EP0354484B1 - Dosierpumpe - Google Patents

Dosierpumpe Download PDFInfo

- Publication number

- EP0354484B1 EP0354484B1 EP89114391A EP89114391A EP0354484B1 EP 0354484 B1 EP0354484 B1 EP 0354484B1 EP 89114391 A EP89114391 A EP 89114391A EP 89114391 A EP89114391 A EP 89114391A EP 0354484 B1 EP0354484 B1 EP 0354484B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pump

- dosing

- stroke

- metering

- ventilation device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009423 ventilation Methods 0.000 claims description 7

- 238000005086 pumping Methods 0.000 abstract description 2

- 230000000740 bleeding effect Effects 0.000 abstract 2

- 239000012528 membrane Substances 0.000 description 13

- 238000013022 venting Methods 0.000 description 6

- 230000006835 compression Effects 0.000 description 4

- 238000007906 compression Methods 0.000 description 4

- 230000002123 temporal effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/06—Venting

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B43/00—Machines, pumps, or pumping installations having flexible working members

- F04B43/02—Machines, pumps, or pumping installations having flexible working members having plate-like flexible members, e.g. diaphragms

- F04B43/04—Pumps having electric drive

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B7/00—Piston machines or pumps characterised by having positively-driven valving

- F04B7/0042—Piston machines or pumps characterised by having positively-driven valving with specific kinematics of the distribution member

- F04B7/0053—Piston machines or pumps characterised by having positively-driven valving with specific kinematics of the distribution member for reciprocating distribution members

Definitions

- the invention relates to a metering pump according to the first part of patent claim 1.

- Such a metering pump is known from US-A-4236881.

- the venting device is coupled to the diaphragm pump in such a way that the venting device is closed during the suction stroke of the diaphragm pump and can be opened via an adjustable part of the pressure stroke of the diaphragm pump. The metering takes place in the remaining part of the pressure stroke.

- a dosing pump is known from DE-C-3631984, in which the venting device closes a small time period before the pressure stroke of the dosing membrane is carried out and opens a small time period after the dosing stroke has ended.

- a pressure valve is provided in the return line. This means that the return is not exactly defined.

- the object of the invention is to improve the ventilation in a metering pump of the type described in the introduction.

- the return should be precisely defined.

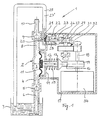

- the metering pump 1 has a pump head 2. This has a pump chamber 3 extending in the vertical direction. At the lower end of the pumping chamber, seen in the vertical direction, there is a suction channel 4, which is connected to a suction line 6 via a suction valve 5. The suction line 6 leads into a dosing agent container 7.

- a riser 8 opens.

- the upper end of the riser as seen in the vertical direction leads via a pressure valve 9 to a connection 10 that can be connected to a metering point.

- a diaphragm pump with a clamped-in metering diaphragm 11, which is firmly connected to a plunger 12 on its rear side, is provided.

- the plunger has a stop 13.

- a compression spring 15 is provided, which biases the membrane 11 in the suction position.

- a motor 34 is fastened in the pump housing 17 connected to the pump head 2 in the manner shown in FIG. 1. This has a motor-driven shaft 18 which carries a metering eccentric 19. The end 16 of the plunger 12 is biased by the compression spring 15 on the metering eccentric 19.

- a cross bore 20 opens as directly as possible at the upper end of the riser 8, that is to say directly in front of the pressure valve 9. This leads into the valve chamber 21 of a ventilation device formed by a membrane valve 22. At the end of the transverse bore 20, a valve seat 23 is incorporated. A return line 25 connects in the upper region of the valve chamber 21 as seen in the vertical direction. In the exemplary embodiment shown, this leads back into the dosing agent container 7.

- the membrane of the membrane valve 22 is firmly connected on its side facing away from the valve chamber with a tappet 26. Between the rear of the membrane and a wall part 27 of the housing, a compression spring 28 is provided, which is biased so that the membrane is initially held in the closed position shown in FIG. 1.

- the end of the plunger facing away from the membrane has a yoke 29.

- a second eccentric 31 running on the shaft 18 runs in the yoke 29.

- the eccentric 31 is connected to the shaft 18 via an intermediate gear 32.

- the second eccentric 31 is designed such that the plunger 26 is moved in the desired angular range so that the membrane of the diaphragm valve 22 executes a stroke against the compression spring 28.

- the two eccentrics 19 and 31 are so angularly offset from each other that the cycle shown in Fig. 4a takes place.

- the diaphragm valve 22 is open during a metering stroke of the metering membrane 11.

- the vent valve formed by the diaphragm valve closes. In this way it is ensured that gas present during the metering stroke exits via the return line.

- the ratio determined by the design of the intermediate gear 32 is selected such that the diaphragm valve 22 does not release the return flow with every metering stroke but with every nth pressure stroke, where n is an integer smaller than the number of Dosing strokes. n also determines the dosing quantity. E.g. Vented every second stroke, halves the original dosage. If the air is only vented every tenth stroke, the dosing quantity is reduced by only 1/10.

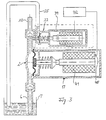

- the embodiment shown in FIG. 2 differs from that shown in FIG. 1 only in that the diaphragm valve 22 is actuated by a separate solenoid 39.

- the solenoid 39 is controlled by a controller 40.

- a sensor 45 is provided which detects the rotational position of the metering eccentric 19 and delivers an output signal via this rotary position to the controller 40 in order to ensure the synchronization of the metering stroke of the diaphragm valve 22 with the diaphragm 11 in the manner described above.

- the controller 40 is designed such that, as in the first embodiment, the venting takes place only on every n-th metering stroke, as can be seen from FIG. 4b.

- a second lifting magnet 41 is provided instead of the motor 34 with shaft 18 and metering eccentric 19.

- the actuation of the two solenoids 39 and 41 takes place via the control 40.

- the temporal work sequence for the membrane 11 and the membrane of the membrane valve 22 takes place in the same way as in the previous two exemplary embodiments, as can be seen from FIG. 4c.

- the venting stroke runs so synchronously with the respective metering stroke that the venting valve is open during the nth metering stroke, otherwise it is closed.

- the number n can be set via the controller 40.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Reciprocating Pumps (AREA)

- Infusion, Injection, And Reservoir Apparatuses (AREA)

- Medicines Containing Plant Substances (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89114391T ATE71434T1 (de) | 1988-08-12 | 1989-08-03 | Dosierpumpe. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3827489A DE3827489C1 (ko) | 1988-08-12 | 1988-08-12 | |

| DE3827489 | 1988-08-12 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0354484A1 EP0354484A1 (de) | 1990-02-14 |

| EP0354484B1 true EP0354484B1 (de) | 1992-01-08 |

Family

ID=6360773

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89114391A Expired - Lifetime EP0354484B1 (de) | 1988-08-12 | 1989-08-03 | Dosierpumpe |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4990066A (ko) |

| EP (1) | EP0354484B1 (ko) |

| JP (1) | JPH02140470A (ko) |

| AT (1) | ATE71434T1 (ko) |

| DE (2) | DE3827489C1 (ko) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4219663A1 (de) * | 1992-06-16 | 1993-12-23 | Prominent Dosiertechnik Gmbh | Flüssigkeits-Dosierpumpe |

| DE4219664A1 (de) * | 1992-06-16 | 1993-12-23 | Prominent Dosiertechnik Gmbh | Fördereinheit für eine Verdrängerdosierpumpe |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB9023552D0 (en) * | 1990-10-30 | 1990-12-12 | Domino Printing Sciences Plc | A two-stage pump for a continuous ink jet printer |

| US5188516A (en) * | 1991-09-20 | 1993-02-23 | Huang Yuh T | Hydraulic/pneumatic pump |

| DE4241030C1 (de) * | 1992-12-05 | 1994-06-01 | Lang Apparatebau Gmbh | Dosierpumpe mit Entlüftungsventil |

| US5354183A (en) * | 1993-02-11 | 1994-10-11 | Elasis Sistema Ricerca Fiat Nel Mezzogiorno Societa Consortile Per Azioni | Pumping device with a main pumping stage and a supply pump |

| DE19712096C1 (de) * | 1997-03-22 | 1998-04-02 | Lang Apparatebau Gmbh | Dosierpumpe zum dosierten Fördern von Flüssigkeiten |

| US6371740B1 (en) * | 1999-05-11 | 2002-04-16 | Jansen's Aircraft Systems Controls, Inc. | Jet engine fuel delivery system with non-pulsating diaphragm fuel metering pump |

| AUPQ616200A0 (en) * | 2000-03-10 | 2000-03-30 | Speight, Christopher | Chemical metering pump |

| EP1132616A1 (de) * | 2000-03-10 | 2001-09-12 | BMO Treuhand und Verwaltung AG | Dosierpumpe |

| DE10044609B4 (de) * | 2000-09-09 | 2004-11-04 | Siemens Ag | Kraftstofffördereinheit |

| JP2005076535A (ja) * | 2003-08-29 | 2005-03-24 | Mitsumi Electric Co Ltd | 排気弁装置及び血圧計に用いられる排気弁装置 |

| JP2005076534A (ja) * | 2003-08-29 | 2005-03-24 | Mitsumi Electric Co Ltd | 排気弁装置付小型ポンプ及びその排気弁装置付小型ポンプを使用した血圧計 |

