EP0244797A2 - Tendeur de poignée pour emballage portatif - Google Patents

Tendeur de poignée pour emballage portatif Download PDFInfo

- Publication number

- EP0244797A2 EP0244797A2 EP87106423A EP87106423A EP0244797A2 EP 0244797 A2 EP0244797 A2 EP 0244797A2 EP 87106423 A EP87106423 A EP 87106423A EP 87106423 A EP87106423 A EP 87106423A EP 0244797 A2 EP0244797 A2 EP 0244797A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- grip

- grip tape

- tensioning

- tape

- elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D25/00—Details of other kinds or types of rigid or semi-rigid containers

- B65D25/28—Handles

- B65D25/32—Bail handles, i.e. pivoted rigid handles of generally semi-circular shape with pivot points on two opposed sides or wall parts of the conainter

Definitions

- the invention relates to a grip tape tensioner with a child-resistant closure of a grip that is tight to be tensioned over the lid of a carrying package suitable as large household containers.

- Containers in the form of rectangular, square or round drums or boxes made of cardboard, cardboard, plastic or the like are suitable as a carrying pack.

- the contact pressure is often not sufficient to preclude a lateral lifting of the cover which enables the product to be removed.

- the known systems are complex, the grip tape consists of two parts to be held together by the respective securing elements.

- the invention has for its object to provide a carry pack with child-resistant grip tape tensioner, which allows the grip tape with so much force over the lid without significant effort to tension that children at risk of age are not able to even partially open the cover when the child lock is activated.

- the solution according to the invention is characterized by a pair of tension elements to be connected to the grip strap, displaceable in its longitudinal direction and via a common tensioning element which is pivotable relative to one another via a common tension axis running in the direction transverse to the longitudinal direction of the strap approximately in the strap plane Swiveling around the clamping axis and folding the clamping elements into place, child-proof locking.

- the invention provides a grip tape tensioner consisting of a pair of tensioning elements which can be folded against one another and which, after being articulated on the grip strap and positioning - by moving along the grip strap - can only be locked against one another in a childproof manner by folding up. After loosening the folded position, it is possible to tighten the grip tape again and again without problems. This tightening takes place by folding one of the tensioning elements onto the other, for example as when closing a case, so that handling can be done not only with little force but also without special thought. For this purpose, the length of the grip tape must be specified so that the tape receives the desired maximum permitted longitudinal tension by folding the tension elements when the childproof lock is activated.

- Snap locks of various types can be used as a child lock for the four-point locking of the folded clamping elements.

- the child-proof locking of the tensioning elements is to be locked in place by pressing the folded tensioning elements against one another and by simultaneously pressing against one another and relative displacement in the belt longitudinal direction Clamping elements to be detached again is formed.

- the hooking connection can consist of a hook provided in a recess of the one tensioning element and a hook designed as a nose of the other tensioning element, which interlock automatically when the tensioning elements are pressed together and cannot be opened by children at risk of age due to the overlapping movements required to release them are.

- the grip tape tensioner should have in each of its tensioning elements a passage channel running transversely to the tensioning axis as a grip tape holder.

- the channel can be designed to thread the grip tape.

- each tensioning element consists of two flaps which are to be fixed flat on one another around a hinge running in the longitudinal direction of the grip tape or the through-channel when the grip tape is inserted.

- the grip tape tensioner can then be articulated by simply placing the tensioning elements on the grip tape and then folding the flaps around the grip tape, displaceable in the longitudinal direction of the tape. If the fixing of the flaps forming the through-channel can be released, the grip-band tensioner can be used again when a new carrying pack is started. Since the grip tape tensioner has to absorb considerable forces, it is advisable to manufacture it from a dimensionally stable plastic.

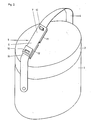

- FIG. 1 shows a carrying drum 1 with a slip cover 2 and a grip tape 4 fastened to the drum circumference with the aid of rivets 3. While carrying drum 1 and cover 2 can consist of cardboard or cardboard, the grip strip 4 should generally be made of a tensile plastic.

- the grip tape tensioner 5 is formed from a pair of tensioning elements 6 and 7, which are connected to one another via a film hinge 8.

- the film hinge 8 enables a pivoting movement of the tensioning elements 6 and 7 against one another about a tensioning axis 10 extending transversely to the longitudinal direction 9 of the tape in the tape plane.

