CN107813037B - Zn系镀层钢板的弧焊接头 - Google Patents

Zn系镀层钢板的弧焊接头 Download PDFInfo

- Publication number

- CN107813037B CN107813037B CN201711244322.0A CN201711244322A CN107813037B CN 107813037 B CN107813037 B CN 107813037B CN 201711244322 A CN201711244322 A CN 201711244322A CN 107813037 B CN107813037 B CN 107813037B

- Authority

- CN

- China

- Prior art keywords

- welding

- end portion

- heat input

- speed

- welded

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000003466 welding Methods 0.000 title claims abstract description 363

- 229910000831 Steel Inorganic materials 0.000 title claims abstract description 59

- 239000010959 steel Substances 0.000 title claims abstract description 59

- 238000000034 method Methods 0.000 claims abstract description 52

- 230000007246 mechanism Effects 0.000 claims description 10

- 239000012535 impurity Substances 0.000 claims description 3

- 239000011248 coating agent Substances 0.000 claims description 2

- 238000000576 coating method Methods 0.000 claims description 2

- 239000011148 porous material Substances 0.000 abstract description 36

- 239000011701 zinc Substances 0.000 description 39

- 238000007747 plating Methods 0.000 description 25

- 239000011324 bead Substances 0.000 description 17

- 238000012360 testing method Methods 0.000 description 17

- 239000002184 metal Substances 0.000 description 15

- 229910052751 metal Inorganic materials 0.000 description 15

- 230000008569 process Effects 0.000 description 14

- 239000011800 void material Substances 0.000 description 12

- 239000010410 layer Substances 0.000 description 11

- 230000000694 effects Effects 0.000 description 7

- 230000007423 decrease Effects 0.000 description 6

- 230000000052 comparative effect Effects 0.000 description 5

- 230000007797 corrosion Effects 0.000 description 5

- 238000005260 corrosion Methods 0.000 description 5

- 238000007599 discharging Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 229910018134 Al-Mg Inorganic materials 0.000 description 4

- 229910018467 Al—Mg Inorganic materials 0.000 description 4

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 238000007711 solidification Methods 0.000 description 4

- 230000008023 solidification Effects 0.000 description 4

- 239000011247 coating layer Substances 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 238000003618 dip coating Methods 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 229910000838 Al alloy Inorganic materials 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000009835 boiling Methods 0.000 description 2

- 229910002092 carbon dioxide Inorganic materials 0.000 description 2

- 239000001569 carbon dioxide Substances 0.000 description 2

- 230000006866 deterioration Effects 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 229910052725 zinc Inorganic materials 0.000 description 2

- 229910018464 Al—Mg—Si Inorganic materials 0.000 description 1

- 208000025865 Ulcer Diseases 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- 229910001297 Zn alloy Inorganic materials 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000005536 corrosion prevention Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000003384 imaging method Methods 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000002436 steel type Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 230000036269 ulceration Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

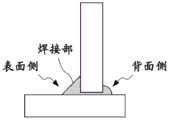

- B23K9/00—Arc welding or cutting

- B23K9/02—Seam welding; Backing means; Inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/02—Seam welding; Backing means; Inserts

- B23K9/032—Seam welding; Backing means; Inserts for three-dimensional seams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/095—Monitoring or automatic control of welding parameters

- B23K9/0953—Monitoring or automatic control of welding parameters using computing means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/095—Monitoring or automatic control of welding parameters

- B23K9/0956—Monitoring or automatic control of welding parameters using sensing means, e.g. optical

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/23—Arc welding or cutting taking account of the properties of the materials to be welded

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C18/00—Alloys based on zinc

- C22C18/04—Alloys based on zinc with aluminium as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C2/00—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor

- C23C2/04—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor characterised by the coating material

- C23C2/06—Zinc or cadmium or alloys based thereon

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C30/00—Coating with metallic material characterised only by the composition of the metallic material, i.e. not characterised by the coating process

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B5/00—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them

- F16B5/08—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them by means of welds or the like

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/18—Sheet panels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/34—Coated articles, e.g. plated or painted; Surface treated articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/02—Iron or ferrous alloys

- B23K2103/04—Steel or steel alloys

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/08—Non-ferrous metals or alloys

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Plasma & Fusion (AREA)

- Physics & Mathematics (AREA)

- Organic Chemistry (AREA)

- Metallurgy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Arc Welding In General (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

- Coating With Molten Metal (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014240402A JP6023156B2 (ja) | 2014-11-27 | 2014-11-27 | Zn系めっき鋼板のアーク溶接方法 |

| JP2014-240402 | 2014-11-27 | ||

| CN201580063975.1A CN107107244B (zh) | 2014-11-27 | 2015-07-31 | Zn系镀层钢板的弧焊方法 |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201580063975.1A Division CN107107244B (zh) | 2014-11-27 | 2015-07-31 | Zn系镀层钢板的弧焊方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107813037A CN107813037A (zh) | 2018-03-20 |

| CN107813037B true CN107813037B (zh) | 2020-03-17 |

Family

ID=56074006

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201711244322.0A Active CN107813037B (zh) | 2014-11-27 | 2015-07-31 | Zn系镀层钢板的弧焊接头 |

| CN201580063975.1A Active CN107107244B (zh) | 2014-11-27 | 2015-07-31 | Zn系镀层钢板的弧焊方法 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201580063975.1A Active CN107107244B (zh) | 2014-11-27 | 2015-07-31 | Zn系镀层钢板的弧焊方法 |

Country Status (16)

| Country | Link |

|---|---|

| US (2) | US10518351B2 (enExample) |

| EP (2) | EP3225346B1 (enExample) |

| JP (1) | JP6023156B2 (enExample) |

| KR (2) | KR101994255B1 (enExample) |

| CN (2) | CN107813037B (enExample) |

| AU (2) | AU2015351713B9 (enExample) |

| BR (2) | BR122018000277A2 (enExample) |

| CA (2) | CA2985236C (enExample) |

| MX (1) | MX363441B (enExample) |

| MY (1) | MY167712A (enExample) |

| NZ (1) | NZ732155A (enExample) |

| PH (2) | PH12017500945B1 (enExample) |

| RU (2) | RU2686400C2 (enExample) |

| SG (2) | SG10201709716PA (enExample) |

| TW (2) | TWI632018B (enExample) |

| WO (1) | WO2016084423A1 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6114785B2 (ja) * | 2015-05-29 | 2017-04-12 | 日新製鋼株式会社 | 溶接部外観と溶接強度に優れた溶融Zn系めっき鋼板のアーク溶接方法、および溶接部材の製造方法 |

| KR102020515B1 (ko) | 2016-12-23 | 2019-09-11 | 주식회사 포스코 | 용접부 내기공성 및 피로 특성이 우수한 도금강판 용접부재 및 이의 제조 방법 |

| EP3587018A4 (en) | 2017-02-22 | 2020-03-25 | Nippon Steel Nisshin Co., Ltd. | MIG BRAZING METHOD, MANUFACTURING METHOD OF COVERED JOINT ELEMENT, AND COVERED JOINT ELEMENT |

| CN110325660A (zh) | 2017-02-22 | 2019-10-11 | 日铁日新制钢株式会社 | 激光钎焊方法及搭接接头构件的制造方法 |

| KR102119964B1 (ko) | 2018-10-29 | 2020-06-05 | 주식회사 포스코 | 아연 도금강판의 겹치기 용접방법 |

| CN115151364B (zh) * | 2020-02-26 | 2023-12-29 | 日本制铁株式会社 | T型接头、建筑结构和t型接头的制造方法 |

| JP7598791B2 (ja) | 2021-03-15 | 2024-12-12 | 日産自動車株式会社 | 重ね溶接継手構造及びサスペンションメンバー |

| CN113846256A (zh) * | 2021-08-16 | 2021-12-28 | 株洲冶炼集团股份有限公司 | 一种高铝热镀锌多元合金 |

| CN113751840A (zh) * | 2021-09-02 | 2021-12-07 | 唐山钢铁集团有限责任公司 | 改善锌铝镁镀层板熔化极气体保护焊焊缝质量的方法 |

| JP2023166120A (ja) * | 2022-05-09 | 2023-11-21 | 日本製鉄株式会社 | アーク溶接継手、自動車部品、及びアーク溶接継手の製造方法 |

| CN115430954A (zh) * | 2022-08-09 | 2022-12-06 | 欣旺达电动汽车电池有限公司 | 焊接方法以及电池模组 |

| DE102024001661A1 (de) | 2024-05-23 | 2025-03-06 | Mercedes-Benz Group AG | Stahlbauteil und Verfahren zu dessen Herstellung |

| CN119772334B (zh) * | 2025-03-12 | 2025-07-08 | 德州润泓五金机电设备有限公司 | 一种钢结构焊接用电弧焊接机的控制方法 |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS55156668A (en) * | 1979-05-24 | 1980-12-05 | Mitsubishi Electric Corp | End face treating method in nonconsumable electrode system arc welding |

| SE8201383L (sv) * | 1981-03-09 | 1982-09-10 | Mitsubishi Electric Corp | Styranleggning for bagsvetsrobot |

| JPH0641025B2 (ja) | 1986-02-04 | 1994-06-01 | トヨタ自動車株式会社 | 重ね合わせア−ク溶接方法 |

| JPH0639554A (ja) * | 1991-06-26 | 1994-02-15 | Kyodo Sanso Kk | ガスシールドメタルアーク溶接方法 |

| JPH05212405A (ja) * | 1992-01-31 | 1993-08-24 | Sumitomo Metal Ind Ltd | 隅肉溶接性に優れためっき鋼板 |

| JP3120929B2 (ja) * | 1993-08-20 | 2000-12-25 | 株式会社神戸製鋼所 | 亜鉛めっき鋼板の溶接方法 |

| JP3491701B2 (ja) | 1994-03-08 | 2004-01-26 | 本田技研工業株式会社 | 構造部材 |

| WO1997032675A1 (fr) * | 1996-03-04 | 1997-09-12 | Nippon Steel Corporation | Procede de laminage a chaud en continu |

| JPH106005A (ja) * | 1996-06-24 | 1998-01-13 | Fanuc Ltd | アーク溶接方法 |

| JP3802642B2 (ja) * | 1997-03-17 | 2006-07-26 | 新日本製鐵株式会社 | 亜鉛めっき鋼板のアーク溶接方法 |

| DE10215442B4 (de) * | 2002-04-09 | 2004-02-19 | Thyssenkrupp Stahl Ag | Dreidimensionale Knotenstruktur |

| JP4776951B2 (ja) | 2005-03-11 | 2011-09-21 | 新日本製鐵株式会社 | 溶接性に優れた溶接用亜鉛系合金めっき鋼材 |

| JP4006009B2 (ja) * | 2005-03-28 | 2007-11-14 | 大陽日酸株式会社 | 亜鉛めっき鋼板のmag溶接用シールドガスおよびこのシールドガスを使用した溶接方法 |

| US9526292B2 (en) * | 2005-05-17 | 2016-12-27 | Michael Waters | Power modules and headgear |

| SG172348A1 (en) * | 2008-12-26 | 2011-07-28 | Nippon Steel Corp | Stainless steel flux-cored welding wire for the welding of galvanized steel sheets and process for arc welding of galvanized steel sheets with the same |

| WO2011025015A1 (ja) | 2009-08-31 | 2011-03-03 | 新日本製鐵株式会社 | スポット溶接継手およびスポット溶接方法 |

| NL2004011C2 (nl) * | 2009-12-23 | 2011-06-27 | Scafom Internat B V | Element van een modulair steigersysteem en werkwijze voor vervaardiging daarvan. |

| JP2011131243A (ja) * | 2009-12-24 | 2011-07-07 | Nippon Steel Corp | 亜鉛めっき鋼板のアーク溶接方法及びアーク溶接継手 |

| JP5450293B2 (ja) * | 2010-07-01 | 2014-03-26 | 株式会社神戸製鋼所 | すみ肉溶接継手およびガスシールドアーク溶接方法 |

| JP2012081514A (ja) | 2010-10-14 | 2012-04-26 | Nippon Steel Corp | 亜鉛めっき鋼板の隅肉アーク溶接方法 |

| CN102029464A (zh) * | 2010-12-30 | 2011-04-27 | 马国红 | 一种热镀锌薄板对接焊接方法 |

| JP5372217B2 (ja) | 2012-02-24 | 2013-12-18 | 日新製鋼株式会社 | アーク溶接構造部材の製造法 |

| EP2839918B1 (en) * | 2012-04-17 | 2020-11-18 | Nippon Steel Corporation | Fillet arc welded joint and method for forming same |

| WO2014054261A1 (ja) * | 2012-10-01 | 2014-04-10 | パナソニック株式会社 | アーク溶接制御方法 |

| JP6505359B2 (ja) * | 2012-11-16 | 2019-04-24 | 日鉄日新製鋼株式会社 | Zn系めっき鋼板製部材のアーク溶接方法 |

| JP5980128B2 (ja) * | 2013-01-04 | 2016-08-31 | 日新製鋼株式会社 | アーク溶接構造部材の製造法 |

| JP2014133259A (ja) | 2013-01-11 | 2014-07-24 | Nisshin Steel Co Ltd | アーク溶接構造部材の製造法 |

| JP2016106032A (ja) * | 2013-03-26 | 2016-06-16 | パナソニック株式会社 | アーク溶接制御方法およびアーク溶接装置 |

| US9221121B2 (en) * | 2013-03-27 | 2015-12-29 | General Electric Company | Welding process for welding three elements using two angled energy beams |

-

2014

- 2014-11-27 JP JP2014240402A patent/JP6023156B2/ja active Active

-

2015

- 2015-07-31 BR BR122018000277A patent/BR122018000277A2/pt not_active Application Discontinuation

- 2015-07-31 CA CA2985236A patent/CA2985236C/en active Active

- 2015-07-31 MX MX2017006848A patent/MX363441B/es unknown

- 2015-07-31 RU RU2017139378A patent/RU2686400C2/ru active

- 2015-07-31 CA CA2968932A patent/CA2968932C/en active Active

- 2015-07-31 WO PCT/JP2015/071744 patent/WO2016084423A1/ja not_active Ceased

- 2015-07-31 BR BR112017011011-3A patent/BR112017011011B1/pt active IP Right Grant

- 2015-07-31 MY MYPI2017000770A patent/MY167712A/en unknown

- 2015-07-31 KR KR1020177033618A patent/KR101994255B1/ko active Active

- 2015-07-31 KR KR1020177017501A patent/KR101849058B1/ko not_active Expired - Fee Related

- 2015-07-31 RU RU2017120205A patent/RU2654226C1/ru active

- 2015-07-31 NZ NZ732155A patent/NZ732155A/en unknown

- 2015-07-31 AU AU2015351713A patent/AU2015351713B9/en active Active

- 2015-07-31 SG SG10201709716PA patent/SG10201709716PA/en unknown

- 2015-07-31 US US15/529,233 patent/US10518351B2/en active Active

- 2015-07-31 CN CN201711244322.0A patent/CN107813037B/zh active Active

- 2015-07-31 EP EP15862715.8A patent/EP3225346B1/en active Active

- 2015-07-31 EP EP17210051.3A patent/EP3330030B1/en active Active

- 2015-07-31 SG SG11201704173VA patent/SG11201704173VA/en unknown

- 2015-07-31 CN CN201580063975.1A patent/CN107107244B/zh active Active

- 2015-09-07 TW TW106134713A patent/TWI632018B/zh active

- 2015-09-07 TW TW104129537A patent/TWI622447B/zh not_active IP Right Cessation

-

2017

- 2017-05-23 PH PH12017500945A patent/PH12017500945B1/en unknown

- 2017-09-18 US US15/707,035 patent/US20180071852A1/en not_active Abandoned

- 2017-11-10 AU AU2017258938A patent/AU2017258938B2/en active Active

- 2017-11-20 PH PH12017502108A patent/PH12017502108A1/en unknown

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107813037B (zh) | Zn系镀层钢板的弧焊接头 | |

| KR101764519B1 (ko) | 가스 실드 아크 용접용 솔리드 와이어, 가스 실드 아크 용접 금속, 용접 조인트, 용접 부재, 용접 방법 및 용접 조인트의 제조 방법 | |

| CN110087812B (zh) | 焊接部件及其制造方法 | |

| JP5980128B2 (ja) | アーク溶接構造部材の製造法 | |

| CN107405667A (zh) | 热冲压构件及其制造方法 | |

| EP4265361A1 (en) | Welded structural member having excellent crack resistance and manufacturing method thereof | |

| AU2016271967C1 (en) | Arc welding method for hot-dip galvanized steel plate having excellent appearance of welded part and high welding strength, method for manufacturing welding member, and welding member | |

| JPH05305477A (ja) | アーク溶接性に優れた亜鉛めっき鋼板用ワイヤー |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |