EP0325738B1 - Elément de serrage - Google Patents

Elément de serrage Download PDFInfo

- Publication number

- EP0325738B1 EP0325738B1 EP88120225A EP88120225A EP0325738B1 EP 0325738 B1 EP0325738 B1 EP 0325738B1 EP 88120225 A EP88120225 A EP 88120225A EP 88120225 A EP88120225 A EP 88120225A EP 0325738 B1 EP0325738 B1 EP 0325738B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- clamping

- bolt

- cover plate

- shoe according

- abutment plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B5/00—Clamps

- B25B5/06—Arrangements for positively actuating jaws

- B25B5/10—Arrangements for positively actuating jaws using screws

- B25B5/104—Arrangements for positively actuating jaws using screws with one screw and one clamping lever and one fulcrum element

- B25B5/106—Arrangements for positively actuating jaws using screws with one screw and one clamping lever and one fulcrum element with one end of the lever resting on an additional block and the screw being positioned between the ends of the lever

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B5/00—Clamps

- B25B5/06—Arrangements for positively actuating jaws

- B25B5/10—Arrangements for positively actuating jaws using screws

- B25B5/104—Arrangements for positively actuating jaws using screws with one screw and one clamping lever and one fulcrum element

- B25B5/106—Arrangements for positively actuating jaws using screws with one screw and one clamping lever and one fulcrum element with one end of the lever resting on an additional block and the screw being positioned between the ends of the lever

- B25B5/107—Blocks therefor

Definitions

- the invention relates to a clamping claw for clamping objects, in particular vices on machine tables, with an essentially rectangular, flat clamping lug, which has a longitudinal slot extending in its longitudinal direction for the passage of a clamping screw which can be anchored in a T-slot of the machine table, and with one with the tensioning plate by means of a bolt which extends at right angles to its plane and which protrudes with respect to the underside of the tensioning plate and which can be rotated relative to the axis of the bolt.

- a known clamping claw of this type (DE-GM 73 15 457) the bolt is designed as a screw which can be screwed into a threaded hole in the clamping lug.

- the distance between the abutment plate, which is rotatably arranged at the lower end of the bolt, and the clamping lug can be changed and the clamping claw can thus be adapted to the thickness of the objects to be clamped.

- fixing clamping devices such as vices on drilling machine tables poses particular problems because neither the size of these drilling machine tables nor the arrangement of the T-slots is standardized.

- the machine vices also have a wide variety of dimensions.

- the machine vices have to be clamped in a wide variety of positions depending on the workpiece and the drilling spindle on the drilling machine table, whereby additional problems may arise due to the small size of the drilling machine tables.

- the known clamping claws it is therefore often not possible to securely clamp the machine vice in the desired position on the drilling machine table.

- the invention is therefore based on the object of providing a clamping claw for clamping objects, in particular vices, on machine tables of the type mentioned at the outset, which makes it possible to securely clamp vices in any desired position on a wide variety of machine tables and is inexpensive to manufacture.

- abutment plate is arranged eccentrically to the bolt axis in the clamping claw of the type mentioned and in that the bolt is displaceable in a longitudinal slot of the clamping bracket.

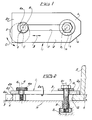

- the clamping claw 1 has a clamping tab 2, which is essentially rectangular and flat.

- the tensioning tab 2 is provided with a longitudinal slot 3 extending in its longitudinal direction and has bevels 4 at one end.

- the tensioning tab 2 can advantageously be punched out of sheet metal or flat steel, the longitudinal slot 3 and the bevels 4 also being punched out at the same time.

- An abutment plate 5 is provided on the underside 2a of the tensioning tab 2, which plate is expediently designed as a cylindrical disk.

- the lower side of the tensioning tab 2 is supported on the upper side 5a of the abutment plate 5.

- the abutment plate 5 is movably connected to the clamping bracket 2 via the bolt 6.

- the abutment plate 5 is eccentric to the Bolt axis A arranged.

- the bolt 6 itself is expediently designed as a knurled screw, the knurled head 6a of which protrudes above the upper side 2b of the tensioning tab 2.

- the bolt 6 is also displaceable in the longitudinal slot 3 of the clamping tab 2.

- This longitudinal slot 3 also serves for the passage of a clamping screw 7 which can be screwed into a sliding block 8.

- the sliding block 8 can be inserted into one of the T-slots 9 of a machine table, in particular a drilling machine table M.

- the head of the tensioning screw 7 is supported with the interposition of a washer 10 on the top 2b of the tensioning tab 2.

- the abutment plate 5 which is arranged eccentrically with respect to the pin axis A, can be moved by means of the pin 6 or the knurled screw both in the direction B of the longitudinal slot 3 and also pivotable about the pin axis A in the direction C.

- the abutment plate 5 can be moved and pivoted by means of the knurled head 6a, the eccentric position of the abutment plate 5 being expediently indicated by a marking 11 provided on the head 6a.

