WO2022106950A1 - グラフェン、電極、二次電池、車両および電子機器 - Google Patents

グラフェン、電極、二次電池、車両および電子機器 Download PDFInfo

- Publication number

- WO2022106950A1 WO2022106950A1 PCT/IB2021/060243 IB2021060243W WO2022106950A1 WO 2022106950 A1 WO2022106950 A1 WO 2022106950A1 IB 2021060243 W IB2021060243 W IB 2021060243W WO 2022106950 A1 WO2022106950 A1 WO 2022106950A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- secondary battery

- active material

- graphene

- positive electrode

- lithium

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/58—Selection of substances as active materials, active masses, active liquids of inorganic compounds other than oxides or hydroxides, e.g. sulfides, selenides, tellurides, halogenides or LiCoFy; of polyanionic structures, e.g. phosphates, silicates or borates

- H01M4/583—Carbonaceous material, e.g. graphite-intercalation compounds or CFx

- H01M4/5835—Comprising fluorine or fluoride salts

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/15—Nano-sized carbon materials

- C01B32/182—Graphene

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/15—Nano-sized carbon materials

- C01B32/182—Graphene

- C01B32/194—After-treatment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

- H01M10/0525—Rocking-chair batteries, i.e. batteries with lithium insertion or intercalation in both electrodes; Lithium-ion batteries

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/13—Electrodes for accumulators with non-aqueous electrolyte, e.g. for lithium-accumulators; Processes of manufacture thereof

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/13—Electrodes for accumulators with non-aqueous electrolyte, e.g. for lithium-accumulators; Processes of manufacture thereof

- H01M4/133—Electrodes based on carbonaceous material, e.g. graphite-intercalation compounds or CFx

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/362—Composites

- H01M4/366—Composites as layered products

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/58—Selection of substances as active materials, active masses, active liquids of inorganic compounds other than oxides or hydroxides, e.g. sulfides, selenides, tellurides, halogenides or LiCoFy; of polyanionic structures, e.g. phosphates, silicates or borates

- H01M4/583—Carbonaceous material, e.g. graphite-intercalation compounds or CFx

- H01M4/587—Carbonaceous material, e.g. graphite-intercalation compounds or CFx for inserting or intercalating light metals

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/62—Selection of inactive substances as ingredients for active masses, e.g. binders, fillers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/62—Selection of inactive substances as ingredients for active masses, e.g. binders, fillers

- H01M4/624—Electric conductive fillers

- H01M4/625—Carbon or graphite

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B2204/00—Structure or properties of graphene

- C01B2204/20—Graphene characterized by its properties

- C01B2204/22—Electronic properties

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2002/00—Crystal-structural characteristics

- C01P2002/01—Crystal-structural characteristics depicted by a TEM-image

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2002/00—Crystal-structural characteristics

- C01P2002/80—Crystal-structural characteristics defined by measured data other than those specified in group C01P2002/70

- C01P2002/82—Crystal-structural characteristics defined by measured data other than those specified in group C01P2002/70 by IR- or Raman-data

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2002/00—Crystal-structural characteristics

- C01P2002/80—Crystal-structural characteristics defined by measured data other than those specified in group C01P2002/70

- C01P2002/85—Crystal-structural characteristics defined by measured data other than those specified in group C01P2002/70 by XPS, EDX or EDAX data

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2004/00—Particle morphology

- C01P2004/01—Particle morphology depicted by an image

- C01P2004/04—Particle morphology depicted by an image obtained by TEM, STEM, STM or AFM

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2006/00—Physical properties of inorganic compounds

- C01P2006/40—Electric properties

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2220/00—Batteries for particular applications

- H01M2220/20—Batteries in motive systems, e.g. vehicle, ship, plane

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Definitions

- the present invention relates to a secondary battery using a positive electrode active material and a method for producing the same.

- the present invention relates to a secondary battery using graphene and a method for producing the same.

- the present invention relates to electronic devices such as personal digital assistants having a secondary battery, vehicles, and the like.

- the uniform state of the present invention relates to a product, a method, or a manufacturing method.

- the invention relates to a process, machine, manufacture, or composition (composition of matter).

- One aspect of the present invention relates to a semiconductor device, a display device, a light emitting device, a power storage device, a lighting device, an electronic device, or a method for manufacturing the same.

- the electronic device refers to all the devices having a power storage device, and the electro-optical device having the power storage device, the information terminal device having the power storage device, and the like are all electronic devices.

- a power storage device refers to an element and a device having a power storage function in general.

- a power storage device also referred to as a secondary battery

- a lithium ion secondary battery such as a lithium ion secondary battery, a lithium ion capacitor, an electric double layer capacitor, and the like.

- lithium-ion secondary batteries with high output and high energy density are mobile information terminals such as mobile phones, smartphones, or notebook computers, portable music players, digital cameras, medical devices, hybrid vehicles (HVs), and electricity.

- HVs hybrid vehicles

- EVs electric vehicles

- PSVs plug-in hybrid vehicles

- Non-Patent Document 1 Japanese Patent Document 1

- Patent Document 1 In order to improve the cycle characteristics and increase the capacity of the lithium ion secondary battery, improvement of the negative electrode having a coating film is being studied (Patent Document 1).

- Non-Patent Document 2 describes the reaction of a compound having fluorine.

- Silicon-based materials have a high capacity and are used as active materials for secondary batteries.

- the silicon material can be characterized by the chemical shift value obtained from the NMR spectrum (Patent Document 2).

- One aspect of the present invention is to provide a novel graphene.

- one aspect of the present invention is to provide a novel graphene compound.

- one aspect of the present invention is to provide an electrode having a high output.

- one aspect of the present invention is to provide a novel electrode.

- one aspect of the present invention is to provide a novel method for producing graphene.

- one aspect of the present invention is to provide a novel method for producing a graphene compound.

- one aspect of the present invention is to provide a novel method for manufacturing an electrode.

- one aspect of the present invention is to provide a secondary battery with less deterioration.

- one aspect of the present invention is to provide a highly safe secondary battery.

- one aspect of the present invention is to provide a novel secondary battery.

- one aspect of the present invention is to provide a novel substance, active material particles, a secondary battery, a power storage device, or a method for producing them.

- One aspect of the present invention is graphene having a hole composed of a multi-membered ring having 9 or more membered rings composed of carbon atoms.

- one or more of the carbon atoms constituting the multi-membered ring are terminated by fluorine.

- one embodiment of the present invention comprises active material particles and graphene, in which graphene has pores composed of 9 or more membered rings composed of carbon atoms, and graphene is active.

- An electrode that covers at least a portion of the surface of a material particle.

- one or more of the carbon atoms constituting the multi-membered ring are terminated by fluorine.

- graphene has a first peak observed at or near 1580 cm -1 and a second peak observed at or near 1360 cm -1 in Raman spectroscopy analysis. Is preferable.

- the active material particles are preferably positive electrode active material particles.

- the active material particles are preferably negative electrode active material particles.

- one aspect of the present invention is a secondary battery having the electrode and the electrolyte according to any one of the above.

- one aspect of the present invention is an electronic device having the secondary battery described above.

- one aspect of the present invention is a vehicle having the secondary battery described above.

- a novel graphene can be provided. Further, according to one aspect of the present invention, a novel graphene compound can be provided. Further, according to one aspect of the present invention, it is possible to provide an electrode having a high output. Further, according to one aspect of the present invention, a novel electrode can be provided.

- a secondary battery with less deterioration. Further, according to one aspect of the present invention, it is possible to provide a highly safe secondary battery. Further, according to one aspect of the present invention, a novel secondary battery can be provided.

