EP0244568A1 - Convoyeur de feuilles pour machines traitant des feuilles - Google Patents

Convoyeur de feuilles pour machines traitant des feuilles Download PDFInfo

- Publication number

- EP0244568A1 EP0244568A1 EP87101908A EP87101908A EP0244568A1 EP 0244568 A1 EP0244568 A1 EP 0244568A1 EP 87101908 A EP87101908 A EP 87101908A EP 87101908 A EP87101908 A EP 87101908A EP 0244568 A1 EP0244568 A1 EP 0244568A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sheet

- gripper

- toothed belt

- support body

- toothed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/003—Delivering or advancing articles from machines; Advancing articles to or into piles by grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/02—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles

- B65H29/04—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles the grippers being carried by endless chains or bands

- B65H29/042—Intermediate conveyors, e.g. transferring devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/02—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles

- B65H29/04—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles the grippers being carried by endless chains or bands

- B65H29/045—Details of grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H5/00—Feeding articles separated from piles; Feeding articles to machines

- B65H5/08—Feeding articles separated from piles; Feeding articles to machines by grippers, e.g. suction grippers

- B65H5/085—Feeding articles separated from piles; Feeding articles to machines by grippers, e.g. suction grippers by combinations of endless conveyors and grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2404/00—Parts for transporting or guiding the handled material

- B65H2404/20—Belts

- B65H2404/23—Belts with auxiliary handling means

- B65H2404/231—Belts with auxiliary handling means pocket or gripper type

Definitions

- the present invention relates to a sheet conveyor for sheet-processing machines, with a positive-locking, rotating feed means, which runs at least over two end deflection wheels and possibly also between intermediate support wheels and carries at least one sheet transport sports gripper on its top, which in the course of the circulation path is opened or closed.

- Such sheet conveyors are known in various variations in the prior art. Such devices are usually designed as chain conveyors, which often feed a sheet to the front mark of a printing press or the like.

- a disadvantage of such chain conveyors is that their structure with the help of chains means that they are relatively complex and therefore cost-intensive. The grabs are common even switched into the chain on a special component in the form of a gripper carriage, which also requires a not inconsiderable design effort.

- chain conveyors run only with a considerable noise and have a considerable mass, so that they are not or only partially usable with high-speed machines.

- the circumferential feed means is formed from a number of toothed belts running over appropriately shaped gears, in which a recess is provided at one or more points along the longitudinal extent, in which a support body carrying a gripper mechanism is detachably inserted that the gears are provided with circumferential recesses which correspond to the inwardly projecting parts of the support body / gripper mechanism speak, and that each gripper mechanism has an actuating lever which is actuated by a cam track when it runs up / down.

- This configuration of the sheet conveyor eliminates the disadvantages in the prior art in a particularly simple manner.

- toothed belts can be equipped at any point with a gripper mechanism which can be exchanged easily in the event of faults.

- the gripper mechanism of the sheet conveyor is actuated in a particularly advantageous manner in that the cam track for the actuating lever is part of the circumferential recesses of the gear or gears.

- the rotating grippers can be actuated particularly simply by running up or down one of the gearwheels, although it is not excluded that a separate (stationary) cam track is also provided for this purpose, especially when opening and / or closing the grippers at a different location than in the area of one of the support or deflection wheels. of the sheet conveyor is desired.

- the support body preferably passes through the toothed belt and rests with its support plate on the outside of the toothed belt, wherein it is clamped by at least two fastening pins which are located on the inside of the toothed belt and are pushed through the support body.

- the gripper mechanism has a hook-shaped gripper which lies in the clamping position on the support plate on the top of the toothed belt. Since the gripper can be pivoted in the direction of the toothed belt about an axis which is arranged at a distance from the toothed belt on its inside in the direction of advance of the toothed belt before the clamping point, the gripper moves in the same direction of rotation in relation to the toothed belt and in the opposite direction when it is closed Direction, that is, that even a sheet conveyed at the speed of the toothed belt can be gripped without problems.