- a flap 13 and 14 is articulated laterally to the edge of each of the tensioning elements 6 and 7 via a film hinge 11 and 12, respectively .

- the film hinges 11 and 12 run approximately parallel to the longitudinal direction 9 of the band.

- On the surface of one clamping element 6 there is a latching lug 15, which is assigned a latching hole 16 in the surface of the other clamping element 7.

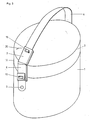

- FIG. 2 shows the state of the grip tape tensioner 5, in which the flaps 13 and 14 have been folded around the axes of the film hinges 11 and 12 in the direction of arrow 17 (FIG. 1) under the grip tape 4 and thus under the tensioning elements 6 and 7.

- FIG. 1 shows the state of the grip tape tensioner 5, in which the flaps 13 and 14 have been folded around the axes of the film hinges 11 and 12 in the direction of arrow 17 (FIG. 1) under the grip tape 4 and thus under the tensioning elements 6 and 7.

- the grip tape 4 is enclosed in a through-channel 18 formed between the tensioning elements 6 and 7 on the one hand and the flaps 13 and 14 on the other hand.

- the through-channel 18 allows the grip tape tensioner 5 according to FIG. 2 to be moved along the grip strap 4 into a permanent position which is favorable for tensioning and does not impede when carrying e.g.

- the grip tape 4 is wrapped around the one tensioning element 6 and shortened by the corresponding amount and thereby stretched tightly over the top of the lid ( Fig. 4).

- FIGS. 5 to 8 The structure and details of the grip tape tensioner 5 are explained with reference to FIGS. 5 to 8. In these figures as well as in the following Figures are designated the same parts as in Figs. 1 to 4.

- Fig. 5 shows the grip tensioner 5 in the fully open position in the view from above.

- 6 shows the handle strap tensioner 5 as a section along the line VI-VI of FIG. 5.

- FIG. 7 is a bottom view of the handle strap tensioner 5 of FIG. 5.

- FIG. 8 is a side view in the direction VII of FIG. 8.

- a continuous recess 21 is provided for receiving the grip tape 4.

- FIGS. 9 and 11 show the grip tape tensioner 5 in the position in which the flaps 13 and 14 have been folded around the associated film hinges 11 and 12 in the direction of arrow 17 on the rear sides of the tensioning elements 6 and 7.

- the grip tape 4 is then located in the through-channel 18. Initially, the tensioning elements 6 and 7 are still stretched on the carrying strap 4.

- FIGS. 9 and 11 show how the carrying strap 4 can be enclosed in the stretched grip strap tensioner 5.

- FIG. 12 shows a side view

- FIG. 13 shows a section corresponding to FIG. 12 through a grip tape tensioner 5 in the tensioned position with a child-resistant closure.

- the grip 4 is to a certain extent by folding the clamping elements 6 and 7 Clamping element 6 wrapped around and shortened by about twice the length of the clamping element 6. If a tight tension of the grip tape 4 is to be achieved with the grip tape tensioner 5 activated, it is therefore necessary to measure the length of the grip tape 4 so that the lengths of the tightly tensioned strap on the one hand and the loosened strap on the other hand are approximately twice the length of the tensioning element 6 differentiate.

- two J-shaped hooks interlock in the locked state.

- One J-hook 24 is located at the end of a locking lug 26 molded onto the tensioning element 6, while the other J-hook 25 is integrated into a locking opening 27 assigned to the locking lug 26.

- the two hooks cannot be separated from one another without an overlapping actuation that requires abstract thinking.

- the locking of the locking of the tensioning elements 6 and 7 according to FIG. 13 is therefore childproof in the prescribed manner.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Package Frames And Binding Bands (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3615698 | 1986-05-09 | ||

| DE19863615698 DE3615698A1 (de) | 1986-05-09 | 1986-05-09 | Griffbandspanner einer tragepackung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0244797A2 true EP0244797A2 (fr) | 1987-11-11 |

| EP0244797A3 EP0244797A3 (fr) | 1990-03-07 |

Family

ID=6300497

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87106423A Withdrawn EP0244797A3 (fr) | 1986-05-09 | 1987-05-04 | Tendeur de poignée pour emballage portatif |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0244797A3 (fr) |

