EP0332072A2 - Emballage pour objets, particulièrement en forme de parallélépipède - Google Patents

Emballage pour objets, particulièrement en forme de parallélépipède Download PDFInfo

- Publication number

- EP0332072A2 EP0332072A2 EP89103743A EP89103743A EP0332072A2 EP 0332072 A2 EP0332072 A2 EP 0332072A2 EP 89103743 A EP89103743 A EP 89103743A EP 89103743 A EP89103743 A EP 89103743A EP 0332072 A2 EP0332072 A2 EP 0332072A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- film

- tear

- packaging according

- packaging

- line

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000004806 packaging method and process Methods 0.000 claims abstract description 42

- 238000007789 sealing Methods 0.000 claims abstract description 15

- 239000000463 material Substances 0.000 claims description 14

- -1 polypropylene Polymers 0.000 claims description 11

- 239000004743 Polypropylene Substances 0.000 claims description 10

- 229920001155 polypropylene Polymers 0.000 claims description 10

- 238000000034 method Methods 0.000 claims description 7

- 238000000926 separation method Methods 0.000 claims 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000012858 packaging process Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- UISARWKNNNHPGI-UHFFFAOYSA-N terodiline Chemical compound C=1C=CC=CC=1C(CC(C)NC(C)(C)C)C1=CC=CC=C1 UISARWKNNNHPGI-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

- B65D75/58—Opening or contents-removing devices added or incorporated during package manufacture

- B65D75/66—Inserted or applied tearing-strings or like flexible elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

- B65D75/58—Opening or contents-removing devices added or incorporated during package manufacture

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/04—Articles or materials wholly enclosed in single sheets or wrapper blanks

- B65D75/06—Articles or materials wholly enclosed in single sheets or wrapper blanks in sheets or blanks initially folded to form tubes

- B65D75/08—Articles or materials wholly enclosed in single sheets or wrapper blanks in sheets or blanks initially folded to form tubes with the ends of the tube closed by folding

Definitions

- the invention relates to packaging for objects, in particular cuboid, consisting of film material which, as an essentially closed film envelope, relatively closely encloses the individual and / or several objects, the film envelope being provided at least with means for tearing open and the film envelope being partially printed and is produced by connecting unprinted areas of the film material by means of a heat sealing process, and a film cutting tape for such packaging and an object, in particular a tape cassette with such a packaging.

- DE-GM 8715168 discloses a film packaging with a tear-open aid consisting of a tear-open thread, with additional perforation being provided at an angle to and near the dividing line of the tear-open thread, which is intended to facilitate tearing in and tearing open the remaining casing.

- This need to use a film with tear thread and the additional attachment of the perforation are complex.

- This known packaging is an unprinted transparent film cover, e.g. made of polypropylene.

- the object of the present invention is to provide an effective and inexpensive tear-open aid which also makes it possible to remove the residual casing from objects, in particular magnetic tape cassettes, which are welded, in particular by means of polypropylene film, without any effort.

- the object is achieved with a packaging for objects, in particular cuboid, consisting of film material which, as an essentially closed film envelope, relatively closely encloses the individual and / or several objects, the film envelope being provided with means for tearing open, and at least partially printed on the film envelope formed and by connecting unprinted areas of the film material by means of Heat sealing process is produced so that the means for tearing open are formed from at least part of the tear-open part which bears a print on the heat-sealable film surface and in the vicinity of which at least one tear line is provided.

- a border line of printing that runs at an angle to a tear line can expediently be provided and the film surface behind the border line can be unprinted.

- two tear-open parts on the film envelope can be arranged essentially one above the other, so that it is possible to have a second, more successful attempt to follow a first tear-open attempt.

- the printing and / or the printing can be provided on both tear-open parts.

- the solution according to the invention is particularly advantageous in the case that the film material is polypropylene film, which is particularly strong and tough and which can usually only be torn or scratched after removal or cutting, which in turn presupposes the presence of a tool.

- the angle of the boundary line should be in the range from about 80 ° to about 10 ° to the tear line.

- the type of packaging is expediently used for a film material whose tensile strength or tear strength of the film is in the range from approximately 120 to 180 N / mm2 in the longitudinal direction and from approximately 140 N / mm2 to approximately 240 N / mm2 in the transverse direction.

- a film cutting tape for a packaging according to the invention is expediently designed such that the imprint of the tear-open part is in each case arranged between two contiguous film cuts, spanning the respective dividing line between the two film cuts.

- the article with the packaging according to the invention e.g. one or more tape cassettes gain significantly in use value by the invention.

- a tape cassette with a packaging is advantageous, the film material of which consists of a polypropylene film with a thickness of 15 to 40 ⁇ m, preferably of 30 ⁇ m.

- Embodiments of the invention are shown schematically in the drawing and described below.

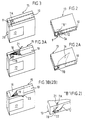

- FIG. 1 shows two connection points (7, 8) between three film blanks 5 'for tape cassettes.

- the dividing lines between the individual blanks 5 ' are designated, which are usually severed during or after the packaging process by means of a separating device.

- Each blank 5 ' consists of the outer contour lines between the dividing lines (11), it is thus composed of a printed one Surface 5 and heat-sealing zones 10, which frame-like, except for one place (7, 8), surround the printed surface 5.

- the tear-open aids in the form of tear-open parts 7 (7A and 7B are the upper and lower tear-off parts) are provided for the blanks 5 'which are still attached to each other and which belong to a blank 5'.

- These tear-open parts 7 are each formed by an imprint 8 on the film surface which is provided for heat sealing by means of a sealing stamp.

- the printing is on the inside of the film facing the cassette.

- the imprint 8, 8 ' consists of a tear-open notice with an arrow each, which indicates the recommended tear direction.

- the imprint 8, 8 ' in addition to the rectangle tear-open label (imprint 8, 8 ') there is further printing, which has an oblique boundary line 12 (angle ⁇ approximately in the range of approximately 10 to 80 °) with respect to the unprinted sealing zone 10 ends.

- This printing the type of which is completely arbitrary, has the effect that after heat sealing, the oblique line 12 simultaneously represents the connection boundary between the fused film surfaces.

- a tear line is provided on one side, especially within the imprint 8 in the longitudinal direction, which serves to initiate the tear process.

- a further tear line could also be provided in the direction of the boundary line 12, essentially within the imprint 8.

- a single vertical tear line 9 is assumed.

- Figure 2 shows, for example, a compact cassette in a conventional cassette box with a printed cassette packaging, which on the long narrow side shows the (upper) tear-open part 7A and the oblique printing (boundary line 12) with an angle ⁇ of approximately 45 °.

- FIG. 2A now shows the case in which the tearing process was continued, but only a film tear occurred, which can be seen as a tear-out cutout 16.

- the lower tear-open indication 7B was completely exposed, so that a tear-off, such as shown in FIG. 2B using the cassette packaging 15, can take place in the tear-off direction 23, as a result of which the remaining packaging can now be removed completely.

- FIG. 3 shows the multi-cassette packaging 15 with an upper tear-open part 7A and a heat-sealing zone 10, which can continue, for example, on the narrow side 20.

- a field of view is designated within the printed film envelope.

- the width of the tab 22 or the tear-open tip 18 is advantageously adapted to a normal finger width (approx. 1 cm).

- the film material of the packaging examples described is e.g. Polypropylene film, e.g. Bicor®, MB400 (® is a registered trademark of the Mobil Oil Corporation), technical data sheet 6 404/4/86 of Mobil Plastics Europe.

- the biaxially stretched film described therein has a relatively high tear or tensile strength of 150 N / mm2 in the longitudinal direction and 220 N / mm2 in the transverse direction.

- the films in which use of the present invention is necessary are generally characterized by a tensile strength of about 120 to about 180 N / mm2 lengthways and of about 140 to 240 N / mm2.

- the edge tear force e.g.

- the edge tear force in the film, with which the invention can be used should be at least 150 N and preferably be in the range from approximately 150 N to 250 N.

- the polypropylene film used for the packaging of tape cassettes had a thickness between approx. 15 ⁇ m and 40 ⁇ m, preferably 30 ⁇ m.

- the packaging can equally be used for one or more bodies, which can then have a cuboid or roll shape.

- the use of the invention is not limited to packaging made of polypropylene films.

- Other films of other material suitable for packaging of this type e.g. PVC, polyethylene, with similar strength and toughness characteristics can also be used for the packaging according to the invention with a double tear-open device.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Basic Packing Technique (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8803229U DE8803229U1 (de) | 1988-03-10 | 1988-03-10 | Verpackung für Gegenstände, insbesondere von Quaderform |

| DE8803229U | 1988-03-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0332072A2 true EP0332072A2 (fr) | 1989-09-13 |

| EP0332072A3 EP0332072A3 (en) | 1990-06-06 |

| EP0332072B1 EP0332072B1 (fr) | 1992-12-23 |

Family

ID=6821677

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89103743A Expired - Lifetime EP0332072B1 (fr) | 1988-03-10 | 1989-03-03 | Emballage pour objets, particulièrement en forme de parallélépipède |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5011014A (fr) |

| EP (1) | EP0332072B1 (fr) |

| JP (1) | JP2730957B2 (fr) |

| KR (1) | KR0148998B1 (fr) |

| CN (1) | CN1021035C (fr) |

| DE (2) | DE8803229U1 (fr) |

| HK (1) | HK75093A (fr) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8915653U1 (de) * | 1989-05-25 | 1991-01-03 | Moreno, Dámaso, 5142 Hückelhoven | Folienartiges Material für eine Faltpackung und derartige Faltpackung |

| DE4020945C2 (de) * | 1990-06-30 | 1994-02-17 | Basf Magnetics Gmbh | Verpackung für einen oder mehrere quaderförmige Magnetband-Behälter |

| JP3121082B2 (ja) * | 1991-11-30 | 2000-12-25 | ティーディーケイ株式会社 | 開封性を改善したフィルム包装体及びその製造方法 |

| US5510165A (en) * | 1992-06-30 | 1996-04-23 | Sony Corporation | Thin film wrapping for cassette case |

| EP0577509B1 (fr) * | 1992-06-30 | 1996-11-13 | Sony Corporation | Procédé d'empaquetage d'un boîtier de cassette dans un film mince |

| DE9214815U1 (de) * | 1992-10-31 | 1993-03-25 | BASF Magnetics GmbH, 6800 Mannheim | Schutzhülle für Gegenstände, insbesondere von Quaderform |

| US6006907A (en) * | 1993-04-01 | 1999-12-28 | Fuji Photo Film Co., Ltd. | Wrapped article |

| JPH0711564U (ja) * | 1993-05-31 | 1995-02-21 | 富士写真フイルム株式会社 | 包装体 |

| JPH074377U (ja) * | 1993-06-21 | 1995-01-24 | 富士写真フイルム株式会社 | 包装体 |

| JP3075138B2 (ja) * | 1995-03-30 | 2000-08-07 | 日本ビクター株式会社 | 包装フイルムの包装構造 |

| JP3253509B2 (ja) * | 1995-12-01 | 2002-02-04 | ティーディーケイ株式会社 | 開封性を改良したフィルム包装体 |

| JP3301319B2 (ja) * | 1996-09-30 | 2002-07-15 | ソニー株式会社 | オーバーラップフィルムによる包装構造 |

| US5996782A (en) * | 1997-04-14 | 1999-12-07 | Sealed Air Corporation | Foam in bag packaging system for manual use |

| GB0204602D0 (en) * | 2002-02-27 | 2002-04-10 | Ucb Sa | Packaging methods and packs made thereby |

| US10239677B2 (en) * | 2015-07-29 | 2019-03-26 | Sonoco Development, Inc. | Easy-open media wrapper |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3360182A (en) * | 1966-08-30 | 1967-12-26 | Procter & Gamble | Easy opening container |

| US3442436A (en) * | 1967-02-10 | 1969-05-06 | Reynolds Metals Co | Package construction means with easy open means therefor |

| DE8715168U1 (de) * | 1987-11-14 | 1988-01-21 | Basf Ag, 67063 Ludwigshafen | Verpackung für Gegenstände, insbesondere von Quaderform |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2079328A (en) * | 1933-06-27 | 1937-05-04 | Beech Nut Packing Co | Package and method of forming the same |

| US2213758A (en) * | 1938-05-09 | 1940-09-03 | Glenn R Eichberg | Wrapper |

| US2864547A (en) * | 1954-10-18 | 1958-12-16 | Waldorf Paper Prod Co | Reclosable carton |

| US4491224A (en) * | 1982-03-05 | 1985-01-01 | C O D Inter Techniques Sa | Weldable tear-off capping film for sealing packages |

| JPS5925670U (ja) * | 1982-08-06 | 1984-02-17 | ティーディーケイ株式会社 | 磁気テ−プカセツト |

| GB2123376B (en) * | 1982-07-12 | 1985-09-11 | Tdk Electronics Co Ltd | Tear-open package |

| US4830186A (en) * | 1985-06-24 | 1989-05-16 | Xerox Corporation | Copy sheet prepackaged, shipping and loading wrapper for use in a high volume duplicator |

-

1988

- 1988-03-10 DE DE8803229U patent/DE8803229U1/de not_active Expired

-

1989

- 1989-03-01 JP JP1046724A patent/JP2730957B2/ja not_active Expired - Fee Related

- 1989-03-03 DE DE8989103743T patent/DE58903064D1/de not_active Expired - Fee Related

- 1989-03-03 EP EP89103743A patent/EP0332072B1/fr not_active Expired - Lifetime

- 1989-03-10 CN CN89102139A patent/CN1021035C/zh not_active Expired - Fee Related

- 1989-03-10 KR KR1019890002971A patent/KR0148998B1/ko not_active IP Right Cessation

