EP0344241B1 - Baguette de coupe pour coupe-papier - Google Patents

Baguette de coupe pour coupe-papier Download PDFInfo

- Publication number

- EP0344241B1 EP0344241B1 EP88909194A EP88909194A EP0344241B1 EP 0344241 B1 EP0344241 B1 EP 0344241B1 EP 88909194 A EP88909194 A EP 88909194A EP 88909194 A EP88909194 A EP 88909194A EP 0344241 B1 EP0344241 B1 EP 0344241B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cutting

- strip according

- cutting strip

- cleat

- groove

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005520 cutting process Methods 0.000 title claims abstract description 43

- 239000004033 plastic Substances 0.000 claims abstract description 12

- 229920003023 plastic Polymers 0.000 claims abstract description 12

- 239000002184 metal Substances 0.000 claims description 7

- 229910052751 metal Inorganic materials 0.000 claims description 7

- -1 polypropylene Polymers 0.000 claims description 3

- 239000004743 Polypropylene Substances 0.000 claims description 2

- 229920001155 polypropylene Polymers 0.000 claims description 2

- 239000004698 Polyethylene Substances 0.000 claims 1

- 230000000295 complement effect Effects 0.000 claims 1

- 239000003000 extruded plastic Substances 0.000 claims 1

- 230000037431 insertion Effects 0.000 claims 1

- 238000003780 insertion Methods 0.000 claims 1

- 229920000573 polyethylene Polymers 0.000 claims 1

- 238000004519 manufacturing process Methods 0.000 abstract description 6

- 239000000463 material Substances 0.000 abstract description 4

- 238000003754 machining Methods 0.000 abstract description 2

- 239000002985 plastic film Substances 0.000 abstract 1

- 238000003860 storage Methods 0.000 abstract 1

- 239000002245 particle Substances 0.000 description 3

- 238000003825 pressing Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 239000004705 High-molecular-weight polyethylene Substances 0.000 description 1

- 241000270295 Serpentes Species 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000010408 film Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 210000003813 thumb Anatomy 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D7/00—Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D7/20—Cutting beds

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00—Cutting

- Y10T83/929—Tool or tool with support

- Y10T83/9309—Anvil

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00—Cutting

- Y10T83/929—Tool or tool with support

- Y10T83/9457—Joint or connection

- Y10T83/9461—Resiliently biased connection

Definitions

- the problem with the present invention was to solve the following problem:

- the plastic strip itself had to be shaped in such a way that it had a tight fit in the groove. This means that on the one hand it was not allowed to have too much leeway, but on the other hand that it had to be easy to push in by hand.

- this problem is solved in such a way that the plastic strip is shaped like a snake, or more precisely, sinusoidally.

- this serpentine shape is then forced into a straight line.

- the plastic strip exerts pressing forces on both sides of the groove and is thereby firmly clamped in it.

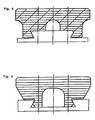

- FIGS. 1 and 2 The shape of the newly created cutting bar can be seen in FIGS. 1 and 2. From these two figures it can be seen that the new cutting bar practically only consists of a thin film, which in the middle with a tube-like structure connected is. The width of this cutting bar or better cutting foil remains the same as the old cutting bar, namely approx. 10 mm. However, it is significantly thinner in thickness, so that one can now speak more of a film. So that these new cutting strips or cutting foils can be inserted into the groove of the existing paper cutting machines, a metal strip 4 is glued into the existing groove. This metal bar 4 has in the middle according to FIG.

- the cutting bar can be used twice by simply turning it over.

- This new strip is no longer PVC, but a notch-resistant plastic e.g. Polypropylene or a high molecular weight polyethylene is used.

- a notch-resistant plastic e.g. Polypropylene or a high molecular weight polyethylene is used.

- cutting strips of different hardness are no longer produced, but only one with a special Shore hardness, while until now different types were produced.

- the new hardness would also no longer be easily achievable with PVC, because it lies between the soft and hard PVC, so you would have to provide the hard PVC with a plasticizer for this purpose, so that the hardness is no longer under control would have.

- With the new cutting bar you have a product that is suitable for all known knives.

- this new cutting bar was also simplified. While the old one had to be brought to the required sinus shape in the heating furnace after cooling, cutting to length and grinding on a special grinding machine (4-surface machining), this new bar no longer needs any reworking. You can also do without the disadvantageous grinding. The cutting bar is therefore only extruded. You can use dimensioned extruders; a high surface quality is achieved at the same time. So it can sharp knives can no longer be damaged by remaining hard grindstone particles.

- the thickness of the cutting bar By reducing the thickness of the cutting bar to a minimum, one not only achieved that the material costs could be reduced, but at the same time ensured that absolute dimensional accuracy and high surface quality can be guaranteed, which prevents individual blades from getting stuck Moving stacks of paper back and forth makes it unimaginable.

- the relatively small dimensions mean that the absolute linear expansion due to temperature fluctuations and moisture absorption is minimized. It must be taken into account that the coefficient of thermal expansion is greater for plastics than for metals, from which e.g. the work table is made.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Forests & Forestry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Knives (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Details Of Cutting Devices (AREA)

Abstract

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88909194T ATE62620T1 (de) | 1987-11-20 | 1988-11-03 | Schneidleiste fuer papierschneidmaschinen. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH4528/87A CH673805A5 (fr) | 1987-11-20 | 1987-11-20 | |

| CH4528/87 | 1987-11-30 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0344241A1 EP0344241A1 (fr) | 1989-12-06 |

| EP0344241B1 true EP0344241B1 (fr) | 1991-04-17 |

Family

ID=4277777

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88909194A Expired - Lifetime EP0344241B1 (fr) | 1987-11-20 | 1988-11-03 | Baguette de coupe pour coupe-papier |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5121664A (fr) |

| EP (1) | EP0344241B1 (fr) |

| JP (1) | JPH02502527A (fr) |

| CH (1) | CH673805A5 (fr) |

| ES (1) | ES2011703A6 (fr) |

| WO (1) | WO1989005219A1 (fr) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4042064A1 (de) * | 1990-01-04 | 1991-07-11 | Friedrich Kadelka | Stabilisierender zusatzstoff fuer asphalt als strassenbelag und andere bituminoes gebundene baustoffe |

| US20040079208A1 (en) * | 2002-10-25 | 2004-04-29 | Raymedica, Inc. | Ultrasonic cutting system with protective sheet |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US847161A (en) * | 1905-10-04 | 1907-03-12 | Charles Egbert Clark | Attachment for newspaper-presses. |

| US1148337A (en) * | 1911-12-12 | 1915-07-27 | Hoe & Co R | Cutting mechanism. |

| US1350399A (en) * | 1917-10-26 | 1920-08-24 | William E Wilson | Wall construction |

| US2281877A (en) * | 1940-10-21 | 1942-05-05 | Frank A Green | Cutting stick |

| US2680484A (en) * | 1950-03-09 | 1954-06-08 | Bolton John W & Sons Inc | Cutting stick |

| DE1103894B (de) * | 1958-04-26 | 1961-04-06 | Rudolf Mohr | Schneidleiste fuer Papierschneide-maschinen |

| US3040389A (en) * | 1959-02-03 | 1962-06-26 | Platenius Vertriebs G M B H | Standardized frame element for windows, doors and the like |

| US3078119A (en) * | 1960-08-01 | 1963-02-19 | Gen Motors Corp | Vehicle closure |

| CH525748A (de) * | 1970-05-08 | 1972-07-31 | Mohr Rudolf | Verfahren zur Herstellung einer Schneidleiste aus einem elastischen Kunststoff zum Einbringen in die Nut des Arbeitstisches einer Papierschneidemaschine |

| JPS54128132A (en) * | 1978-03-29 | 1979-10-04 | Norihiro Umezawa | Joint structure of waterway |

-

1987

- 1987-11-20 CH CH4528/87A patent/CH673805A5/de not_active IP Right Cessation

-

1988

- 1988-11-03 WO PCT/CH1988/000202 patent/WO1989005219A1/fr active IP Right Grant

- 1988-11-03 EP EP88909194A patent/EP0344241B1/fr not_active Expired - Lifetime

- 1988-11-03 JP JP63508386A patent/JPH02502527A/ja active Pending

- 1988-11-18 ES ES888803521A patent/ES2011703A6/es not_active Expired - Lifetime

-

1990

- 1990-12-14 US US07/628,698 patent/US5121664A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0344241A1 (fr) | 1989-12-06 |