| DE (1) | DE3615698A1 (fr) |

| ES (1) | ES1006911Y (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2615534A (en) * | 2022-02-09 | 2023-08-16 | Ds Smith Packaging Ltd | Method for wrapping a plurality of articles |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NZ201731A (en) * | 1981-09-01 | 1986-03-14 | Unilever Plc | Container having a carrying strap adjustable to secure lid on container |

| DE3205062A1 (de) * | 1982-02-12 | 1983-08-18 | Henkel KGaA, 4000 Düsseldorf | Kindersicherung und verfahren zum betrieb der sicherung |

| DE3204984A1 (de) * | 1982-02-12 | 1983-08-25 | Henkel KGaA, 4000 Düsseldorf | Kindersicherung und verfahren zum betrieb der sicherung |

| DE3206531A1 (de) * | 1982-02-24 | 1983-09-01 | Hermann 6920 Sinsheim Thomin | Trageband fuer einen mit deckel versehenen behaelter |

-

1986

- 1986-05-09 DE DE19863615698 patent/DE3615698A1/de not_active Withdrawn

-

1987

- 1987-05-04 EP EP87106423A patent/EP0244797A3/fr not_active Withdrawn

- 1987-05-08 ES ES8701562U patent/ES1006911Y/es not_active Expired

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2615534A (en) * | 2022-02-09 | 2023-08-16 | Ds Smith Packaging Ltd | Method for wrapping a plurality of articles |

Also Published As

| Publication number | Publication date |

|---|---|

| ES1006911Y (es) | 1989-08-01 |

| DE3615698A1 (de) | 1987-11-12 |

| ES1006911U (es) | 1989-01-16 |

| EP0244797A3 (fr) | 1990-03-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69000890T2 (de) | Selbstverriegelnder behaelter und verpackungsverfahren. | |

| DE1953696C3 (de) | Verpackung für Zigaretten o.dgl | |

| DE69701886T2 (de) | Zusammenlegbarer behälter | |

| DE69100135T2 (de) | Aus Pappe, Wellpappe oder anderem passend geschnittenem und gefaltetem Folienmaterial hergestellte Verpackung mit einem wiederverschliessbaren, mit einem Handgriff versehenen Deckel und entsprechender Zuschnitt. | |

| DD289504A5 (de) | Baueinheit | |

| DE127120T1 (de) | Sackverschluss mit zwei oeffnungen. | |

| CH418178A (de) | Behälter und Verfahren zur Herstellung des Behälters | |

| DE2845750C2 (fr) | ||

| DE2231324A1 (de) | Spannverschluss zum spannen sowie zur halterung von pack- oder zurrungszwecken dienenden gurtstuecken | |

| CH429565A (de) | Aus zwei gegenseitig schwenkbaren Teilen bestehende Schachtel | |

| DE69302905T2 (de) | Vorrichtung zum schliessen von beuteln oder dergleichen und sicherheitssiegel | |

| DE3340798A1 (de) | Verpackung in form einer schachtel aus karton | |

| DE2220274B2 (de) | Karton zum Verpacken von Eiern u.dgl | |

| EP0244797A2 (fr) | Tendeur de poignée pour emballage portatif | |

| DE2433711A1 (de) | Umschlag-faltschachtel | |

| DE2950629C2 (de) | Griffschnur für einen Batteriekasten | |

| DE19854097C2 (de) | Verpackungskarton | |

| DE69300594T2 (de) | Aufbewahrungsvorrichtung mit Handkoffer und Ablage. | |

| DE8337667U1 (de) | Behaelter fuer einen klettenverschluss | |

| EP0232550B1 (fr) | Récipient portable à fermeture inviolable par les enfants | |

| DE2647669A1 (de) | Verschluss fuer handkoffer u.dgl. | |

| DE2344053C3 (de) | Verpackungskarton für zerbrechliche Gegenstände, insbesondere Eier | |

| WO2025210158A1 (fr) | Conteneur réutilisable doté d'une fermeture, agencement de fermeture et utilisation dudit agencement de fermeture | |

| EP0094103A2 (fr) | Gobelet à fermeture de securité | |

| DE2346610A1 (de) | Traggriff |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI NL |

|

| 17P | Request for examination filed |

Effective date: 19900326 |

|

| 17Q | First examination report despatched |

Effective date: 19900822 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19901210 |

|

| R18W | Application withdrawn (corrected) |

Effective date: 19901210 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KUENZEL, WERNER Inventor name: VIERKOETTER, PETER |