EP0559556A1 - Installation for producing corrugated cardboard - Google Patents

Installation for producing corrugated cardboard Download PDFInfo

- Publication number

- EP0559556A1 EP0559556A1 EP93400540A EP93400540A EP0559556A1 EP 0559556 A1 EP0559556 A1 EP 0559556A1 EP 93400540 A EP93400540 A EP 93400540A EP 93400540 A EP93400540 A EP 93400540A EP 0559556 A1 EP0559556 A1 EP 0559556A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- installation

- cardboard

- smooth

- rollers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000009434 installation Methods 0.000 title claims abstract description 37

- 239000000123 paper Substances 0.000 claims abstract description 68

- 238000010438 heat treatment Methods 0.000 claims abstract description 17

- 238000007664 blowing Methods 0.000 claims abstract description 5

- 238000001035 drying Methods 0.000 claims description 22

- 239000000853 adhesive Substances 0.000 claims description 11

- 230000001070 adhesive effect Effects 0.000 claims description 11

- 230000008901 benefit Effects 0.000 claims description 4

- 238000005520 cutting process Methods 0.000 claims description 4

- 238000003825 pressing Methods 0.000 claims description 3

- 230000009471 action Effects 0.000 abstract description 4

- 238000000034 method Methods 0.000 description 11

- 238000003860 storage Methods 0.000 description 9

- 230000008569 process Effects 0.000 description 8

- 238000005304 joining Methods 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000007639 printing Methods 0.000 description 3

- 230000000284 resting effect Effects 0.000 description 3

- 206010044565 Tremor Diseases 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000006698 induction Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 239000004411 aluminium Substances 0.000 description 1

- 230000003042 antagnostic effect Effects 0.000 description 1

- 238000010420 art technique Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 230000002542 deteriorative effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F—MECHANICAL WORKING OR DEFORMATION OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F1/00—Mechanical deformation without removing material, e.g. in combination with laminating

- B31F1/20—Corrugating; Corrugating combined with laminating to other layers

- B31F1/24—Making webs in which the channel of each corrugation is transverse to the web feed

- B31F1/26—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions

- B31F1/28—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions combined with uniting the corrugated webs to flat webs ; Making double-faced corrugated cardboard

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F—MECHANICAL WORKING OR DEFORMATION OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F1/00—Mechanical deformation without removing material, e.g. in combination with laminating

- B31F1/20—Corrugating; Corrugating combined with laminating to other layers

- B31F1/24—Making webs in which the channel of each corrugation is transverse to the web feed

- B31F1/26—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions

- B31F1/28—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions combined with uniting the corrugated webs to flat webs ; Making double-faced corrugated cardboard

- B31F1/2845—Details, e.g. provisions for drying, moistening, pressing

- B31F1/285—Heating or drying equipment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F—MECHANICAL WORKING OR DEFORMATION OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F1/00—Mechanical deformation without removing material, e.g. in combination with laminating

- B31F1/20—Corrugating; Corrugating combined with laminating to other layers

- B31F1/24—Making webs in which the channel of each corrugation is transverse to the web feed

- B31F1/26—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions

- B31F1/28—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions combined with uniting the corrugated webs to flat webs ; Making double-faced corrugated cardboard

- B31F1/2845—Details, e.g. provisions for drying, moistening, pressing

- B31F1/2877—Pressing means for bringing facer sheet and corrugated webs into contact or keeping them in contact, e.g. rolls, belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F—MECHANICAL WORKING OR DEFORMATION OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31F1/00—Mechanical deformation without removing material, e.g. in combination with laminating

- B31F1/20—Corrugating; Corrugating combined with laminating to other layers

- B31F1/24—Making webs in which the channel of each corrugation is transverse to the web feed

- B31F1/26—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions

- B31F1/28—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions combined with uniting the corrugated webs to flat webs ; Making double-faced corrugated cardboard

- B31F1/289—Making webs in which the channel of each corrugation is transverse to the web feed by interengaging toothed cylinders cylinder constructions combined with uniting the corrugated webs to flat webs ; Making double-faced corrugated cardboard from discrete sheets

Definitions

- the present invention relates to an installation for producing corrugated cardboard.

- corrugated cardboard Traditionally, the production of corrugated cardboard consists in first corrugating the intermediate paper by inserting said paper between two rollers having corrugated surfaces whose profiled-section is identical to that required for the corrugated cardboard.

- the corrugated paper remains applied on one of the corrugating rollers under the action of a vacuum or of a positive pressure generated by the air blown inside a closed chamber which surrounds the mechanical parts from where the corrugations start in the paper to the area where the second paper is adhesively joined to the crests of the corrugations.

- This process is applied in continuous installations comprising devices for feeding strips of paper, a corrugating train, a storage of the one-layer corrugate (a smooth paper bonded to the crests on one side of the corrugated paper), one zone for drying the cardboard and another zone for cutting, slitting and stacking the cardboard sheets.

- This drying method does not make it possible to obtain a uniform drying or humidity over the various layers of paper, since the heat of the plates is conveyed to the upper layers of the cardboard by passing through the lower paper and since owing to the bad conductivity of the paper, great differences of temperatures are observed on the different layers.

- the strips of paper are fed from reel holders and automatically assembled "end-to-end".

- Another characteristic of the invention lies in the fact that the bonding of the first smooth layer is effected without any pressure being applied between the corrugating and the smooth roller.

- a clever solution is provided which enables the bonding of the first smooth layer of paper over the corrugated core without any pressure being exerted between the two rollers, thus avoiding the above-mentioned vibrations, and permitting an increase of the process speed.

- the first smooth paper which is bonded over the corrugated paper is maintained on the corrugating roller after the joining point of the two papers until a second smooth roller is reached, which roller is also a heating roller, thus making it possible to keep the two papers in contact with the heating rollers for a longer period and speeding up the adhesive drying process.

- the method used for drying the cardboard once the second smooth layer has been positioned is different from the conventional method using flat plates arranged in alignment, and employs two large heating rollers, which turn at a tangential speed which is equal to the speed of the cardboard, thereby avoiding any friction between the faces of the paper, and furthermore, the two drying rollers are arranged in such a way that the cardboard can receive heat on both faces, by passing from one roller to the other and by alternating the contact between the two faces. It receives the same quantity of heat on both faces, and comes out completely dry and with a uniformity of heat and humidity which enables it to be treated in continous manner.

- the method according to the invention in avoiding the conventional storage and passing directly from the corrugating train to the drying phase, permits a great saving in thermal energy while avoiding the cooling of the first two papers in the storage.

- this solution prevents the printed faces from deteriorating when preprinted paper is used.

- another basic characteristic of the present invention lies in the way in which the corrugated paper is held in close contact with the corrugating roller, from the corrugation point between the corrugating rollers up to its point of joining with the second paper.

- two hollow section pieces are provided, one between the corrugating rollers and the adhesive dosing roller, and the other between the dosing roller and the meeting point between the corrugated paper and the smooth paper.

- These section pieces are provided with orifices on the face adjacent to the corrugating roller conveying the corrugated paper. Pressurized air is injected at the ends of the section pieces and said air comes out through the orifices by exerting a sufficient pressure on the paper in order to keep it in contact with the corrugating roller.

- the corrugating roller is composed of a basic body on the surface of which a plurality of grooves are defined, said basic body being enclosed in a casing defining, with the grooves, steam pipes and vacuum pipes, the latter communicating with the outside, such that the inlet of steam and the outlet of condensation water occur at one end of the roller while the vacuum is transmitted at the other end; all this being such that a uniform heating of the whole surface of the roller is obtained as well as a vacuum which retains the paper at multiple points of the surface of the corrugating roller.

