EP0024621B1 - Plaque de cuisson électrique - Google Patents

Plaque de cuisson électrique Download PDFInfo

- Publication number

- EP0024621B1 EP0024621B1 EP80104743A EP80104743A EP0024621B1 EP 0024621 B1 EP0024621 B1 EP 0024621B1 EP 80104743 A EP80104743 A EP 80104743A EP 80104743 A EP80104743 A EP 80104743A EP 0024621 B1 EP0024621 B1 EP 0024621B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cover plate

- electric cooking

- cooking plate

- plate

- screw

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000010411 cooking Methods 0.000 title claims description 50

- 229910052751 metal Inorganic materials 0.000 claims description 28

- 239000002184 metal Substances 0.000 claims description 28

- 238000012856 packing Methods 0.000 claims description 12

- 239000011888 foil Substances 0.000 claims description 8

- 239000002274 desiccant Substances 0.000 claims description 6

- 238000009413 insulation Methods 0.000 claims description 6

- 238000010438 heat treatment Methods 0.000 claims description 5

- 229920002379 silicone rubber Polymers 0.000 claims description 2

- 239000004945 silicone rubber Substances 0.000 claims description 2

- 239000002966 varnish Substances 0.000 claims description 2

- 239000005030 aluminium foil Substances 0.000 claims 1

- 239000002657 fibrous material Substances 0.000 claims 1

- 230000002265 prevention Effects 0.000 claims 1

- 238000007789 sealing Methods 0.000 description 8

- 238000009434 installation Methods 0.000 description 6

- 238000004806 packaging method and process Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 4

- 239000000741 silica gel Substances 0.000 description 3

- 229910002027 silica gel Inorganic materials 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 241000538562 Banjos Species 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 239000010425 asbestos Substances 0.000 description 2

- 239000011810 insulating material Substances 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 229910052895 riebeckite Inorganic materials 0.000 description 2

- 239000003566 sealing material Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 230000037303 wrinkles Effects 0.000 description 2

- 229910001018 Cast iron Inorganic materials 0.000 description 1

- 239000005909 Kieselgur Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000012671 ceramic insulating material Substances 0.000 description 1

- 239000011093 chipboard Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000012784 inorganic fiber Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000011120 plywood Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 229920002050 silicone resin Polymers 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/68—Heating arrangements specially adapted for cooking plates or analogous hot-plates

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C7/00—Stoves or ranges heated by electric energy

- F24C7/06—Arrangement or mounting of electric heating elements

- F24C7/067—Arrangement or mounting of electric heating elements on ranges

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/68—Heating arrangements specially adapted for cooking plates or analogous hot-plates

- H05B3/70—Plates of cast metal

Definitions

- the invention relates to an electric hotplate with a hotplate body, which has a downward, annular edge on the outer circumference, on which a cover plate is supported.

- Such an electric hotplate with a middle sensor is known.

- the baffle plate is placed flat on the edge and fastened there with two threaded bolts.

- the cover plate is not very tight and is difficult to center. If, under extreme conditions, for example after a sea transport, moisture has penetrated into the interior of the space separated from the cover plate, it can increase the leakage currents.

- the object of the invention is to provide an electric hotplate in which the cover plate is well centered without complex measures and with improved sealing on the hotplate body.

- the cover plate has a step directed towards the inside of the hotplate, which adjoins the edge region supported on the free lower edge of the edge and cooperates with the inner circumference of the edge to center the cover plate.

- the cover plate is advantageously pressed on very uniformly from the central region.

- This shape of the cover plate also makes it possible to accommodate insulation, which can advantageously consist of an inserted metal foil.

- a drying agent can also be provided which regenerates itself when the hotplate is in operation due to the high temperature.

- the heat-resistant insulated connecting leads leading out of the electric hotplate flexible and to lead them to a common, freely moveable connecting piece with connecting terminals, the connecting lines being long enough to arrange the connecting piece outside the area of the electric hotplate.

- this connector can be moved flexibly and adapts to all installation requirements, it is located outside the heated area of the hotplate, but does not interfere with the installation.

- the connection piece can be bent so that it does not have a greater height than the electric hotplate itself. It can either be folded outwards, in the spaces formed between the round hotplates, or folded inwards in a recess in the cover plate of the hotplate lie.

- the hotplate can preferably be further improved for particularly space-saving and safe transport if the hotplate is placed on top of one another with opposing cooking surfaces and undersides, but in each case in a position offset by 180 ° in the circumferential direction, an insulating piece then penetrating into a depression in the cover plate. Furthermore, since the above fastening and anti-rotation bolts are preferably missing, the hotplate can be stacked at a height which is even less than its own overall height.

- the screw securing the cover plate to the hotplate body is advantageously a hollow cap screw with an external and internal thread, which fixes the cover plate with its head and into which a fastening screw for the electric hotplate can be screwed, then it is only necessary for the hotplate production to produce the hollow one Screw in the screw to fix the cover plate.

- a conventional cap screw is then used to fix the hotplate.

- the banjo bolt is easier to secure and the packaging and transport costs are reduced. It is also easier to adapt to different installation heights by simply using other cap screws.

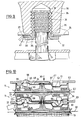

- an electric hotplate 11 which has a hotplate body 12 made of cast iron with an upper flat and closed cooking surface 13.

- the unheated central zone 14 is lowered, so that an annular cooking surface is created.

- the hotplate body overlaps on its outer circumference via an overhang edge 15 made of sheet material of essentially U-shaped cross section, which is supported on the raised opening edge 16 of the worktop 17 of an electric cooker or hob.

- the hotplate In the heated ring area, the hotplate is provided with spirally extending ribs, which likewise form spiral grooves 18 between them, in which heating coils 19 lie in a ceramic investment 20.

- the edge 21 has a cutout 26 in the form of a square cutout (FIG. 8), in which a corresponding design 27 of the cover plate is placed and thus ensures that the cover plate 24 is secured against rotation on the hotplate body despite a relatively tight seal.

- the shape 27 of the cover plate in turn ensures that the finished hotplate can be aligned in the circumferential direction during its handling during manufacture. As a result, no inner projection is necessary at the edge 21.

- Adjoining the step 25 is an area 28 of the cover plate which springs back relative to the edge area 23 and is adjoined by a central area 29 which projects somewhat in relation to the edge area 23.

- the hotplate body has a downwardly projecting pin 30, into which a blind threaded bore 31 projects from below.

- a hollow cap screw 32 which is shown in detail in FIG. 9, is screwed into this threaded bore. It consists of a sheet metal stamping or deep-drawn part with a flange-like head region 33 with a hexagon key surface and an adjoining sleeve-shaped threaded section 34, into which an internal and external thread is pressed or pressed.

- the screw 32 projects through a central hole 36 of the cover plate 24 and is screwed into the thread 35 of the bore 31, so that the cover plate 24 is pressed with its edge region 23 against the lower edge 22 of the edge 21 of the hotplate body 12.

- a sheet metal part 37 (FIG. 2) is interposed, which has the shape of a sheet metal strip which has a hole 38 on one side through which the screw 32 projects, while the other end is somewhat tapered and with a bent end 39 (FIGS. 1 and 2) comprises an earth line 40.

- the grounding line can be pressed or welded to the sheet metal part 37.

- This sheet metal part is simply placed under the screw head 33 in the manner of a washer and enables a safe earth connection. It is particularly advantageous that the sheet metal part during manufacture and Shipping lies flat on the underside of the cover plate 24 and only if it is necessary, something is bent from this. The earth connection therefore does not significantly increase the height of the hotplate.

- FIG. 9 shows on the left-hand side that the contact surface of the head 33 can be provided with a preferably star-shaped corrugation 41. Accordingly, the sheet metal part 37 is provided on its top and bottom and the cover plate 24 (see FIGS. 2 and 15), whereby the screw 32 is secured against accidental loosening. However, it is also possible to provide other types of backup.

- the hotplate is held in the worktop opening receiving it by a bracket 42, which is supported on the underside of the worktop 17 and has a flat U-shape. Its long back is stiffened by side bends 43.

- a cap screw 45 projects through a hole 44 in the middle of the bracket and is screwed into the internal thread in the hollow screw 32.

- Screw 32 is a simple stamped sheet metal part and screw 45 is a simple machine screw. So far, the hot plates have been provided with bolts which were screwed into the pin 30 and which protruded far beyond the underside of the hot plate.

- An upwardly projecting pin 47 is riveted to the bracket 42, which engages in a sleeve-like recess 46, which is integrally formed inwardly from the cover plate and thus secures the hotplate against rotation against the bracket.

- a sleeve-like recess 46 which is integrally formed inwardly from the cover plate and thus secures the hotplate against rotation against the bracket.

- several recesses 46 can be provided on the circumference, possibly also offset by 90 ° from one another.

- Fig. 3 shows a variant for the recess 46, which can be selected if the sheet metal from which the cover plate 24 is made should not be subjected to excessive deformation.

- a separately produced sleeve 46 ' is tightly fastened in an opening of the cover plate 24 by a two-sided flange 46 ". It is also possible to provide the sleeve with a pressed-in thread, for example in the region of the flange 46", for subsequently screwing in a pin.

- Fig. 4 shows in a detailed representation that between the edge region 23 of the cover plate 24 and the lower edge 22 of the hotplate edge 21, a sealing ring 25 is interposed, which can have a flat or circular cross-sectional shape and consists of a heat-resistant sealing material. Silicone rubber, asbestos-containing sealing materials, etc. are suitable for this. Further seal designs are shown in FIGS. 5 and 6, wherein in FIG. 5 the seal 25a consists of a paste which has been introduced into the angle between the edge region 23 and the step 25 and which, when pressed on, passes over the lower edge 22 and the inside of the edge 21 distributed. In this embodiment, the possibility of sealing in the region of the recess 26 is particularly advantageous.

- This sealing ring can consist of a molding compound which is made from an alumina-silicate fiber and is impregnated with a varnish based on silicone resin.

- the seal is intended to prevent moisture from penetrating into the interior 48 of the hotplate and thus possibly. in the investment 20 to avoid when the hotplate is exposed to extreme conditions, such as sea transport. Although the hotplate immediately expels any moisture that may have entered itself without generating previously unacceptable leakage currents, the seal represents an additional security.

- the seal is made possible in particular by the cover plate being placed on the lower flange, because this seals the seal into one Range comes lower temperature and can be designed better. Previous cover plates were on the underside of the investment material 20. Level 25 ensures additional sealing and perfect centering.

- FIG. 7 shows an embodiment in which the edge 21 'of the hotplate body has a step-shaped recess 49 on its inner underside, so that an outer circumferential edge section 50 of the edge 21' is formed, which extends somewhat further downward than the contact surface for the edge area 23 of the cover plate 24.

- the edge 21 'of the hotplate body has a step-shaped recess 49 on its inner underside, so that an outer circumferential edge section 50 of the edge 21' is formed, which extends somewhat further downward than the contact surface for the edge area 23 of the cover plate 24.

- a metal foil 51 which is in particular a bare aluminum wrinkle foil, lies approximately parallel to the cover plate in the interior 48. It is clamped between the edge 21 and the cover plate 24 or the seals provided (see FIGS. 4 to 7) and encloses a layer 52 between itself and the cover plate 24, which preferably consists of or contains silica gel or diatomaceous earth.

- This material not only ensures good insulation, but also ensures that e.g. water which has penetrated with the atmospheric moisture is taken up in the silica gel serving as a drying agent.

- the drying agent is always regenerated automatically when the water is expelled, so that it always remains effective.

- a desiccant it may be appropriate to perforate the metal foil or to place the desiccant in other containers in the interior 48 to ensure its effectiveness.

- the layer 52 is possible to produce the layer 52 from highly heat-resistant insulating materials, for example inorganic fibers such as asbestos or other known insulating materials. Together with the overlying metal foil, a very effective insulation is formed, which further reduces the heat losses due to radiation and convection downwards, which are already low in a contact hotplate. However, this above all keeps the temperature of the cover plate 24 low, so that it can be installed even in the flattest cooktops near wooden parts in kitchen furniture.

- highly heat-resistant insulating materials for example inorganic fibers such as asbestos or other known insulating materials.

- FIG. 10 shows three hotplates stacked one on top of the other, which apart from the fact that the sheet metal part 37 '(see also FIG. 11) is provided with a flat tongue 53 for connecting a corresponding flat connector 54 for the grounding line 40, with the hotplate according to FIG 1 are identical.

- like reference numerals designate like parts.

- the cut in FIG. 10 is offset by 45 ° in relation to FIG. 1, so that it can be seen that an insulating piece 55, which is supported on the inside of the latter and which contains a temperature limiter in its section 48 in the interior 48, projects through the cover plate 24 and is continuous Openings 57 (FIG.

- connection lines 58 provided with highly heat-resistant insulation from the interior 48, where they are welded with connection pins protruding from the investment material 20.

- the basic shape of the insulating piece 55 is elongated in the circumferential direction and it projects in the region of a bulge 60 through the cover plate.

- the connecting lines 58 are connected to a common connecting piece 75 made of ceramic insulating material (FIGS. 10 and 15), which contains plug-in or screw-type connection terminals 76 for connecting current supply lines 78. Due to the arrangement of the insulating piece in the radial direction approximately in the middle of the annular heated area and the dimensioning of the connecting lines, the outer edge 77 of the connecting piece 75 is preferably at a maximum distance of less than a hotplate radius from its outer edge and can be flexibly adapted to the installation conditions , whereby the connecting lines act like a flexible band, which allows easy swiveling and greater mobility of the connecting piece in the vertical direction, but more restricting twisting and lateral movement.

