CN100430204C - 用于箔片后注塑的方法 - Google Patents

用于箔片后注塑的方法 Download PDFInfo

- Publication number

- CN100430204C CN100430204C CNB028147863A CN02814786A CN100430204C CN 100430204 C CN100430204 C CN 100430204C CN B028147863 A CNB028147863 A CN B028147863A CN 02814786 A CN02814786 A CN 02814786A CN 100430204 C CN100430204 C CN 100430204C

- Authority

- CN

- China

- Prior art keywords

- foil

- melt

- paillon foil

- wall

- die cavity

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

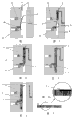

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C45/1418—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles the inserts being deformed or preformed, e.g. by the injection pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C45/14065—Positioning or centering articles in the mould

- B29C45/14073—Positioning or centering articles in the mould using means being retractable during injection

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C45/14065—Positioning or centering articles in the mould

- B29C45/14073—Positioning or centering articles in the mould using means being retractable during injection

- B29C2045/14081—Positioning or centering articles in the mould using means being retractable during injection centering means retracted by the injection pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C45/14065—Positioning or centering articles in the mould

- B29C2045/14155—Positioning or centering articles in the mould using vacuum or suction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C45/1418—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles the inserts being deformed or preformed, e.g. by the injection pressure

- B29C2045/14303—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles the inserts being deformed or preformed, e.g. by the injection pressure progressively transferring the insert from one mould wall to the other mould wall of the mould cavity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/14—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor incorporating preformed parts or layers, e.g. injection moulding around inserts or for coating articles

- B29C2045/1486—Details, accessories and auxiliary operations

- B29C2045/14901—Coating a sheet-like insert smaller than the dimensions of the adjacent mould wall

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Finishing Walls (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Laminated Bodies (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10135816A DE10135816A1 (de) | 2001-07-23 | 2001-07-23 | Verfahren zum Hinterspritzen von Folien |

| DE10135816.4 | 2001-07-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1535200A CN1535200A (zh) | 2004-10-06 |

| CN100430204C true CN100430204C (zh) | 2008-11-05 |

Family

ID=7692785

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB028147863A Expired - Fee Related CN100430204C (zh) | 2001-07-23 | 2002-07-10 | 用于箔片后注塑的方法 |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US7276197B2 (enExample) |

| EP (1) | EP1412155B9 (enExample) |

| JP (1) | JP4295090B2 (enExample) |

| KR (1) | KR100876269B1 (enExample) |

| CN (1) | CN100430204C (enExample) |

| AT (1) | ATE435107T1 (enExample) |

| BR (1) | BR0211339A (enExample) |

| CA (1) | CA2454411C (enExample) |

| DE (2) | DE10135816A1 (enExample) |

| MX (1) | MXPA04000624A (enExample) |

| TW (1) | TW587982B (enExample) |

| WO (1) | WO2003011555A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10312610A1 (de) * | 2003-03-21 | 2004-09-30 | Bayer Ag | Verfahren zum Hinterspritzen von dekorierten Folien |

| DE10314032A1 (de) * | 2003-03-28 | 2004-10-21 | Braun Formenbau Gmbh | Werkzeugsystem sowie Verfahren zum Mehrkomponentenspritzgießen, insbesondere Zweikomponentenspritzgießen, von Kunststoffkörpern |

| WO2005058574A2 (de) * | 2003-12-16 | 2005-06-30 | Weidmann Plastics Technology Ag | Verfahren zum herstellen von spritzgussteilen, spritzgussvorrichtung zur durchführung des verfahrens sowie nach dem verfahren hergestelltes spritzgussteil |

| JP2006130870A (ja) * | 2004-11-09 | 2006-05-25 | Hitachi Housetec Co Ltd | 成形品の製造方法 |

| FR2884751B1 (fr) * | 2005-04-22 | 2007-07-20 | Europlastiques Soc Par Actions | Procede de pose d'un opercule pelable sur un objet fabrique par moulage d'injection de matiere plastique |