- the large cylinders for drying the cardboard are arranged so as to couple a system for continuously introducing printed sheets, this possibility giving the process the great advantage of allowing the small-scale manufacture of high quality boxes, at costs much lower than those required for small-scale printing with rotary printing machines.

- Figures 1 and 2 show by way of example a conventional installation for producing corrugated cardboard.

- This installation uses reel holders 6 fitted with conventional non"-end-to-end” assembling apparatus; such that where the strips of paper 2, 3 and 5 are joined up, their thickness is doubled and that when they pass through a corrugating machine 1, shakings and vibrations occur.

- the intermediate strip 2 passes between the two toothed rollers 7 which produce its corrugation and, once corrugated, said strip on the crests of the corrugations of one of its faces, the corresponding adhesive from the bonding machine 8 in order to ensure bonding of the first smooth layer of paper 3, the two layers 2 and 3 passing between one of the toothed rollers 7 and a smooth roller 10

- the rollers 7 and 10 are in pressurized contact together and as a result, due to the toothed form of the roller 7, shakings and vibrations occur after a certain speed is reached.

- the next step to the corrugating machine 1 is a storage 11 which is necessary to solve any problems which can arise with the joints between the strips of paper inside the reel holders 6.

- the next step is a zone in which the corrugated intermediate layer 2 receives an adhesive on its free face such that the second smooth layer of paper 5 can adhere thereon when passing onto a flat drying table 21 where final bonding and drying take place.

- friction of the cardboard on the fixed lower plates entails deformations thereof, including defects in any printed parts which the cardboard may comprise on its lower smooth face.

- the installation according to the invention comprises for feeding the sheets of paper 2, 3 and 5, respective feeding reel holders 6, which, in this case, are especially fitted with automatic "end-to-end” assembling machines for consecutively assembling the respective reels, such that, in this way, the excess thickness of the aforesaid sheets of paper is small, and that it does not correspond to twice the initial thickness as observed with the overlapping joints which are made with the conventional reel holders 6 of the conventional installations.

- the "end-to-end” assembling machines it is possible with the "end-to-end” assembling machines to obtain, for example if paper strips of three tenths of thickness are used, a joining thickness limited to a mere four tenths, against the six tenths obtained with the conventional solutions. This smaller thickness prevents the vibrations in the corrugating machine 1 and increases the speed.

- the reliability of "end-to-end" assembling machines makes it possible to eliminate the storage 11.

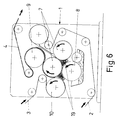

- the corrugating machine 1 of the installation according to the invention comprises a set of two toothed rollers 7 which are one into the other and between which the paper strip 2 to be corrugated passes, the latter thus acquires the corrugations which corresponds to the teeth of rollers 7 while, by means of the bonding machine 8, it is impregnated with adhesive on the crests of the corrugations of one of its faces, so that the first smooth layer 3 can be bonded over this strip, as shown in Figure 6.

- said unit 1 consists of an arrangement of elements which is such that both layers 2 and 3 remain on the output roller 7, although at a certain distance downstream of the assembly, remaining thereafter in resting contact around a contiguous heating drum 9 which it encircles nearly completely.

- Roller 9 turns at a tangential speed which is slightly greater than the speed of paper 3 and that of roller 10, in order to cause a pressurization or a tension on the paper 3 in the zone of contact with the toothed roller 7, thus enhancing the bonding quality thanks to the pressure applying the paper 3 on the crests of the corrugations and on the adhesive of the paper 2.

- the effect of the heating of the assembly 4 composed of layers 2 and 3, which is carried out by the drum 9 along the path covered by said assembly before coming out of the corrugating machine 1, is that the layers 2 and 3 are already assembled at the outlet from said unit with a degree of drying which makes it ready to be used in the next phase; this eliminating the other drawback of the conventional installations in which the storage 11 is necessary to ensure the drying of said assembly 4 of strips 2 and 3.