- the insulating piece 55 diametrically opposite and at a corresponding radial distance from the hotplate center there is a recess 61 in the cover plate 24, the dimensions of which are selected such that they reliably accommodate the projecting part of the insulating piece in the mutual assignment of the hotplate shown in FIG can, without the connecting lines 58 being bent too sharply.

- the width of the depression is considerably larger than that of the insulating piece, so that, as can be seen from FIG. 10 for the two upper hot plates, the connecting lines 58 can be folded inwards and the connecting piece 77 can lie next to the insulating piece in the depression 61 . It is also possible to store the connection piece 77 (FIG. 10 below) folded outward approximately in one plane with the hotplate, the connection lines 58 leading through a corresponding cutout of the packing plate 63.

- the hotplates with their central axes are stacked one above the other with their flat cooking surfaces 13 and with their undersides covered by the cover plates 24, only a sheet or film 62 being inserted between the cooking surfaces 13 to prevent scratches, while between the hotplates

- a packing plate 63 is placed on the underside, which can consist of plywood or chipboard and has recesses which are selected such that the hotplate is centered on it when it is placed on it. Parts of the hotplate projecting downward from the outer edge 23 of the cover plate protrude into the recess 64 of the packing plate 63.

- the hot plates 11 are each offset by 180 ° in the circumferential direction, so that the insulating piece 55 with the connecting lines protrudes into the depression 61 and the hot plate even requires a smaller packing space than its total height.

- the edges 21 are supported with the interposition of the packing plate 63, in that a solid stack is formed which does not tend to tip over.

- the aligned arrangement of the hot plates also contributes to this.

- the packing plates 63 have numerous recesses 64 next to one another and one behind the other in accordance with the desired packaging or pallet size, so that a large number of hot plates can be stored and transported in a solid block, not only saving on storage and transport costs, but also on accident safety elevated. Packing can also be done fully automatically by grippers.

- FIGS. 12 to 15 Another device is shown in FIGS. 12 to 15 in order to ensure that the hotplate is secured against rotation relative to fastening parts, for example the bracket 42.

- a sheet metal part 65 is used, which has the shape of a flat right-angled strip which extends in the area of the bend 66. Lateral incisions 67 separate edge areas at the ends of the sections 68, which are bent or rolled up around the ends (see in particular FIG. 13), so that the ends are pin-like.

- U-shaped cutouts 70 are provided in the sections 68, so that sheet metal tabs 71 are formed which are bent out of the plane of the sections 68. 14 shows this sheet metal part 65 in the installed state.

- the ends 69 are preferably only when the hotplate is installed in a stove or the like. bent by about 90 °, which is easily possible due to the incisions 67. It is only necessary to bend the end 69 which is to be inserted into a hole 73 in the mounting bracket 42 '. An anti-rotation lock is also created here without increasing the transport space.

- the anti-rotation sheet metal part 65 could be provided with a third section 37 ", at the end of which a flat tongue 53 is arranged for connecting an earth line.

- a single part can have a dual function, namely anti-rotation and 15, it is also possible, as shown in Fig. 15, that the sheet metal part 37 'is screwed on in addition to the anti-rotation sheet metal part 65 by means of the screw 32. Since the part 65 is secured against rotation in any case, a corrugation 41 on it is sufficient without it that it would be necessary on the cover plate.

- the depression 61 lies diametrically opposite the insulating part 55. It would of course also be possible to provide an offset at a different angle. Accordingly, the depression 61 would also have to be offset by a different angle with respect to the insulating piece 55.

- the end plate has the advantage that, despite sufficient rigidity, it is easy to manufacture due to the not very deep deformation and creates a well-insulated, closed interior.

- the cover could rest on the outer edge 21 as well as on the inner edge surrounding the sensor recess with one step following the cover plate. The fastening could also be done there using banjo bolts. In this case, the pin with the internal thread would not lie centrally but, for example, in the area of the outer edge.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Baking, Grill, Roasting (AREA)

- Resistance Heating (AREA)

- Electric Stoves And Ranges (AREA)

- Cookers (AREA)

- Table Devices Or Equipment (AREA)

Claims (17)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT80104743T ATE4267T1 (de) | 1979-08-17 | 1980-08-12 | Elektrokochplatte. |

| AT82108180T ATE23771T1 (de) | 1979-08-17 | 1980-08-12 | Elektrokochplatte. |

| AT82108179T ATE29099T1 (de) | 1979-08-17 | 1980-08-12 | Elektrokochplatte. |

| DE8282108179T DE3072014D1 (en) | 1979-08-17 | 1980-08-12 | Electric cooking plate |

| DE8282108180T DE3071840D1 (en) | 1979-08-17 | 1980-08-12 | Electric cooking plate |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19792933296 DE2933296A1 (de) | 1979-08-17 | 1979-08-17 | Elektrokochplatte |

| DE2933296 | 1979-08-17 |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82108179.1 Division-Into | 1980-08-12 | ||

| EP82108180.9 Division-Into | 1980-08-12 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0024621A1 EP0024621A1 (fr) | 1981-03-11 |

| EP0024621B1 true EP0024621B1 (fr) | 1983-07-20 |

Family

ID=6078643

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82108180A Expired EP0070043B1 (fr) | 1979-08-17 | 1980-08-12 | Plaque de cuisson électrique |

| EP82108179A Expired EP0070042B1 (fr) | 1979-08-17 | 1980-08-12 | Plaque de cuisson électrique |

| EP80104743A Expired EP0024621B1 (fr) | 1979-08-17 | 1980-08-12 | Plaque de cuisson électrique |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82108180A Expired EP0070043B1 (fr) | 1979-08-17 | 1980-08-12 | Plaque de cuisson électrique |

| EP82108179A Expired EP0070042B1 (fr) | 1979-08-17 | 1980-08-12 | Plaque de cuisson électrique |

Country Status (17)

| Country | Link |

|---|---|

| US (3) | US4348581A (fr) |

| EP (3) | EP0070043B1 (fr) |

| JP (1) | JPS5631717A (fr) |

| AU (1) | AU537864B2 (fr) |

| CA (1) | CA1163298A (fr) |

| DE (4) | DE2933296A1 (fr) |

| DK (2) | DK352880A (fr) |

| ES (1) | ES494268A0 (fr) |

| FI (1) | FI67464C (fr) |

| GR (1) | GR68424B (fr) |

| HK (1) | HK59184A (fr) |

| NO (1) | NO153669C (fr) |

| PL (1) | PL122796B1 (fr) |

| PT (1) | PT71703B (fr) |

| TR (1) | TR21050A (fr) |

| YU (1) | YU42531B (fr) |

| ZA (1) | ZA805011B (fr) |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3131463C2 (de) * | 1981-08-08 | 1986-02-06 | Fischer, Karl, 7519 Oberderdingen | Elektrische Kochplatte mit einem metallischen Kochplattenkörper |

| DE8301364U1 (fr) * | 1982-07-07 | 1987-06-25 | E.G.O. Elektro-Geraete Blanc U. Fischer, 7519 Oberderdingen, De | |

| DE3324783A1 (de) * | 1983-07-08 | 1985-01-17 | Bosch-Siemens Hausgeräte GmbH, 7000 Stuttgart | Kochmulde |

| DE3425896A1 (de) * | 1984-07-13 | 1986-01-23 | E.G.O. Elektro-Geräte Blanc u. Fischer, 7519 Oberderdingen | Elektrokochplatte |

| DE3527533A1 (de) * | 1985-08-01 | 1987-02-12 | Ego Elektro Blanc & Fischer | Elektrokochplatte |

| DE8528062U1 (de) * | 1985-10-02 | 1987-01-29 | E.G.O. Elektro-Geräte Blanc u. Fischer, 7519 Oberderdingen | Einbauvorrichtung für eine Elektrokochplatte |

| DE3540816A1 (de) * | 1985-11-16 | 1987-05-21 | Ego Elektro Blanc & Fischer | Elektrokochplatte sowie vorrichtung fuer deren anschluss |

| ZA866439B (en) * | 1986-08-26 | 1987-02-18 | E.G.O. Elektro-Geraete Blanc U. Fischer | Sealed electric hotplate |

| US4888470A (en) * | 1986-08-26 | 1989-12-19 | E.G.O. Elektro-Gerate Blanc U. Fischer | Sealed electric hotplate |

| EP0279367A3 (fr) * | 1987-02-18 | 1989-07-26 | E.G.O. Elektro-Geräte Blanc u. Fischer | Appareil pour la cuisson |

| DE3709438A1 (de) * | 1987-03-22 | 1988-10-06 | Ego Elektro Blanc & Fischer | Elektrokochplatte |

| US4767915A (en) * | 1987-03-30 | 1988-08-30 | Raytheon Company | Solid plate plug-in heating element |

