by a relative motion substantially perpendicular to the plane of the seat

- B65D47/241—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge with poppet valves or lift valves, i.e. valves opening or closing a passageway by a relative motion substantially perpendicular to the plane of the seat the valve being opened or closed by actuating a cap-like element

- B65D47/242—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge with poppet valves or lift valves, i.e. valves opening or closing a passageway by a relative motion substantially perpendicular to the plane of the seat the valve being opened or closed by actuating a cap-like element moving helically

Definitions

- the invention relates to a rotary closure in the preamble of Claim 1 mentioned Art.

- twist lock in the Neck of a container a plug forming the body with the help of a one-piece Suspension used.

- the stopper consists of a coaxial central post attached to the its axial end one with an axial through hole of the rotary cover cooperating valve body carries. With the help of the suspension, the coaxial Middle post and thus also the valve body with the rotating lid closed axially be pressed inwards, creating the through hole in the rotating lid is released so that the container can be filled from the outside.

- the rotating lid is partially unscrewed, whereby the through hole of the rotary cover of the valve body in the axial Direction away to reveal a free outlet cross section.

- the stopper or the suspension holding the mullion comprises radial ribs on the Inner lateral surface of the body are fixed and with the coaxial mullion are connected.

- DE-A-26 24 354 discloses a dispenser for distributing flowable, liquid Adhesive known, the one of the hollow cylindrical body receiving the adhesive and has a hollow cylindrical sleeve placed on the upper part thereof opens into a discharge surface having a circular cylindrical shape at the top.

- the Body has a recess formed on its upper part Screw thread, which with a on the inner surface of the sleeve as Projection trained corresponding screw thread meshes to a To form a thread that is axial when the sleeve is rotated by approximately 180 ° Displacement of the sleeve relative to the body causes.

- each other axial sides of the sleeve and the body run in one to the axis of the body plane inclined by a certain angle, this angle from the Slope of the threads depends.

- These axial sides are essentially aligned with one another.

- On the top Part of the body is one with a narrow cannula extending upwards screwed cap.

- the cannula forms one at its free end circular cylindrical discharge surface of small diameter to liquid adhesive in small quantities or in areas with limited dimensions to be able to apply.

- the sleeve with the help of the thread in the axial direction upwards until the Discharge surface of the sleeve is aligned with the discharge surface of the cannula to create a to form a relatively large discharge area for applying adhesive.

- the upper The cannula can be opened with the sleeve lowered using a separate cap be closed, which is attached to the sleeve via a flexible retaining strap.

- the object of the invention is to design such a twist lock so that it is simple to manufacture, easy to use and unimpeded Dispensing of contents contained in the body enables.

- this task is performed by the characterizing part of claim 1 specified features.

- the rotary lock according to the invention is characterized in that the Rotary cover with the help of the elliptical guide elements an axial displacement to the body when it is rotated 180 ° relative to it.

- the rotating lid in the open position of the container however, not detached from the body, but rather becomes one in that Rotary cover axially or radially provided opening to open in the body to be able to deliver existing contents to the outside.

- the facing each other axial side edges of both the rotating lid and the body run in one inclined at a certain angle with respect to the axis of the body Level.

- the screw cap and body of the screw cap are also in normal operation the open position are not separated from each other, they are considered separate Items preferably made of plastic, which makes them different Colors can have to give the aesthetic impression of the twist lock optimize.

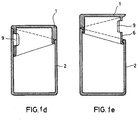

- the rotating lid 1 has one engaging in the interior of the container 2 Shell surface 6, in which they in the radial direction penetrating opening 9 is provided.

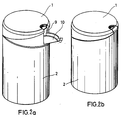

- Embodiment of the twist lock is the provided previously described embodiment radial opening 9 in the rotating lid 1 with a dispensing spout 10 provided by a hinge joint 18 on the outer surface 6 of the rotating lid 1 is articulated.

- the twist lock is the dispensing spout 10 by hand or swung outward by the action of gravity, so that about them the contents in the container 2 can be deliberately released to the outside.

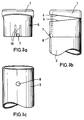

- 3a to 3c is a further embodiment of the twist lock shown to the versatile Applicability of such a screw cap also for to show other purposes.

- this embodiment serves the rotating cover 1 for closing a tube or a hollow cylindrical rod, e.g. For Towel holder or the like can be used.

- On the in the Interior of the body 2 engaging outer surface 6 of the Rotary cover 1 is a locking projection 7 with the help of grooves 19 arranged resiliently.

- This locking tab 7 can in a in the inner surface of the Engage body 2 provided locking recess 8, as shown in particular in Fig. 3b.

- Locking projection 7 and locking recess 8 can not only be arranged in the manner shown here be in which the rotating lid 1 in the "Open position" of the body 2 is locked. As before previously explained, diverge in this "open position” the mutually facing axial sides 4 and 5 of the rotating cover 1 and the body 2.

- locking projection 7 and locking recess 8 in a manner not shown here also be arranged so that they lock together, when the rotating cover 1 is in its "closed position" located in which the mutually facing axial Pages 4 and 5 are aligned.

- rotating lid 1 and the body 2 as separate Parts made for each. Preferably be these parts are injection molded from plastic or in another Manufactured way.

- Rotary lid 1 and body 2 can therefore have different colors to match the aesthetic To further optimize the impression of the screw cap.

- the rotating lid 1 can be different on its outside Shaping and patterning around the aesthetic impression of the required requirements and adapt applications. It can also Rotating lid 1 against another rotating lid 1 at one otherwise the same screw cap can be replaced.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Centrifugal Separators (AREA)

- Pipe Accessories (AREA)

- Glass Compositions (AREA)

- Control Of Motors That Do Not Use Commutators (AREA)

- Prostheses (AREA)

- Closing And Opening Devices For Wings, And Checks For Wings (AREA)

- Seal Device For Vehicle (AREA)

- Pressure Vessels And Lids Thereof (AREA)

- Pens And Brushes (AREA)

- Fluid-Damping Devices (AREA)

Claims (6)

- Fermeture rotative pour l'obturation de l'ouverture d'un corps creux cylindrique (2), un couvercle tournant (1) creux cylindrique mobile à l'intérieur du corps et le corps (2) ayant des éléments de guidage en prise par correspondance de forme les uns avec les autres, qui, lors d'une rotation du couvercle tournant (1), provoquent un déplacement axial du couvercle tournant (1) par rapport au corps (2), caractérisée en ce que les éléments de guidage comprennent un élément de guidage formé sur une zone de la surface latérale du couvercle tournant (1) décalée vers l'intérieur, avançant radialement vers l'extérieur et tournant en ellipse et un élément de guidage formé sur une surface latérale correspondante du corps (2), avançant radialement vers l'intérieur et tournant en ellipse, qui s'étendent chacun dans un plan incliné selon un angle aigu par rapport à l'axe du corps (2), et en ce que les bordures latérales axiales (4, 5) tournées l'une vers l'autre des surfaces latérales de la zone décalée vers l'extérieur du couvercle tournant (1) et du corps (2) s'étendent dans un plan incliné selon cet angle aigu, de telle manière que, dans la position fermée, ces bordures latérales (4, 5) et aussi les surfaces latérales extérieures du couvercle tournant (1) et du corps (2) soient alignées ensemble.

- Fermeture rotative selon la revendication 1, caractérisée en ce que, sur la surface latérale (6) du couvercle tournant (1) s'engageant dans le corps creux cylindrique (2), il est prévu une saillie de verrouillage (7) s'étendant radialement vers l'extérieur, qui peut s'engager de manière élastique dans un évidement de verrouillage (8) correspondant dans la surface latérale intérieure du corps (2) (fig. 3).

- Fermeture rotative selon la revendication 1, caractérisée en ce que, sur la surface latérale (6) du couvercle tournant (1) s'engageant dans le corps creux cylindrique (2), il est prévu une ouverture (9) qui traverse celle-ci de telle manière qu'elle soit complètement masquée par la surface latérale du corps (2) dans la position fermée et dégagée de la surface latérale du corps (2) dans la position d'ouverture obtenue par le déplacement axial, et en ce que le corps (2) est un récipient recevant une matière distribuable par l'ouverture (9) (fig. 1).

- Fermeture rotative selon la revendication 3, caractérisée en ce que l'ouverture (9) est pourvue d'un verseur de distribution (10) monté de manière articulée sur le couvercle tournant (1), qui, lors du déplacement axial du couvercle tournant (1) dans le sens de fermeture, bascule automatiquement dans une position alignée avec la surface latérale (6) du couvercle tournant (1) et obturant l'ouverture (9) (fig. 2).

- Fermeture rotative selon l'une des revendications 1 à 4, caractérisée en ce que le corps (2) et le couvercle tournant (1) sont fabriqués en matière plastique sous la forme d'éléments séparés.