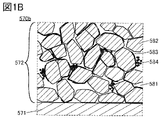

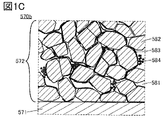

- FIG. 1A, 1B and 1C are views showing an example of a cross section of an electrode.

- 2A and 2B are views showing an example of a cross section of an electrode.

- FIG. 3 is a diagram illustrating the crystal structure of the positive electrode active material.

- FIG. 4 is a diagram illustrating the crystal structure of the positive electrode active material.

- FIG. 5 is a phase diagram.

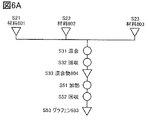

- 6A and 6B are views showing an example of a manufacturing method.

- FIG. 7 is a diagram showing an example of a method for manufacturing an electrode according to an aspect of the present invention.

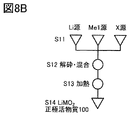

- 8A and 8B are diagrams illustrating an example of a method for producing a positive electrode active material according to one aspect of the present invention.

- FIG. 9 is a diagram illustrating an example of a method for producing a positive electrode active material according to one aspect of the present invention.

- FIG. 10 is a diagram illustrating an example of a method for producing a positive electrode active material according to one aspect of the present invention.

- FIG. 11 is a diagram illustrating an example of a method for producing a positive electrode active material according to one aspect of the present invention.

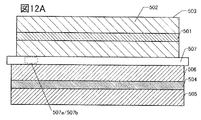

- 12A and 12B are examples of cross-sectional views of the secondary battery.

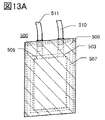

- 13A and 13B are views showing an example of the appearance of the secondary battery.

- 14A and 14B are diagrams illustrating a method for manufacturing a secondary battery.

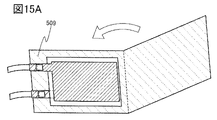

- 15A and 15B are diagrams illustrating a method for manufacturing a secondary battery.

- FIG. 16 is a diagram showing an example of the appearance of the secondary battery.

- FIG. 17 is a top view showing an example of a secondary battery manufacturing apparatus.

- FIG. 18 is a cross-sectional view showing an example of a method for manufacturing a secondary battery.

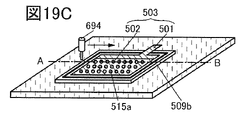

- 19A to 19C are perspective views showing an example of a method for manufacturing a secondary battery.

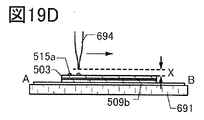

- FIG. 19D is a cross-sectional view corresponding to FIG. 19C.

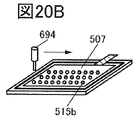

- 20A to 20F are perspective views showing an example of a method for manufacturing a secondary battery.

- FIG. 21 is a cross-sectional view showing an example of a secondary battery.

- FIG. 22A is a diagram showing an example of a secondary battery.

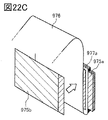

- 22B and 22C are views showing an example of a method for producing a laminated body.

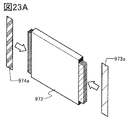

- 23A to 23C are diagrams showing an example of a method for manufacturing a secondary battery.

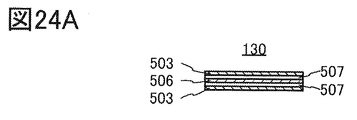

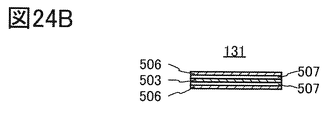

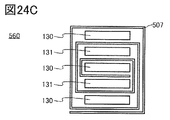

- FIG. 24A and 24B are cross-sectional views showing an example of the laminated body.

- FIG. 24C is a cross-sectional view showing an example of a secondary battery.

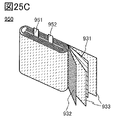

- 25A and 25B are diagrams showing an example of a secondary battery.

- FIG. 25C is a diagram showing the inside of the secondary battery.

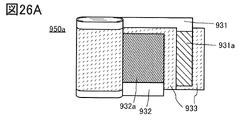

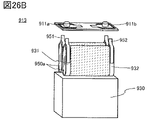

- 26A to 26C are views showing an example of a secondary battery.

- FIG. 27A is a perspective view showing an example of a battery pack.

- FIG. 27B is a block diagram showing an example of a battery pack.

- FIG. 27C is a block diagram showing an example of a vehicle having a motor.

- 28A to 28E are views showing an example of a transportation vehicle.

- 29A is a diagram showing an electric bicycle, FIG.

- FIG. 29B is a diagram showing a secondary battery of the electric bicycle

- FIG. 29C is a diagram illustrating an electric motorcycle.

- 30A and 30B are diagrams showing an example of a power storage device.

- 31A to 31E are diagrams showing an example of an electronic device.

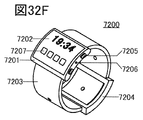

- 32A to 32H are diagrams illustrating an example of an electronic device.

- 33A to 33C are diagrams illustrating an example of an electronic device.

- FIG. 34 is a diagram illustrating an example of an electronic device.

- 35A to 35C are diagrams illustrating an example of an electronic device.

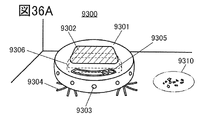

- 36A to 36C are views showing an example of an electronic device.

- FIG. 37 is an optical micrograph.

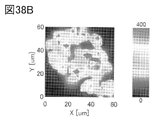

- 38A, 38B and 38C are the evaluation results of Raman spectroscopy.

- FIG. 39 is a Raman spectrum.

- FIG. 40 is a TEM image.

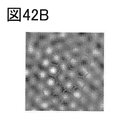

- 41A and 41B are FFT filtering images of TEM images.

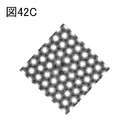

- 42A and 42B are FFT filtering images of TEM images.

- FIG. 42C is a TEM image obtained by calculation.

- FIG. 43A is an STEM image.

- FIG. 43B is an EDX analysis result.

- the crystal plane and the direction are indicated by the Miller index.

- the notation of the crystal plane and direction is to add a bar to the number, but in the present specification etc., due to the limitation of the application notation, instead of adding a bar to the number,-(minus) before the number. It may be expressed with a code).

- the individual orientation indicating the direction in the crystal is []

- the aggregate orientation indicating all equivalent directions is ⁇ >

- the individual plane indicating the crystal plane is ()

- the aggregate plane having equivalent symmetry is ⁇ . Express each with.

- segregation refers to a phenomenon in which a certain element (for example, B) is spatially unevenly distributed in a solid composed of a plurality of elements (for example, A, B, C).

- the surface layer portion of particles such as active substances is, for example, a region preferably within 50 nm, more preferably within 35 nm, still more preferably within 20 nm from the surface.

- the surface created by cracks and cracks can also be called the surface.

- the area deeper than the surface layer is called the inside.

- the charging depth when all the lithium that can be inserted and removed is inserted into the positive electrode active material is 0, and the charging depth when all the lithium that can be inserted and removed from the positive electrode active material is removed. Is set to 1.

- charging means moving lithium ions from the positive electrode to the negative electrode in the battery and moving electrons from the positive electrode to the negative electrode in an external circuit.

- the positive electrode active material the release of lithium ions is called charging.

- a positive electrode active material having a charging depth of 0.7 or more and 0.9 or less may be referred to as a positive electrode active material charged at a high voltage.

- discharging means moving lithium ions from the negative electrode to the positive electrode in the battery and moving electrons from the negative electrode to the positive electrode in an external circuit.

- inserting lithium ions is called electric discharge.

- a positive electrode active material having a charging depth of 0.06 or less, or a positive electrode active material in which 90% or more of the charging capacity is discharged from a state of being charged at a high voltage is defined as a sufficiently discharged positive electrode active material. ..

- a non-equilibrium phase change means a phenomenon that causes a non-linear change in a physical quantity.

