EP0469188B1 - Blindnähmaschine - Google Patents

Blindnähmaschine Download PDFInfo

- Publication number

- EP0469188B1 EP0469188B1 EP90124188A EP90124188A EP0469188B1 EP 0469188 B1 EP0469188 B1 EP 0469188B1 EP 90124188 A EP90124188 A EP 90124188A EP 90124188 A EP90124188 A EP 90124188A EP 0469188 B1 EP0469188 B1 EP 0469188B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fabric

- drive shaft

- blind

- bulger

- sewing machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009958 sewing Methods 0.000 title claims abstract description 69

- 239000004744 fabric Substances 0.000 claims abstract description 153

- 239000000463 material Substances 0.000 claims abstract description 36

- 238000010276 construction Methods 0.000 abstract description 2

- 230000006835 compression Effects 0.000 description 9

- 238000007906 compression Methods 0.000 description 9

- 230000035515 penetration Effects 0.000 description 6

- 230000000694 effects Effects 0.000 description 3

- 230000008719 thickening Effects 0.000 description 3

- 238000013459 approach Methods 0.000 description 2

- 235000013405 beer Nutrition 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B1/00—General types of sewing apparatus or machines without mechanism for lateral movement of the needle or the work or both

- D05B1/24—General types of sewing apparatus or machines without mechanism for lateral movement of the needle or the work or both for making blind-stitch seams

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B85/00—Needles

- D05B85/06—Curved needles

Definitions

- the invention relates to a blind sewing machine specified in the preamble of claim 1.

- the plate-shaped fabric flexor is pivotally mounted in the middle or at one end on its support and is loaded by a tension or compression spring away from the massive drive shaft for the fabric flexor, which is rotatably mounted in the fabric support arm of the blind sewing machine and when sewing in cycles the swinging bow needle of the blind sewing machine as well as the timed step-by-step feed feed swings back and forth.

- the slot of the carrier running transversely to the drive shaft for receiving the fabric flexor with a slot width corresponding to the fabric flexor width is provided at that end of the support which projects perpendicularly from the drive shaft.

- the tension spring engages on the one hand at one end of the fabric flexor and on the other hand on an arm of the carrier which also extends radially to the drive shaft in order to press the fabric flexor with a stop against the bottom of the slot in the carrier. From this position, the fabric flexor can pivot against the action of the tension spring, its other end moving away from the path of movement of the curved needle toward the drive shaft of the fabric flexor.

- the compression spring is arranged in a longitudinal bore of the support and is supported on the one hand by an adjusting screw which can be screwed therein to change the pretension of the compression spring and on the other hand by a ball on the end of the fabric flexor remote from the pivot axis.

- the carrier is provided with a stop pin, which extends transversely in the slot through an elongated hole of the fabric flexor, which is formed in a circular arc and is arranged concentrically to the pivot axis of the fabric flexor.

- the compression spring presses the fabric flexor with the adjacent end of the elongated hole against the stop pin.

- the fabric flexor can pivot against the action of the compression spring until the other end of its elongated hole rests on the stop pin, the compression spring end of the fabric flexer moving away from the path of movement of the curved needle toward the drive shaft of the fabric flexor.

- the fabric flexor always pivots out of the first-mentioned position when a sewing material thickening between the fabric flexor and a stop on the stitch plate of the blind sewing machine, against which the fabric flexor bulges the material and which is spring-loaded on the material, counteracts the effect of the spring load to be able to dodge, to an extent that can be changed by means of an adjusting screw.

- the two fabric flexors are each rod-shaped and can be moved axially back and forth by means of the associated drive shaft, each fabric flexor being resiliently mounted, specifically in a sleeve connected to the respective drive shaft, in which a compression spring loading the fabric flexor is arranged, the bias of which can be changed by means of an adjusting screw.

- the drive shaft of one fabric flexor is hollow and rotatably mounted on the drive shaft of the other fabric flexor, which in turn is rotatably mounted in the fabric arm of the blind sewing machine.

- the latter is spring-loaded in the sewing position for abutment against a stop, which is used to change the distance of the fabric support arm in the sewing position from the path of movement of the curved needle of the blind sewing machine and thus to adjust the penetration depth of the curved needle into the material bulged by the fabric flexors by means of an adjusting screw Linkage is adjustable.

- the two fabric flexors bulge the material against a common stop, which is arranged on the throat plate of the blind sewing machine and is spring-loaded on the material in order to be able to deflect against the effect of the spring load by a variable amount by means of an adjusting screw (GB-A 13 31 476 ).

- the invention has for its object to provide a blind sewing machine of the type specified in the preamble of claim 1, in which the flexor and its support can be kept extremely narrow, but still such a large installation space for the spring acting between the fabric flexor and the carrier It is available that the requirement for a characteristic curve as flat as possible for this spring can be met without further ado, and the possibility is opened for measures in order to be able to change the preload of the spring in an exceptionally wide range and to be able to set it to different values.

- the narrow design of the fabric flexor and the carrier makes it possible to arrange the same feed elements for the sewing material on both sides at a very small mutual distance.

- a second corresponding fabric flexor can also be provided without the narrow arrangement of the feed members having to be changed significantly.

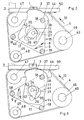

- the bow needle 1 and the needle plate 2 are arranged on the head of the blind sewing machine, the fabric flexor 3 and the conveyor belts 4 on its fabric support arm 5.

- the bow needle 1 swings back and forth in the direction of arrows 6 and 7, the fabric flexor 3 oscillates in the direction of Arrows 8 and 9 and move the conveyor belts 4 step by step in the direction of arrows 10, the vibrations of the bow needle 1, the oscillations of the fabric flexor 3 and the movement steps of the conveyor belts 4 being coordinated with one another in the usual manner, so that the bow needle 1, the fabric flexor 3 and the conveyor belts 4 act in the required sequence on the sewing material, not shown, which extends between the needle plate 2 and the conveyor belts 4.

- the fabric flexor 3 is designed as an approximately rectangular plate, extends along the plane defined by the line II-II in FIG. 1 and becomes in this plane perpendicular to the circular path of the curved needle 1 by means of a drive shaft 11 running perpendicular to the same in the direction of the arrows 8 and 9 swung back and forth.

- the drive shaft 11 is rotatably mounted in the fabric support arm 5 and is provided at the end facing away from the fabric flexor 3 with an arm 12 which is articulated by means of a bolt 13 to a rod 14, through which the drive shaft 11 via the arm 12 in the direction of arrows 8 and 9 and can be swung here.

- the fabric flexor 3 is connected to the drive shaft 11 by means of a carrier 15.

- the carrier 15 for the fabric flexor 3 consists of two parallel plates 16 and 17 with identical triangular contours, which are connected to each other by a bolt 18 at the three corners of the two mutually aligned contours, extend perpendicular to the drive shaft 11 and approximately concentrically to the same are arranged so that the three bolts 18 run parallel to the drive shaft 11 and are approximately the same distance from the drive shaft 11.

- the plates 16 and 17 delimit a slot 19 for receiving the plate-shaped fabric flexor 3, the width W of which corresponds to the width B of the fabric flexor 3 and which extends transversely in front of the adjacent end of the drive shaft 11.

- the drive shaft side plate 17 of the carrier 15 is fastened by means of a clamping screw 20. The latter is screwed into a radial threaded bore 21 of a hub 22 of the plate 17 which is plugged onto the end of the drive shaft 11.

- the drive shaft 11 is hollow and has a through bore 23 in which a cylindrical pin 24 is rotatably mounted and a torsion spring 25 is arranged.

- the pin 24 protrudes with one end into the slot 19 of the carrier 15 and is provided at this end with a radially projecting cam 26 and an axially projecting extension 27 of smaller diameter, which is accommodated in a bore 28 of corresponding diameter of the plate 16 of the carrier 15 remote from the drive shaft is.

- the torsion spring 25 engages.

- the torsion spring 25 is designed as a helical spring with two ends 29 and 30 extending transversely to the longitudinal axis of the helical spring, which are each received in a transverse slot 31 at the adjacent end of the pin 24 or in a transverse slot 32 at the adjacent end of a holder 33.

- the latter is cylindrical, rotatably mounted in the bore 23 of the drive shaft 11 and with four evenly distributed in the circumferential direction Longitudinal grooves 34 are provided for the engagement of a clamping screw 35 which fixes the holder 33 with respect to the drive shaft 11 and is screwed into a radial threaded bore 36 thereof.

- the fabric flexor 3 is pivotally mounted in the slot 19 of the carrier 15 and is loaded by the torsion spring 25 via the pin 24 away from the drive shaft 11 and onto the path of movement of the curved needle 1.

- the pin 18 of the latter which is adjacent to the needle plate 2 and which moves when the carrier 15 is pivoted in the direction of arrow 8 towards the needle plate 2, is used to mount the fabric flexor 3 on the carrier 15.

- This bolt 18 passes through a corresponding bearing bore 37 of the fabric flexor 3, which is provided in the region of the corner 38 which is adjacent to the throat plate 2 and when the fabric flexor 3 is pivoted by means of the drive shaft 11 via the carrier 15 in the direction of arrow 8.

- the fabric flexor 3 has an opening 39 which receives the cam 26 and the relevant end of the pin 24.

- the opening 39 has such a shape that there are a nose 40 and two stop edges 41 and 42 on the fabric flexor 3.

- the cam 26 of the pin 24 interacts with the nose 40 of the fabric flexor 3 in order to press the fabric flexor 3 as a result of the action of the torsion spring 25 into the position according to FIG. 2 with respect to the carrier 15, in which the stop edge 41 of the fabric flexor 3 on the cam side

- the end of the pin 24 abuts and from which the fabric flexor 3 can pivot counterclockwise, specifically counter to the action of the torsion spring 25 by correspondingly pivoting the cam 26 resting on the nose 40 and rotating the pin 24 in the bore 23 of the drive shaft 11 up to 3 with respect to the support 15, in which the stop edge 42 of the fabric flexor 3 bears against the cam-side end of the pin 24.

- the two stop edges 41 and 42 of the fabric flexor 3 thus limit the area in which the fabric flexor 3 can pivot within the slot 19 of the carrier 15.

- the force with which the torsion spring 25 loads the flexor 3 into the position according to FIG. 2 with respect to the carrier 15 can be changed step by step.

- To set the force required for the desired force Biasing the torsion spring 25 is sufficient to loosen the clamping screw 35 of the drive shaft 11 which interacts with the holder 33 for the torsion spring 25, the holder 33 by means of a screwdriver inserted in a transverse slot 43 at the end of the drive spring 11 facing away from the torsion spring 25 in the bore 23 of the drive shaft 11 to rotate accordingly, so that again a longitudinal groove 34 of the holder 33 comes in front of the clamping screw 35, and tighten the latter again.

- the two conveyor belts 4 extend parallel to the plane defined by line II-II in FIG. 1, in which the fabric flexor 3 and its carrier 15 can be pivoted back and forth by means of the drive shaft 11 and the fabric flexor 3 can pivot with respect to the carrier 15 , namely on both sides of the fabric flexor 3 and the carrier 15.

- Each endless conveyor belt 4 runs via a pressure lever 44, a deflection wheel 45 and a drive wheel 46.

- the pressure lever 44 is pivoted at one end about an axis 47 on the fabric support arm 5 and on the needle plate 2 too spring loaded.

- the deflection wheel 45 is rotatably mounted on an axis 48 on the fabric support arm 5.

- the drive wheel 46 is fastened on a drive shaft 49, which is rotatably mounted in the fabric support arm 5 and carries the drive wheels 46 of both conveyor belts 4.

- the two axes 47 and 48 and the drive shaft 49 extend parallel to the drive shaft 11 of the fabric flexor 3.

- the two conveyor belts 4 can be arranged very closely next to one another, so that the mutual distance is very small.

- the fabric flexor 3 can have a width B of approximately 1.2 mm and the two plates 16 and 17 of the carrier 15 can each have a thickness of approximately 0.8 mm.

- the conveyor belts 4 move the sewing material step by step in the direction of the arrows 10 and the fabric flexor 3 bulges the sewing material after each feed step through a slot 50 of the needle plate 2 running in the sewing material advancing direction 10, after which the curved needle 1 pierces the bulging sewing material, and although the deeper, the further the fabric flexor 3 has bulged the sewing material over the circular path of movement of the curved needle 1, which depends on the thickness of the bulging sewing material and depends on the distance up to which the fabric flexor 3 approaches the path of movement of the curved needle 1 when it is pivoted by means of the drive shaft 11 via the carrier 15 in the direction of arrow 8.