- the unit used for fastening the second smooth layer of paper 5 consists as shown in Figure 7, in the case of the installation according to the invention, in a set of two large rollers 12 and 13 on the first one of which the joined assembly composed of said layers 2 and 3 penetrates by resting on the smooth layer 3 and by encircling nearly completely said roller, such that, on this path, the second smooth layer of paper 5 positions itself on said assembly by adhering to the crests of the free corrugations of the corrugated layer 2 which have been impregnated beforehand with adhesive by means of a bonding machine 14.

- the assembly formed of the three layers 2, 3 and 5 passes from this roller 12 to the other roller 13, on which it rests via the strip 5, i.e. unlike the prior art technique, and on which roller 13 said assembly in turn rests nearly all around said roller, thereafter coming out thereof by resting on a conveyor belt 15 provided with a vacuum suction which facilitates the fixing and actuation, to lead said assembly constituting the cardboard up to the outlet where, by means of shears 16 and slitting machines 17, the formed cardboard is slit and cut so as to be collected in a final container 20.

- the two big rollers 12 and 13 turn at a tangential speed equal to the linear speed of the cardboard thus avoiding the friction on the faces of the cardboard.

- the rollers 12 and 13 are also heating rollers, such that the assembly constituting the cardboard is subjected to an efficient drying process while following the path where the second layer 5 is fixed, coming out towards the conveyor belt 15 without having to maintain a confinement above said conveyor belt and, such that this assembly constituting the cardboard covers its path without slipping on the bearing elements, thus preventing the surfaces of the outer faces where orusemental or informative printings may be applied from being scratched; there being, on the other hand, no risk of the corrugated intermediate layer 2 being deformed since there is no antagonistic frictions between the bearing elements and the pressure elements.

- this arrangement as well as the heating produced by the bearing rollers 12 and 13 result in the drying of the assembly constituting the aforesaid cardboard, is efficient and uniform throughout the thickness since, thanks to the fact that it rests first of all on the roller 12 via the face 3 and then, on the roller 13 via the other face 5, heating occurs through the two faces, such that it is truly efficient and uniform throughout the assembly.

- reference 19 designates section pieces which may be produced in aluminium or any other similar material, such that pressurized air may be brought in, and come out through corresponding orifices, provided on the faces in facing relationship with the toothed roller 7 contiguous to the smooth roller 10.

- section pieces 19 take advantage of the free spaces defined between the rollers 7, 8 and 10 in order to take up a priviledged position in which, acting as intake openings, they blow pressurized air onto the corresponding roller 7 so as to maintain the already corrugated layer of paper 2 in close contact with said roller 7, without this requiring any other fastening means.

- blowing section pieces 19 can either be located in other strategic points than those represented in Figure 6, or section pieces with a different configuration can be adopted without departing from the scope of the invention, which lies in the fact that the fastening of the corrugated layer 2 on the corresponding toothed roller 8 or the fastening of the assembly of layers 2 and 3 is obtained by applying pressurized air in localized spots, using blowing section pieces 19 arranged in strategic points.

- section pieces 19 can be completed or replaced by a particular embodiment of corrugating rollers 7 represented in Figures 10 and 11.

- Figure 10 shows that the roller 7 is composed of an inner body 22 on the surface of which are defined a series of grooves 24 and 25.

- the inner body 22 is surrounded by a sheath 23 thus forming pipes with the grooves 24 and 25, of which pipes those corresponding to the grooves 25 are used for circulating the steam and those corresponding to the grooves 24 are used for the vacuum.

- Grooves 24 open onto the outside through induction holes 26, such that each hole 26 gives rise to an induction point which makes it possible to maintain the paper in close contact with the roller 7.

- Figure 11 shows how the roller 7 is produced for this solution, according to a non-limiting example of practical embodiment.

- One end of the roller 7 is provided with inlet for the steam 27 which communicates with a steam collector 29 from which the grooves 25 start.

- the condensed steam returns through duct 32 up to outlet 34.

- the vacuum is created through the opening 31 located at the other end of the roller 7 and a vacuum collector is also provided wherefrom the grooves 24 start.

- the depth of the grooves 25, as shown in Figure 11, increase progressively so as to obtain a greater contact surface between the steam and the steel, in order to make the temperatures equal at both ends.

- two presses 17 are provided, which presses are rotary presses.

- one of them can be in operation while the cutting means are automatically changed on the other said means being conveyed from a magazine up to their mounting location, via a rolling bridge, such that said cutting means are ready for use without having to interrupt the operation.

- the very principle of rotary presses makes them more adaptable to the high speeds supported by the installation according to the invention.

- the corrugating machine 1 makes it possible, while retaining all of its main characteristics, to advance the position of its bonding machine 8 and to arrange the rollers 7, 9 and 10 such as to simplify the changing of the corrugating rollers 7.

- Figure 8 shows a solution in which the pair of toothed rollers 7 can be easily extracted by one side, merely by slightly tipping the bonding machine 8, such that once extracted, the pair can be cleaned up, replaced, etc...

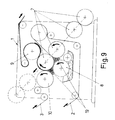

- Figure 9 shows another practical variant of embodiment in which a plurality of pairs of toothed rollers 7 are provided, said pairs being arranged diagonally and in such a way that either one of said pairs can be positioned selectively in its working position as a function of the needs of each operation.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Machines For Manufacturing Corrugated Board In Mechanical Paper-Making Processes (AREA)

- Paper (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES09200456A ES2053377B1 (es) | 1992-03-02 | 1992-03-02 | Sistema para la fabricacion de carton ondulado. |

| ES9200456 | 1992-03-02 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0559556A1 true EP0559556A1 (en) | 1993-09-08 |

Family

ID=8276248

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93400540A Ceased EP0559556A1 (en) | 1992-03-02 | 1993-03-02 | Installation for producing corrugated cardboard |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0559556A1 (enExample) |

| JP (2) | JP3406344B2 (enExample) |

| AU (1) | AU3386193A (enExample) |

| CA (1) | CA2090661A1 (enExample) |

| ES (1) | ES2053377B1 (enExample) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2070726A2 (es) * | 1993-03-24 | 1995-06-01 | Torres Martinez M | Rodillo ondulador de papel para carton ondulado. |

| EP0657275A1 (de) * | 1993-12-08 | 1995-06-14 | BHS Corrugated Maschinen- und Anlagenbau GmbH | Riffelwalze für die Herstellung von Wellpappe |

| FR2719521A1 (fr) * | 1994-05-06 | 1995-11-10 | Otor Sa | Machine et procédé de fabrication d'une feuille de carton ondulé simple face par encollage sous traction. |

| EP0753400A1 (en) * | 1995-07-14 | 1997-01-15 | Scm Container Machinery Limited | Apparatus for producing corrugated paperboard |

| EP0750986A3 (en) * | 1995-06-26 | 1997-05-07 | Marquip Inc | Layer holding-down mechanism and gear for a device for producing corrugated cardboard |

| GR1002719B (el) * | 1996-06-18 | 1997-06-10 | Μηχανισμος και τροπος παραγωγης κυματοειδους χαρτου στο επιθυμητο πλατος δια συγκολλησεως δυο χαρτορολλων διαφορων διαστασεων σε μηχανη παραγωγης κυματοειδους χαρτου -οντουλε-. | |

| GB2313135A (en) * | 1996-05-14 | 1997-11-19 | Isowa Kk | Corrugating:single facer |

| WO1998003331A1 (fr) * | 1996-07-23 | 1998-01-29 | Otor | Machine et procede de fabrication d'une feuille de carton ondule simple face avec traction en amont |