- an unbalanced phase change occurs before and after the peak in the dQ / dV curve obtained by differentiating the capacitance (Q) with the voltage (V) (dQ / dV), and the crystal structure changes significantly. ..

- the secondary battery has, for example, a positive electrode and a negative electrode.

- a positive electrode active material As a material constituting the positive electrode, there is a positive electrode active material.

- the positive electrode active material is, for example, a substance that undergoes a reaction that contributes to the charge / discharge capacity.

- the positive electrode active material may contain a substance that does not contribute to the charge / discharge capacity as a part thereof.

- the positive electrode active material of one aspect of the present invention may be expressed as a positive electrode material, a positive electrode material for a secondary battery, or the like. Further, in the present specification and the like, it is preferable that the positive electrode active material of one aspect of the present invention has a compound. Further, in the present specification and the like, it is preferable that the positive electrode active material of one aspect of the present invention has a composition. Further, in the present specification and the like, it is preferable that the positive electrode active material of one aspect of the present invention has a complex.

- the discharge rate is the relative ratio of the current at the time of discharge to the battery capacity, and is expressed in the unit C.

- the current corresponding to 1C is X (A).

- X (A) When discharged with a current of 2X (A), it is said to be discharged at 2C, and when discharged with a current of X / 5 (A), it is said to be discharged at 0.2C.

- the charging rate is also the same.

- When charged with a current of 2X (A) it is said to be charged with 2C, and when charged with a current of X / 5 (A), it is charged with 0.2C. It is said that it was.

- Constant current charging refers to, for example, a method of charging with a constant charging rate.

- Constant voltage charging refers to, for example, a method of charging by keeping the voltage constant when the charging reaches the upper limit voltage.

- the constant current discharge refers to, for example, a method of discharging with a constant discharge rate.

- the graphene of one aspect of the present invention has a hole composed of a multi-membered ring composed of carbon.

- the multi-membered ring is preferably 9-membered or more.

- examples of a multi-membered ring having 9 or more members include a 12-membered ring, an 18-membered ring, and a 22-membered ring.

- the pores of graphene according to one aspect of the present invention cause a eutectic reaction between a material that becomes graphene as a first material, a compound having a halogen as a second material, and a second material as a third material. It is preferably provided by mixing the compound and heating.

- graphene oxide can be used as the material to be graphene.

- the graphene according to one aspect of the present invention preferably has a halogen. It is preferable that one or more of the carbons constituting the multi-membered ring are terminated by a halogen atom. Fluorine is particularly preferable as the halogen.

- the graphene according to one aspect of the present invention preferably has a functional group.

- the functional group of graphene in one aspect of the present invention include a hydroxy group, an epoxy group and a carboxy group.

- the functional group of the graphene of one aspect of the present invention may be bonded to the carbon constituting the multi-membered ring of the graphene of the present invention.

- the graphene of one aspect of the present invention has a sheet-like shape.

- Graphene has a two-dimensional structure formed by a 6-membered carbon ring. It can be rephrased that graphene is a sheet having a two-dimensional structure formed of a carbon 6-membered ring, and the graphene of one aspect of the present invention is composed of a carbon multi-membered ring as a part of the sheet. Has a hole to be made.

- the electrode of one aspect of the present invention has active material particles and graphene.

- Graphene preferably covers at least a portion of the surface of the active material particles.

- the electrode of one aspect of the present invention has active material particles and a plurality of graphenes. At least a part of the surface of the active material particles may be covered with a plurality of graphenes.

- the plurality of graphenes may have a region that overlaps with each other and a region that does not overlap with each other. By stacking a part of a plurality of graphenes on each other, a sheet having a larger area can be formed.

- the first graphene has a first region that overlaps the active material particles and the second graphene. The first region is located on the surface of the active material particles. The first region is sandwiched between the active material particles and the second graphene.

- the first graphene and a part of the second graphene can be overlapped with each other.

- the first graphene and the second graphene may have a bond in a region where they overlap each other.

- they may be attracted by intramolecular force.

- Graphene is provided so as to cling to the surface of the active material particles. Further, graphene preferably has a region in which it comes into surface contact with the active material particles. Further, graphene is preferably provided so as to adhere to the surface of the active material.

- the electrode of one aspect of the present invention has a plurality of active material particles and graphene.

- Graphene preferably covers at least a portion of each of the surfaces of the active material.

- Graphene is also preferably clinging across a plurality of active material particles.

- the electrode of one aspect of the present invention has a plurality of active material particles and a plurality of graphene.

- a plurality of graphenes By having a plurality of graphenes overlapping each other, it is possible to form a sheet having a larger area.

- the sheet preferably covers at least a portion of each of the surfaces of the plurality of active material particles. Further, it is preferable that the sheet clings to a plurality of active substances.

- graphene forms a bag-shaped region.

- the bag-shaped area may be composed of a plurality of graphenes.

- a plurality of graphenes can form a bag-like region by having regions that overlap each other.

- the plurality of active material particles are encapsulated in a bag-shaped region.

- a plurality of graphenes can form a three-dimensional conductive path. Further, in the electrode of one aspect of the present invention, a plurality of graphenes may form a three-dimensional network structure.

- the electrode of one aspect of the present invention has, for example, a current collector and an active material layer.

- the active material layer is provided on the current collector.

- the active material layer has an active material and graphene. Further, the active material layer may have a binder.

- a sheet-like shape, a net-like shape, a punching metal-like shape, an expanded metal-like shape, or the like can be appropriately used. It is preferable to use a current collector having a thickness of 10 ⁇ m or more and 30 ⁇ m or less.

- the current collector used for the negative electrode it is preferable to use a material that does not alloy with carrier ions such as lithium.

- a titanium compound may be provided by laminating on the metal element shown above.

- titanium compounds include titanium nitride, titanium oxide, titanium nitride in which a part of nitrogen is replaced with oxygen, titanium oxide in which a part of oxygen is replaced with nitrogen, and titanium oxide (TIO z N w , 0 ⁇ z. One selected from ⁇ 2, 0 ⁇ w ⁇ 1), or two or more thereof can be mixed or laminated and used.

- titanium nitride is particularly preferable because it has high conductivity and a high function of suppressing oxidation.

- the active material layer contains a compound having oxygen

- the oxidation reaction between the metal element and oxygen can be suppressed.

- the active material layer contains a compound having oxygen

- the oxidation reaction between the metal element and oxygen can be suppressed.

- the active material layer contains a compound having oxygen

- the oxidation reaction between the metal element and oxygen can be suppressed.

- the strength of the active material layer can be increased by distributing a plurality of graphenes in the electrode so as to spread three-dimensionally and cover the active material.

- the strength of the active material layer for example, the collapse of the active material layer can be suppressed.

- peeling of the active material layer from the current collector can be suppressed by contacting a part of each of the graphenes with the current collector.

- Graphene may function as a conductive agent that imparts a conductive path in the electrode, and may also function as a binder that enhances the strength of the active material layer and the electrode.

- a three-dimensional conductive path can be formed by binding a plurality of graphenes to each other.

- the three-dimensional conductive path formed by bonding a plurality of graphenes in this way is hereinafter referred to as a graphene net.

- the graphene net can also function as a binder for binding the active materials to each other. Therefore, since the amount of the binder can be reduced or not used, the ratio of the active material to the electrode volume and the electrode weight can be increased. That is, the charge / discharge capacity of the secondary battery can be increased.

- the active material layer can be prepared, for example, using graphene oxide and an active material.

- graphene oxide having extremely high dispersibility in a polar solvent in the preparation of the active material layer graphene oxide can be uniformly dispersed in a slurry containing graphene oxide and the active material. Therefore, in the produced active material layer, graphene can be dispersed substantially uniformly in the internal region of the active material layer.