- the sewing material is held particularly securely because the gap between the two conveyor belts 4 pressing the sewing material on both sides of the fabric flexor 3 by means of the pressing lever 44 against the needle plate 2 is relatively narrow.

- the fabric support arm 5 can be adjusted with respect to the head of the blind sewing machine in such a way that the distance required for the desired penetration depth, taking into account the normal thickness of the respective sewing material, is obtained, up to which there is the fabric flexor 3 when pivoting in the direction of arrow 8 together with the carrier 15 in the mutual position according to FIG. 2 can approach the path of movement of the bow needle 1.

- the set penetration depth is maintained even when a thickening of the material, such as a transverse seam, comes into the area of the fabric flexor 3 because this then moves from the position according to FIG.

- the fabric support arm 5 of the blind sewing machine is shown in the position with respect to its head in which the two conveyor belts 4 for the material to be sewn in the area of the pressure lever 44 lie directly on the needle plate 2 and the smallest possible distance of the fabric flexor 3 from the movement path the bow needle 1 is zero.

- the carrier 15 and the drive shaft 11 of the fabric flexor 3 are illustrated in the position which they assume at the end of the pivoting movement in the direction of the arrow 8 and at the beginning of the pivoting movement in the direction of the arrow 9.

- the blind sewing machine according to FIGS. 4 and 5 differs essentially only from that according to FIGS. 1 to 3 in that a second fabric flexor 3 ' is provided, which is identical in design, arrangement and mode of operation with the first fabric flexor 3, apart from the fact that the drive shaft 11 ', the carrier 15', the pin 24 'and the torsion spring 25' of the second fabric flexor 3 'mirror image of the drive shaft 11, the carrier 15, the pin 24 and the torsion spring 25 of the first fabric flexor 3 are formed and arranged, as is the holder 33 ′ for the torsion spring 25 ′ of the second fabric flexor 3 ′ to the holder 33 for the torsion spring 25 of the first fabric flexor 3

- the two hollow drive shafts 11 and 11 'thus extend aligned with one another on both sides of the pair of fabric flexors 3, 3', each away from the carrier 15 or 15 'of the associated fabric flexor 3 or 3'.

- the hollow drive shaft 11 'of the second fabric flexor 3' is rotatably supported in a support 51 and connected via a toothed belt drive to a further drive shaft 52 which is arranged parallel to the two hollow drive shafts 11 and 11 '.

- the toothed belt drive consists of a toothed belt wheel 53 fastened on the hollow drive shaft 11 ', a toothed belt wheel 54 fastened on the additional drive shaft 52 and an endless toothed belt 55 which loops around the two toothed belt wheels 53 and 54.

- the further drive shaft 52 is provided with an arm 12 ', which is articulated by means of a bolt 13' on a rod 14 ', by means of which the drive shaft 52 can be pivoted back and forth over the arm 12'.

- the two fabric flexors 3 and 3 ' can be driven from the same side, namely the right side in FIG. 4 and the free end of the fabric support arm 5.

- the support 51 is pivotably mounted on the fabric support arm 5 and is provided with a hollow axis 56 on the side facing away from the toothed belt drive and facing the pair of fabric flexors 3, 3 '.

- a hollow axis 56 In its bore 57, which is also passed through the support 51 and extends transversely therethrough, is the second drive shaft 52 for the second fabric flexor 3 ' rotatably mounted.

- the axis 56 is in turn rotatably mounted in a longitudinal bore 58 of the fabric support arm 5.

- the fabric support arm 5 is pivotally mounted on the housing 59 of the blind sewing machine about an axis 60 and is loaded by a tension spring 61 into the sewing position shown, in which the fabric support arm 5 is supported on the housing 59 via a first adjusting screw 62, which is supported in one after tongue 63 projecting below the front longitudinal wall 64 of the fabric support arm 5 can be screwed.