| DE3728528A1 (de) * | 1987-08-27 | 1989-03-09 | Ego Elektro Blanc & Fischer | Elektrokochplatten-anschlussstueck |

| DE8712088U1 (de) * | 1987-09-05 | 1987-10-22 | E.G.O. Elektro-Geräte Blanc u. Fischer, 7519 Oberderdingen | Elektro-Kochplatte |

| JPH0192794U (fr) * | 1987-12-14 | 1989-06-19 | ||

| US4993553A (en) * | 1988-02-09 | 1991-02-19 | E.G.O. Elektro Gerate Blanc U. Fischer | Electric hotplate stacking aid |

| DE8805230U1 (de) * | 1988-04-20 | 1989-08-24 | E.G.O. Elektro-Geräte Blanc u. Fischer, 7519 Oberderdingen | Elektro-Kochplatte |

| US6314867B1 (en) | 2000-06-02 | 2001-11-13 | David K. Russell | Inductively coupled beverage warmer |

| US6984237B2 (en) | 2002-05-22 | 2006-01-10 | Orthopaedic Biosystems Ltd., Inc. | Suture passing surgical instrument |

| WO2006007399A1 (fr) | 2004-06-16 | 2006-01-19 | Smith & Nephew, Inc. | Passage de suture |

| US7326885B2 (en) * | 2006-05-02 | 2008-02-05 | Barnstead/Thermolyne Corporation | Hot plate with stainless steel top |

| KR101306725B1 (ko) * | 2007-03-08 | 2013-09-10 | 엘지전자 주식회사 | 히팅장치 |

| US7783176B2 (en) * | 2007-06-28 | 2010-08-24 | Strix Limited | Heaters for liquid heating vessels |

| US8556916B2 (en) | 2011-02-14 | 2013-10-15 | Smith & Nephew, Inc. | Method and device for suture manipulation |

| US10765420B2 (en) | 2014-04-24 | 2020-09-08 | Smith & Nephew, Inc. | Suture passer |

| US10406590B2 (en) * | 2014-07-07 | 2019-09-10 | Physical Systems, Inc. | Hollow metal screw and method of making |

| KR102549127B1 (ko) * | 2014-07-07 | 2023-06-29 | 피지컬 시스템즈, 인코포레이티드 | 중공 스크류의 제조 방법 |

| US9936943B1 (en) | 2014-08-07 | 2018-04-10 | Nicholas MANCINI | Suture passing surgical device with atraumatic grasper preventing accidental perforations |

| CN106322445B (zh) * | 2015-07-09 | 2019-12-20 | 博西华电器(江苏)有限公司 | 燃气灶及其组件 |

| EP3206459B1 (fr) * | 2016-02-10 | 2019-04-03 | E.G.O. ELEKTRO-GERÄTEBAU GmbH | Plaque de cuisson et plan de cuisson comprenant une plaque de cuisson |

| US10682133B2 (en) | 2016-10-31 | 2020-06-16 | Smith & Nephew, Inc. | Suture passer and grasper instrument and method |

| EP4290139A1 (fr) * | 2022-06-09 | 2023-12-13 | Electrolux Appliances Aktiebolag | Appareil de cuisson |

Family Cites Families (40)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE153865C (fr) * | ||||

| FR432000A (fr) * | 1911-07-06 | 1911-11-24 | Johannsson Et Cie Soc | Procédé de fabrication de crème pour chaussures |

| US1093754A (en) * | 1912-12-14 | 1914-04-21 | Gen Electric | Expansion member for electric heating devices. |

| US1174367A (en) * | 1913-06-12 | 1916-03-07 | Gen Electric | Ship's electric range. |

| CH68454A (de) * | 1914-06-17 | 1915-03-16 | Therma Ag | Elektrischer Heizkörper |

| US1174030A (en) * | 1915-08-02 | 1916-02-29 | William S Hadaway Jr | Electric stove. |

| US1659986A (en) * | 1925-04-02 | 1928-02-21 | Bankers Savings & Credit Syste | Electric stove |

| US1660556A (en) * | 1925-07-14 | 1928-02-28 | Mcclary Mfg Co | Detachable terminal connection for electric stove elements |

| US1639382A (en) * | 1926-06-08 | 1927-08-16 | Frederick W Moffat | Electric heating element |

| US1644255A (en) * | 1926-09-02 | 1927-10-04 | Arthur J Kercher | Electrical heating device |

| US1998308A (en) * | 1933-04-18 | 1935-04-16 | Gen Electric | Electric heater |

| DE631467C (de) * | 1933-12-14 | 1936-06-20 | Siemens Schuckertwerke Akt Ges | Elektrisch beheizte Kochplatte |

| GB451052A (en) * | 1935-03-04 | 1936-07-29 | Gen Electric Co Ltd | Improvements in and relating to electrically heated hotplates |

| FR844739A (fr) * | 1937-11-16 | 1939-07-31 | Plaque chauffante électrique | |

| US2301085A (en) * | 1938-04-29 | 1942-11-03 | John E Smith | Electric heating unit |

| US2260165A (en) * | 1940-06-06 | 1941-10-21 | Edwin L Wiegand | Heating means |

| US2422057A (en) * | 1945-12-15 | 1947-06-10 | Carl J Weinhardt | Electric heating unit |

| CH262513A (de) * | 1948-01-09 | 1949-07-15 | Alpha Ag Werkstaette Fuer Elek | Elektrische Kochplatte. |

| US2666979A (en) * | 1948-03-06 | 1954-01-26 | Dusen Engineering Company Van | Method for attaching members by vacuum pressure |

| US2691719A (en) * | 1951-10-05 | 1954-10-12 | Marco Ind Company | Indicator light with adjustable shutter |

| CH365848A (de) * | 1957-12-20 | 1962-11-30 | Fischer Karl | Kochplattenanordnung an einer Küchenkombination mit einer festmontierten Tischplatte |

| DK99599C (da) * | 1959-04-16 | 1964-08-24 | Karl Fischer | Anordning ved elektriske kogeplader for fastholdelse og centrering af pladen over et kogehul i en komfurplade. |

| US3093433A (en) * | 1960-12-27 | 1963-06-11 | Underwriters Safety Device Co | Wire terminals and lead connector devices |

| US3300621A (en) * | 1964-04-22 | 1967-01-24 | Fischer Karl | Electric hotplate and method of making same |

| US3324447A (en) * | 1965-05-28 | 1967-06-06 | Gen Electric | Electrical connector |

| US3348025A (en) * | 1965-06-24 | 1967-10-17 | Gen Motors Corp | Spider supported electric heater |

| SE323846B (fr) * | 1967-07-07 | 1970-05-11 | Bofors Ab | |

| DE2000745C3 (de) * | 1970-01-09 | 1979-01-04 | Bbc Brown Boveri & Cie | Steckdose für elektrische Installationen |

| US3593653A (en) * | 1970-05-01 | 1971-07-20 | Norris Industries | Electric cooktop with a removable spillover device |

| US3816704A (en) * | 1972-03-20 | 1974-06-11 | Gen Electric | Surface heating apparatus |

| US3838249A (en) * | 1972-04-21 | 1974-09-24 | Siemens Elektrogeraete Gmbh | Cooking tray |

| DE2334209A1 (de) * | 1973-07-05 | 1975-01-23 | Licentia Gmbh | Verkabelung elektrischer baugruppen in nachrichtengeraeten |

| US4084876A (en) * | 1975-10-15 | 1978-04-18 | Amp Incorporated | Electrical connector |

| US4052117A (en) * | 1975-10-20 | 1977-10-04 | A P Products Incorporated | Integrated circuit socket |

| DE2620004C3 (de) * | 1976-05-06 | 1979-05-31 | Fischer, Karl, 7519 Oberderdingen | Elektrokochplatte mit einem Temperaturbegrenzer |

| FR2358577A1 (fr) * | 1976-07-13 | 1978-02-10 | Esswein Sa | Dispositif de fixation de pieces avec l'aide d'une portee d'assemblage en matiere plastique ou en elastomere |

| DE2651848C3 (de) * | 1976-11-13 | 1981-07-16 | E.G.O. Elektro-Geräte Blanc u. Fischer, 7519 Oberderdingen | Anschlußstück für den elektrischen Anschluß von Elektrokochplatten |

| US4153833A (en) * | 1977-05-05 | 1979-05-08 | Karl Fischer | Electric hot plate assembly with a temperature limiter |

| JPS5453283A (en) * | 1977-09-30 | 1979-04-26 | Matsushita Electric Works Ltd | Screwless terminal device |

| DE7837478U1 (de) * | 1978-12-18 | 1979-03-22 | E.G.O. Elektro-Geraete Blanc U. Fischer, 7519 Oberderdingen | AnschluBteU für elektrische Leitungen |

-

1979

- 1979-08-17 DE DE19792933296 patent/DE2933296A1/de not_active Withdrawn

-

1980

- 1980-08-06 GR GR62615A patent/GR68424B/el unknown

- 1980-08-12 EP EP82108180A patent/EP0070043B1/fr not_active Expired

- 1980-08-12 DE DE8282108180T patent/DE3071840D1/de not_active Expired

- 1980-08-12 CA CA000358108A patent/CA1163298A/fr not_active Expired

- 1980-08-12 EP EP82108179A patent/EP0070042B1/fr not_active Expired

- 1980-08-12 DE DE8282108179T patent/DE3072014D1/de not_active Expired

- 1980-08-12 DE DE8080104743T patent/DE3064273D1/de not_active Expired

- 1980-08-12 EP EP80104743A patent/EP0024621B1/fr not_active Expired

- 1980-08-13 FI FI802550A patent/FI67464C/fi not_active IP Right Cessation

- 1980-08-14 US US06/177,873 patent/US4348581A/en not_active Expired - Lifetime

- 1980-08-14 YU YU2050/80A patent/YU42531B/xx unknown

- 1980-08-14 PT PT71703A patent/PT71703B/pt unknown

- 1980-08-14 AU AU61459/80A patent/AU537864B2/en not_active Ceased

- 1980-08-14 ES ES494268A patent/ES494268A0/es active Granted

- 1980-08-14 NO NO802436A patent/NO153669C/no unknown

- 1980-08-15 ZA ZA00805011A patent/ZA805011B/xx unknown

- 1980-08-15 DK DK352880A patent/DK352880A/da not_active Application Discontinuation

- 1980-08-15 JP JP11185980A patent/JPS5631717A/ja active Granted

- 1980-08-16 PL PL1980226286A patent/PL122796B1/pl unknown

- 1980-08-18 TR TR21050A patent/TR21050A/xx unknown

-

1982

- 1982-08-25 US US06/411,426 patent/US4414466A/en not_active Expired - Fee Related

- 1982-08-25 US US06/411,458 patent/US4467181A/en not_active Expired - Fee Related

-

1984

- 1984-08-02 HK HK591/84A patent/HK59184A/xx unknown

-

1987

- 1987-02-11 DK DK069487A patent/DK69487D0/da not_active Application Discontinuation

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0024621B1 (fr) | Plaque de cuisson électrique | |

| EP0056150B1 (fr) | Radiateur électrique | |

| DE69520563T2 (de) | Gefässe zum erhitzen von flüssigkeiten | |

| DE69700974T2 (de) | Elektrischer Kessel mit heizender metallischer Platte | |

| EP0285839A2 (fr) | Dispositif électrique de chauffage | |

| EP0047490A2 (fr) | Réchaud électrique | |

| EP0101002B1 (fr) | Dispositif de montage encastré pour une plaque de cuisson électrique avec un anneau de support entourant ladite plaque | |

| EP0113923B1 (fr) | Plaque de cuisson électrique | |

| DE2933349C2 (de) | Elektrokochplatte | |

| EP0386533A2 (fr) | Plaque de cuisson électrique | |

| DE3709438A1 (de) | Elektrokochplatte | |

| DE2821662A1 (de) | Einbau-kochfeld | |

| DE2933350A1 (de) | Elektrokochplatte | |

| DE60004485T2 (de) | Wasserkocher mit heizplatte aus metall | |

| EP0957661B1 (fr) | Utilisation d'une plaque de cuisson électrique dans une cuisinière électrique et cuisinière électrique | |

| DE4425238C2 (de) | Wärmeaustauscher, insbesondere Kühler | |

| DE2933295A1 (de) | Elektrokochplatte | |

| CH647118A5 (de) | Einbauanordnung fuer eine fuehlerdose in einem durchbruch einer elektrischen kochplatte. | |

| DE3324783A1 (de) | Kochmulde | |

| EP0258590B1 (fr) | Elément de passage destiné à passer des câbles de raccordement pour un réchaud électrique | |

| DE102008042993A1 (de) | Behälter mit einem Einsatz, und Montageverfahren | |

| DE2820139A1 (de) | Elektrischer heizkoerper | |

| EP0442284B1 (fr) | Plaque de cuisson électrique | |

| DE19846512A1 (de) | Einbau eines Gehäuses einer Schalteinrichtung | |

| DE1950156A1 (de) | Herdplatte bzw. Herdmulde |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19810218 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 4267 Country of ref document: AT Date of ref document: 19830815 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3064273 Country of ref document: DE Date of ref document: 19830825 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19850831 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19870301 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19910918 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19920817 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19920824 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19920825 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19920831 Ref country code: CH Effective date: 19920831 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19920907 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19930812 Ref country code: AT Effective date: 19930812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930813 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19931018 Year of fee payment: 14 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19930812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940429 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 80104743.2 Effective date: 19940310 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950503 |