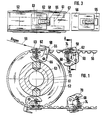

- two toothed belts (band 56) arranged parallel to the plane of the drawing are tensioned with the aid of two deflection rollers / gear wheels 52/54, of which, however, only one deflection roller 52 with one part in FIGS. 1 and 3 of the toothed belt 56 is shown.

- the belts 56 are designed as toothed belts and the associated deflection rollers 52/54 as corresponding toothed wheels. However, other forms of belts and deflection rollers are possible.

- the toothed belt 56 has a centrally arranged recess 55 at certain points along its longitudinal extent, into which the support body 60 with the gripper mechanism of the gripper 58 can be detachably inserted can.

- the support body 60 has an approximately T-shaped shape which is provided with a central recess and has a support arranged on the upper side of the toothed belt 56 plate 62 and two perpendicularly extending middle parts 64 which receive between them the gripper 58, which is penetrated at some distance from the support plate 62 or the toothed belt 56 by a hinge pin 66 which is supported in the two middle parts 64.

- the hook-shaped gripper 58 can thus be pivoted about the hinge pin 66 and the hook-shaped upper end of the gripper 58 which projects upwards over the support plate 62 above the top of the toothed belt 56 lies in the gripping position on the continuous part 63 of the support plate 62.

- a compression spring 68 is stretched between the support plate 62, 63 and a cam lever-like extension 70 of the hook-shaped gripper 58.

- the gripper 58 is normally pivoted into its clamping or gripping position, which it assumes in the entire course of the upper and lower run of the conveyor belt-like device and when walking around the deflection roller 54. Only when the gripper mechanism runs around the deflection roller / gear 52 does the gripper, as shown in FIG. 1, assume the open position by the cam-like extension 70 on the middle part 72 (which is larger than the deflection roller 54) (Cam track 61) runs up.

- both the deflecting roller 54 and the deflecting roller 52 have a nutenar in their central planes term recess 57, which corresponds approximately to the width of the lower part of the gripper mechanism ( Figure 2), but the groove-shaped recess in the deflection roller 52 is less deep than in the deflection roller 54, so that the gripper mechanism does not open the latter.

- the depth of the recess of the deflection roller 54 is indicated by dashed lines at 53 in FIG. 1 and also in FIG. 4.

- the gripping mechanism is easily detachably fastened to the toothed belt 56 by two locking pins 74 inserted through it. After removing these fastening pins 74, the gripper mechanism in FIG. 1 can simply be lifted up out of the recess in the toothed belt 56.

- These pins 75 are provided with a section of reduced diameter in the middle for better locking on the middle parts 64 of the T-shaped support body 60, as can be clearly seen in FIG. 2.

- the mounting pins 74 are preferably arranged so that they just - as shown - fill two adjacent depressions of the toothed belt. Accordingly, the teeth must then be left out at the corresponding points on the gear wheels 52, 54, as is indicated in the lower left part of FIG. 1. Such an arrangement of the mounting pins then requires also that the grippers on the toothed belt 5'6 are arranged just at a distance which corresponds to the pitch circle diameter of the gear wheels 52, 54 or a whole multiple thereof.

- these fastening pins 74 it is conceivable to give these fastening pins 74 a cross section which corresponds to an elevation or a tooth of the toothed belt and then to arrange the fastening pins in place of such a tooth. In this case, the position of the grippers on the toothed belt can be chosen practically freely.

- a gripper mechanism is shown which is just beginning to leave the deflection roller 52 and thus initiates the closing process of the gripper 58.

- the path of a printing sheet emerging, for example, from a printing press is indicated by an arrow 59.

- the printing sheet hits the plate 62/63 on the upper run of the toothed belt 56 at an acute angle. This allows any undulations on the front edge of the printing sheet to be compensated for, since the sheet thus aligns itself on the plate 62/63.

- the sheet to be clamped is placed on the toothed belt 56 or the support plate 62, 63 at such a speed that the differences limit speed is zero or approximately zero. Since the hinge pin 66 lies in the direction of movement of the toothed belt 56 in front of and below (in FIG.

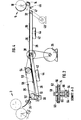

- FIG. 4 shows a basic illustration of a specific application of the sheet conveyor according to the invention, namely as a turning device 50 of a sheet conveying and turning device between two printing machines 3, 5 connected in tandem, of which only one or two printing rollers and one toward the other and oscillating suction roller for receiving and inserting a sheet to be printed are indicated by dash-dotted lines.

- an elongated belt conveyor 26 which consists of a number of endlessly arranged parallel to one another (and to the drawing plane) sen elastic bands 28 with a large coefficient of friction. These belts 28 are guided over two deflection rollers 30 and 32 at the beginning and end of the elongated belt conveyor. 26, further support rollers being distributed over the length of this conveyor as required.

- a support and drive roller is indicated in the middle at 38.

- the conveyor constructed in this way works in a very similar manner to a conventional conveyor belt, ie the printed sheets 36 deposited on its upper side by the turning device 50 and, if necessary, overlapping more or less are conveyed from the first printing press (left) to the second printing press (right) at a speed that depends on the circumstances of the individual case.

- the conveyor does not have to consist of individual endless belts 28 (approximately with a circular cross section) arranged parallel to one another, but it is readily conceivable that a coherent broad belt - for example with large holes in it or a network-like structure etc. - is also used .

- the belt conveyor 26 being able to be driven either centrally at the central support and drive roller 38 via the main motor 39, which simultaneously drives the two printing presses 3, 5 synchronously , or alternatively - as shown - by a separate, controllable drive motor 40, which acts, for example, on the deflection roller 32 at the end of the conveyor 26 and only drives the belt conveyor 26, while the main motor 39 drives the turning device 50 and the two printing presses 3, 5.

- suction chambers 42 are arranged just below the belt conveyor 26, which are subjected to a vacuum by suitable means.

- These suction chambers 42 have suction openings 44 pointing upwards, that is to say in the direction of the conveyor 26, so that there is a considerable air flow in the direction of the suction chambers, which then results in a more than over the large area of each printed sheet 36 deposited on the conveyor sufficient pressing force of the printed sheets against the conveyor having a significant coefficient of friction or its belts 28 leads.

- the printed sheets are thus fixed on the conveyor belt or belts of the conveyor and inevitably moved in the direction of the second printing press, where the front edge of each printing sheet finally abuts against a stop 46 serving as the front mark of the second printing press.

- the printed sheets are also aligned laterally, if this is necessary at all is.

- the sheet fed is fed in a known manner to the counter-pressure cylinder 18 of the second printing press by a reciprocating suction roll 14.

- a test device for example in the form of a reflex head 47, is provided in the area of the abovementioned stop 46 (front mark of the second printing press). On the one hand, it checks the correct entry of the sheets into the machine 5 in terms of time and distance, and on the other hand it controls the activation of the offset cylinder 20 of the machine 5 if a sheet is available at the time of the query.

- the printing sheet running out of the first printing machine 3 is guided straight to the beginning of the upper run of the turning device 50, in such a way that the leading edge of the printing sheet is below the gripper 58 of the turning device which closes at this point is given.

- the turning device runs at a peripheral speed which corresponds exactly to the output speed of the printing sheet from the first printing machine 3, so that the entire sheet is pulled off the printing machine and - without the gripper 58 opening - is guided around the deflection roller 54 of the turning device.

- the upper side of the printing sheet running out of the printing press is turned downward, since the printed side of the printing sheet points downward, ie towards the conveyor 26, after reaching the lower run of the turning device.

- this gripper 58 attached to the toothed belt 56 of the turning device hits the deflection roller 52 at the end of the lower run (located in the direction of rotation of the belt)

- this gripper opens and releases the front edge of the printing sheet, which now has the previously generated print image on the lower, ie the side facing the conveyor 26.

- the leading edge of the thus released, turned printing sheet then runs against a stop 51 at the end of the gap which is formed by the upper run of the belt conveyor 26 and the lower run of the turning device 50.