- Fermeture rotative selon l'une des revendications 1 à 5, caractérisée en ce que les éléments de guidage elliptiques conjugués sont munis d'encoches afin de créer des positions de crantage aux points d'extrémité de la rotation à 180°.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8904496U | 1989-04-10 | ||

| DE8904496U DE8904496U1 (de) | 1989-04-10 | 1989-04-10 | Drehverschluß |

| EP90106302A EP0392314B1 (fr) | 1989-04-10 | 1990-04-02 | Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90106302.4 Division | 1990-04-02 | ||

| EP90106302A Division EP0392314B1 (fr) | 1989-04-10 | 1990-04-02 | Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0615917A1 EP0615917A1 (fr) | 1994-09-21 |

| EP0615917B1 true EP0615917B1 (fr) | 1998-07-29 |

Family

ID=6838139

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94107235A Expired - Lifetime EP0615917B1 (fr) | 1989-04-10 | 1990-04-02 | Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique |

| EP90106302A Expired - Lifetime EP0392314B1 (fr) | 1989-04-10 | 1990-04-02 | Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90106302A Expired - Lifetime EP0392314B1 (fr) | 1989-04-10 | 1990-04-02 | Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5135139A (fr) |

| EP (2) | EP0615917B1 (fr) |

| AT (2) | ATE114591T1 (fr) |

| DE (3) | DE8904496U1 (fr) |

| DK (2) | DK0615917T3 (fr) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH680360A5 (fr) * | 1991-09-17 | 1992-08-14 | Supermatic Kunststoff Ag | |

| US5743444A (en) * | 1996-12-06 | 1998-04-28 | Creative Packaging Corp. | Twist dispensing closure |

| US6223957B1 (en) | 2000-02-17 | 2001-05-01 | Richard G. Hoppe | Plug for insertion into and removably sealing an annulus in a nozzle connected to a container of extrudable material and method of use |

| US6422433B2 (en) * | 2000-06-02 | 2002-07-23 | Sussex Technologies, Inc. | Dispensing cap with flexible sealing post |

| US6675995B2 (en) * | 2000-06-05 | 2004-01-13 | Stull Technologies, Inc. | Traversing twist cap |

| US6299038B1 (en) | 2000-09-06 | 2001-10-09 | Courtesy Corporation | Telescoping twist closure |

| US8408432B2 (en) * | 2009-07-16 | 2013-04-02 | Aptar Freyung Gmbh | Dispensing closure |

| BR112012032739A2 (pt) * | 2010-06-23 | 2016-11-08 | Müslüm Yildirim | recipiente distribuidor,e método para formar um recipiente distribuidor. |

| DE202010015802U1 (de) * | 2010-11-25 | 2011-02-10 | Hidde, Axel R., Dr. Ing. | Trinkflaschenverschluß mit Rückstellfunktion |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1917833A (en) * | 1931-12-15 | 1933-07-11 | Henry B Finley | Collapsible tube structure |

| US1997863A (en) * | 1933-03-28 | 1935-04-16 | Hansen James | Valve |

| US2129687A (en) * | 1937-01-19 | 1938-09-13 | Gustav Drews | Collapsible tube closure and method for making the same |

| FR1132199A (fr) * | 1955-10-08 | 1957-03-06 | Salines De Dombasle Sa Des | Bec verseur et récipient sur lequel il est monté |

| DE1736919U (de) * | 1956-10-17 | 1956-12-27 | Eisenwerk Streuber & Lohmann G | Verschraubung fuer behaelter, faesser od. dgl. mit ausziehbarem auslaufrohr. |

| US3342385A (en) * | 1965-12-20 | 1967-09-19 | Johnson & Johnson | Container with closure and dispensing cap |

| US3357605A (en) * | 1966-05-09 | 1967-12-12 | Formold Plastics Inc | Dispensing closure |

| US3370764A (en) * | 1966-12-29 | 1968-02-27 | Stull Engraving Co | Dispensing screw-type closure cap |

| DE1586601A1 (de) * | 1967-01-03 | 1970-06-25 | Martin Espinal | Registrierende Pillenabgabevorrichtung |

| DE1946268C3 (de) * | 1969-09-12 | 1980-01-03 | Friedrich Sanner Kg, 6140 Bensheim | Sicherheitsdose für Medikamente |

| FR2157690B3 (fr) * | 1971-10-25 | 1974-06-07 | Maestracci Charles | |

| DE2353742C2 (de) * | 1973-10-26 | 1983-08-04 | Robert Finke Kunststoff-Spritzguss-Werk, 5950 Finnentrop | Kappenverschluß für Flaschen u. dgl. mit Kinderschutzsicherung |

| DE2624354A1 (de) * | 1976-05-31 | 1977-12-15 | Lingner & Fischer Gmbh | Spender, insbesondere zum verteilen von fliessfaehigem, fluessigem klebstoff |

| DE2644947A1 (de) * | 1976-10-05 | 1978-04-06 | Creative Closure Ass | Verschlusseinrichtung, welche durch druck betaetigbar ist |

| US4234093A (en) * | 1979-05-21 | 1980-11-18 | Tyson Raymond K | Pill dispenser with safety features |

| DE3147903A1 (de) * | 1981-12-03 | 1983-06-16 | Ferber, Rolf, Dr., 8057 Zürich | Scharniergelenkanordnung aus kunststoff |

| FR2575443B1 (fr) * | 1984-12-28 | 1987-10-30 | Air Sec | Fermeture de securite pour tube en matiere plastique |