- the axis 60 runs parallel to the drive shafts 11, 11 'and 52 for the textile beers 3 and 3' and the helical tension spring 61 engages on the one hand on the tongue 63 and on the other hand on the housing 59.

- the support 51 of the first drive shaft 11 'for the second fabric flexor 3' which can be pivoted about the common longitudinal axis of the second drive shaft 52 for the second fabric flexor 3 'about the common longitudinal axis of the second drive shaft 52', and the support 51 of the first drive shaft 11 'for the second fabric flexor 3', which is coaxial with the same, is loaded by a helical compression spring 65, which is self-supporting is supported on the one hand on a downwardly projecting projection 66 of the support 51 and on the other hand on the fabric support arm 5 or on the housing 59 of the blind sewing machine and the projection 66 provided on the bearing axis 56 alongside the arm 12 ′ of the second drive shaft 52 according to FIG.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Sewing Machines And Sewing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4024715 | 1990-08-03 | ||

| DE4024715A DE4024715C1 (es) | 1990-08-03 | 1990-08-03 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0469188A1 EP0469188A1 (de) | 1992-02-05 |

| EP0469188B1 true EP0469188B1 (de) | 1994-03-09 |

Family

ID=6411617

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90124188A Expired - Lifetime EP0469188B1 (de) | 1990-08-03 | 1990-12-14 | Blindnähmaschine |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US5129339A (es) |

| EP (1) | EP0469188B1 (es) |

| JP (1) | JPH04240473A (es) |

| AT (1) | ATE102665T1 (es) |

| DE (1) | DE4024715C1 (es) |

| ES (1) | ES2050924T4 (es) |

| HU (1) | HUT65009A (es) |

| RU (1) | RU2015226C1 (es) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19701341C1 (de) * | 1997-01-16 | 1998-01-15 | Strobel & Soehne Gmbh & Co J | Blindstichnähmaschine |

| US6904853B2 (en) * | 2003-09-09 | 2005-06-14 | Ching Chi Machine Co., Ltd. | Take-up cam phase adjustment structure of looper thread take-up apparatus of a sewing machine |

| CN106529121B (zh) * | 2016-09-30 | 2019-01-29 | 飞依诺科技(苏州)有限公司 | 超声动态聚焦延时数据的恢复方法及恢复系统 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB191509134A (en) * | 1915-06-22 | 1916-06-01 | James Mcculloch | Improvements in or relating to Sewing Machines especially applicable for Blind Stitch Machines. |

| FR21045E (fr) * | 1917-10-12 | 1920-02-19 | Philippe Maurice Favre Bulle D | Indicateur de vitesse de rotation |

| US2194149A (en) * | 1937-08-18 | 1940-03-19 | Lewis Invisible Stitch Machine | Blind stitch sewing machine |

| US2250573A (en) * | 1939-07-21 | 1941-07-29 | American Blind Stitch Machine | Sewing machine construction |

| US2355904A (en) * | 1940-06-17 | 1944-08-15 | Us Blind Stitch Machine Corp | Blind-stitch sewing machine |

| GB727340A (en) * | 1952-12-16 | 1955-03-30 | Us Blind Stitch Machine Corp | Improvements in sewing machines |

| US3572269A (en) * | 1969-12-03 | 1971-03-23 | Union Special Machine Co | Blindstitch sewing machine |

| US3747546A (en) * | 1970-07-29 | 1973-07-24 | Union Special Maschinenfab | Blindstitch sewing machine |

| DE2037502A1 (en) * | 1970-07-29 | 1972-02-03 | Union Special Maschinenfabrik Gmbh, 7000 Stuttgart | Swivelable plunger mechanism for blind stitch sewing machines |

| DE2736780C2 (de) * | 1977-08-16 | 1981-11-12 | Maier-Unitas GmbH, 7316 Köngen | Blindstichnähmaschine |

| GB2119415B (en) * | 1982-04-29 | 1985-07-10 | William Arthur Allen | Blind stitch sewing machine |

| GB2187212A (en) * | 1986-02-27 | 1987-09-03 | Textile Handling And Technolog | Device for sewing materials with nap or pile |

-

1990

- 1990-08-03 DE DE4024715A patent/DE4024715C1/de not_active Expired - Fee Related