- the printed sheet is stopped and drawn against the belt conveyor 26 by the suction air generated by the suction chambers 42.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87101908T ATE48267T1 (de) | 1986-02-20 | 1987-02-11 | Bogenfoerderer fuer bogenverarbeitende maschinen. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863605534 DE3605534A1 (de) | 1986-02-20 | 1986-02-20 | Bogen-foerderer fuer bogenverarbeitende maschinen |

| DE3605534 | 1986-02-20 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0244568A1 true EP0244568A1 (fr) | 1987-11-11 |

| EP0244568B1 EP0244568B1 (fr) | 1989-11-29 |

Family

ID=6294582

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87101908A Expired EP0244568B1 (fr) | 1986-02-20 | 1987-02-11 | Convoyeur de feuilles pour machines traitant des feuilles |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4799664A (fr) |

| EP (1) | EP0244568B1 (fr) |

| JP (1) | JPS62255345A (fr) |

| AT (1) | ATE48267T1 (fr) |

| DE (2) | DE3605534A1 (fr) |

| ES (1) | ES2012061B3 (fr) |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH683913A5 (de) * | 1987-10-23 | 1994-06-15 | Ferag Ag | Transporteur für kontinuierlich anfallende Flächengebilde, insbesondere Druckereiprodukte. |

| JPH01127537A (ja) * | 1987-11-09 | 1989-05-19 | Sharp Corp | シート材の給送装置 |

| US4972234A (en) * | 1989-02-17 | 1990-11-20 | Fujitsu Limited | Endless belt with recess for receiving sheet feeding grippers |

| US5054621A (en) * | 1989-12-18 | 1991-10-08 | Hybrid Systems, Inc. | Document sorting apparatus |

| US5265868A (en) * | 1990-05-03 | 1993-11-30 | Bell & Howell Phillipsburg | Sheet feeder |

| US5145161A (en) * | 1990-05-03 | 1992-09-08 | Bell & Howell Phillipsburg Co. | Sheet feeder |

| US5053826A (en) * | 1990-12-21 | 1991-10-01 | Xerox Corporation | Transfer loop synchronization in recirculating color printers |

| US5211392A (en) * | 1991-09-05 | 1993-05-18 | Xerox Corporation | Sheet transport apparatus for use in an electrophotographic printing machine |

| SE9103290L (sv) * | 1991-11-07 | 1993-05-08 | Wamag Idab Ab | Foerfarande och anordning foer att oeppna en sjaelvstaengande gripare paa en griparetransportoer |

| US5244203A (en) * | 1992-04-24 | 1993-09-14 | Eastman Kodak Company | Sheet transporting apparatus with a transport belt to which sheets are selectively clamped |

| DE4223232A1 (de) * | 1992-07-15 | 1994-01-20 | Heidelberger Druckmasch Ag | Vorrichtung zur Steuerung des Öffnungszeitpunktes von Greifern eines Bogenauslegers einer bogenverarbeitenden Maschine |

| DE4244343C2 (de) * | 1992-12-28 | 1996-08-29 | Wifag Maschf | Verfahren und Vorrichtung zur Bildung eines Schuppenstroms von gefalzten Druckexemplaren |

| SE502958C2 (sv) * | 1994-08-19 | 1996-02-26 | Sten Wallsten Ind Ab | Anordning för avlämnande av utvalda exemplar av föremål från en transportbana |

| DE19519374C2 (de) * | 1995-05-26 | 1999-11-18 | Heidelberger Druckmasch Ag | Vorrichtung zur automatischen Bogenaussonderung im Ausleger einer Bogenrotationsdruckmaschine |

| US6336310B1 (en) * | 1998-09-08 | 2002-01-08 | Sanford Redmond | Method and apparatus for making compact packages for speadable product |

| DE19916668B4 (de) * | 1999-04-14 | 2010-06-24 | Michael Hörauf Maschinenfabrik GmbH & Co. KG | Vorrichtung zum Transportieren von flach liegenden Zuschnitten |

| DE10047040A1 (de) * | 1999-10-15 | 2001-04-19 | Heidelberger Druckmasch Ag | Modulares Druckmaschinensystem zum Bedrucken von Bogen |