- the graphene oxide may be reduced, for example, by heat treatment or by using a reducing agent.

- the slurry is, for example, a mixture of a raw material of an active material layer and a solvent.

- graphene which is a conductive agent

- graphene is formed as a film by covering at least a part of the surface of the active material in advance, and the active materials on which the graphene film is formed are further electrically connected by graphene. It is also possible to form a conductive path.

- graphene means, for example, graphene, multi-layer graphene, multi-graphene, graphene oxide, multi-layer graphene oxide, multi-graphene oxide, reduced graphene oxide, reduced multi-layer graphene oxide, reduced multi-graphene oxide, graphene. It may contain quantum dots and the like.

- Graphene has carbon, has a flat plate shape, a sheet shape, or the like, and has a two-dimensional structure formed by a carbon 6-membered ring. The two-dimensional structure formed by the carbon 6-membered ring may be called a carbon sheet.

- Graphene may have a functional group. Further, graphene preferably has a bent shape. Graphene may also be curled up to look like carbon nanofibers.

- graphene oxide means, for example, one having carbon and oxygen, having a sheet-like shape, and having a functional group, particularly an epoxy group, a carboxy group or a hydroxy group.

- the reduced graphene oxide in the present specification and the like means, for example, a graphene oxide having carbon and oxygen, having a sheet-like shape, and having a two-dimensional structure formed by a carbon 6-membered ring. It may be called a carbon sheet. Although one reduced graphene oxide functions, a plurality of reduced graphene oxides may be laminated.

- the reduced graphene oxide preferably has a portion having a carbon concentration of more than 80 atomic% and an oxygen concentration of 2 atomic% or more and 15 atomic% or less. By setting at least one or both of such carbon concentration and oxygen concentration, even a small amount can function as a highly conductive conductive agent.

- end portion of graphene may be terminated with a halogen atom, particularly fluorine.

- the G band refers to a peak at or near 1580 cm -1 in the Raman spectrum. Observations of the G band suggest a sp2 bond of carbon. Further, when graphene has a defect such as a hole, a peak called a D band may be observed. The D band refers to a peak at or near 1360 cm -1 in the Raman spectrum.

- the ratio (D / G) of the peak intensity of the D band to the G band is less than 1, it is suggested that the defect density of graphene is low, for example. Further, when graphene has a defect such as a hole, the D / G may be 1 or more, for example, 1 or more and 3 or less, or 1 or more and 2 or less.

- a hole composed of a multi-membered ring is observed by TEM observation. Further, in the graphene of one aspect of the present invention, it is particularly preferable that a hole composed of a 9-membered ring or more is observed by TEM observation.

- Graphene can be observed by, for example, an FFT filtering image of TEM.

- the FFT filtering image refers to an image obtained by performing an FFT (Fast Fourier Transform) process on a TEM image and then performing an IFFT (Inverse Fast Fourier Transform) process on the image.

- FFT Fast Fourier Transform

- IFFT Inverse Fast Fourier Transform

- the electrode of one aspect of the present invention can be suitably used for a lithium ion secondary battery.

- the graphene having a pore allows lithium ion, which is a carrier ion, to pass through the pore. Therefore, even when graphene covers the surface of the active material, it does not inhibit the insertion and desorption of lithium into the active material, and excellent secondary battery characteristics can be realized.

- graphene it is preferable that graphene has a pore composed of a 9-membered ring or more, because lithium ions easily pass through the pore.

- the carbon atom constituting the pore and the lithium ion are appropriately separated from each other, the energy is stable, and the barrier energy through which the lithium ion passes through the pore may be low. ..

- halogens especially fluorine, have a high electronegativity and tend to be negatively charged. Therefore, when the carbon atoms constituting the pores are terminated by halogen, the interaction occurs due to the approach of positively charged lithium ions, the energy is stabilized, and the barrier energy for the lithium ions to pass through the pores is increased. Can be lowered.

- Halogen especially fluorine, can form hydrogen bonds with hydrogen atoms.

- the graphene of one aspect of the present invention has a halogen and the active material has a region terminated by a hydrogen atom or a region terminated by a functional group having a hydrogen atom, a hydrogen bond can be formed and the graphene can be formed. Can be clinging to active substances.

- the electrode of one aspect of the present invention can be used for the positive electrode and the negative electrode of the secondary battery.

- the secondary battery of one aspect of the present invention has a positive electrode having graphene of one aspect of the present invention and a negative electrode having graphene of one aspect of the present invention.

- a positive electrode active material may be used as the active material.

- the negative electrode active material may be used as the active material.

- FIG. 1A is a schematic cross-sectional view showing an electrode according to an aspect of the present invention.

- the electrode 570 shown in FIG. 1A can be applied to the positive electrode and the negative electrode of the secondary battery.

- the electrode 570 includes at least the current collector 571 and the active material layer 572 formed in contact with the current collector 571.

- FIG. 1B, 1C, 2A and 2B are enlarged views of a square region 570b surrounded by a broken line in FIG. 1A.

- the active material layer 572 has an electrolyte 581, particles 582, and graphene 583.

- the active material layer 572 shown in FIG. 1B has particles 582 covered with graphene 583. Further, in FIG. 1B, graphene 583 may cover the surface of a plurality of particles 582.

- graphene 583 may also cover the surface of the plurality of particles 582. Further, graphene 583 is distributed in the electrode so as to form a three-dimensional conductive path.

- a plurality of particles 582 are aggregated. Of the plurality of agglomerated particles 582, some particles are covered with graphene 583. Further, graphene 583 is distributed in the electrode so as to form a three-dimensional conductive path.

- the plurality of graphene 583s form a three-dimensional network structure, and particles 582 are arranged between the plurality of graphene 583s.

- Particle 582 preferably functions as an active material.

- a material that functions as an active material can be used.

- the particles 582 preferably have, for example, a material that functions as an active material. In the present specification and the like, the particles 582 are referred to as active material particles.

- active material particles Various materials can be used as the particles 582. The materials that can be used as the particles 582 will be described later.

- the active material layer 572 has graphene 583.

- Graphene 583 can function as a conductive agent.

- the active material layer 572 has a carbon-based material such as carbon black, graphite, carbon fiber, fullerene, etc. in addition to graphene.

- a carbon-based material such as carbon black, graphite, carbon fiber, fullerene, etc.

- acetylene black (AB) or the like can be used as the carbon black.

- graphite for example, natural graphite, artificial graphite such as mesocarbon microbeads, or the like can be used.

- These carbon-based materials have high conductivity and can function as a conductive agent in the active material layer.

- these carbon-based materials may function as an active material.

- 1B and 1C show an example in which the active material layer 572 has acetylene black 584.

- the carbon fiber for example, a mesophase pitch carbon fiber, an isotropic pitch carbon fiber, or the like can be used. Further, as the carbon fiber, carbon nanofiber, carbon nanotube, or the like can be used. The carbon nanotubes can be produced, for example, by a vapor phase growth method.

- the active material layer may have one or more selected from metal powders such as copper, nickel, aluminum, silver, and gold, metal fibers, and conductive ceramic materials as the conductive agent.

- the content of the conductive auxiliary agent with respect to the total amount of the active material layer is preferably 1 wt% or more and 10 wt% or less, and more preferably 1 wt% or more and 5 wt% or less.

- graphene oxide is used with respect to the total amount of the active material, graphene oxide and binder in the slurry for forming the active material layer.

- the content of is preferably 1 wt% or more and 10 wt% or less, and more preferably 1 wt% or more and 5 wt% or less.

- the graphene of one aspect of the present invention allows lithium to easily pass through, the charge / discharge rate of the secondary battery can be increased.

