EP0508397A1 - Boîte dépliable - Google Patents

Boîte dépliable Download PDFInfo

- Publication number

- EP0508397A1 EP0508397A1 EP92106061A EP92106061A EP0508397A1 EP 0508397 A1 EP0508397 A1 EP 0508397A1 EP 92106061 A EP92106061 A EP 92106061A EP 92106061 A EP92106061 A EP 92106061A EP 0508397 A1 EP0508397 A1 EP 0508397A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wall part

- side walls

- wall

- box according

- walls

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/20—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form

- B65D5/24—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form with adjacent sides interconnected by gusset folds

- B65D5/248—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form with adjacent sides interconnected by gusset folds and at least one side being extended and doubled-over to enclose the adjacent gusset flaps

Definitions

- the invention relates to an erection box according to the preamble of claim 1.

- Such an erection box is known for example from DE 33 02 972 C2.

- This is designed as an open, stackable crate, in which tongues protruding from the end of the side walls engage in corresponding recesses at the end of the end walls and thus hold the box in an erect state.

- the tongues lose their rigidity, so that the stability of the box is impaired.

- the known erection box is therefore unsuitable for repeated use if, for transport reasons, it requires folding and re-erecting the box.

- the tongues are also subjected to additional pressure when pressure is exerted against the side walls, which can also lead to a rapid loss of rigidity and thus the stability of the box.

- the invention has for its object to provide an erection box that is stable, foldable and re-erectable in many ways, without affecting its stability, the folding and re-erection can also be carried out by inexperienced people.

- the proposed design with the features of claim 1 gives a dimensionally stable box, in which the recesses or recesses are only exposed to the load caused by the slight prestressing of the inner wall part of the end walls. External loads, however, do not act on the recesses and wall parts engaging therein, so that they remain dimensionally stable and their function is not impaired.

- locking tabs are provided in the corner area of the inner wall part of the end walls, which latch into correspondingly shaped recesses on the side walls.

- the locking tab is not subjected to bending, but only to pressure in the material direction, which results in greater stability due to the higher resilience of cardboard or cardboard in this direction of stress.

- the side walls are preferably also double-walled, the inner wall part containing the recesses for receiving the inner wall part or the locking tabs, so that they fold and rest on the outer wall part of the side walls, and are thereby securely fixed in position.

- the outer wall part of the side walls advantageously contains through-holes in the area of the cutouts for pressing the locking tabs out of the cutouts, as a result of which the collapsing of the erected box is very simplified. If a large number of collapsed boxes are stacked on top of one another, bolts, rods, wires, strips or the like clamping means can be passed through the through holes, so that a compact, easily transportable package is obtained.

- the erection box Since the erection box has an opening that is limited only by the narrow upper edges of the side and end walls, it can be used both on the one hand as a base part and on the other hand as a cover part for a closed box.

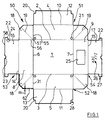

- the bottom 1 of the erecting box 50 is connected via folds 2 and 3 to the outer parts 4 and 5 of the side walls 51, 52 and via folds 6 and 7 to the outer parts 8 and 9 of the end walls 53, 54.

- the outer parts 4 and 5 are connected by folds 10 and 11 to inner parts 12 and 13 of the side walls 51, 52;

- the outer parts 8 and 9 are connected via folds 14 and 15 to inner parts 16 and 17 of the end walls 53, 54.

- the end and side walls 51, 52, 53, 54 are connected to one another by connecting lugs 18, which are each connected to the adjacent end of an outer part of the end and side wall to be connected via a fold 55, 56.

- Each connecting plate 18 contains a diagonal fold 19, which starts from the associated corner 57 of the base 1 and divides the connecting plate 18 symmetrically. The folds are drawn in thinner lines than the outline.

- the inner parts 12 and 13 of the side walls 51, 52 have cutouts 20 at their outer corners.

- the outer parts 4 and 5 of the side walls 51, 52 are in the vicinity of the folds 2 and 3 and the provided with through holes 21 at the ends adjoining the connecting straps 18.

- the inner parts 16 and 17 of the end walls 53, 54 carry two locking tabs 22 on each side of their outer edge 58 via a short bending fold 24; this outer edge 58 also contains a punched-out portion 23 in its center, which serves to engage the fingers when folded after use.