| DE19949751A1 (de) * | 1999-10-15 | 2001-04-19 | Heidelberger Druckmasch Ag | Modulares Druckmaschinensystem zum Bedrucken von Bogen |

| DE50005320D1 (de) * | 1999-12-07 | 2004-03-25 | Ferag Ag | Vorrichtung und Verfahren zum Transport von Ergänzungsprodukten |

| US7017640B2 (en) * | 2001-02-09 | 2006-03-28 | Winter Steven B | Method and apparatus for manufacture of swatch-bearing sheets |

| AUPS061402A0 (en) * | 2002-02-19 | 2002-03-14 | Tna Australia Pty Limited | A device to aid packaging items |

| DE102004007599A1 (de) | 2003-03-27 | 2004-10-07 | Heidelberger Druckmaschinen Ag | Bogen verarbeitende Maschine mit einem Bogenentroller |

| JP4484819B2 (ja) * | 2003-04-03 | 2010-06-16 | 富士機械製造株式会社 | 電子回路部品供給装置 |

| PL1655244T3 (pl) * | 2004-09-15 | 2009-07-31 | Ferag Ag | Sposób i urządzenie do oddzielania płaskich przedmiotów z ułożonego stosu |

| DE102006039987A1 (de) * | 2006-08-25 | 2008-02-28 | Koenig & Bauer Aktiengesellschaft | Vorrichtung zur Stapelbildung in einer Bogen verarbeitenden Maschine |

| DE102009016067A1 (de) | 2009-03-17 | 2010-09-23 | Steinemann Technology Ag | Vorrichtung zum Befördern eines Bogens |

| US8376356B2 (en) * | 2009-09-21 | 2013-02-19 | Goss International Americas, Inc. | Infinitely variable format signature collection apparatus and method of collecting signatures |

| CH703119A1 (de) * | 2010-05-10 | 2011-11-15 | Ferag Ag | Vorrichtung und Verfahren zum Transportieren von flexiblen, flächigen Produkten. |

| MX2017013921A (es) * | 2015-05-01 | 2018-01-15 | Joa Curt G Inc | Aparato y metodo para sujetar mecanicamente y transportar en entramados de material. |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2724979B2 (de) * | 1977-06-02 | 1979-04-12 | Bielomatik Leuze & Co, 7442 Neuffen | Transportvorrichtung für flache Gegenstände |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1462923A (en) * | 1921-07-02 | 1923-07-24 | United Printing Machinery Comp | Sheet gripper |

| US3266796A (en) * | 1964-12-21 | 1966-08-16 | Ibm | Document handling apparatus |

| SE413007B (sv) * | 1977-04-12 | 1980-03-31 | Wifag Maschf | Anordning for att bilda en strom av overlappade falsade tryckprodukter |

| US4203590A (en) * | 1978-01-09 | 1980-05-20 | Levi Strauss & Co. | Gripper belt transfer |

-

1986

- 1986-02-20 DE DE19863605534 patent/DE3605534A1/de not_active Withdrawn

-

1987

- 1987-02-11 DE DE8787101908T patent/DE3761044D1/de not_active Expired - Fee Related

- 1987-02-11 ES ES87101908T patent/ES2012061B3/es not_active Expired - Lifetime

- 1987-02-11 AT AT87101908T patent/ATE48267T1/de not_active IP Right Cessation

- 1987-02-11 EP EP87101908A patent/EP0244568B1/fr not_active Expired

- 1987-02-19 US US07/016,574 patent/US4799664A/en not_active Expired - Fee Related

- 1987-02-20 JP JP62035939A patent/JPS62255345A/ja active Pending

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2724979B2 (de) * | 1977-06-02 | 1979-04-12 | Bielomatik Leuze & Co, 7442 Neuffen | Transportvorrichtung für flache Gegenstände |

Also Published As

| Publication number | Publication date |

|---|---|

| US4799664A (en) | 1989-01-24 |

| ATE48267T1 (de) | 1989-12-15 |

| DE3605534A1 (de) | 1987-08-27 |

| ES2012061B3 (es) | 1990-03-01 |

| JPS62255345A (ja) | 1987-11-07 |

| DE3761044D1 (de) | 1990-01-04 |

| EP0244568B1 (fr) | 1989-11-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0244568B1 (fr) | Convoyeur de feuilles pour machines traitant des feuilles | |

| CH637091A5 (de) | Vorrichtung zum zufuehren von in einem schuppenstrom anfallenden flaechigen erzeugnissen, insbesondere druckprodukten, zu einem transporteur. | |

| DE2346898C2 (de) | Vorrichtung zum Aussondern eines biegeschlaffen, flachen Gegenstandes aus einer Reihe von auf einer Förderstrecke bewegten sich überlappenden Gegenständen | |

| DE10005323A1 (de) | Vorrichtung zur Produkthandhabung | |

| DE3306815C2 (de) | Vorrichtung zum transportieren von in einer schuppenformation anfallenden flaechigen erzeugnissen, insbesondere druckprodukten | |

| CH670619A5 (fr) | ||

| DE1561146C3 (de) | Vorrichtung zum ausgerichteten Zufuhren einzelner Blatter zu bogen verarbeitenden Maschinen Ausscheidung aus 1242246 | |

| DE2058606A1 (de) | Verfahren und Vorrichtung zum seitlichen Ausrichten von Blaettern,insbesondere bei einer Druckpresse | |

| EP0303053A2 (fr) | Dispositif de transfert de feuilles | |

| EP0242702B1 (fr) | Procédé et dispositif pour tourner des objets plats | |

| EP0564812A1 (fr) | Procédé et dispositif pour ouvrir des produits d'imprimerie pliés | |

| EP0300171B1 (fr) | Dispositif de transport pour produits plats, en particulier des produits imprimés | |

| EP0241663B1 (fr) | Dispositif pour convoyer et tourner des feuilles pour machines traitant des feuilles | |

| DE2539799B2 (de) | Lichtpausmaschine mit einer Repetiervorrichtung | |

| EP1072546B1 (fr) | Convoyeur pour assembler et traiter des produits imprimés | |

| EP0210494A1 (fr) | Dispositif de rassemblement pour feuilles pliées | |

| EP0478911A1 (fr) | Dispositif de transfert sélectif d'articles se chevauchant d'un premier chemin de transport à un deuxième chemin de transport | |

| EP1132324A2 (fr) | Entraínement par courroie pour une machine de traitement de matériaux imprimés plats | |

| DE3308069C2 (de) | Vorrichtung zum Zusammenführen von Teilbahnen über Umlenkwalzen in eine gemeinsame Ebene | |

| EP0647582A1 (fr) | Dispositif pour ouvrir et transporter des produits imprimés | |

| EP0014233B1 (fr) | Dispositif pour amener des feuilles à une imprimeuse | |

| DE4424964C2 (de) | Bogenleiteinrichtung zum Wenden von Bogen | |

| DE2624170C3 (de) | Seitenausrichtvorrichtung | |

| DE69912189T2 (de) | Vorrichtung zur Abgabe und Regelung der Teilung von Bögen für den Ausleger einer Falzmaschine | |

| CH686829A5 (de) | Vorrichtung zum Ueberfuehren von einzelnen Druckprodukten eines Schuppenstromes. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19870928 |

|

| 17Q | First examination report despatched |

Effective date: 19881118 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19891129 Ref country code: NL Effective date: 19891129 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19891129 |

|

| REF | Corresponds to: |

Ref document number: 48267 Country of ref document: AT Date of ref document: 19891215 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3761044 Country of ref document: DE Date of ref document: 19900104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19900211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19900212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19900228 Ref country code: LI Effective date: 19900228 Ref country code: CH Effective date: 19900228 Ref country code: BE Effective date: 19900228 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| BERE | Be: lapsed |

Owner name: NEUE ROTAPRINT G.M.B.H. Effective date: 19900228 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19901031 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19901101 |

|

| 26N | No opposition filed | ||

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19910211 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050211 |