- Particle-like carbon-containing compounds such as carbon black and graphite, and fibrous carbon-containing compounds such as carbon nanotubes easily enter minute spaces.

- the minute space refers to, for example, a region between a plurality of active materials.

- a carbon-containing compound that easily enters a minute space and a sheet-shaped carbon-containing compound such as graphene that can impart conductivity over multiple particles, the density of the electrodes can be increased and an excellent conductive path can be obtained. Can be formed.

- the secondary battery has the electrolyte of one aspect of the present invention, the operational stability of the secondary battery can be enhanced. That is, the secondary battery of one aspect of the present invention can have both high energy density and stability, and is effective as an in-vehicle secondary battery.

- the energy required to move it increases, and the cruising range also decreases.

- the cruising range can be extended with almost no change in the total weight of the vehicle equipped with the secondary battery of the same weight.

- the ratio in the electrodes can be reduced. Therefore, since the surface area of the conductive agent can be reduced in the electrode, decomposition of the electrolytic solution can be suppressed. Decomposition of electrolytes can occur significantly, especially at high temperatures. Therefore, the secondary battery using the electrode of one aspect of the present invention can suppress deterioration at a high temperature. Further, since graphene has high conductivity, the secondary battery can be operated with a high output even at a low temperature. Therefore, by using the electrode of one aspect of the present invention, it is possible to obtain an in-vehicle secondary battery having a wide operating temperature range. Further, by using an ionic liquid as the electrolyte, decomposition of the electrolytic liquid at a high temperature can be suppressed, and a secondary battery operating at a high temperature can be obtained.

- the secondary battery of one aspect of the present invention can be miniaturized due to its high energy density, and can be quickly charged because of its high conductivity. Therefore, the configuration of the secondary battery according to one aspect of the present invention is also effective in a portable information terminal.

- the active material layer 572 preferably has a binder (not shown).

- the binder binds or fixes the electrolyte and the active material, for example. Further, the binder can bind or fix an electrolyte and a carbon-based material, an active material and a carbon-based material, a plurality of active materials to each other, a plurality of carbon-based materials, and the like.

- binders polystyrene, methyl polyacrylate, methyl polymethacrylate (polymethylmethacrylate, PMMA), sodium polyacrylate, polyvinyl alcohol (PVA), polyethylene oxide (PEO), polypropylene oxide, polyimide, polyvinyl chloride, polytetra It is preferable to use materials such as fluoroethylene, polyethylene, polypropylene, polyisobutylene, polyethylene terephthalate, nylon, polyvinylidene fluoride (PVDF), polyacrylonitrile (PAN), ethylenepropylene diene polymer, polyvinyl acetate, and nitrocellulose.

- PVDF polyvinylidene fluoride

- PAN polyacrylonitrile

- Polyimide has excellent stable properties thermally, mechanically and chemically.

- a dehydration reaction and a cyclization (imidization) reaction are carried out. These reactions can be carried out, for example, by heat treatment.

- graphene having a functional group containing oxygen is used as graphene and polyimide is used as a binder in the electrode of one aspect of the present invention

- graphene can be reduced by the heat treatment, and the process can be simplified.

- heat treatment can be performed at a heating temperature of, for example, 200 ° C. or higher. By performing the heat treatment at a heating temperature of 200 ° C. or higher, the reduction reaction of graphene can be sufficiently performed, and the conductivity of the electrode can be further enhanced.

- Fluoropolymer which is a polymer material having fluorine, specifically polyvinylidene fluoride (PVDF) or the like can be used.

- PVDF is a resin having a melting point in the range of 134 ° C. or higher and 169 ° C. or lower, and is a material having excellent thermal stability.

- a rubber material such as styrene-butadiene rubber (SBR), styrene-isoprene-styrene rubber, acrylonitrile-butadiene rubber, butadiene rubber, or ethylene-propylene-diene copolymer as the binder.

- SBR styrene-butadiene rubber

- fluororubber can be used as the binder.

- a water-soluble polymer for example, a polysaccharide or the like can be used.

- a polysaccharide one or more selected from cellulose derivatives such as carboxymethyl cellulose (CMC), methyl cellulose, ethyl cellulose, hydroxypropyl cellulose, diacetyl cellulose, and regenerated cellulose, and starch and the like can be used. Further, it is more preferable to use these water-soluble polymers in combination with the above-mentioned rubber material.

- the binder may be used in combination of a plurality of the above.

- graphene 583 is flexible and has flexibility, and can cling to particles 582 like natto. Further, for example, the particles 582 can be compared to soybean, and the graphene 583 can be compared to a sticky component, for example, polyglutamic acid.

- a sticky component for example, polyglutamic acid.

- a plurality of graphenes 583 form a three-dimensional network structure, a structure in which polygons are arranged, for example, a honeycomb structure in which hexagons are arranged in a matrix, and an electrolyte, a plurality of active materials, and a plurality of carbon-based materials are formed in the mesh.

- graphene can form a three-dimensional conductive path and suppress the dropping of the electrolyte from the current collector.

- polygons having different numbers of sides may be mixed and arranged. Therefore, graphene 583 may function as a conductive agent and a binder in the active material layer 572.

- the particles 582 can have various shapes such as a rounded shape and a shape having corners. Further, in the cross section of the electrode, the particles 582 can have various cross-sectional shapes such as a circle, an ellipse, a figure having a curve, a polygon, and the like. For example, FIG. 2A shows an example in which the cross-sectional shape of the particle 582 has a rounded shape, but the cross-sectional shape of the particle 582 may have an angle. Further, a part may be rounded and a part may have corners.

- Negative negative active materials include materials that can react with carrier ions of secondary batteries, materials that can insert and remove carrier ions, materials that can alloy with metals that become carrier ions, and carrier ions. It is preferable to use a material capable of dissolving and precipitating the metal.

- Silicon can be used as the negative electrode active material.

- the electrode 570 it is preferable to use particles having silicon as the particles 582.

- a metal or compound having one or more elements selected from tin, gallium, aluminum, germanium, lead, antimony, bismuth, silver, zinc, cadmium, and indium can be used as the negative electrode active material.

- alloy-based compounds using such elements include Mg 2 Si, Mg 2 Ge, Mg 2 Sn, SnS 2 , V2 Sn 3 , FeSn 2 , CoSn 2 , Ni 3 Sn 2 , and Cu 6 Sn 5 .

- a material having a low resistance may be used by adding phosphorus, arsenic, boron, aluminum, gallium or the like as impurity elements to silicon.

- a silicon material predoped with lithium may be used.

- a predoping method there are methods such as mixing and annealing lithium fluoride or lithium carbonate and silicon, and a mechanical alloy of lithium metal and silicon.

- lithium is doped by a charge / discharge reaction in combination with an electrode such as lithium metal, and then an electrode that becomes a counter electrode using the doped electrode (for example, a positive electrode with respect to a pre-doped negative electrode). May be combined to produce a secondary battery.

- silicon nanoparticles can be used as the particles 582.

- the average diameter of the silicon nanoparticles is, for example, preferably 5 nm or more and less than 1 ⁇ m, more preferably 10 nm or more and 300 nm or less, and further preferably 10 nm or more and 100 nm or less.

- Silicon nanoparticles may have crystallinity. Further, the silicon nanoparticles may have a crystalline region and an amorphous region.

- the material having silicon for example, a material represented by SiO z (z is preferably smaller than 2, more preferably 0.5 or more and 1.6 or less) can be used.

- a form having a plurality of crystal grains in one particle can be used.

- a form having one or a plurality of silicon crystal grains in one particle can be used.

- the one particle may have silicon oxide around the crystal grain of silicon.

- the silicon oxide may be amorphous. It may be a particle in which graphene is clinging to a secondary particle of silicon.