- the shape of the locking tabs 22 corresponds to the cutouts 20, in which they engage in the folded and erected state of the erecting box 50 (cf. FIG. 3).

- the wall part 9 has a punched-out viewing window 25, through which, in the erected state (FIG. 3), an inscription 26, for example, printed on the wall part 17 or fastened in some other way. B. is visible as a label.

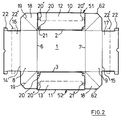

- the inner parts 12 and 13 of the side walls 51, 52 are bent inwards about the folds 10 and 11 and placed on the associated outer parts 4 and 5 and glued to them , so that the blank has the shape shown in FIG. 2.

- the cutouts 20 lie in the inner parts 12 and 13 over the regions of the outer parts 4 and 5 containing the through holes 21.

- the inwardly folded wall parts 12, 13, 16, 17 extend only over part of the height of the wall parts 4, 5, 8, 9 extend z. B. only over half, as indicated in dashed lines and the reference numerals 20 'and 22'.

- the interlocking parts 20 'and 22' in contrast to FIG. 3, are not arranged in the area of the base part 1, but rather approximately half the height of the end or side walls 51, 52, 53, 54.

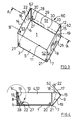

- the box is erected in such a way that the double-walled side walls 51, 52 around the folds 2 and 3 and the End walls 53, 54 are bent upwards about the folds 6 and 7 perpendicular to the bottom 1 (FIG. 4).

- the connecting tabs 18 are bent along the diagonal fold 19 towards the inside of the box (right half of FIG. 4), their two mirror-image halves abutting one another.

- the kinked connecting tabs 18 are then pressed in the direction of the respective outer part 8 or 9 of the end walls, and the corresponding inner part 16 or 17 is bent inward about the fold 14 or 15 then lying at the top, so that the side walls 51, 52 are vertical are erected and the connecting straps 18 are clamped between the outer part 8 and 9 and the inner part 16 and 17, respectively.

- the side walls 51, 52 are also fixed in their vertical position.

- the locking tabs 22 they carry, preferably provided, are bent at a right angle such that they point parallel to the side walls 51, 52 into the interior of the box.

- the erection box shown in FIG is and has a high stability.

- the degree of prestress can be varied. If, for example, the offset m of its outer edge 62 with respect to the fold 14 is chosen to be larger, as shown in broken lines in FIG. 1 is shown, the wall part 16 can be folded more easily over the wall part 8 and the clamping tab 18 clamped in between, so that the pretension is less.

- the support edge 28 on the recess 20 in the corner region of the erecting box can also be realized in that instead of the double-walled design of the side walls 51, 52 one or more support strips 29, 30 are glued to the inside of the side wall 4, 5 with the omission of the wall part 12, 13 be, as shown in chain lines in Fig. 3.

- the locking tabs 22 are slightly bent inwards through the through holes 21 from the outside by finger pressure, so that they are moved out of the cutouts 20.

- the inner parts 16 and 17 are also moved parallel to the side walls 51, 52, so that they no longer coincide with the recesses 20 and can no longer spring back into them after being released by the finger.

- the inner parts 16 and 17 are now gripped behind in the area of the punched-out areas 23 and bent outwards, so that the box 50 folded flat is obtained again according to FIG. 2.

- a closed box can be formed from two erection boxes 60 serving as the bottom part and the lid part according to FIG. 3, the lid part being slightly larger than the bottom part in order to be able to be put over it.

- the boxes can be used in such a way that their intended contents are transported from the supplier to the customer, that after the contents have been removed, the customer folds the boxes together and, preferably in large numbers, sends them back to the supplier, who sets them up again and can provide new content.

- reusable use of the erecting boxes is e.g. B. possible as a shoe box.

- the box can also be erected mechanically by folding up the end walls 53, 54 and pressing together the inner and outer parts 8, 9, 16, 17 until the snap connection snaps into the recess 20.

- the half of the connecting bracket 18 facing the wall part 8, 9 is preferably attached to the wall part 8, 9, preferably glued or clamped, as shown in dotted lines.

- a simplified embodiment is shown in the lower half of FIG. 5, which has no locking tabs 22 compared to the embodiment described above.

- the snap-in connection in the erected state is achieved by engaging the outer edge 27 of the wall part 16, 17 in the recess 20, which are formed here by cutting edges of the wall part 13 offset by the dimension 31 relative to the fold 31. These cut edges also form the support edges 28 on which the outer edges 27 of the wall parts 16, 17 are supported in the erected state, as is shown in plan view in FIG. 6.