- 1990-12-14 AT AT90124188T patent/ATE102665T1/de not_active IP Right Cessation

- 1990-12-14 EP EP90124188A patent/EP0469188B1/de not_active Expired - Lifetime

- 1990-12-14 ES ES90124188T patent/ES2050924T4/es not_active Expired - Lifetime

-

1991

- 1991-07-05 JP JP3165876A patent/JPH04240473A/ja active Pending

- 1991-08-02 HU HU912591A patent/HUT65009A/hu unknown

- 1991-08-02 US US07/739,664 patent/US5129339A/en not_active Expired - Fee Related

- 1991-08-02 RU SU915001140A patent/RU2015226C1/ru active

Also Published As

| Publication number | Publication date |

|---|---|

| HUT65009A (en) | 1994-03-28 |

| US5129339A (en) | 1992-07-14 |

| DE4024715C1 (es) | 1991-08-01 |

| HU912591D0 (en) | 1992-01-28 |

| ES2050924T3 (es) | 1994-06-01 |

| RU2015226C1 (ru) | 1994-06-30 |

| ATE102665T1 (de) | 1994-03-15 |

| EP0469188A1 (de) | 1992-02-05 |

| ES2050924T4 (es) | 1995-12-01 |

| JPH04240473A (ja) | 1992-08-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2611820A1 (de) | Insbesondere in verbindung mit rotations-schnelldruck-pressen verwendbare faltvorrichtung | |

| DE2718607C2 (de) | Nähmaschine mit einer angetriebenen Vorschubrolle | |

| DE69509871T2 (de) | Etikettiermaschine | |

| DE3539371A1 (de) | Vorrichtung zum einstellen des nadelhubs an einer naehmaschine | |

| DE3810663A1 (de) | Walzenzufuehrungseinrichtung | |

| CH679134A5 (es) | ||

| DE2400741A1 (de) | Bandfuehrungsvorrichtung | |

| DE3011368C2 (es) | ||

| EP0469188B1 (de) | Blindnähmaschine | |

| EP0484591B1 (de) | Nähmaschine | |

| DE4316410C2 (de) | Nähmaschine mit einer Nähgutvorschubeinrichtung | |

| DE4231834C2 (de) | Tufting-Maschine | |

| DE2056529C3 (de) | Stoffdrücker für Nähmaschinen | |

| CH639149A5 (en) | Drive device for the band wheel of a band-type gripper weaving machine | |

| DE3313831C2 (de) | Nähmaschine mit Hauptantriebswelle und Differential-Stoffschiebereinrichtung | |

| DE3805419A1 (de) | Einschnittvorrichtung fuer streifen von einwickelmaterial | |

| DE3313196C1 (de) | Vorrichtung zum Spannen eines bandförmigen Förderorganes | |

| DE3027310A1 (de) | Nadelantriebsvorrichtung fuer naehmaschinen | |

| DD206732A5 (de) | Fischbearbeitungsmaschine mit einer steuereinrichtung fuer die bearbeitungswerkzeuge | |

| DE69803929T2 (de) | Transportvorrichtung für leiterrahmen und transportanordnung | |

| DE2248827C2 (de) | Nadelstangenführung einer Nähmaschine | |

| DE3610125C1 (de) | Naehmaschine mit Differential-Stoffvorschub | |

| DE19750614C2 (de) | Vorrichtung zum Verändern des Verdrängungsvolumens einer hydrostatischen Maschine | |

| DE2928257C2 (de) | Schloß für eine Flachstrickmaschine | |

| DE2035156B2 (de) | Vorrichtung zum Schleifen von Spiralbohrerspitzen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19910909 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH ES FR GB IT LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19930714 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH ES FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 102665 Country of ref document: AT Date of ref document: 19940315 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19940314 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| ET1 | Fr: translation filed ** revision of the translation of the patent or the claims | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: BA2A Ref document number: 2050924 Country of ref document: ES Kind code of ref document: T4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19941214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19941231 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 90124188.5 |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: J. STROBEL & SOHNE G.M.B.H. & CO. Effective date: 19941231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19950701 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19950701 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 90124188.5 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19961129 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19961202 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19961209 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19961224 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971231 Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19971231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971231 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19971214 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981215 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051214 |