| ES2011703A6 (es) | 1990-02-01 |

| WO1989005219A1 (fr) | 1989-06-15 |

| US5121664A (en) | 1992-06-16 |

| JPH02502527A (ja) | 1990-08-16 |

| CH673805A5 (fr) | 1990-04-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3341651C2 (de) | Vorrichtung zum Herstellen von Zuschnitten aus einem zerbrechbaren Flachmaterial | |

| DE2829718C2 (de) | Vakuumtiefziehvorrichtung zum Herstellen von napfförmigen Gegenständen durch Saugunterdruck aus einer Bahn aus thermoplastischem Kunststoff | |

| DE1154263B (de) | Vorrichtung zur Herstellung plattenfoermiger Profilteile aus poroesen und elastischen Werkstoffen | |

| DE19726629A1 (de) | Schere mit Führungen | |

| DE2300669A1 (de) | Presse fuer material verformende bearbeitung | |

| EP0344241B1 (fr) | Baguette de coupe pour coupe-papier | |

| DE1452590C3 (de) | Verfahren zum Herstellen von Trockenrasietapparat-Scherfolien | |

| EP0546392B1 (fr) | Lame pour le découpage ainsi que dispositif avec celle-ci | |

| DE2234482A1 (de) | Verfahren und vorrichtung zur herstellung von gipsbauteilen mit einwandfreien kanten | |

| DE2244449A1 (de) | Verfahren und vorrichtung zur herstellung von keramischen platten | |

| DE69609207T2 (de) | Schneidvorrichtung mit bewegbarem Stanz | |

| EP0265632A2 (fr) | Procédé de fabrication d'une pièce en contreplaqué présentant des découpes et l'outil de poinçonnage pour sa mise en oeuvre | |

| DE2125799A1 (de) | Verfahren zur Herstellung von Flikken in Holzstücken, insbesondere von Harzgallenflicken und Einrichtung zur Durchführung des Verfahrens | |

| EP0023747B1 (fr) | Procédé et dispositif pour la fabrication de carreaux en terre cuite | |

| DE2950968C2 (de) | Vorrichtung zum automatischen Herstellen von Strangdachziegeln und dgl. aus einem Tonstrang | |

| DE2424912C2 (de) | Einrichtung zur Herstellung von Formungen, insbesondere Spaltplatten | |

| DE2703242A1 (de) | Maschine zum behauen von sparren | |

| DE4438284A1 (de) | Vorrichtung zur Bildung einer winkelförmigen Ausnehmung in einem Profilstab | |

| CH683161A5 (de) | Schutzleiste für Papierschneidmaschinen. | |

| DE1949882B2 (de) | Gerät zum Aufrauhen eines zu fälzelnden Buchblockrückens | |

| DE2100510A1 (de) | Verfahren und Vorrichtung zur Her stellung eines Stanzmessers | |

| DE3536058C2 (de) | Vorrichtung zum Kerbtrennen von Buchrücken | |

| DE2822844A1 (de) | Fuehrungsvorrichtung zum zu- bzw. beschneiden einer papiertapetenbahn oder eines aehnlichen materials | |

| DE71998C (de) | Vorrichtung zum Abschneiden gleichmäfsig breiter Streifen von Papierbogen und Anlegen derselben an Papptafeln | |

| AT26585B (de) | Werkzeuge für Pressen zur Herstellung von Heftzwecken mit aus dem Kopfteil derselben ausgestanzter Spitze. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE DE FR GB IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19891212 |

|

| 17Q | First examination report despatched |

Effective date: 19900625 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE FR GB IT LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 62620 Country of ref document: AT Date of ref document: 19910515 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3862469 Country of ref document: DE Date of ref document: 19910523 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET1 | Fr: translation filed ** revision of the translation of the patent or the claims | ||

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19931001 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19931004 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19931015 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19931116 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19931125 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19931130 Year of fee payment: 6 Ref country code: FR Payment date: 19931130 Year of fee payment: 6 |

|

| EPTA | Lu: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19931230 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19941103 Ref country code: GB Effective date: 19941103 Ref country code: AT Effective date: 19941103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19941130 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 88909194.8 |

|

| BERE | Be: lapsed |

Owner name: POLATECH G.M.B.H. Effective date: 19941130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19950601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19941103 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19950731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950801 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 88909194.8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051103 |