- Li 2 SiO 3 and Li 4 SiO 4 can be used as the compound having silicon.

- Li 2 SiO 3 and Li 4 SiO 4 may be crystalline or amorphous, respectively.

- the analysis of the compound having silicon can be performed using NMR, XRD, Raman spectroscopy, SEM, TEM, EDX and the like.

- the negative electrode active material for example, carbon-based materials such as graphite, graphitizable carbon, non-graphitizable carbon, carbon nanotubes, carbon black and graphene can be used.

- the negative electrode active material for example, an oxide having one or more elements selected from titanium, niobium, tungsten and molybdenum can be used.

- the negative electrode active material a plurality of metals, materials, compounds, etc. shown above can be used in combination.

- Examples of the negative electrode active material include SnO, SnO 2 , titanium dioxide (TIO 2 ), lithium titanium oxide (Li 4 Ti 5 O 12 ), lithium-graphite interlayer compound ( Liz C 6 ), and niobium pentoxide (Nb 2 O). 5 ) Oxides such as tungsten oxide (WO 2 ) and molybdenum oxide (MoO 2 ) can be used.

- Li 3 -z Mz N (M Co, Ni, Cu, z of 0 or more and less than 3) having a Li 3N type structure, which is a compound nitride of lithium and a transition metal, is used.

- Li 3N type structure which is a compound nitride of lithium and a transition metal.

- Li 2.6 Co 0.4 N 3 shows a large charge / discharge capacity (900 mAh / g) and is preferable.

- a double nitride of lithium and a transition metal as a negative electrode material because it can be combined with a material such as V2 O 5 and Cr 3 O 8 which does not contain lithium ions as a positive electrode material. Even when a material containing lithium ions is used as the positive electrode material, a double nitride of lithium and a transition metal can be used as the negative electrode material by desorbing the lithium ions contained in the positive electrode material in advance.

- a material that causes a conversion reaction can also be used as a negative electrode active material.

- a transition metal oxide that does not undergo an alloying reaction with lithium such as cobalt oxide (CoO), nickel oxide (NiO), and iron oxide (FeO)

- CoO cobalt oxide

- NiO nickel oxide

- FeO iron oxide

- Materials that cause a conversion reaction include oxides such as Fe 2 O 3 , CuO, Cu 2 O, RuO 2 , Cr 2 O 3 , sulfides such as CoS 0.89 , NiS, and CuS, and Zn 3 N 2 .

- Cu nitrides such as Cu 3 N, Ge 3 N 4 and the like

- phosphodies such as NiP 2 , FeP 2 and CoP 3

- fluorides such as FeF 3 and BiF 3 . Since the potential of the fluoride is high, it may be used as a positive electrode material.

- the particles 582 may change in volume due to charge / discharge, but by arranging an electrolyte having fluorine between a plurality of particles 582 in the electrode, the particles are slippery even if the volume changes during charge / discharge. Since the formation of cracks is suppressed, there is an effect that the cycle characteristics are dramatically improved. It is important that an organic compound having fluorine is present between the plurality of active substances constituting the electrode.

- the electrode 570 is a positive electrode

- particles having a positive electrode active material can be used as the particles 582.

- the positive electrode active material include an olivine-type crystal structure, a layered rock salt-type crystal structure, and a composite oxide having a spinel-type crystal structure. Examples thereof include compounds such as LiFePO 4 , LiFeO 2 , LiNiO 2 , LiMn 2 O 4 , V 2 O 5 , Cr 2 O 5 , and MnO 2 .

- lithium nickelate LiNiO 2 or LiNi 1 -z Mj z O 2 ( 0 ⁇ z ⁇ 1)

- Mj Co, Al, etc.

- a lithium manganese composite oxide that can be represented by the composition formula Li a Mn b Mk c Od can be used.

- the element Mk a metal element selected from other than lithium and manganese, silicon, and phosphorus are preferably used, and nickel is more preferable.

- the lithium-manganese composite oxide refers to an oxide containing at least lithium and manganese, and includes chromium, cobalt, aluminum, nickel, iron, magnesium, molybdenum, zinc, indium, gallium, copper, titanium, niobium, and silicon. And may contain at least one element selected from the group consisting of phosphorus and the like.

- the positive electrode active material particles having a plurality of the positive electrode active materials listed above may be used.

- one of the positive electrode active materials and the other one mentioned above may be used as particles having a structure in which at least a part of one of the positive electrode active materials is covered by the other.

- Such particles having a structure in which at least a part of one is covered by the other may be referred to as a positive electrode active material complex.

- the compounding treatment includes, for example, a compounding process using mechanical energy such as a mechanochemical method, a mechanofusion method, and a ball mill method, and a compounding process by a liquid phase reaction such as a co-precipitation method, a hydrothermal method, and a sol-gel method.

- the treatment and the composite treatment can be performed by a gas phase reaction such as a barrel sputtering method, an ALD (Atomic Layer Deposition) method, a vapor deposition method, and a CVD (Chemical Vapor Deposition) method. can. Further, it is preferable to perform a heat treatment after the compounding treatment.

- the compounding treatment may be referred to as a surface coating treatment or a coating treatment.

- the positive electrode active material particles may form secondary particles.

- the particles 582 may be replaced with secondary particles formed by the positive electrode active material particles.

- a material having a layered rock salt type crystal structure such as lithium cobalt oxide (LiCoO 2 ) has a high discharge capacity and is excellent as a positive electrode active material for a secondary battery.

- the material having a layered rock salt type crystal structure include a composite oxide represented by LiMO 2 .

- the element M is, for example, one or more elements including a transition metal.

- the element M is, for example, one or more metals containing cobalt.

- the element M can contain, for example, one or more elements selected from magnesium, calcium, zirconium, lanthanum, barium, copper, potassium, sodium, and zinc in addition to one or more metals including cobalt.

- the positive electrode active material has lithium, an element M, and an additive element X.

- the additive element X for example, magnesium, calcium, zirconium, lanthanum, barium, copper, potassium, sodium, zinc, titanium, ittrium, nickel, aluminum, cobalt, manganese, vanadium, iron, chromium, niobium, hafnium, silicon, sulfur, Examples include phosphorus, boron, arsenic, chlorine, and fluorine.

- Examples of the lithium composite oxide represented by LiMO 2 include lithium cobalt oxide, nickel-cobalt-lithium manganate, nickel-cobalt-lithium aluminum oxide, and nickel-cobalt-manganese-lithium aluminum oxide.

- cobalt When cobalt is used as the element M in an amount of 75 atomic% or more, preferably 90 atomic% or more, more preferably 95 atomic% or more, there are many advantages such as relatively easy synthesis, easy handling, and excellent cycle characteristics.

- the raw material when nickel is used as the element M in an amount of 33 atomic% or more, preferably 60 atomic% or more, more preferably 80 atomic% or more, the raw material may be cheaper than the case where the amount of cobalt is large, and the weight per weight is increased. It is preferable because the charge / discharge capacity may increase.

- the particle size may become smaller. Therefore, for example, the above-mentioned third particle preferably contains nickel as the element M in an amount of 33 atomic% or more, preferably 60 atomic% or more, and more preferably 80 atomic% or more.

- the element M has a part of nickel together with cobalt, the displacement of the layered structure composed of the octahedron of cobalt and oxygen may be suppressed. Therefore, the crystal structure may become more stable especially in a charged state at a high temperature, which is preferable.

- nickel easily diffuses into the inside of lithium cobalt oxide, and it is considered that nickel may be present at the cobalt site during discharge but may be cation-mixed and located at the lithium site during charging.

- Nickel present in lithium sites during charging functions as a pillar supporting the layered structure consisting of cobalt and oxygen octahedrons, and is thought to contribute to the stabilization of the crystal structure.

- the element M does not necessarily have to contain manganese. Also, it does not necessarily have to contain nickel. Further, it does not necessarily have to contain cobalt.

- the particles of one aspect of the invention have lithium, element M, and oxygen. Further, the particles of one aspect of the present invention include a lithium composite oxide represented by LiMO 2 . Further, the particles of one aspect of the present invention have one or more selected from magnesium, fluorine, aluminum and nickel on the surface layer portion. By having one or more of these elements in the surface layer portion of the particles of one aspect of the present invention, it is possible to reduce the structural change due to charging and discharging in the surface layer portion of the particles and suppress the formation of cracks. In addition, irreversible structural changes in the surface layer portion of the particles can be suppressed, and capacity reduction due to repeated charging and discharging can be suppressed.

- the concentration of these elements in the surface layer portion is preferably higher than the concentration of these elements in the entire particle.

- the particles of one aspect of the present invention may have a structure in which a part of atoms is substituted with one or more selected from magnesium, fluorine, aluminum and nickel in the surface layer portion, for example, in the lithium composite oxide. ..

- the positive electrode active material will be described with reference to FIGS. 3 and 4.

- cations and anions alternate with the layered rock salt type crystal structure belonging to the space group R-3m, which is possessed by the composite oxide containing lithium and transition metals such as cobalt. It has a rock salt-type ion arrangement arranged in, and since transition metals and lithium are regularly arranged to form a two-dimensional plane, it refers to a crystal structure capable of two-dimensional diffusion of lithium. There may be defects such as cation or anion defects. Strictly speaking, the layered rock salt crystal structure may have a distorted lattice of rock salt crystals.

- the rock salt type crystal structure means a structure having a cubic crystal structure including a space group Fm-3m in which cations and anions are alternately arranged. There may be a cation or anion deficiency.

- TEM Transmission Electron Microscope, transmission electron microscope

- STEM Scanning Transmission Electron Microscope, scanning transmission electron microscope

- HAADF-STEM High Electron Microscope

- the contrast derived from the crystal plane can be obtained.

- the contrast from the (0003) plane is a bright band (bright strip) and a dark band (dark strip). ) Is repeated. Therefore, in the TEM image, when the angles between the bright lines are 0 degrees or more and 5 degrees or less, or 0 degrees or more and 2.5 degrees or less, the crystal planes are substantially the same, that is, the crystal orientations are substantially the same. Can be judged. Similarly, when the angle between the dark lines is 5 degrees or less, or 2.5 degrees or less, it can be determined that the orientation of the crystals is rough.

- the positive electrode active material produced according to one aspect of the present invention can reduce the displacement of the CoO 2 layer in repeated charging and discharging of a high voltage. Furthermore, the change in volume can be reduced. Therefore, the compound can realize excellent cycle characteristics. In addition, the compound can have a stable crystal structure in a high voltage state of charge. Therefore, the compound may not easily cause a short circuit when it is maintained in a high voltage charge state. In such a case, safety is further improved, which is preferable.

- the difference in crystal structure and the difference in volume per the same number of transition metal atoms between a fully discharged state and a state charged at a high voltage are small.

- FIG. 3 shows an example of the crystal structure before and after charging and discharging the positive electrode active material.

- the positive electrode active material shown in FIG. 3 preferably has a layered rock salt type crystal structure attributable to the space R-3m in the discharged state.

- the surface layer portion of the positive electrode active material has titanium, magnesium and oxygen in addition to or in place of the region represented by the layered rock salt type structure, and has crystals represented by a structure different from the layered rock salt type structure. You may. For example, it may have titanium, magnesium and oxygen, and may have crystals represented by a spinel structure.

- the theoretical capacity of the positive electrode active material means the amount of electricity when all the lithium that can be inserted and removed from the positive electrode active material is desorbed.

- the theoretical capacity of LiCoO 2 is 274 mAh / g

- the theoretical capacity of LiNiO 2 is 274 mAh / g

- the theoretical capacity of LiMn 2 O 4 is 148 mAh / g.

- the amount of lithium that can be inserted and removed in the positive electrode active material is indicated by x in the composition formula, for example, x in Li x CoO 2 or x in Li x MO 2 .

- Li x CoO 2 in the present specification can be appropriately read as Li x MO 2 .

- x (theoretical capacity-charging capacity) / theoretical capacity can be set.

- x in Li x CoO 2 is small means, for example, 0.1 ⁇ x ⁇ 0.24.

- the term "discharge completed" as used herein means a state in which the voltage is 2.5 V (counterpolar lithium) or less at a current of 100 mA / g, for example.

- the discharge voltage drops sharply by the time the discharge voltage reaches 2.5 V, so it is assumed that the discharge is completed under the above conditions.

- the charge capacity and / or the discharge capacity used for calculating x in Li x CoO 2 is preferably measured under conditions where there is no influence of short circuit and / or decomposition of the electrolyte. For example, data from a secondary battery with a sudden change in capacity, which appears to be a short circuit, should not be used to calculate x.

- the crystal structure of FIG. 3 at a charging depth of 0 (state in which discharging is completed) is R-3m (O3), which is the same as that of FIG.

- the positive electrode active material shown in FIG. 3 is an H1-3 type crystal when the charge depth is sufficiently charged, for example, when x is 0.24 or less, for example, about 0.2 or about 0.12 in the above. It has a crystal with a structure different from that of the structure.

- This structure is a space group R-3m, and the symmetry of the CoO2 layer is the same as that of the O3 type. Therefore, this structure is referred to as an O3'type crystal structure in the present specification and the like.

- the O3'type crystal structure is a space group R-3m, and ions such as cobalt and magnesium occupy the oxygen 6 coordination position.

- Light elements such as lithium may occupy the oxygen 4-coordination position.

- the O3'type crystal structure has Li at random between layers, but is similar to the CdCl 2 type crystal structure.

- This crystal structure similar to CdCl type 2 is similar to the crystal structure when lithium nickel oxide is charged to a charging depth of 0.94 (Li 0.06 NiO 2 ), but contains a large amount of pure lithium cobalt oxide or cobalt. It is known that layered rock salt type positive electrode active materials do not usually have this crystal structure.

- Layered rock salt crystals and anions of rock salt crystals have a cubic close-packed structure (face-centered cubic lattice structure). It is presumed that the O3'type crystal also has a cubic close-packed structure for anions. Therefore, when the layered rock salt type crystal and the rock salt type crystal come into contact with each other, there is a crystal plane in which the directions of the cubic close-packed structure composed of anions are aligned.

- the space group of layered rock salt type crystals and O3'type crystals is R-3m, which is different from the space group Fm-3m of rock salt type crystals (space group of general rock salt type crystals).

- the mirror index of the crystal plane satisfying the condition is different between the layered rock salt type crystal and the O3'type crystal and the rock salt type crystal.

- the orientations of the crystals are substantially the same when the orientations of the cubic close-packed structures composed of anions are aligned. be.

- the change in the crystal structure when charged at a high voltage and a large amount of lithium is desorbed is further suppressed as compared with the positive electrode active material shown in FIG.

- the dotted line in FIG. 3 there is almost no deviation of the CoO2 layer in these crystal structures.

- the positive electrode active material shown in FIG. 3 has high structural stability even when the charging voltage is high.

- the positive electrode active material shown in FIG. 3 is a crystal of R-3m (O3). Can retain structure.

- the positive electrode active material shown in FIG. 3 has a region capable of forming an O3'type crystal structure.

- the positive electrode active material in FIG. 3 may have an O3'type crystal structure. be.

- the voltage of the secondary battery is lower than the voltage based on the potential of the lithium metal described above by the potential of the graphite.