| ES2110871A2 (es) * | 1994-03-16 | 1998-02-16 | Talleres Iruna S A | Perfeccionamientos en sistemas de vapor. |

| EP0829693A1 (fr) * | 1996-09-12 | 1998-03-18 | Talleres Iruna, S.A. | Perfectionnements a des rouleaux onduleurs chauffes par la vapeur |

| EP0976540A3 (en) * | 1998-07-30 | 2001-01-17 | Ingg. Terzaghi & De Castiglione Industriale S.p.A. | Device for the production of corrugated cardboard with a single flat surface |

| EP1484171A3 (en) * | 2003-06-04 | 2005-08-10 | FOSBER S.p.A. | Corrugating roller for machines to produce corrugated cardboard and machine comprising said roller |

| EP1980389A1 (en) * | 2007-04-13 | 2008-10-15 | Aiki Kogyo Kabushiki Kaisha | Apparatus for producing corrugated cardboard |

| CN110053313A (zh) * | 2019-03-13 | 2019-07-26 | 抚顺东旭精工制辊科技有限公司 | 一种真空吸附瓦楞辊 |

| CN113371489A (zh) * | 2021-05-30 | 2021-09-10 | 许金祥 | 一种瓦楞纸板的一体化制造输送装置 |

| CN113684713A (zh) * | 2021-08-17 | 2021-11-23 | 浙江森然工贸有限公司 | 一种利用废弃瓦楞纸制成的环保型的瓦楞复合纸板的生产工艺及其加工设备 |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FI970921L (fi) * | 1995-07-04 | 1997-04-07 | Snow Brand Milk Products Co Ltd | Prosessoitu heraproteiini |

| JP2007106054A (ja) * | 2005-10-14 | 2007-04-26 | Aiki Kogyo Kk | 段ボール紙製造装置 |

| CN103419411A (zh) * | 2013-08-14 | 2013-12-04 | 朱丹华 | 瓦楞辊的风门控制结构 |

| CN110588084B (zh) * | 2019-09-18 | 2021-03-19 | 浦江丰收包装有限公司 | 防水高强度的瓦楞纸箱加工方法 |

| CN112389069B (zh) * | 2020-11-06 | 2022-09-23 | 新疆訫美包装有限公司 | 一种瓦楞纸生产用导向预加热装置及加热方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0229338A2 (de) * | 1985-12-19 | 1987-07-22 | Europa Carton Aktiengesellschaft | Verfahren zur Herstellung von mit Dekor-Oberflächen versehenen Wellpappe-Zuschnitten |

| GB2194974A (en) * | 1986-09-09 | 1988-03-23 | Rengo Co Ltd | Corrugating machine |

| DE8909841U1 (de) * | 1989-08-17 | 1989-10-05 | BHS-Bayerische Berg-, Hütten- und Salzwerke AG, 8000 München | Vorrichtung zur Herstellung von Wellpappe |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3232774C2 (de) * | 1982-09-03 | 1986-06-19 | Werner H.K. Peters Maschinenfabrik Gmbh, 2000 Hamburg | Einseitige Wellpappenmaschine |

| JPS59155031A (ja) | 1982-12-13 | 1984-09-04 | モ−リンズ・マシ−ン・カンパニ−・インコ−ポレイテツド | 段ボ−ル製造装置 |

| BR8800608A (pt) * | 1987-02-18 | 1988-09-27 | Amcor Ltd | Aparelho e metodo para fabricar papelao corrugado de face unica |

| FI891649A7 (fi) * | 1989-04-06 | 1990-10-07 | Enso Gutzeit Oy | Foerfarande foer tillverkning av wellpapp eller dylikt. |

| ES2013482A6 (es) * | 1989-05-04 | 1990-05-01 | Torres Martinez M | Empalmador automatico para alimentadores de bandas de papel. |

| JP5828109B2 (ja) | 2011-05-16 | 2015-12-02 | パナソニックIpマネジメント株式会社 | エネルギー管理システム、エネルギー管理システムに用いられるエネルギー管理装置および管理サーバ |