-

1989

- 1989-04-10 DE DE8904496U patent/DE8904496U1/de not_active Expired - Lifetime

-

1990

- 1990-04-02 DK DK94107235T patent/DK0615917T3/da active

- 1990-04-02 EP EP94107235A patent/EP0615917B1/fr not_active Expired - Lifetime

- 1990-04-02 AT AT90106302T patent/ATE114591T1/de not_active IP Right Cessation

- 1990-04-02 EP EP90106302A patent/EP0392314B1/fr not_active Expired - Lifetime

- 1990-04-02 AT AT94107235T patent/ATE168956T1/de not_active IP Right Cessation

- 1990-04-02 DE DE59007793T patent/DE59007793D1/de not_active Expired - Fee Related

- 1990-04-02 DK DK90106302.4T patent/DK0392314T3/da active

- 1990-04-02 DE DE59010842T patent/DE59010842D1/de not_active Expired - Fee Related

- 1990-04-03 US US07/504,119 patent/US5135139A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0392314B1 (fr) | 1994-11-30 |

| EP0615917A1 (fr) | 1994-09-21 |

| DK0392314T3 (da) | 1995-03-13 |

| EP0392314A3 (en) | 1990-12-05 |

| US5135139A (en) | 1992-08-04 |

| DK0615917T3 (da) | 1999-04-26 |

| EP0392314A2 (fr) | 1990-10-17 |

| DE8904496U1 (de) | 1990-06-21 |

| DE59007793D1 (de) | 1995-01-12 |

| ATE168956T1 (de) | 1998-08-15 |

| DE59010842D1 (de) | 1998-09-03 |

| ATE114591T1 (de) | 1994-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69004182T2 (de) | Rohrförmiger Behälter mit nichtabnehmbarem Abgabeverschluss. | |

| DE69309397T2 (de) | Spenderkappe für einen flüssige Substanzen enthaltenden Behälter mit einem beweglichen Ausgiesser | |

| DE1782279A1 (de) | Fluessigkeitsbehaelter mit Ventilverschluss | |

| DE1486735B1 (de) | Entnahme- oder Ablasshahn | |

| EP0142651B1 (fr) | Brosse à dents ou blaireau muni d'un réservoir | |

| DE2646027A1 (de) | Abgabevorrichtung mit auftragekugel | |

| DE69905855T2 (de) | Spenderkappe für einen flüssige Substanzen enthaltenden Behälter | |

| WO1989000958A1 (fr) | Fermeture pour recipients avec bec verseur escamotable | |

| EP0615917B1 (fr) | Fermeture rotative pour la fermeture de l'ouverture axiale d'un corps creux cylindrique | |

| DE8815673U1 (de) | Spenderbehälter-Verschluß | |

| DE2226556C3 (de) | Schraubverschluß eines Flüssigkeitsbehälters | |

| EP1746041A1 (fr) | Un bouchon rotatif et refermable | |

| EP0163109B1 (fr) | Dispositif doseur | |

| DE3619455A1 (de) | Fluessigkeitsspender zum wiederholten ausgeben von zugemessenen mengen eines fluessigen produktes | |

| DE19652148C2 (de) | Behälter, insbesondere Flasche | |

| DE69101625T2 (de) | Verschluss für Flaschen. | |

| DE7534301U (de) | Kindersicherer Verschluss fuer Behaelter insbesondere fuer rieselfaehige Gueter enthaltende Behaelter | |

| DE29914452U1 (de) | Rollkugelspender | |

| DE3830641C1 (en) | Closure for a bottle for correction fluid | |

| DE8808369U1 (de) | Drehverschluß für Behälter | |

| DE102004017765B3 (de) | Verschluss für eine Zwei-Komponenten-Packung | |

| DE60303516T2 (de) | Ausgabepistole | |

| DE8214974U1 (de) | Behaelter fuer Zweikomponenten-Produkte | |

| DE69807022T2 (de) | Kapsel zum Verschliessen von Behältern | |

| DE1453010C (de) | Verschluß an einem Behalter mit Auftrage und Verteileinnch tung fur flussiges Füllgut |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 392314 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19950321 |

|

| 17Q | First examination report despatched |

Effective date: 19960523 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 392314 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 168956 Country of ref document: AT Date of ref document: 19980815 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENTANWAELTE Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19980729 |

|

| REF | Corresponds to: |

Ref document number: 59010842 Country of ref document: DE Date of ref document: 19980903 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990402 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990402 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990403 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990430 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990430 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990430 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: CREANOVA A.G. Effective date: 19990430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990402 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991231 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19991101 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 94107235.7 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000201 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050402 |