| DE102009021413B4 (de) * | 2009-05-14 | 2011-03-31 | Peguform Gmbh | Vorrichtung und Verfahren zur Herstellung eines eine Dekoroberfläche aufweisenden Bauteils |

| DE102012201875B4 (de) * | 2012-02-08 | 2020-12-10 | Rotho Kunststoff Ag | Verfahren zum Herstellen eines spritzgegossenen Kunststoffartikels |

| WO2014149685A1 (en) * | 2013-03-15 | 2014-09-25 | Basf Se | Method of forming a frame of a seat back for a vehicle |

| DE102016226214A1 (de) * | 2016-12-23 | 2018-06-28 | Faurecia Innenraum Systeme Gmbh | Formwerkzeug und Verfahren zum Verformen und Hinterspritzen einer biegbaren Platte |

| KR20180131028A (ko) * | 2017-05-31 | 2018-12-10 | 현대자동차주식회사 | 기재와 표피재의 성형장치 및 성형방법 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1992016349A1 (fr) * | 1991-03-15 | 1992-10-01 | Ams Europe | Procede de decoration d'une piece realisee par injection et piece decoree ainsi realisee |

| EP0546234A1 (en) * | 1991-12-12 | 1993-06-16 | Ab Cerbo | An arrangement in moulding tools intended for the injection moulding of a container while simultaneously affixing a label or the like thereto |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK146709C (da) * | 1980-12-09 | 1984-05-21 | Eskesen Brdr As | Fremgangsmaade til fremstilling af sproejtestoebte plastemner med indstoebte folier med dekorative og/eller beskrivende tryk samt apparat til brug ved udoevelse af fremgangsmaaden |

| US5053179A (en) * | 1987-04-30 | 1991-10-01 | Sumitomo Chemical Company, Limited | Process for producing a multilayer molded article |

| JPH03243312A (ja) | 1990-02-21 | 1991-10-30 | Mitsubishi Plastics Ind Ltd | 金属複合材の成形方法 |

| NL1010605C2 (nl) | 1998-11-20 | 2000-05-23 | Schoeller Wavin Trepak B V | Door spuitgieten vervaardigde kunststof krat. |

| JP2001038766A (ja) | 1999-07-29 | 2001-02-13 | Toyota Autom Loom Works Ltd | 射出成形型のフィルム又はシート保持装置 |

-

2001

- 2001-07-23 DE DE10135816A patent/DE10135816A1/de not_active Withdrawn

-

2002

- 2002-07-10 EP EP02751126A patent/EP1412155B9/de not_active Expired - Lifetime

- 2002-07-10 MX MXPA04000624A patent/MXPA04000624A/es unknown

- 2002-07-10 KR KR1020047000992A patent/KR100876269B1/ko not_active Expired - Fee Related

- 2002-07-10 WO PCT/EP2002/007666 patent/WO2003011555A1/de not_active Ceased

- 2002-07-10 BR BR0211339-2A patent/BR0211339A/pt not_active Application Discontinuation

- 2002-07-10 CA CA2454411A patent/CA2454411C/en not_active Expired - Fee Related

- 2002-07-10 CN CNB028147863A patent/CN100430204C/zh not_active Expired - Fee Related

- 2002-07-10 US US10/484,289 patent/US7276197B2/en not_active Expired - Lifetime

- 2002-07-10 DE DE50213652T patent/DE50213652D1/de not_active Expired - Lifetime

- 2002-07-10 JP JP2003516773A patent/JP4295090B2/ja not_active Expired - Fee Related