- the through holes 21 are no longer provided in the side walls, but in the outer wall part 8 of the end wall, as indicated by the arrow 21 '(see FIG. 5, lower half). By pushing through the through holes 21 ', the inner wall part 16 is bent so that its two outer edges 27 slide out of the recess 20 and then the erection box can be folded flat again.

- FIG. 7 shows a packaging formed from two erection boxes described above, an intermediate piece 42 being inserted between a base part 40 erected according to FIG. 3 and a cover part 41.

- the intermediate piece 42 is preferably formed in one piece, which can be folded flat by folding over the four edges 43, 44, 45, 46, as is indicated in FIG. 8 by dashed lines with corresponding reference symbols 44 ', 45'.

- the intermediate piece 42 can also be in several parts, for. B. be composed of two overlapping U-shaped sections.

- end wall and side wall are not limited to the shorter or longer boundary wall of the erection box.

- recess 20 on the longer side wall 51, 52 and the wall parts 16, 17 engaging therein are preferably provided with locking tabs 22 on the shorter end wall 53, 54, the arrangement can also be reversed.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

- Making Paper Articles (AREA)

- Passenger Equipment (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE9305614U DE9305614U1 (de) | 1992-04-08 | 1993-04-08 | Aufrichteschachtel |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE9104391U | 1991-04-08 | ||

| DE9104391U DE9104391U1 (de) | 1991-04-08 | 1991-04-08 | Aufrichteschachtel |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0508397A1 true EP0508397A1 (fr) | 1992-10-14 |

| EP0508397B1 EP0508397B1 (fr) | 1996-01-10 |

Family

ID=6866187

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92106061A Expired - Lifetime EP0508397B1 (fr) | 1991-04-08 | 1992-04-08 | Boîte dépliable |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5211330A (fr) |

| EP (1) | EP0508397B1 (fr) |

| AT (1) | ATE132824T1 (fr) |

| CA (1) | CA2065132A1 (fr) |

| DE (2) | DE9104391U1 (fr) |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5364015A (en) * | 1993-09-01 | 1994-11-15 | Climax Manufacturing Company | Box with simulated loose wrap |

| DE29620886U1 (de) * | 1996-11-12 | 1997-02-20 | HCH Sieger GmbH Wellpappenwerke, 50321 Brühl | Behälter |

| US6793071B2 (en) | 2001-12-18 | 2004-09-21 | World Kitchen, Inc. | Cover/pan packaging |

| US7062414B2 (en) * | 2003-07-18 | 2006-06-13 | Metrotech Corporation | Method and apparatus for digital detection of electromagnetic signal strength and signal direction in metallic pipes and cables |

| CA2601585A1 (fr) | 2005-03-17 | 2006-09-28 | Industrial Origami, Llc | Structures pliees de precision a haute resistance mecanique et resistant a la fatigue et feuille a cet effet |

| MX2009004478A (es) | 2006-10-26 | 2009-05-28 | Ind Origami Inc | Formacion de objeto tridimensional. |

| WO2008098217A2 (fr) | 2007-02-09 | 2008-08-14 | Industrial Origami, Inc. | Structure tridimensionnelle portant une charge |

| WO2009086317A1 (fr) * | 2007-12-21 | 2009-07-09 | Industrial Origami, Inc. | Structure très résistante en 3d et son procédé de fabrication |

| US7959061B2 (en) | 2009-09-25 | 2011-06-14 | Multi Packaging Solutions, Inc. | Folded pot cover |

| US9676511B2 (en) | 2009-09-25 | 2017-06-13 | Multi Packaging Solutions, Inc. | Foldable packaging container |

| US8550331B2 (en) | 2011-05-20 | 2013-10-08 | Multi Packaging Solutions, Inc. | Foldable container and attachments |

| US8936164B2 (en) | 2012-07-06 | 2015-01-20 | Industrial Origami, Inc. | Solar panel rack |

| USD675107S1 (en) | 2012-07-20 | 2013-01-29 | Multi Packaging Solutions, Inc. | Wrap packaging |

| USD676337S1 (en) | 2012-07-20 | 2013-02-19 | Multi Packaging Solutions, Inc. | Wrap packaging |

| US10336500B2 (en) | 2014-11-07 | 2019-07-02 | Graphic Packaging International, Llc | Tray for holding a food product |

| US10232973B2 (en) | 2014-11-07 | 2019-03-19 | Graphic Packaging International, Llc | Tray for holding a food product |

| US10208961B2 (en) * | 2015-07-16 | 2019-02-19 | Pennant Moldings, Inc. | One-piece sheet-metal structure formed with clench locked corners |

| CN208915652U (zh) * | 2018-08-13 | 2019-05-31 | 厦门市金玺彩印有限公司 | 免折快速成型盒体 |

| EP3887271B1 (fr) * | 2018-11-26 | 2024-04-24 | Gamma-Wopla SA | Récipient pliable |

| CA3200678A1 (fr) | 2020-11-06 | 2022-05-12 | Graphic Packaging International, Llc | Plateau pour produits alimentaires |

| USD1042117S1 (en) | 2021-05-27 | 2024-09-17 | Graphic Packaging International, Llc | Tray |

| USD1042120S1 (en) | 2021-05-27 | 2024-09-17 | Graphic Packaging International, Llc | Tray |

| USD1042116S1 (en) | 2021-05-27 | 2024-09-17 | Graphic Packaging International, Llc | Carton |

| USD1042121S1 (en) | 2021-05-27 | 2024-09-17 | Graphic Packaging International, Llc | Tray |

| USD1042122S1 (en) | 2021-05-27 | 2024-09-17 | Graphic Packaging International, Llc | Tray |

| USD1044494S1 (en) | 2021-05-27 | 2024-10-01 | Graphic Packaging International, Llc | Tray |

| USD1042119S1 (en) | 2021-05-27 | 2024-09-17 | Graphic Pachaging International, LLC | Tray |

| USD1042118S1 (en) | 2021-05-27 | 2024-09-17 | Graphic Packaging International, Llc | Tray |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2702663A (en) * | 1952-04-16 | 1955-02-22 | Empire Box Corp | Nested carton blank |

| GB959208A (en) * | 1961-01-20 | 1964-05-27 | Smith & Young Ltd | Improvements in or relating to box-like envelopes and blanks therefor |

| GB965590A (en) * | 1961-04-19 | 1964-07-29 | Weyerhaeuser Co | Improvements in or relating to cartons |

| US4762226A (en) * | 1983-10-12 | 1988-08-09 | White Consolidated Industries, Inc. | Shipping container for major appliances |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US695205A (en) * | 1901-12-20 | 1902-03-11 | J W Sefton Mfg Company | Paper box. |

| US1144746A (en) * | 1915-02-05 | 1915-06-29 | Stecher Lithographic Company | Folding box. |

| US1778462A (en) * | 1928-01-16 | 1930-10-14 | Ralph C C Nourse | Foldable box |

| US1755694A (en) * | 1928-04-09 | 1930-04-22 | Brown & Bailey Company | Packing and display box |

| US1726682A (en) * | 1928-09-15 | 1929-09-03 | Howard S Scholes | Foldable box |

| US2143308A (en) * | 1934-03-29 | 1939-01-10 | Flach Paul | Folded box |

| US2179421A (en) * | 1938-05-27 | 1939-11-07 | John J Murray | Paper box, carton, or tray |

| US2453614A (en) * | 1946-05-15 | 1948-11-09 | Belsinger Inc | Easy packing container |

| US2859906A (en) * | 1955-03-07 | 1958-11-11 | Waldorf Paper Prod Co | Telescoping carton |

| US2915235A (en) * | 1956-10-29 | 1959-12-01 | Swift & Co | Container for frozen foods |

| US3910483A (en) * | 1974-11-07 | 1975-10-07 | Int Paper Co | Two-piece, paperboard container construction |

| US4037777A (en) * | 1976-06-15 | 1977-07-26 | Westvaco Corporation | Handhole closure for containers |

| US4055293A (en) * | 1977-02-04 | 1977-10-25 | Container Corporation Of America | Tray with reinforced walls |

| US4127228A (en) * | 1977-08-04 | 1978-11-28 | Willamette Industries, Inc. | Asparagus box |

| DE3302972A1 (de) * | 1982-03-13 | 1983-09-22 | Allgäuer Holzspanschachtelfabrik und Kartonagenwerk Albert Frey, 8949 Dirlewang | Stapelbare aufrichteschachtel |

-

1991

- 1991-04-08 DE DE9104391U patent/DE9104391U1/de not_active Expired - Lifetime

-

1992

- 1992-04-03 CA CA002065132A patent/CA2065132A1/fr not_active Abandoned

- 1992-04-06 US US07/864,294 patent/US5211330A/en not_active Expired - Fee Related

- 1992-04-08 DE DE59204970T patent/DE59204970D1/de not_active Expired - Fee Related

- 1992-04-08 AT AT92106061T patent/ATE132824T1/de not_active IP Right Cessation

- 1992-04-08 EP EP92106061A patent/EP0508397B1/fr not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2702663A (en) * | 1952-04-16 | 1955-02-22 | Empire Box Corp | Nested carton blank |

| GB959208A (en) * | 1961-01-20 | 1964-05-27 | Smith & Young Ltd | Improvements in or relating to box-like envelopes and blanks therefor |

| GB965590A (en) * | 1961-04-19 | 1964-07-29 | Weyerhaeuser Co | Improvements in or relating to cartons |

| US4762226A (en) * | 1983-10-12 | 1988-08-09 | White Consolidated Industries, Inc. | Shipping container for major appliances |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE132824T1 (de) | 1996-01-15 |

| US5211330A (en) | 1993-05-18 |

| DE9104391U1 (de) | 1991-08-01 |

| EP0508397B1 (fr) | 1996-01-10 |

| DE59204970D1 (de) | 1996-02-22 |

| CA2065132A1 (fr) | 1992-10-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0508397B1 (fr) | Boîte dépliable | |

| DE69702930T2 (de) | Kartonschachtel mit zentrierlaschen und zuschnitt für ihre herstellung | |

| DE2643720C2 (de) | Stapelbarer Transportbehälter | |

| DE9017110U1 (de) | Verpackungseinrichtung | |

| EP0507909B1 (fr) | Systeme de conteneurs, en particulier systeme de conteneurs de transport et/ou d'emballage | |

| DE69314588T2 (de) | Kartonschale | |

| DE4204075C2 (de) | Transportverpackung | |

| DE19709969C2 (de) | Verpackung für Bilderhalter, insbesondere rahmenlose Bilderhalter | |

| EP3403941A1 (fr) | Emballage | |

| DE2914882A1 (de) | Faltbehaelter | |

| DE69204937T2 (de) | Stapelbare Verpackung aus Wellpappe. | |

| DE29820547U1 (de) | Vielseitig verwendbare Faltschachtel | |

| DE9305614U1 (de) | Aufrichteschachtel | |

| CH591369A5 (en) | Corner reinforced folded cardboard box - has end walls doubled over and inclined inwards to form stacking supports at corners (OE 15.6.77) | |

| DE102021119779A1 (de) | Behälter | |

| EP1522498A1 (fr) | Conteneur pour le transport et le stockage | |

| DE1914542U (de) | Zusammenlegbarer behaelter. | |

| DE9312950U1 (de) | Faltschachtel | |

| DE8803426U1 (de) | Zuschnittsbogen für eine Steige aus Pappe | |

| DE1134330B (de) | Faltschachtel, insbesondere fuer Flaschenreihen | |

| DE29509021U1 (de) | Steige, insbesondere für Obst und Gemüse | |

| DE20112752U1 (de) | Verpackungseinheit mit achteckigem Querschnitt | |

| DE9420580U1 (de) | Einstückiger Karton-Zuschnitt für eine Verpackung sowie hieraus hergestellte Verpackung | |

| DE4124452A1 (de) | Faltschachtel | |

| DE20105978U1 (de) | Quaderförmige Faltschachtel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19930409 |

|

| 17Q | First examination report despatched |

Effective date: 19940715 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19960110 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19960110 Ref country code: FR Effective date: 19960110 Ref country code: DK Effective date: 19960110 Ref country code: BE Effective date: 19960110 Ref country code: GB Effective date: 19960110 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19960110 |

|

| REF | Corresponds to: |

Ref document number: 132824 Country of ref document: AT Date of ref document: 19960115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59204970 Country of ref document: DE Date of ref document: 19960222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19960408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19960410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19960430 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19960430 Ref country code: CH Effective date: 19960430 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| EN | Fr: translation not filed | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19960110 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19970101 |

|

| 26N | No opposition filed |