-

1990

- 1990-04-24 US US07/515,646 patent/US5011014A/en not_active Expired - Lifetime

-

1993

- 1993-07-29 HK HK750/93A patent/HK75093A/xx not_active IP Right Cessation

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3360182A (en) * | 1966-08-30 | 1967-12-26 | Procter & Gamble | Easy opening container |

| US3442436A (en) * | 1967-02-10 | 1969-05-06 | Reynolds Metals Co | Package construction means with easy open means therefor |

| DE8715168U1 (de) * | 1987-11-14 | 1988-01-21 | Basf Ag, 67063 Ludwigshafen | Verpackung für Gegenstände, insbesondere von Quaderform |

Also Published As

| Publication number | Publication date |

|---|---|

| DE8803229U1 (de) | 1988-07-07 |

| JPH02109870A (ja) | 1990-04-23 |

| KR890014330A (ko) | 1989-10-23 |

| DE58903064D1 (de) | 1993-02-04 |

| US5011014A (en) | 1991-04-30 |

| CN1021035C (zh) | 1993-06-02 |

| EP0332072A3 (en) | 1990-06-06 |

| JP2730957B2 (ja) | 1998-03-25 |

| CN1036739A (zh) | 1989-11-01 |

| HK75093A (en) | 1993-08-06 |

| KR0148998B1 (ko) | 1998-10-15 |

| EP0332072B1 (fr) | 1992-12-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69503780T2 (de) | Öffnungsvorrichtung für flexible behälter, behälter versehen mit einer solchen vorrichtung und verfahren zu ihrer anbringung | |

| DE3871872T2 (de) | Ein etikett. | |

| DE69006944T2 (de) | Wiederverschliessbare beutelartige Verpackung mit Originalitätssicherung. | |

| DE69501736T2 (de) | Öffnungs-und verschlussvorrichtung für flexible behälter und behälter versehen mit einer solchen vorrichtung | |

| DE69704495T2 (de) | Sicherheitsmanschette für gegenstände,insbesondere für behälter mit verschlussvorrichtung | |

| EP0332072B1 (fr) | Emballage pour objets, particulièrement en forme de parallélépipède | |

| DE69314755T2 (de) | Verpackter Gegenstand | |

| DE3877962T2 (de) | Beutel fuer aufheizbares nahrungsmittel. | |

| DE2729185C3 (de) | öffnungseinrichtung für Verpackungsbehälter | |

| DE69309216T2 (de) | Verpackung, eine mit einer lösbaren Lasche versehene Verpackungsfolie verwendend, sowie Verfahren zum Umhüllen eines Gegenstandes mit der Folie | |

| EP0030601A1 (fr) | Emballage souple formé à partir d'une feuille de matière plastique, en particulier pour des mouchoirs en papier | |

| EP0545136A1 (fr) | Emballage souple pour mouchoirs en papier | |

| DE69201753T2 (de) | Vorrichtung zum Verschliessen und Öffnen eines Beutels aus Kunststoffolie. | |

| DE3545733C2 (fr) | ||

| DE8715168U1 (de) | Verpackung für Gegenstände, insbesondere von Quaderform | |

| EP0226835A2 (fr) | Emballage en matière souple | |

| DE69506457T2 (de) | Selbstklebeetikett für eine versiegelbare Verpackung | |

| EP0081791A1 (fr) | Sac à parfum et procédé pour sa fabrication | |

| EP0582953A2 (fr) | Emballage pour cigarettes en film de matière plastique | |

| DE4240207C2 (de) | Leicht zu öffnende Folienverpackung und Verfahren zu deren Herstellung | |

| DE3002195C3 (de) | Umhüllung zur Befestigung eines blattförmigen Elements an einer flachen Oberfläche eines gegen unbefugte Beförderung durch eine Überwachungszone zu überwachenden Gegenstands und Klingenanordnung zur Entnahme des Elements | |

| DE69404897T2 (de) | Verpackung mit verpacktem Gegenstand | |

| DE60211851T2 (de) | Verpackung für einen rohrförmigen stapel von runden keksen | |

| DE69100165T2 (de) | Aufreissbarer Versandsumschlag. | |

| EP0680896B1 (fr) | Emballage en feuille souple |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19900512 |

|

| 17Q | First examination report despatched |

Effective date: 19910722 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT NL |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 58903064 Country of ref document: DE Date of ref document: 19930204 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930112 |

|

| ET | Fr: translation filed | ||

| ET1 | Fr: translation filed ** revision of the translation of the patent or the claims | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19960229 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19960301 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19970303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19971001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19970303 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19971001 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20020309 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20020315 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031127 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050303 |