| US7544048B2 (en) * | 2003-09-04 | 2009-06-09 | Grigori Lishanski | Universal vibratory pump |

| JP2005204903A (ja) * | 2004-01-22 | 2005-08-04 | Mitsumi Electric Co Ltd | 血圧計用ポンプユニットの強制排気機構 |

| US7140847B2 (en) * | 2004-08-11 | 2006-11-28 | The Boc Group, Inc. | Integrated high vacuum pumping system |

| JP4723218B2 (ja) * | 2004-09-10 | 2011-07-13 | シーケーディ株式会社 | 薬液供給用ポンプユニット |

| EP2194270B1 (de) * | 2008-12-05 | 2013-06-12 | ebm-papst St. Georgen GmbH & Co. KG | Dosierpumpe |

| DE102008061904A1 (de) * | 2008-12-15 | 2010-06-17 | Alldos Eichler Gmbh | Verfahren und Vorrichtung zur Entgasung des Förderraums einer Dosierpumpe |

| WO2010085840A1 (en) * | 2009-01-27 | 2010-08-05 | Doig Ian D | Pumps with extended surface valves and vent system |

| AU2010256350B2 (en) | 2009-06-02 | 2015-11-12 | Topcon Precision Agriculture Pty Ltd | Vehicle guidance system |

| US20120107150A1 (en) * | 2010-11-02 | 2012-05-03 | Bogdan Pawlak | Radial Diaphragm Pump |

| JP5816446B2 (ja) * | 2011-03-22 | 2015-11-18 | 株式会社川本製作所 | 給水ユニット |

| US10107279B2 (en) | 2012-12-10 | 2018-10-23 | Kongsberg Automotive Ab | Unitary fluid flow apparatus for inflating and deflating a device |

| DE102014204478B4 (de) | 2013-03-11 | 2023-06-15 | Herrmann Gmbh & Co. Kg | Mikrodosierpumpe und Verfahren hierfür |

| US10697447B2 (en) * | 2014-08-21 | 2020-06-30 | Fenwal, Inc. | Magnet-based systems and methods for transferring fluid |

| DE102014112833A1 (de) * | 2014-09-05 | 2016-03-10 | Prominent Gmbh | Verdrängerpumpe mit Fluidreservoir |

| CN105221380A (zh) * | 2015-09-29 | 2016-01-06 | 苏州巧泰精密机械有限公司 | 计量泵 |

| DE102017121274B3 (de) * | 2017-09-14 | 2019-02-21 | Wollin Gmbh | Sprühdüse für ein Sprühwerkzeug |

| WO2019161259A1 (en) * | 2018-02-15 | 2019-08-22 | Jacobsen Innovations, Inc. | Digital hydraulic system |

| DE102018133214A1 (de) * | 2018-12-20 | 2020-06-25 | Lutz-Jesco Gmbh | Dosierpumpe mit integriertem Überströmventil und Ventileinsatz für eine Dosierpumpe |

| CN111577568B (zh) * | 2020-06-02 | 2023-01-17 | 威海东椿电子有限公司 | 一种同步带定量泵及方法 |

| DE102020119502A1 (de) | 2020-07-23 | 2022-01-27 | Washtec Holding Gmbh | Verfahren zum betreiben einer dosierpumpe in einem flüssigkeitsversorgungssystem |

| CN112343803B (zh) * | 2020-11-03 | 2022-05-13 | 常州拓川泵业科技有限公司 | 一种旋转推力式计量泵 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4734891U (ko) * | 1971-05-11 | 1972-12-18 | ||

| DE2318713A1 (de) * | 1973-04-13 | 1974-10-24 | Bayer Ag | Dosierpumpe mit selbsttaetiger entluefung |

| US4236881A (en) * | 1978-05-03 | 1980-12-02 | Ecodyne Corporation | Liquid metering pump |

| US4453931A (en) * | 1980-08-01 | 1984-06-12 | Oximetrix, Inc. | Intravenous metering device |

| DE3410529A1 (de) * | 1984-03-22 | 1985-10-03 | Fa. J. Eberspächer, 7300 Esslingen | Steuereinrichtung fuer eine dosierpumpe |

| JPS62228683A (ja) * | 1986-03-31 | 1987-10-07 | Keihin Seiki Mfg Co Ltd | ダイヤフラム式電磁ポンプ |

| DE3631984C1 (de) * | 1986-09-19 | 1987-12-17 | Hans Ing Kern | Dosierpumpe |

| DE3631982C1 (de) * | 1986-09-19 | 1988-02-04 | Hans Ing Kern | Dosierpumpe |

| DE8801774U1 (de) * | 1988-02-11 | 1988-05-11 | Brown, Gary, Dipl.-Ing., 6454 Bruchköbel | Förder- und Dosierpumpe für Flüssigkeiten |