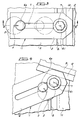

- a vice S to be clamped on the machine table M has a clamping bar 12 on each of its two longitudinal sides.

- One end of the clamping tab 2 is brought into contact with the clamping surface 12a of this clamping bar 12, as shown in FIGS. 2 and 3.

- By moving the abutment plate 5 in the direction B and pivoting the same in the direction C it can be brought into a suitable position in which it is supported on the surface of the machine table M or the edge thereof.

- the abutment plate 5 and clamping screw 7 can also be brought into the position shown in broken lines in FIG. 3. If necessary, it is also possible to interchange the position of the clamping screw 7 and the abutment plate 5. The exchange of abutment plate 5 and clamping screw 7 makes it possible to bring the clamping screw even closer to the vice.

- the longitudinal slot 3 can namely extend at the end 2c of the tensioning tab facing away from the bevels 4 up to the vicinity of this end, since the cross section of the tensioning tab at this end 2c is not weakened by bevels.

- the clamping tab 2 can also be attached obliquely to a vice S or its clamping strip 12. Again, the abutment plate 5 can be brought into a favorable position by pivoting and moving.

- Figure 5 shows a position of the clamping tab 2, in which it is arranged with its long side parallel to the clamping bar 12.

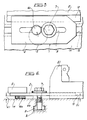

- the height H of the abutment plate 5 should correspond to the height h of the clamping bar 12 of the vice S. If a vice has a clamping bar with a different height h, the abutment plate 5 can optionally also be exchanged for one with a different height.

- a vice S1 is to be clamped with an internal groove 13 and this internal groove is removed from the surface of the machine table M has a smaller distance h1, then one can also turn the clamping tab 2 so that its top 2b comes to lie down.

- the knurled head 6a which has a smaller height H1 than the height H of the abutment plate 5, forms the abutment.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Jigs For Machine Tools (AREA)

- Electrical Discharge Machining, Electrochemical Machining, And Combined Machining (AREA)

Claims (7)

- Griffe de serrage pour assujettir des objets, en particulier des étaux, sur des tables de machines, comprenant une bride plane (2), essentiellement rectangulaire, qui présente une fente longitudinale (3), s'étendant dans le sens de sa longueur, pour le passage d'une vis de serrage (7) susceptible d'être ancrée dans une rainure en T de la table de la machine, ainsi qu'une plaque de contre-appui appelée cale (5), qui est reliée à la bride au moyen d'un tourillon (6) d'orientation perpendiculaire au plan de la bride et faisant saillie du dessous (2a) de celle-ci, cale qui est rotative autour de l'axe (A) du tourillon par rapport à la bride, caractérisée en ce que la cale (5) est excentrée par rapport à l'axe (A) du tourillon et que le tourillon (6) est déplaçable en translation dans une fente longitudinale (3) de la bride (2).

- Griffe de serrage selon la revendication (1), caractérisée en ce que la bride (2) s'appuie par son dessous (2a) sur le dessus (5a) de la cale (5).

- Griffe de serrage selon la revendication 1 ou 2, caractérisée en ce que le tourillon (6) est déplaçable en translation dans la fente longitudinale (3) par laquelle passe également la vis de serrage (7).

- Griffe de serrage selon la revendication 1 ou 2, caractérisée en ce que la cale (5) est réalisée sous la forme d'un disque cylindrique.

- Griffe de serrage selon la revendication 1, caractérisée en ce que le tourillon (6) est formé par la tige d'une vis moletée dont la tête moletée (6a) fait saillie du dessus (2b) de la bride (2).

- Griffe de serrage selon la revendication 1 ou 4, caractérisée en ce que la hauteur (H) de la cale (5) correspond à la hauteur (h) de rebords d'ablocage (12) d'étaux (S).

- Griffe de serrage selon la revendication 5 ou 6, caractérisée en ce que la tête moletée (6a) possède une plus faible hauteur (H1) que la cale (5).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88120225T ATE75981T1 (de) | 1988-01-26 | 1988-12-03 | Spannpratze. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3802091A DE3802091C1 (fr) | 1988-01-26 | 1988-01-26 | |

| DE3802091 | 1988-01-26 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0325738A2 EP0325738A2 (fr) | 1989-08-02 |

| EP0325738A3 EP0325738A3 (en) | 1990-03-07 |

| EP0325738B1 true EP0325738B1 (fr) | 1992-05-13 |

Family

ID=6345932

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88120225A Expired - Lifetime EP0325738B1 (fr) | 1988-01-26 | 1988-12-03 | Elément de serrage |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0325738B1 (fr) |

| JP (1) | JPH01222834A (fr) |

| AT (1) | ATE75981T1 (fr) |

| DE (1) | DE3802091C1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108127439A (zh) * | 2017-12-22 | 2018-06-08 | 合肥仨力机械制造有限公司 | 一种叉车零件打孔装置 |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU4842797A (en) * | 1996-05-13 | 1997-12-05 | Rainer Forster | Work bench for assembly of workpieces |