- the potential of graphite is about 0.05V to 0.2V with respect to the potential of lithium metal. Therefore, for example, even when the voltage of the secondary battery using graphite as the negative electrode active material is 4.3 V or more and 4.5 V or less, the positive electrode active material shown in FIG.

- the positive electrode active material shown in FIG. 3 may have an O3'type crystal structure.

- the crystal structure does not easily collapse even if charging and discharging are repeated at a high voltage.

- x 1 lithium cobalt oxide in Li x CoO 2 .

- the CoO 2 layer is a structure in which an octahedral structure in which oxygen is coordinated to cobalt is continuous with a plane in a shared ridge state. This may be referred to as a layer consisting of an octahedron of cobalt and oxygen.

- one CoO layer is present in the unit cell. Therefore, it may be called O1 type or monoclinic O1 type.

- the lithium cobalt oxide shown in FIG. 4 has a crystal structure of the space group R-3m.

- the coordinates of cobalt and oxygen in the unit cell are set to Co (0, 0, 0.42150 ⁇ 0.00016), O1 (0, It can be expressed as 0, 0.27671 ⁇ 0.00045) and O2 (0, 0, 0.11535 ⁇ 0.00045).

- O1 and O2 are oxygen atoms, respectively.

- Which unit cell should be used to represent the crystal structure of the positive electrode active material can be determined, for example, by Rietveld analysis of the XRD pattern. In this case, a unit cell having a small GOF (goodness of fit) value may be adopted.

- the change in the crystal structure between the discharged state where x is 1 and the state where x is 0.24 or less in Li x CoO 2 is further smaller than that in FIG. More specifically, the deviation between the two CoO layers in the state where x is 1 and the state where x is 0.24 or less can be reduced. In addition, it is possible to reduce the change in volume when compared per cobalt atom.

- the difference in volume per cobalt atom of the same number of R-3m (O3) in the discharged state and the O3'type crystal structure is 2.5% or less, and more specifically, 2. It is 2% or less, typically 1.8%.

- the coordinates of cobalt and oxygen in the unit cell are within the range of Co (0,0,0.5), O (0,0,x), 0.20 ⁇ x ⁇ 0.25. Can be indicated by.

- Magnesium which is randomly and dilutely present between the two CoO layers, that is, at the lithium site, has an effect of suppressing the displacement of the two CoO layers when charged at a high voltage. Therefore, if magnesium is present between the CoO 2 layers, it tends to have an O3'type crystal structure.

- a halogen compound such as a fluorine compound

- lithium cobalt oxide before the heat treatment for distributing magnesium throughout the particles.

- a halogen compound causes a melting point depression of lithium cobalt oxide. By lowering the melting point, it becomes easy to distribute magnesium throughout the particles at a temperature at which cationic mixing is unlikely to occur. Further, if a fluorine compound is present, it can be expected that the corrosion resistance to hydrofluoric acid generated by the decomposition of the electrolyte is improved.

- the magnesium concentration is higher than the desired value, the effect on stabilizing the crystal structure may be reduced. It is thought that magnesium enters cobalt sites in addition to lithium sites.

- the number of atoms of magnesium contained in the positive electrode active material produced by one aspect of the present invention is preferably 0.001 times or more and 0.1 times or less, and more than 0.01 times and less than 0.04 times the number of atoms of cobalt. More preferably, about 0.02 times is further preferable.

- the magnesium concentration shown here may be, for example, a value obtained by elemental analysis of the entire particles of the positive electrode active material using ICP-MS or the like, or a value of the blending of raw materials in the process of producing the positive electrode active material. May be based.

- the number of nickel atoms contained in the positive electrode active material is preferably 7.5% or less, preferably 0.05% or more and 4% or less, and more preferably 0.1% or more and 2% or less of the number of cobalt atoms.

- the nickel concentration shown here may be, for example, a value obtained by elemental analysis of the entire particles of the positive electrode active material using ICP-MS or the like, or a value of the blending of raw materials in the process of producing the positive electrode active material. It may be based.

- the average particle diameter is preferably 1 ⁇ m or more and 100 ⁇ m or less, more preferably 2 ⁇ m or more and 40 ⁇ m or less, and further preferably 5 ⁇ m or more and 30 ⁇ m or less.

- a positive electrode active material exhibits an O3'type crystal structure when charged at a high voltage is determined by XRD, electron beam diffraction, neutron beam diffraction, electron spin resonance (ESR), and electron spin resonance (ESR). It can be determined by analysis using nuclear magnetic resonance (NMR) or the like.

- XRD can analyze the symmetry of transition metals such as cobalt possessed by the positive electrode active material with high resolution, compare the height of crystallinity and the orientation of crystals, and analyze the periodic strain and crystallite size of the lattice. It is preferable in that sufficient accuracy can be obtained even if the positive electrode obtained by disassembling the secondary battery is measured as it is.

- the positive electrode active material is characterized in that the crystal structure does not change much between the state of being charged with a high voltage and the state of being discharged.

- a material in which a crystal structure having a large change from the discharged state occupies 50 wt% or more in a state of being charged at a high voltage is not preferable because it cannot withstand the charging / discharging of a high voltage.

- the desired crystal structure may not be obtained simply by adding an impurity element. For example, even if lithium cobalt oxide having magnesium and fluorine is common, the O3'type crystal structure becomes 60 wt% or more when charged at a high voltage, and the H1-3 type crystal structure becomes 50 wt% or more. There are cases where it occupies.

- the O3'type crystal structure becomes approximately 100 wt%, and when the predetermined voltage is further increased, an H1-3 type crystal structure may occur. Therefore, it is preferable that the crystal structure of the positive electrode active material is analyzed by XRD or the like. By using it in combination with measurement such as XRD, more detailed analysis can be performed.

- the positive electrode active material charged or discharged at a high voltage may change its crystal structure when exposed to the air.

- the O3'type crystal structure may change to the H1-3 type crystal structure. Therefore, it is preferable to handle all the samples in an inert atmosphere such as an atmosphere containing argon.

- the positive electrode active material shown in FIG. 4 is lithium cobalt oxide (LiCoO 2 ) to which the additive element X is not added.

- the crystal structure of lithium cobalt oxide shown in FIG. 4 changes depending on the charging depth.

- the lithium cobalt oxide having a charge depth of 0 (discharged state) has a region having a crystal structure of the space group R-3 m, and three CoO layers are present in the unit cell. Therefore, this crystal structure may be referred to as an O3 type crystal structure.

- the CoO 2 layer is a structure in which an octahedral structure in which oxygen is coordinated to cobalt is continuous with a plane in a shared ridge state.

- the space group P-3m1 has a crystal structure, and one CoO layer is present in the unit cell. Therefore, this crystal structure may be referred to as an O1 type crystal structure.

- lithium cobalt oxide when the charging depth is about 0.8 has a crystal structure of the space group R-3m.

- This structure can be said to be a structure in which CoO 2 structures such as P-3m1 (O1) and LiCoO 2 structures such as R-3m (O3) are alternately laminated. Therefore, this crystal structure may be referred to as an H1-3 type crystal structure.

- the H1-3 type crystal structure has twice the number of cobalt atoms per unit cell as the other structures.

- the c-axis of the H1-3 type crystal structure is shown by halving the unit cell.

- the coordinates of cobalt and oxygen in the unit cell are set to Co (0, 0, 0.42150 ⁇ 0.00016), O 1 (0, 0, 0.267671 ⁇ 0.00045). , O 2 (0, 0, 0.11535 ⁇ 0.00045).

- O 1 and O 2 are oxygen atoms, respectively.

- the H1-3 type crystal structure is represented by a unit cell using one cobalt and two oxygens.

- the O3'type crystal structure of one aspect of the present invention is preferably represented by a unit cell using one cobalt and one oxygen.