- 2002-07-10 AT AT02751126T patent/ATE435107T1/de active

- 2002-07-22 TW TW091116208A patent/TW587982B/zh not_active IP Right Cessation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1992016349A1 (fr) * | 1991-03-15 | 1992-10-01 | Ams Europe | Procede de decoration d'une piece realisee par injection et piece decoree ainsi realisee |

| EP0546234A1 (en) * | 1991-12-12 | 1993-06-16 | Ab Cerbo | An arrangement in moulding tools intended for the injection moulding of a container while simultaneously affixing a label or the like thereto |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2454411C (en) | 2010-12-21 |

| JP2004535959A (ja) | 2004-12-02 |

| KR100876269B1 (ko) | 2008-12-26 |

| US7276197B2 (en) | 2007-10-02 |

| WO2003011555A1 (de) | 2003-02-13 |

| EP1412155A1 (de) | 2004-04-28 |

| CN1535200A (zh) | 2004-10-06 |

| DE50213652D1 (de) | 2009-08-13 |

| MXPA04000624A (es) | 2004-06-25 |

| CA2454411A1 (en) | 2003-02-13 |

| ATE435107T1 (de) | 2009-07-15 |

| KR20040017829A (ko) | 2004-02-27 |

| DE10135816A1 (de) | 2003-02-06 |

| US20040169315A1 (en) | 2004-09-02 |

| EP1412155B9 (de) | 2009-09-16 |

| EP1412155B1 (de) | 2009-07-01 |

| BR0211339A (pt) | 2004-09-28 |

| JP4295090B2 (ja) | 2009-07-15 |

| TW587982B (en) | 2004-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100430204C (zh) | 用于箔片后注塑的方法 | |

| JP2004526591A (ja) | 複数成分射出成形による複合部品の製造方法 | |

| KR100357910B1 (ko) | 삽입물 부착 통형상 물품, 그것의 성형 방법 및 성형 장치 | |

| US6464921B1 (en) | Method for manufacturing a tube shoulder | |

| CN101218084A (zh) | 注射压缩成型用模具 | |

| EP0933183A4 (en) | FILM FOR PUSHED FILM DECORATION AND METHOD FOR PRODUCING A MOLDED PLASTIC WITH PUSHED FILM DECORATION USING THE FILM | |

| CN102756458A (zh) | 成形同时装饰用模具和成形同时装饰品的制造方法 | |

| DE69423149D1 (de) | Verfahren zum begrenzten Einfügen eines Dekors in einem thermoplastischen Substrat | |

| JP3689513B2 (ja) | 射出成形同時絵付装置及び方法 | |

| JP3531269B2 (ja) | 芯材を有する樹脂成形品の製造方法および装置 | |

| EP0829337A2 (en) | An injection molded plastic article and a method of molding same | |

| JP3680437B2 (ja) | 表皮で被われた成形品の射出成形方法とその射出成形型装置 | |

| JPH03151230A (ja) | 接続部材を備えた容器の作製方法とその装置 | |

| JPH10156870A (ja) | 射出成形同時絵付装置及び方法 | |

| CN223545698U (zh) | 一种软水机uv灯固定支架模具 | |

| CN220661588U (zh) | 一种便于对模内片材定位的注塑模具 | |

| EP3781379B1 (en) | Method for making a plastic object and system for manufacturing said object | |

| JPH05309686A (ja) | 樹脂成形装置のプランジャ | |

| JPH1024443A (ja) | 車両用風防部材の製造方法及び車両用風防部材の製造装置 | |

| JP3821753B2 (ja) | フイルムを有する樹脂成形品の製造方法 | |

| JP2005103996A (ja) | 成形同時加飾成形品の製造方法およびそれに用いる転写シート | |

| JP2003320578A (ja) | 凹凸模様成形品の製造方法、および押し釦スイッチの製造方法 | |

| JPS63128921A (ja) | 成形装置 | |

| JP2002001758A (ja) | 帯状成形品の移送機構及び部品テープ | |

| JPH06166050A (ja) | 樹脂モールド装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C41 | Transfer of patent application or patent right or utility model | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20160614 Address after: Leverkusen, Germany Patentee after: BAYER MATERIALSCIENCE AG Address before: Germany Leverkusen Patentee before: Bayer Aktiengesellschaft |

|

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20081105 Termination date: 20170710 |