-

1992

- 1992-03-02 ES ES09200456A patent/ES2053377B1/es not_active Expired - Fee Related

-

1993

- 1993-02-26 AU AU33861/93A patent/AU3386193A/en not_active Abandoned

- 1993-03-01 CA CA002090661A patent/CA2090661A1/en not_active Abandoned

- 1993-03-02 JP JP06613893A patent/JP3406344B2/ja not_active Expired - Fee Related

- 1993-03-02 EP EP93400540A patent/EP0559556A1/en not_active Ceased

-

2003

- 2003-01-17 JP JP2003010255A patent/JP2003181957A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0229338A2 (de) * | 1985-12-19 | 1987-07-22 | Europa Carton Aktiengesellschaft | Verfahren zur Herstellung von mit Dekor-Oberflächen versehenen Wellpappe-Zuschnitten |

| GB2194974A (en) * | 1986-09-09 | 1988-03-23 | Rengo Co Ltd | Corrugating machine |

| DE8909841U1 (de) * | 1989-08-17 | 1989-10-05 | BHS-Bayerische Berg-, Hütten- und Salzwerke AG, 8000 München | Vorrichtung zur Herstellung von Wellpappe |

Cited By (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2070726A2 (es) * | 1993-03-24 | 1995-06-01 | Torres Martinez M | Rodillo ondulador de papel para carton ondulado. |

| EP0657275A1 (de) * | 1993-12-08 | 1995-06-14 | BHS Corrugated Maschinen- und Anlagenbau GmbH | Riffelwalze für die Herstellung von Wellpappe |

| ES2110871A2 (es) * | 1994-03-16 | 1998-02-16 | Talleres Iruna S A | Perfeccionamientos en sistemas de vapor. |

| WO1995030537A1 (fr) * | 1994-05-06 | 1995-11-16 | Otor | Machine et procede de fabrication d'une feuille de carton ondule simple face par encollage sous traction |

| FR2719521A1 (fr) * | 1994-05-06 | 1995-11-10 | Otor Sa | Machine et procédé de fabrication d'une feuille de carton ondulé simple face par encollage sous traction. |

| AU703956B2 (en) * | 1994-05-06 | 1999-04-01 | Otor | Machine and method for the manufacture of single-face corrugated cardboard |

| US6068724A (en) * | 1994-05-06 | 2000-05-30 | Otor | Machine and method for manufacture of a sheet of single-face corrugated board by gluing under tension |

| EP0750986A3 (en) * | 1995-06-26 | 1997-05-07 | Marquip Inc | Layer holding-down mechanism and gear for a device for producing corrugated cardboard |

| EP0753400A1 (en) * | 1995-07-14 | 1997-01-15 | Scm Container Machinery Limited | Apparatus for producing corrugated paperboard |

| GB2313135A (en) * | 1996-05-14 | 1997-11-19 | Isowa Kk | Corrugating:single facer |

| US6289960B1 (en) | 1996-05-14 | 2001-09-18 | Kabushiki Kaisha Isowa | Apparatus having a wrapped roll for making a single faced corrugated board |

| GR1002719B (el) * | 1996-06-18 | 1997-06-10 | Μηχανισμος και τροπος παραγωγης κυματοειδους χαρτου στο επιθυμητο πλατος δια συγκολλησεως δυο χαρτορολλων διαφορων διαστασεων σε μηχανη παραγωγης κυματοειδους χαρτου -οντουλε-. | |

| WO1998003331A1 (fr) * | 1996-07-23 | 1998-01-29 | Otor | Machine et procede de fabrication d'une feuille de carton ondule simple face avec traction en amont |

| EP0829693A1 (fr) * | 1996-09-12 | 1998-03-18 | Talleres Iruna, S.A. | Perfectionnements a des rouleaux onduleurs chauffes par la vapeur |

| EP0976540A3 (en) * | 1998-07-30 | 2001-01-17 | Ingg. Terzaghi & De Castiglione Industriale S.p.A. | Device for the production of corrugated cardboard with a single flat surface |

| EP1484171A3 (en) * | 2003-06-04 | 2005-08-10 | FOSBER S.p.A. | Corrugating roller for machines to produce corrugated cardboard and machine comprising said roller |

| EP1980389A1 (en) * | 2007-04-13 | 2008-10-15 | Aiki Kogyo Kabushiki Kaisha | Apparatus for producing corrugated cardboard |

| CN110053313A (zh) * | 2019-03-13 | 2019-07-26 | 抚顺东旭精工制辊科技有限公司 | 一种真空吸附瓦楞辊 |

| CN113371489A (zh) * | 2021-05-30 | 2021-09-10 | 许金祥 | 一种瓦楞纸板的一体化制造输送装置 |

| CN113684713A (zh) * | 2021-08-17 | 2021-11-23 | 浙江森然工贸有限公司 | 一种利用废弃瓦楞纸制成的环保型的瓦楞复合纸板的生产工艺及其加工设备 |

Also Published As

| Publication number | Publication date |

|---|---|

| AU3386193A (en) | 1993-09-09 |

| ES2053377R (enExample) | 1995-08-16 |

| ES2053377A2 (es) | 1994-07-16 |

| JPH0623884A (ja) | 1994-02-01 |

| ES2053377B1 (es) | 1996-01-16 |

| JP3406344B2 (ja) | 2003-05-12 |

| JP2003181957A (ja) | 2003-07-03 |

| CA2090661A1 (en) | 1993-09-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0559556A1 (en) | Installation for producing corrugated cardboard | |

| JP2923538B2 (ja) | 多重段ボール及びその成形方法と装置 | |

| AU678909B2 (en) | Double-ply corrugated paperboard | |

| CA2055403C (en) | Assembling device for weblike workpieces consisting of superposed and glued layers designed for being used with a double-facer of a machine producing corrugated board | |

| HK1207603A1 (en) | Improvements in and relating to paperboard manufacture | |

| US5766410A (en) | Corrugating machine with an elastic press plate | |

| JPH0532280Y2 (enExample) | ||

| GB2144077A (en) | Improvement in or related to corrugated products | |

| US5996246A (en) | Edge seal for vacuum preheater | |

| AU615053B2 (en) | Manufacturing corrugated board | |

| JP2622330B2 (ja) | 片面段ボール製造機 | |

| JPH0744467U (ja) | 段ボール製造装置における糊付装置 | |

| US20050139312A1 (en) | Corrugating machine | |

| JPS58132323A (ja) | コルゲ−テイング装置 | |

| ES2121530A1 (es) | Revestidor simple en una maquina para la fabricacion de carton ondulado. | |

| JP2919824B1 (ja) | ダブルフェーサ | |

| SU1301894A1 (ru) | Способ изготовлени влагопрочного гофрированного картона | |

| EP4190549A1 (en) | Corrugated cardboard production plant with double output side | |

| JP3509801B2 (ja) | 段ボールシートの反り防止装置 | |

| JPS59109345A (ja) | コルゲ−テイングマシンのダブルフエ−サ | |

| JPH06286032A (ja) | 片面段ボール製造装置 | |

| JP3787007B2 (ja) | 交差波板積層体の製造方法 | |

| SU1757906A1 (ru) | Способ изготовлени полотен гофрокартона и устройство дл его осуществлени | |

| FI59358B (fi) | Vaermefoerseglingsapparat | |

| GB2263486A (en) | Producing corrugated sheets |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE DK FR GB GR IE IT LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19940304 |

|

| 17Q | First examination report despatched |

Effective date: 19950808 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19961021 |