-

1988

- 1988-08-12 DE DE3827489A patent/DE3827489C1/de not_active Expired

-

1989

- 1989-08-03 DE DE8989114391T patent/DE58900696D1/de not_active Expired - Lifetime

- 1989-08-03 AT AT89114391T patent/ATE71434T1/de not_active IP Right Cessation

- 1989-08-03 EP EP89114391A patent/EP0354484B1/de not_active Expired - Lifetime

- 1989-08-11 US US07/393,527 patent/US4990066A/en not_active Expired - Fee Related

- 1989-08-14 JP JP1208015A patent/JPH02140470A/ja active Pending

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4219663A1 (de) * | 1992-06-16 | 1993-12-23 | Prominent Dosiertechnik Gmbh | Flüssigkeits-Dosierpumpe |

| DE4219664A1 (de) * | 1992-06-16 | 1993-12-23 | Prominent Dosiertechnik Gmbh | Fördereinheit für eine Verdrängerdosierpumpe |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3827489C1 (ko) | 1989-10-12 |

| US4990066A (en) | 1991-02-05 |

| JPH02140470A (ja) | 1990-05-30 |

| ATE71434T1 (de) | 1992-01-15 |

| DE58900696D1 (de) | 1992-02-20 |

| EP0354484A1 (de) | 1990-02-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0354484B1 (de) | Dosierpumpe | |

| EP0260464B1 (de) | Dosierpumpe | |

| DE2954163C2 (de) | Modulator für eine hydraulische Bremsanlage mit Blockierschutzeinrichtung | |

| EP0825348B1 (de) | Druckverstärker für Fluide, insbesondere für Hydraulikflüssigkeiten | |

| DE4241073C1 (de) | Apparat für die dosierte Abgabe von einem Fluid, insbesondere von einem Schmiermittelfluid | |

| DE3431969A1 (de) | Fluessigkeitskreislauf fuer den betrieb eines hydraulischen zweirichtungsmotors unter verminderung von erschuetterungen | |

| DE3119050A1 (de) | "brennstoffeinspritzvorrichtung mit elektromagnetisch betaetigtem umschaltventil" | |

| EP0226070B1 (de) | Pumpenanordnung zur dosierten Abgabe von mindestens zwei Komponenten | |

| DE3420345C2 (ko) | ||

| DE69221642T2 (de) | Schmierungsanlage für punktschmierung der arbeitszylinder in grosskolbenmaschinen, insbesondere schiffdieselmotoren | |

| DE3016609A1 (de) | Vorrichtung zum regeln der foerdermenge einer pumpe | |

| EP0051800A1 (de) | Antiblockiervorrichtung | |

| DE2155310B2 (de) | Brennstoff-Einspritzpumpe für Dieselrammen | |

| DE19616191A1 (de) | Steuerventil für eine Membranpumpe | |

| DE69519520T2 (de) | Doppelmembranpumpe | |

| DE69200955T2 (de) | Bremsdruckregeleinrichtung. | |

| EP0032172B1 (de) | Kraftstoffeinspritzeinrichtung für Brennkraftmaschinen, insbesondere für Dieselmotoren | |

| DE3922660C2 (ko) | ||

| DE19531064B4 (de) | Pulsationsfreie Pumpe | |

| DE2933567A1 (de) | Vorrichtung zur begrenzung der hoechstdrehzahl einer verbrennungskraftmaschine eines kraftfahrzeuges | |

| DE4118600C2 (de) | Dosierpumpeneinrichtung mit einem Entlüftungsventil | |

| DE628474C (de) | Druckregler fuer das Druckregelventil der Fluessigkeitsbremse eines Kraftfahrzeuges | |

| DE3001051A1 (de) | Kraftstoffeinspritzeinrichtung fuer brennkraftmaschinen, insbesondere fuer dieselmotoren | |

| DE2907033A1 (de) | Einrichtung zur betaetigung eines gaswechselventils bei brennkraftmaschinen | |

| DE3200531A1 (de) | Anordnung fuer die zufuhr eines kompressiblen antriebsmediums zu einem antrieb |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| 17P | Request for examination filed |

Effective date: 19900307 |

|

| 17Q | First examination report despatched |

Effective date: 19900820 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| REF | Corresponds to: |

Ref document number: 71434 Country of ref document: AT Date of ref document: 19920115 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 58900696 Country of ref document: DE Date of ref document: 19920220 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19960729 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960810 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19960822 Year of fee payment: 8 Ref country code: AT Payment date: 19960822 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960823 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19960828 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970803 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970831 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970831 |

|

| BERE | Be: lapsed |

Owner name: GRUNBECK WASSERAUFBEREITUNG G.M.B.H. Effective date: 19970831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980301 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19970803 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980430 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19980301 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20000830 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050803 |