| CN102626732B (zh) * | 2012-04-28 | 2014-01-29 | 苏州市达圣机械有限公司 | 一种铝条的侧推夹紧装置 |

| CN102922497B (zh) * | 2012-10-09 | 2015-08-26 | 中船澄西船舶修造有限公司 | 辅机连杆修理工作台 |

| CN103921232A (zh) * | 2014-05-06 | 2014-07-16 | 安徽工程大学 | 一种夹紧装置 |

| CN110666710A (zh) * | 2019-09-25 | 2020-01-10 | 温州市强达表业有限公司 | 一种手表表带拉丝抛光器 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1189676A (fr) * | 1958-01-10 | 1959-10-06 | Const Mecaniques Soc Et | Dispositif de fixation sur tables rainurées de machines-outils |

| FR1375736A (fr) * | 1963-05-21 | 1964-10-23 | Feinmechanik G M B H | Dispositif de fixation ou de montage |

| US3850421A (en) * | 1973-04-23 | 1974-11-26 | R Orris | Clamp apparatus |

| DE7315457U (de) * | 1973-04-24 | 1973-10-18 | Duevel W | Gerät zum Festspannen von Werkstücken |

-

1988

- 1988-01-26 DE DE3802091A patent/DE3802091C1/de not_active Expired

- 1988-12-03 EP EP88120225A patent/EP0325738B1/fr not_active Expired - Lifetime

- 1988-12-03 AT AT88120225T patent/ATE75981T1/de active

-

1989

- 1989-01-26 JP JP1017405A patent/JPH01222834A/ja active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108127439A (zh) * | 2017-12-22 | 2018-06-08 | 合肥仨力机械制造有限公司 | 一种叉车零件打孔装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE75981T1 (de) | 1992-05-15 |

| EP0325738A3 (en) | 1990-03-07 |

| DE3802091C1 (fr) | 1988-11-03 |

| JPH01222834A (ja) | 1989-09-06 |

| EP0325738A2 (fr) | 1989-08-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1155782B1 (fr) | Dispositif de support avec une tête de soutien pour tenir une piéce à travailler | |

| CH675977A5 (fr) | ||

| EP0325738B1 (fr) | Elément de serrage | |

| EP0203888A1 (fr) | Système de construction pour monter des pièces et son application | |

| DE7341746U (de) | Maschinenschraubstock | |

| DE2931517C2 (de) | Schraubzwingenträger zum Halten von Schraubzwingen | |

| DE3419323C2 (de) | Kopierdrehmaschine | |

| DE1256514B (de) | Schneidplatte fuer ein spanabhebendes Werkzeug, insbesondere Drehwerkzeug | |

| DE2613673A1 (de) | Spannvorrichtung | |

| DE828943C (de) | Spannbacken fuer eine Spannvorrichtung fuer Werkstuecke | |

| DE2513319C3 (de) | Spannvorrichtung mit zugehöriger Schraubzwinge | |

| DE8800873U1 (de) | Spannpratze | |

| DE2551344C3 (de) | Winkeleinstellvorrichtung, insbesondere für Maschinenschraubstöcke | |

| DE4329372A1 (de) | Spanneinrichtung zum Halten von Werkstücken | |

| DE2158191C3 (de) | Vorrichtung zum Entgraten von geraden Blechbändern | |

| DE9105405U1 (de) | Haltevorrichtung mit einer zum Festspannen eines Werkstücks vorgesehenen Schraubspindel | |

| DE2323054B2 (de) | Vorrichtung zum Befestigen von Nutenplatten od. dgl. zur Aufnahme von Steuernocken an Werkzeugmaschinen bzw. an Voreinstelleinrichtungen | |

| EP1125692A2 (fr) | Equerre à rapporteur et talon | |

| DE1292099B (de) | Schraubstock | |

| DE202023002402U1 (de) | Vorrichtung zur winkelgenauen Führung einer Handsäge | |

| DE20304531U1 (de) | In eine Bohrung einer Werkplatte einsteckbares Kunststoff-Spannelement | |

| CH676443A5 (fr) | ||

| DE8914776U1 (de) | Vorrichtung zum Zuschneiden von Fliesen | |

| DE8800392U1 (de) | Vorrichtung zum Spannen von senkrecht zueinander verlaufenden Werkstücken | |

| DE645108C (de) | Saeulenfuehrungsgestell, bei dem Stempel und Matrize seitlich herausnehmbar angeordnet sind |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900829 |

|

| 17Q | First examination report despatched |

Effective date: 19911002 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19920513 Ref country code: SE Effective date: 19920513 Ref country code: NL Effective date: 19920513 Ref country code: BE Effective date: 19920513 |

|

| REF | Corresponds to: |

Ref document number: 75981 Country of ref document: AT Date of ref document: 19920515 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19921125 Year of fee payment: 5 Ref country code: GB Payment date: 19921125 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19921203 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19930201 Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19931203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19931231 Ref country code: LI Effective date: 19931231 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940831 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |