WO2021235549A1 - Composé, matériau électroluminescent et élément électroluminescent - Google Patents

Composé, matériau électroluminescent et élément électroluminescent Download PDFInfo

- Publication number

- WO2021235549A1 WO2021235549A1 PCT/JP2021/019431 JP2021019431W WO2021235549A1 WO 2021235549 A1 WO2021235549 A1 WO 2021235549A1 JP 2021019431 W JP2021019431 W JP 2021019431W WO 2021235549 A1 WO2021235549 A1 WO 2021235549A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- substituted

- light emitting

- carbazole

- ring

- Prior art date

Links

- 150000001875 compounds Chemical class 0.000 title claims abstract description 243

- 239000000463 material Substances 0.000 title claims abstract description 158

- 125000004435 hydrogen atom Chemical group [H]* 0.000 claims abstract description 59

- 125000003118 aryl group Chemical group 0.000 claims abstract description 28

- 125000001072 heteroaryl group Chemical group 0.000 claims abstract description 26

- 125000004432 carbon atom Chemical group C* 0.000 claims abstract description 22

- 229910052799 carbon Inorganic materials 0.000 claims abstract description 19

- 229910052805 deuterium Inorganic materials 0.000 claims abstract description 19

- 125000004431 deuterium atom Chemical group 0.000 claims abstract description 8

- -1 carbazole-9-yl group Chemical group 0.000 claims description 104

- 125000000623 heterocyclic group Chemical group 0.000 claims description 70

- 125000001424 substituent group Chemical group 0.000 claims description 30

- UJOBWOGCFQCDNV-UHFFFAOYSA-N 9H-carbazole Chemical compound C1=CC=C2C3=CC=CC=C3NC2=C1 UJOBWOGCFQCDNV-UHFFFAOYSA-N 0.000 claims description 24

- 229910052757 nitrogen Inorganic materials 0.000 claims description 23

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 claims description 21

- 125000004429 atom Chemical group 0.000 claims description 18

- 125000004433 nitrogen atom Chemical group N* 0.000 claims description 17

- YLQBMQCUIZJEEH-UHFFFAOYSA-N Furan Chemical group C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 claims description 16

- YTPLMLYBLZKORZ-UHFFFAOYSA-N Thiophene Chemical group C=1C=CSC=1 YTPLMLYBLZKORZ-UHFFFAOYSA-N 0.000 claims description 14

- 125000004430 oxygen atom Chemical group O* 0.000 claims description 13

- 125000000609 carbazolyl group Chemical group C1(=CC=CC=2C3=CC=CC=C3NC12)* 0.000 claims description 10

- 125000004434 sulfur atom Chemical group 0.000 claims description 10

- 229910052717 sulfur Inorganic materials 0.000 claims description 9

- 125000004076 pyridyl group Chemical group 0.000 claims description 8

- 125000000168 pyrrolyl group Chemical group 0.000 claims description 8

- 150000003233 pyrroles Chemical group 0.000 claims description 3

- 229930192474 thiophene Natural products 0.000 claims description 2

- UFHFLCQGNIYNRP-VVKOMZTBSA-N Dideuterium Chemical group [2H][2H] UFHFLCQGNIYNRP-VVKOMZTBSA-N 0.000 claims 1

- 125000005842 heteroatom Chemical group 0.000 abstract description 13

- 125000004556 carbazol-9-yl group Chemical group C1=CC=CC=2C3=CC=CC=C3N(C12)* 0.000 abstract 1

- 239000010410 layer Substances 0.000 description 230

- 239000010408 film Substances 0.000 description 79

- 230000004888 barrier function Effects 0.000 description 67

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 45

- 230000015572 biosynthetic process Effects 0.000 description 35

- 239000000758 substrate Substances 0.000 description 33

- 238000003786 synthesis reaction Methods 0.000 description 33

- 230000032258 transport Effects 0.000 description 31

- 238000000034 method Methods 0.000 description 30

- 230000003111 delayed effect Effects 0.000 description 29

- 230000005525 hole transport Effects 0.000 description 29

- 239000000203 mixture Substances 0.000 description 28

- 238000006243 chemical reaction Methods 0.000 description 25

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 24

- 238000002347 injection Methods 0.000 description 23

- 239000007924 injection Substances 0.000 description 23

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 22

- 238000005401 electroluminescence Methods 0.000 description 20

- 239000012044 organic layer Substances 0.000 description 19

- 239000010409 thin film Substances 0.000 description 19

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 18

- 125000000217 alkyl group Chemical group 0.000 description 18

- 238000007740 vapor deposition Methods 0.000 description 18

- YZCKVEUIGOORGS-OUBTZVSYSA-N Deuterium Chemical group [2H] YZCKVEUIGOORGS-OUBTZVSYSA-N 0.000 description 17

- 229920000642 polymer Polymers 0.000 description 17

- 239000007787 solid Substances 0.000 description 16

- CSNNHWWHGAXBCP-UHFFFAOYSA-L Magnesium sulfate Chemical compound [Mg+2].[O-][S+2]([O-])([O-])[O-] CSNNHWWHGAXBCP-UHFFFAOYSA-L 0.000 description 14

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 14

- 150000001975 deuterium Chemical group 0.000 description 14

- 230000006870 function Effects 0.000 description 14

- 150000001721 carbon Chemical group 0.000 description 13

- 229910052751 metal Inorganic materials 0.000 description 13

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 12

- 239000002184 metal Chemical class 0.000 description 12

- 125000003277 amino group Chemical group 0.000 description 11

- 238000010898 silica gel chromatography Methods 0.000 description 11

- IANQTJSKSUMEQM-UHFFFAOYSA-N 1-benzofuran Chemical group C1=CC=C2OC=CC2=C1 IANQTJSKSUMEQM-UHFFFAOYSA-N 0.000 description 10

- 125000003545 alkoxy group Chemical group 0.000 description 10

- 230000000052 comparative effect Effects 0.000 description 10

- BWHMMNNQKKPAPP-UHFFFAOYSA-L potassium carbonate Chemical compound [K+].[K+].[O-]C([O-])=O BWHMMNNQKKPAPP-UHFFFAOYSA-L 0.000 description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 10

- FCEHBMOGCRZNNI-UHFFFAOYSA-N 1-benzothiophene Chemical compound C1=CC=C2SC=CC2=C1 FCEHBMOGCRZNNI-UHFFFAOYSA-N 0.000 description 9

- 125000003342 alkenyl group Chemical group 0.000 description 9

- 239000004642 Polyimide Substances 0.000 description 8

- 238000000576 coating method Methods 0.000 description 8

- 239000000470 constituent Substances 0.000 description 8

- 238000005520 cutting process Methods 0.000 description 8

- 238000004519 manufacturing process Methods 0.000 description 8

- 229920001721 polyimide Polymers 0.000 description 8

- 239000002904 solvent Substances 0.000 description 8

- QUIANDCGBNCTHV-UHFFFAOYSA-N 4,6-difluoro-5-phenylbenzene-1,3-dicarbonitrile Chemical compound C1(C#N)=C(F)C(C2=CC=CC=C2)=C(F)C(C#N)=C1 QUIANDCGBNCTHV-UHFFFAOYSA-N 0.000 description 7

- 238000005538 encapsulation Methods 0.000 description 7

- 239000007788 liquid Substances 0.000 description 7

- 229910052943 magnesium sulfate Inorganic materials 0.000 description 7

- 235000019341 magnesium sulphate Nutrition 0.000 description 7

- 239000011541 reaction mixture Substances 0.000 description 7

- 230000005469 synchrotron radiation Effects 0.000 description 7

- SIKJAQJRHWYJAI-UHFFFAOYSA-N Indole Chemical compound C1=CC=C2NC=CC2=C1 SIKJAQJRHWYJAI-UHFFFAOYSA-N 0.000 description 6

- 125000004414 alkyl thio group Chemical group 0.000 description 6

- 150000001555 benzenes Chemical class 0.000 description 6

- 239000002019 doping agent Substances 0.000 description 6

- 125000005647 linker group Chemical group 0.000 description 6

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 6

- 238000006862 quantum yield reaction Methods 0.000 description 6

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical group C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 5

- KEAYESYHFKHZAL-UHFFFAOYSA-N Sodium Chemical compound [Na] KEAYESYHFKHZAL-UHFFFAOYSA-N 0.000 description 5

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 5

- 125000004104 aryloxy group Chemical group 0.000 description 5

- 239000003086 colorant Substances 0.000 description 5

- 150000002894 organic compounds Chemical class 0.000 description 5

- 229910000027 potassium carbonate Inorganic materials 0.000 description 5

- 238000001226 reprecipitation Methods 0.000 description 5

- 239000012312 sodium hydride Substances 0.000 description 5

- 229910000104 sodium hydride Inorganic materials 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 238000001429 visible spectrum Methods 0.000 description 5

- ZHNUHDYFZUAESO-UHFFFAOYSA-N Formamide Chemical compound NC=O ZHNUHDYFZUAESO-UHFFFAOYSA-N 0.000 description 4

- 125000005110 aryl thio group Chemical group 0.000 description 4

- 239000007772 electrode material Substances 0.000 description 4

- 238000005530 etching Methods 0.000 description 4

- 239000000706 filtrate Substances 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 125000005553 heteroaryloxy group Chemical group 0.000 description 4

- 125000005368 heteroarylthio group Chemical group 0.000 description 4

- 239000000178 monomer Substances 0.000 description 4

- 238000002161 passivation Methods 0.000 description 4

- IAZDPXIOMUYVGZ-UHFFFAOYSA-N Dimethylsulphoxide Chemical compound CS(C)=O IAZDPXIOMUYVGZ-UHFFFAOYSA-N 0.000 description 3

- 229910001374 Invar Inorganic materials 0.000 description 3

- NSGDYZCDUPSTQT-UHFFFAOYSA-N N-[5-bromo-1-[(4-fluorophenyl)methyl]-4-methyl-2-oxopyridin-3-yl]cycloheptanecarboxamide Chemical compound Cc1c(Br)cn(Cc2ccc(F)cc2)c(=O)c1NC(=O)C1CCCCCC1 NSGDYZCDUPSTQT-UHFFFAOYSA-N 0.000 description 3

- 125000002947 alkylene group Chemical group 0.000 description 3

- 229910045601 alloy Inorganic materials 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- 150000004945 aromatic hydrocarbons Chemical group 0.000 description 3

- 150000001716 carbazoles Chemical group 0.000 description 3

- 238000005229 chemical vapour deposition Methods 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 238000005336 cracking Methods 0.000 description 3

- 125000004093 cyano group Chemical group *C#N 0.000 description 3

- 230000005281 excited state Effects 0.000 description 3

- 238000004770 highest occupied molecular orbital Methods 0.000 description 3

- PZOUSPYUWWUPPK-UHFFFAOYSA-N indole Natural products CC1=CC=CC2=C1C=CN2 PZOUSPYUWWUPPK-UHFFFAOYSA-N 0.000 description 3

- RKJUIXBNRJVNHR-UHFFFAOYSA-N indolenine Natural products C1=CC=C2CC=NC2=C1 RKJUIXBNRJVNHR-UHFFFAOYSA-N 0.000 description 3

- 125000001041 indolyl group Chemical group 0.000 description 3

- 239000000411 inducer Substances 0.000 description 3

- 238000004768 lowest unoccupied molecular orbital Methods 0.000 description 3

- 230000003287 optical effect Effects 0.000 description 3

- 239000003960 organic solvent Substances 0.000 description 3

- 230000001443 photoexcitation Effects 0.000 description 3

- 125000004309 pyranyl group Chemical group O1C(C=CC=C1)* 0.000 description 3

- 125000001567 quinoxalinyl group Chemical group N1=C(C=NC2=CC=CC=C12)* 0.000 description 3

- 238000005215 recombination Methods 0.000 description 3

- 230000006798 recombination Effects 0.000 description 3

- 239000000243 solution Substances 0.000 description 3

- 238000004544 sputter deposition Methods 0.000 description 3

- 238000003756 stirring Methods 0.000 description 3

- JYEUMXHLPRZUAT-UHFFFAOYSA-N 1,2,3-triazine Chemical group C1=CN=NN=C1 JYEUMXHLPRZUAT-UHFFFAOYSA-N 0.000 description 2

- UZKBSZSTDQSMDR-UHFFFAOYSA-N 1-[(4-chlorophenyl)-phenylmethyl]piperazine Chemical compound C1=CC(Cl)=CC=C1C(C=1C=CC=CC=1)N1CCNCC1 UZKBSZSTDQSMDR-UHFFFAOYSA-N 0.000 description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N Alumina Chemical compound [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 229940126062 Compound A Drugs 0.000 description 2

- 238000003775 Density Functional Theory Methods 0.000 description 2

- NLDMNSXOCDLTTB-UHFFFAOYSA-N Heterophylliin A Natural products O1C2COC(=O)C3=CC(O)=C(O)C(O)=C3C3=C(O)C(O)=C(O)C=C3C(=O)OC2C(OC(=O)C=2C=C(O)C(O)=C(O)C=2)C(O)C1OC(=O)C1=CC(O)=C(O)C(O)=C1 NLDMNSXOCDLTTB-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical group [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- JFBZPFYRPYOZCQ-UHFFFAOYSA-N [Li].[Al] Chemical compound [Li].[Al] JFBZPFYRPYOZCQ-UHFFFAOYSA-N 0.000 description 2

- JHYLKGDXMUDNEO-UHFFFAOYSA-N [Mg].[In] Chemical compound [Mg].[In] JHYLKGDXMUDNEO-UHFFFAOYSA-N 0.000 description 2

- 150000001338 aliphatic hydrocarbons Chemical group 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- SNAAJJQQZSMGQD-UHFFFAOYSA-N aluminum magnesium Chemical compound [Mg].[Al] SNAAJJQQZSMGQD-UHFFFAOYSA-N 0.000 description 2

- 125000005577 anthracene group Chemical group 0.000 description 2

- 125000000732 arylene group Chemical group 0.000 description 2

- 150000007980 azole derivatives Chemical class 0.000 description 2

- JFDZBHWFFUWGJE-UHFFFAOYSA-N benzenecarbonitrile Natural products N#CC1=CC=CC=C1 JFDZBHWFFUWGJE-UHFFFAOYSA-N 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 125000004122 cyclic group Chemical group 0.000 description 2

- 125000000582 cycloheptyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 2

- 125000000113 cyclohexyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 2

- 125000001511 cyclopentyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 2

- 238000000151 deposition Methods 0.000 description 2

- 238000001035 drying Methods 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 125000001153 fluoro group Chemical group F* 0.000 description 2

- 230000005283 ground state Effects 0.000 description 2

- 125000005843 halogen group Chemical group 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- AMGQUBHHOARCQH-UHFFFAOYSA-N indium;oxotin Chemical compound [In].[Sn]=O AMGQUBHHOARCQH-UHFFFAOYSA-N 0.000 description 2

- 238000004020 luminiscence type Methods 0.000 description 2

- SJCKRGFTWFGHGZ-UHFFFAOYSA-N magnesium silver Chemical compound [Mg].[Ag] SJCKRGFTWFGHGZ-UHFFFAOYSA-N 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 239000011812 mixed powder Substances 0.000 description 2

- 125000002950 monocyclic group Chemical group 0.000 description 2

- 125000001624 naphthyl group Chemical group 0.000 description 2

- 150000004866 oxadiazoles Chemical class 0.000 description 2

- YNPNZTXNASCQKK-UHFFFAOYSA-N phenanthrene Chemical group C1=CC=C2C3=CC=CC=C3C=CC2=C1 YNPNZTXNASCQKK-UHFFFAOYSA-N 0.000 description 2

- 238000000206 photolithography Methods 0.000 description 2

- 238000005424 photoluminescence Methods 0.000 description 2

- 230000000379 polymerizing effect Effects 0.000 description 2

- 238000007639 printing Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 125000003373 pyrazinyl group Chemical group 0.000 description 2

- 125000000714 pyrimidinyl group Chemical group 0.000 description 2

- 239000010453 quartz Substances 0.000 description 2

- 125000002943 quinolinyl group Chemical group N1=C(C=CC2=CC=CC=C12)* 0.000 description 2

- 238000011160 research Methods 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 239000002356 single layer Substances 0.000 description 2

- 150000003384 small molecules Chemical class 0.000 description 2

- 230000003595 spectral effect Effects 0.000 description 2

- 150000003518 tetracenes Chemical class 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 239000012780 transparent material Substances 0.000 description 2

- LWIHDJKSTIGBAC-UHFFFAOYSA-K tripotassium phosphate Chemical compound [K+].[K+].[K+].[O-]P([O-])([O-])=O LWIHDJKSTIGBAC-UHFFFAOYSA-K 0.000 description 2

- 238000001771 vacuum deposition Methods 0.000 description 2

- 238000003631 wet chemical etching Methods 0.000 description 2

- OBETXYAYXDNJHR-SSDOTTSWSA-M (2r)-2-ethylhexanoate Chemical compound CCCC[C@@H](CC)C([O-])=O OBETXYAYXDNJHR-SSDOTTSWSA-M 0.000 description 1

- UWRZIZXBOLBCON-VOTSOKGWSA-N (e)-2-phenylethenamine Chemical class N\C=C\C1=CC=CC=C1 UWRZIZXBOLBCON-VOTSOKGWSA-N 0.000 description 1

- 0 *c1c(*)c(C#N)c(*)c(C#N)c1* Chemical compound *c1c(*)c(C#N)c(*)c(C#N)c1* 0.000 description 1

- YJTKZCDBKVTVBY-UHFFFAOYSA-N 1,3-Diphenylbenzene Chemical group C1=CC=CC=C1C1=CC=CC(C=2C=CC=CC=2)=C1 YJTKZCDBKVTVBY-UHFFFAOYSA-N 0.000 description 1

- VERMWGQSKPXSPZ-BUHFOSPRSA-N 1-[(e)-2-phenylethenyl]anthracene Chemical compound C=1C=CC2=CC3=CC=CC=C3C=C2C=1\C=C\C1=CC=CC=C1 VERMWGQSKPXSPZ-BUHFOSPRSA-N 0.000 description 1

- 125000001637 1-naphthyl group Chemical group [H]C1=C([H])C([H])=C2C(*)=C([H])C([H])=C([H])C2=C1[H] 0.000 description 1

- MVWPVABZQQJTPL-UHFFFAOYSA-N 2,3-diphenylcyclohexa-2,5-diene-1,4-dione Chemical class O=C1C=CC(=O)C(C=2C=CC=CC=2)=C1C1=CC=CC=C1 MVWPVABZQQJTPL-UHFFFAOYSA-N 0.000 description 1

- 125000003229 2-methylhexyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])(C([H])([H])[H])C([H])([H])* 0.000 description 1

- 125000001622 2-naphthyl group Chemical group [H]C1=C([H])C([H])=C2C([H])=C(*)C([H])=C([H])C2=C1[H] 0.000 description 1

- 125000004105 2-pyridyl group Chemical group N1=C([*])C([H])=C([H])C([H])=C1[H] 0.000 description 1

- 125000003349 3-pyridyl group Chemical group N1=C([H])C([*])=C([H])C([H])=C1[H] 0.000 description 1

- QUGSIDOEKIVAOT-UHFFFAOYSA-N 4,5-difluoro-6-phenylbenzene-1,3-dicarbonitrile Chemical compound N#CC(C(C1=CC=CC=C1)=C1F)=CC(C#N)=C1F QUGSIDOEKIVAOT-UHFFFAOYSA-N 0.000 description 1

- UAKXPKOAUDLYKN-UHFFFAOYSA-N 4,6-difluorobenzene-1,3-dicarbonitrile Chemical group FC1=CC(F)=C(C#N)C=C1C#N UAKXPKOAUDLYKN-UHFFFAOYSA-N 0.000 description 1

- HQSCPPCMBMFJJN-UHFFFAOYSA-N 4-bromobenzonitrile Chemical compound BrC1=CC=C(C#N)C=C1 HQSCPPCMBMFJJN-UHFFFAOYSA-N 0.000 description 1

- 125000000339 4-pyridyl group Chemical group N1=C([H])C([H])=C([*])C([H])=C1[H] 0.000 description 1

- ZYASLTYCYTYKFC-UHFFFAOYSA-N 9-methylidenefluorene Chemical class C1=CC=C2C(=C)C3=CC=CC=C3C2=C1 ZYASLTYCYTYKFC-UHFFFAOYSA-N 0.000 description 1

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 1

- VVJKKWFAADXIJK-UHFFFAOYSA-N Allylamine Chemical class NCC=C VVJKKWFAADXIJK-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 238000004057 DFT-B3LYP calculation Methods 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- 229910000799 K alloy Inorganic materials 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- PAYRUJLWNCNPSJ-UHFFFAOYSA-N N-phenyl amine Natural products NC1=CC=CC=C1 PAYRUJLWNCNPSJ-UHFFFAOYSA-N 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- RWRDLPDLKQPQOW-UHFFFAOYSA-N Pyrrolidine Chemical group C1CCNC1 RWRDLPDLKQPQOW-UHFFFAOYSA-N 0.000 description 1

- NRCMAYZCPIVABH-UHFFFAOYSA-N Quinacridone Chemical class N1C2=CC=CC=C2C(=O)C2=C1C=C1C(=O)C3=CC=CC=C3NC1=C2 NRCMAYZCPIVABH-UHFFFAOYSA-N 0.000 description 1

- 229910004205 SiNX Inorganic materials 0.000 description 1

- 229910006404 SnO 2 Inorganic materials 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- OWXLRKWPEIAGAT-UHFFFAOYSA-N [Mg].[Cu] Chemical compound [Mg].[Cu] OWXLRKWPEIAGAT-UHFFFAOYSA-N 0.000 description 1

- 239000011149 active material Substances 0.000 description 1

- OBETXYAYXDNJHR-UHFFFAOYSA-N alpha-ethylcaproic acid Natural products CCCCC(CC)C(O)=O OBETXYAYXDNJHR-UHFFFAOYSA-N 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 229940051880 analgesics and antipyretics pyrazolones Drugs 0.000 description 1

- 150000001454 anthracenes Chemical class 0.000 description 1

- 150000008425 anthrones Chemical class 0.000 description 1

- 125000005428 anthryl group Chemical group [H]C1=C([H])C([H])=C2C([H])=C3C(*)=C([H])C([H])=C([H])C3=C([H])C2=C1[H] 0.000 description 1

- 125000006615 aromatic heterocyclic group Chemical group 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 125000003785 benzimidazolyl group Chemical group N1=C(NC2=C1C=CC=C2)* 0.000 description 1

- 150000008359 benzonitriles Chemical class 0.000 description 1

- 125000003354 benzotriazolyl group Chemical group N1N=NC2=C1C=CC=C2* 0.000 description 1

- YNHIGQDRGKUECZ-UHFFFAOYSA-L bis(triphenylphosphine)palladium(ii) dichloride Chemical compound [Cl-].[Cl-].[Pd+2].C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1 YNHIGQDRGKUECZ-UHFFFAOYSA-L 0.000 description 1

- FJDQFPXHSGXQBY-UHFFFAOYSA-L caesium carbonate Chemical compound [Cs+].[Cs+].[O-]C([O-])=O FJDQFPXHSGXQBY-UHFFFAOYSA-L 0.000 description 1

- 229910000024 caesium carbonate Inorganic materials 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 150000001718 carbodiimides Chemical class 0.000 description 1

- 229910000175 cerite Inorganic materials 0.000 description 1

- 229910052801 chlorine Inorganic materials 0.000 description 1

- 125000001309 chloro group Chemical group Cl* 0.000 description 1

- 150000001846 chrysenes Chemical class 0.000 description 1

- WCZVZNOTHYJIEI-UHFFFAOYSA-N cinnoline Chemical compound N1=NC=CC2=CC=CC=C21 WCZVZNOTHYJIEI-UHFFFAOYSA-N 0.000 description 1

- 238000010549 co-Evaporation Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 229920001940 conductive polymer Polymers 0.000 description 1

- 238000007334 copolymerization reaction Methods 0.000 description 1

- 150000001893 coumarin derivatives Chemical class 0.000 description 1

- 150000001907 coumarones Chemical class 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 125000004986 diarylamino group Chemical group 0.000 description 1

- 125000005240 diheteroarylamino group Chemical group 0.000 description 1

- 239000000539 dimer Substances 0.000 description 1

- 238000004821 distillation Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000609 electron-beam lithography Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 230000005669 field effect Effects 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 150000002219 fluoranthenes Chemical class 0.000 description 1

- 150000008376 fluorenones Chemical class 0.000 description 1

- 125000003983 fluorenyl group Chemical class C1(=CC=CC=2C3=CC=CC=C3CC12)* 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- 238000007646 gravure printing Methods 0.000 description 1

- 125000005549 heteroarylene group Chemical group 0.000 description 1

- 150000007857 hydrazones Chemical class 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 150000002460 imidazoles Chemical class 0.000 description 1

- 125000002636 imidazolinyl group Chemical group 0.000 description 1

- 125000002883 imidazolyl group Chemical group 0.000 description 1

- 125000003454 indenyl group Chemical group C1(C=CC2=CC=CC=C12)* 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 1

- VVVPGLRKXQSQSZ-UHFFFAOYSA-N indolo[3,2-c]carbazole Chemical class C1=CC=CC2=NC3=C4C5=CC=CC=C5N=C4C=CC3=C21 VVVPGLRKXQSQSZ-UHFFFAOYSA-N 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 229940079865 intestinal antiinfectives imidazole derivative Drugs 0.000 description 1

- 125000000959 isobutyl group Chemical group [H]C([H])([H])C([H])(C([H])([H])[H])C([H])([H])* 0.000 description 1

- 125000004491 isohexyl group Chemical group C(CCC(C)C)* 0.000 description 1

- 125000000904 isoindolyl group Chemical group C=1(NC=C2C=CC=CC12)* 0.000 description 1

- 125000001972 isopentyl group Chemical group [H]C([H])([H])C([H])(C([H])([H])[H])C([H])([H])C([H])([H])* 0.000 description 1

- LAQPNDIUHRHNCV-UHFFFAOYSA-N isophthalonitrile Chemical class N#CC1=CC=CC(C#N)=C1 LAQPNDIUHRHNCV-UHFFFAOYSA-N 0.000 description 1

- 125000000555 isopropenyl group Chemical group [H]\C([H])=C(\*)C([H])([H])[H] 0.000 description 1

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- 125000002183 isoquinolinyl group Chemical group C1(=NC=CC2=CC=CC=C12)* 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 238000001459 lithography Methods 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- CUONGYYJJVDODC-UHFFFAOYSA-N malononitrile Chemical class N#CCC#N CUONGYYJJVDODC-UHFFFAOYSA-N 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- 125000004370 n-butenyl group Chemical group [H]\C([H])=C(/[H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000004108 n-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000003136 n-heptyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000001280 n-hexyl group Chemical group C(CCCCC)* 0.000 description 1

- 125000000740 n-pentyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000004123 n-propyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 238000007645 offset printing Methods 0.000 description 1

- 230000005693 optoelectronics Effects 0.000 description 1

- 239000011368 organic material Substances 0.000 description 1

- AICOOMRHRUFYCM-ZRRPKQBOSA-N oxazine, 1 Chemical compound C([C@@H]1[C@H](C(C[C@]2(C)[C@@H]([C@H](C)N(C)C)[C@H](O)C[C@]21C)=O)CC1=CC2)C[C@H]1[C@@]1(C)[C@H]2N=C(C(C)C)OC1 AICOOMRHRUFYCM-ZRRPKQBOSA-N 0.000 description 1

- 150000007978 oxazole derivatives Chemical class 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 230000037361 pathway Effects 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 125000002080 perylenyl group Chemical group C1(=CC=C2C=CC=C3C4=CC=CC5=CC=CC(C1=C23)=C45)* 0.000 description 1

- 125000000843 phenylene group Chemical group C1(=C(C=CC=C1)*)* 0.000 description 1

- 150000004986 phenylenediamines Chemical class 0.000 description 1

- 125000003386 piperidinyl group Chemical group 0.000 description 1

- 238000001020 plasma etching Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- BITYAPCSNKJESK-UHFFFAOYSA-N potassiosodium Chemical compound [Na].[K] BITYAPCSNKJESK-UHFFFAOYSA-N 0.000 description 1

- 229910000160 potassium phosphate Inorganic materials 0.000 description 1

- 235000011009 potassium phosphates Nutrition 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 125000002924 primary amino group Chemical group [H]N([H])* 0.000 description 1

- JEXVQSWXXUJEMA-UHFFFAOYSA-N pyrazol-3-one Chemical class O=C1C=CN=N1 JEXVQSWXXUJEMA-UHFFFAOYSA-N 0.000 description 1

- 150000003219 pyrazolines Chemical class 0.000 description 1

- 125000003226 pyrazolyl group Chemical group 0.000 description 1

- 150000003220 pyrenes Chemical class 0.000 description 1

- PBMFSQRYOILNGV-UHFFFAOYSA-N pyridazine Chemical group C1=CC=NN=C1 PBMFSQRYOILNGV-UHFFFAOYSA-N 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 125000002294 quinazolinyl group Chemical group N1=C(N=CC2=CC=CC=C12)* 0.000 description 1

- 229910052761 rare earth metal Inorganic materials 0.000 description 1

- YYMBJDOZVAITBP-UHFFFAOYSA-N rubrene Chemical class C1=CC=CC=C1C(C1=C(C=2C=CC=CC=2)C2=CC=CC=C2C(C=2C=CC=CC=2)=C11)=C(C=CC=C2)C2=C1C1=CC=CC=C1 YYMBJDOZVAITBP-UHFFFAOYSA-N 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 239000002195 soluble material Substances 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 125000003107 substituted aryl group Chemical group 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- 229940042055 systemic antimycotics triazole derivative Drugs 0.000 description 1

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 125000005579 tetracene group Chemical group 0.000 description 1

- VLLMWSRANPNYQX-UHFFFAOYSA-N thiadiazole Chemical compound C1=CSN=N1.C1=CSN=N1 VLLMWSRANPNYQX-UHFFFAOYSA-N 0.000 description 1

- 150000007979 thiazole derivatives Chemical class 0.000 description 1

- 230000036962 time dependent Effects 0.000 description 1

- OVTCUIZCVUGJHS-VQHVLOKHSA-N trans-dipyrrin Chemical class C=1C=CNC=1/C=C1\C=CC=N1 OVTCUIZCVUGJHS-VQHVLOKHSA-N 0.000 description 1

- PJANXHGTPQOBST-VAWYXSNFSA-N trans-stilbene Chemical class C=1C=CC=CC=1/C=C/C1=CC=CC=C1 PJANXHGTPQOBST-VAWYXSNFSA-N 0.000 description 1

- 230000001052 transient effect Effects 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

- WLPUWLXVBWGYMZ-UHFFFAOYSA-N tricyclohexylphosphine Chemical compound C1CCCCC1P(C1CCCCC1)C1CCCCC1 WLPUWLXVBWGYMZ-UHFFFAOYSA-N 0.000 description 1

- 239000013638 trimer Substances 0.000 description 1

- 125000005580 triphenylene group Chemical group 0.000 description 1

- 238000007738 vacuum evaporation Methods 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 230000004580 weight loss Effects 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D491/00—Heterocyclic compounds containing in the condensed ring system both one or more rings having oxygen atoms as the only ring hetero atoms and one or more rings having nitrogen atoms as the only ring hetero atoms, not provided for by groups C07D451/00 - C07D459/00, C07D463/00, C07D477/00 or C07D489/00

- C07D491/02—Heterocyclic compounds containing in the condensed ring system both one or more rings having oxygen atoms as the only ring hetero atoms and one or more rings having nitrogen atoms as the only ring hetero atoms, not provided for by groups C07D451/00 - C07D459/00, C07D463/00, C07D477/00 or C07D489/00 in which the condensed system contains two hetero rings

- C07D491/04—Ortho-condensed systems

- C07D491/044—Ortho-condensed systems with only one oxygen atom as ring hetero atom in the oxygen-containing ring

- C07D491/048—Ortho-condensed systems with only one oxygen atom as ring hetero atom in the oxygen-containing ring the oxygen-containing ring being five-membered

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K85/00—Organic materials used in the body or electrodes of devices covered by this subclass

- H10K85/60—Organic compounds having low molecular weight

- H10K85/649—Aromatic compounds comprising a hetero atom

- H10K85/657—Polycyclic condensed heteroaromatic hydrocarbons

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D487/00—Heterocyclic compounds containing nitrogen atoms as the only ring hetero atoms in the condensed system, not provided for by groups C07D451/00 - C07D477/00

- C07D487/02—Heterocyclic compounds containing nitrogen atoms as the only ring hetero atoms in the condensed system, not provided for by groups C07D451/00 - C07D477/00 in which the condensed system contains two hetero rings

- C07D487/04—Ortho-condensed systems

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D491/00—Heterocyclic compounds containing in the condensed ring system both one or more rings having oxygen atoms as the only ring hetero atoms and one or more rings having nitrogen atoms as the only ring hetero atoms, not provided for by groups C07D451/00 - C07D459/00, C07D463/00, C07D477/00 or C07D489/00

- C07D491/12—Heterocyclic compounds containing in the condensed ring system both one or more rings having oxygen atoms as the only ring hetero atoms and one or more rings having nitrogen atoms as the only ring hetero atoms, not provided for by groups C07D451/00 - C07D459/00, C07D463/00, C07D477/00 or C07D489/00 in which the condensed system contains three hetero rings

- C07D491/14—Ortho-condensed systems

- C07D491/153—Ortho-condensed systems the condensed system containing two rings with oxygen as ring hetero atom and one ring with nitrogen as ring hetero atom

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D519/00—Heterocyclic compounds containing more than one system of two or more relevant hetero rings condensed among themselves or condensed with a common carbocyclic ring system not provided for in groups C07D453/00 or C07D455/00

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/06—Luminescent, e.g. electroluminescent, chemiluminescent materials containing organic luminescent materials

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K85/00—Organic materials used in the body or electrodes of devices covered by this subclass

- H10K85/60—Organic compounds having low molecular weight

- H10K85/649—Aromatic compounds comprising a hetero atom

- H10K85/657—Polycyclic condensed heteroaromatic hydrocarbons

- H10K85/6572—Polycyclic condensed heteroaromatic hydrocarbons comprising only nitrogen in the heteroaromatic polycondensed ring system, e.g. phenanthroline or carbazole

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2211/00—Chemical nature of organic luminescent or tenebrescent compounds

- C09K2211/10—Non-macromolecular compounds

- C09K2211/1003—Carbocyclic compounds

- C09K2211/1007—Non-condensed systems

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2211/00—Chemical nature of organic luminescent or tenebrescent compounds

- C09K2211/10—Non-macromolecular compounds

- C09K2211/1018—Heterocyclic compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2211/00—Chemical nature of organic luminescent or tenebrescent compounds

- C09K2211/10—Non-macromolecular compounds

- C09K2211/1018—Heterocyclic compounds

- C09K2211/1025—Heterocyclic compounds characterised by ligands

- C09K2211/1029—Heterocyclic compounds characterised by ligands containing one nitrogen atom as the heteroatom

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2211/00—Chemical nature of organic luminescent or tenebrescent compounds

- C09K2211/10—Non-macromolecular compounds

- C09K2211/1018—Heterocyclic compounds

- C09K2211/1025—Heterocyclic compounds characterised by ligands

- C09K2211/1029—Heterocyclic compounds characterised by ligands containing one nitrogen atom as the heteroatom

- C09K2211/1033—Heterocyclic compounds characterised by ligands containing one nitrogen atom as the heteroatom with oxygen

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2211/00—Chemical nature of organic luminescent or tenebrescent compounds

- C09K2211/10—Non-macromolecular compounds

- C09K2211/1018—Heterocyclic compounds

- C09K2211/1025—Heterocyclic compounds characterised by ligands

- C09K2211/1044—Heterocyclic compounds characterised by ligands containing two nitrogen atoms as heteroatoms

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K2101/00—Properties of the organic materials covered by group H10K85/00

- H10K2101/20—Delayed fluorescence emission

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K50/00—Organic light-emitting devices

- H10K50/10—OLEDs or polymer light-emitting diodes [PLED]

- H10K50/11—OLEDs or polymer light-emitting diodes [PLED] characterised by the electroluminescent [EL] layers

Definitions

- the present invention relates to a compound useful as a light emitting material and a light emitting device using the compound.

- organic electroluminescence elements organic electroluminescence elements

- various measures have been taken to improve the luminous efficiency by newly developing and combining electron transport materials, hole transport materials, light emitting materials and the like constituting organic electroluminescence devices.

- research on organic electroluminescence devices using delayed fluorescent materials can be seen.

- the delayed fluorescent material is a material that emits fluorescence when returning from the excited singlet state to the ground state after an intersystem crossing from the excited triplet state to the excited singlet state occurs in the excited state. Fluorescence by such a pathway is called delayed fluorescence because it is observed later than the fluorescence from the excited singlet state directly generated from the ground state (normal fluorescence).

- the probability of occurrence of the excited singlet state and the excited triplet state is statistically 25%: 75%, so that the excited singlet state directly generated is used. There is a limit to the improvement of light emission efficiency only by the fluorescence of.

- the delayed fluorescent material not only the excited singlet state but also the excited triplet state can be used for fluorescence emission by the path via the above-mentioned inverse intersystem crossing, so that the emission is higher than that of the ordinary fluorescent material. Efficiency will be obtained.

- any material that emits delayed fluorescence is not immediately useful as a light emitting material.

- Some delayed fluorescent materials are relatively unlikely to have an inverse intersystem crossing, and some have a long delayed fluorescence lifetime.

- excitons may accumulate in the high current density region to reduce the luminous efficiency, or the drive may deteriorate rapidly if the drive is continued for a long time. Therefore, the reality is that there are an extremely large number of delayed fluorescent materials that have room for improvement in terms of practicality. Therefore, it has been pointed out that the benzonitrile compound known as a delayed fluorescent material also has a problem.

- a compound having the following structure is a material that emits delayed fluorescence (see Patent Document 1), it has problems that the delayed fluorescence has a long life and the device durability is insufficient.

- the present inventors have conducted repeated studies for the purpose of providing a more useful compound as a light emitting material for a light emitting device. Then, we proceeded with diligent studies for the purpose of deriving and generalizing the general formulas of compounds that are more useful as luminescent materials.

- the present inventors have found that among the isophthalonitrile derivatives, a compound having a structure satisfying a specific condition is useful as a light emitting material.

- the present invention has been proposed based on these findings, and specifically has the following configurations.

- R is a hydrogen atom, a deuterium atom, a substituted or unsubstituted aryl group, or a substituted or unsubstituted heteroaryl group bonded at a carbon atom.

- Ar is a substituted or unsubstituted aryl group, or a substituted or unsubstituted heteroaryl group bonded at a carbon atom.

- D 1 and D 2 each independently represent a donor group, of which at least one is a heterocyclic condensed carbazole-9-yl group (the heterocycle and the carbazole may be substituted).

- the thiophene ring and the pyrrole ring may be further fused with another ring), and two heterocycles selected from the group are condensed, any one of [1] to [9].

- [17] The compound according to any one of [1] to [16], which comprises an atom selected from the group consisting of a carbon atom, a hydrogen atom, a heavy hydrogen atom, a nitrogen atom, an oxygen atom and a sulfur atom.

- a luminescent material comprising the compound according to any one of [1] to [17].

- a light emitting device comprising the compound according to any one of [1] to [17].

- the light emitting device according to [20] wherein the light emitting device has a light emitting layer, the light emitting layer contains the compound and the light emitting material, and mainly emits light from the light emitting material.

- the compound of the present invention is useful as a light emitting material. Further, the compound of the present invention includes a compound having a short delayed fluorescence lifetime. Further, the organic light emitting device using the compound of the present invention has high device durability and is useful.

- the description of the constituent elements described below may be based on typical embodiments and specific examples of the present invention, but the present invention is not limited to such embodiments and specific examples.

- the numerical range represented by using "-" in the present specification means a range including the numerical values before and after "-" as the lower limit value and the upper limit value.

- part or all of the hydrogen atoms present in the molecule of the compound used in the present invention can be replaced by deuterium atoms (2 H, deuterium D).

- the hydrogen atom is indicated as H or the indication is omitted.

- At least one of D 1 and D 2 in the general formula (1) represents a heterocyclic condensed carbazole-9-yl group.

- the heterocycle and the carbazole ring constituting the heterocyclic condensed carbazole-9-yl group may or may not be substituted, respectively.

- the number of heterocycles fused to the carbazole-9-yl group is one or more, preferably one or two, and more preferably one. When two or more heterocycles are fused, they may be the same or different.

- the heterocycle is condensed at positions 1 and 2 of the carbazole-9-yl group.

- the heterocycle is condensed to the 2nd and 3rd positions of the carbazole-9-yl group.

- the heterocycle is fused to the 3rd and 4th positions of the carbazole-9-yl group.

- the heterocycle condensed on the carbazole-9-yl group is a ring containing a heteroatom.

- the heteroatom is preferably selected from an oxygen atom, a sulfur atom, a nitrogen atom and a silicon atom, and more preferably selected from an oxygen atom, a sulfur atom and a nitrogen atom.

- the heteroatom is an oxygen atom.

- the heteroatom is a sulfur atom.

- the heteroatom is a nitrogen atom.

- the number of heteroatoms contained as ring skeleton constituent atoms of the heterocycle is one or more, preferably 1 to 3, and more preferably 1 or 2. In one preferred embodiment, the number of heteroatoms is one. When the number of heteroatoms is two or more, they are preferably heteroatoms of the same type, but may be composed of heteroatoms of different types. For example, two or more heteroatoms may all be nitrogen atoms. Ring skeleton constituent atoms other than heteroatoms are carbon atoms. The number of ring skeleton constituent atoms constituting the heterocycle condensed with the carbazole-9-yl group is preferably 4 to 8, more preferably 5 to 7, and further preferably 5 or 6. preferable.

- the number of ring skeleton constituent atoms constituting the heterocycle is 5. It is preferable that two or more conjugated double bonds are present in the heterocycle, and it is preferable that the conjugated system of the carbazole ring is expanded by condensing the heterocycle (having aromaticity). preferable).

- Preferred examples of the heterocycle include a furan ring, a thiophene ring, and a pyrrole ring. Further, another ring may be condensed on the heterocycle condensed on the carbazole-9-yl group. Further, the ring to be condensed may be a monocyclic ring or a condensed ring.

- Examples of the ring to be condensed include an aromatic hydrocarbon ring, an aromatic heterocycle, an aliphatic hydrocarbon ring, and an aliphatic heterocycle.

- Examples of the aromatic hydrocarbon ring include a benzene ring.

- Examples of the aromatic heterocycle include a pyridine ring, a pyridazine ring, a pyrimidine ring, a pyrazine ring, a triazine ring, a pyrrole ring, a pyrazole ring, and an imidazole ring.

- Examples of the aliphatic hydrocarbon ring include a cyclopentane ring, a cyclohexane ring, and a cycloheptane ring.

- Examples of the aliphatic heterocycle include a piperidine ring, a pyrrolidine ring, and an imidazoline ring.

- Specific examples of the fused ring include naphthalene ring, anthracene ring, phenanthren ring, pyran ring, tetracene ring, indole ring, isoindole ring, benzimidazole ring, benzotriazole ring, quinoline ring, isoquinoline ring, quinazoline ring, quinoxaline ring, and cinnoline. You can raise the ring.

- the heterocyclic condensed carbazole-9-yl group is a benzofuran condensed carbazole-9-yl group, a benzothiophene condensed carbazole-9-yl group, an indole condensed carbazole-9-yl group, or a silinden condensation. It is a carbazole-9-yl group.

- the heterocyclic condensed carbazole-9-yl group is a benzofuran condensed carbazole-9-yl group, a benzothiophene condensed carbazole-9-yl group, or an indole condensed carbazole-9-yl group. ..

- a substituted or unsubstituted benzofuran [2,3-a] carbazole-9-yl group can be adopted as the benzofuran condensed carbazole-9-yl group.

- a substituted or unsubstituted benzoflo [3,2-a] carbazole-9-yl group can also be adopted.

- a substituted or unsubstituted benzoflo [2,3-b] carbazole-9-yl group can also be adopted.

- a substituted or unsubstituted benzoflo [3,2-b] carbazole-9-yl group can also be adopted.

- a substituted or unsubstituted benzoflo [2,3-c] carbazole-9-yl group can also be adopted.

- a substituted or unsubstituted benzoflo [3,2-c] carbazole-9-yl group can also be adopted.

- the preferred benzofuran-condensed carbazole-9-yl group is a carbazole-9-yl group in which only one benzofuran ring is condensed at the 2nd and 3rd positions and the other heterocycle is not condensed (the benzene ring is condensed). May be good).

- it is a group having any of the following structures, and hydrogen atoms in the following structures may be substituted.

- a hydrogen atom in the following structure in which a part of the hydrogen atom is substituted with a heavy hydrogen atom, or a hydrogen atom in the following structure in which all the hydrogen atoms are substituted with a heavy hydrogen atom can be preferably exemplified. Those that are not substituted can also be preferably adopted.

- a carbazole-9-yl group in which two benzofuran rings are condensed at the 2nd and 3rd positions and the heterocycle is not condensed is also preferable (the benzene ring may be condensed).

- the benzene ring may be condensed.

- it is a group having any of the following structures, and hydrogen atoms in the following structures may be substituted.

- a hydrogen atom in the following structure in which a part of the hydrogen atom is substituted with a heavy hydrogen atom or a hydrogen atom in the following structure in which all the hydrogen atoms are substituted with a heavy hydrogen atom can be preferably exemplified. Those that are not substituted can also be preferably adopted.

- a substituted or unsubstituted benzothioeno [2,3-a] carbazole-9-yl group can be adopted as the benzothiophene condensed carbazole-9-yl group. Further, a substituted or unsubstituted benzothieno [3,2-a] carbazole-9-yl group can also be adopted. Further, a substituted or unsubstituted benzothieno [2,3-b] carbazole-9-yl group can also be adopted. Further, a substituted or unsubstituted benzothieno [3,2-b] carbazole-9-yl group can also be adopted.

- a substituted or unsubstituted benzothieno [2,3-c] carbazole-9-yl group can also be adopted.

- a substituted or unsubstituted benzothieno [3,2-c] carbazole-9-yl group can also be adopted.

- a preferred benzothiophene-fused carbazole-9-yl group is a carbazole-9-yl group in which only one benzothiophene ring is condensed at the 2nd and 3rd positions and the other heterocycle is not condensed (the benzene ring is condensed). May be). Specifically, it is a group having any of the following structures, and hydrogen atoms in the following structures may be substituted.

- a hydrogen atom in the following structure in which a part of the hydrogen atom is substituted with a heavy hydrogen atom, or a hydrogen atom in the following structure in which all the hydrogen atoms are substituted with a heavy hydrogen atom can be preferably exemplified. Those that are not substituted can also be preferably adopted.

- a carbazole-9-yl group in which two benzothiophene rings are condensed at the 2nd and 3rd positions and the heterocycle is not condensed is also preferable (the benzene ring may be condensed).

- the benzene ring may be condensed.

- it is a group having any of the following structures, and hydrogen atoms in the following structures may be substituted.

- a hydrogen atom in the following structure in which a part of the hydrogen atom is substituted with a heavy hydrogen atom, or a hydrogen atom in the following structure in which all the hydrogen atoms are substituted with a heavy hydrogen atom can be preferably exemplified. Those that are not substituted can also be preferably adopted.

- a substituted or unsubstituted indro [2,3-a] carbazole-9-yl group can be adopted as the indole condensed carbazole-9-yl group. Further, a substituted or unsubstituted indro [3,2-a] carbazole-9-yl group can also be adopted. Further, a substituted or unsubstituted indro [2,3-b] carbazole-9-yl group can also be adopted. Further, a substituted or unsubstituted indro [3,2-b] carbazole-9-yl group can also be adopted. Further, a substituted or unsubstituted indro [2,3-c] carbazole-9-yl group can also be adopted.

- a substituted or unsubstituted indro [3,2-c] carbazole-9-yl group can also be adopted.

- the preferred indole-condensed carbazole-9-yl group is a carbazole-9-yl group in which only one indole ring is condensed at the 2nd and 3rd positions and the other heterocycle is not condensed (the benzene ring is condensed). May be good).

- R'in the following structure represents a hydrogen atom, a deuterium atom or a substituent (preferably R'is a substituent).

- R' is preferably a substituted or unsubstituted aryl group.

- the hydrogen atom in the following structure may be substituted.

- a hydrogen atom in the following structure in which a part of the hydrogen atom is substituted with a heavy hydrogen atom, or a hydrogen atom in the following structure in which all the hydrogen atoms are substituted with a heavy hydrogen atom can be preferably exemplified. Those that are not substituted can also be preferably adopted.

- the heterocycle and the carbazole ring constituting the heterocyclic condensed carbazole-9-yl group may be substituted, respectively. When substituted, it may be substituted with a deuterium atom or it may be substituted with another substituent.

- substituent here include an alkyl group, an alkenyl group, an aryl group, a heteroaryl group, an alkoxy group, an alkylthio group, an aryloxy group, an arylthio group, a heteroaryloxy group, a heteroarylthio group and a cyano group. can. These substituents may be substituted with yet another substituent.

- an embodiment substituted with a heavy hydrogen atom, an alkyl group, an aryl group, an alkoxy group, and an alkylthio group can be mentioned.

- the "alkyl group” referred to here may be linear, branched or cyclic. Further, two or more of the linear portion, the annular portion and the branched portion may be mixed.

- the number of carbon atoms of the alkyl group can be, for example, 1 or more, 2 or more, and 4 or more. Further, the number of carbon atoms can be 30 or less, 20 or less, 10 or less, 6 or less, and 4 or less.

- alkyl group examples include methyl group, ethyl group, n-propyl group, isopropyl group, n-butyl group, isobutyl group, tert-butyl group, n-pentyl group, isopentyl group, n-hexyl group and isohexyl group.

- 2-Ethylhexyl group, n-heptyl group, isoheptyl group, n-octyl group, isooctyl group, n-nonyl group, isononyl group, n-decanyl group, isodecanyl group, cyclopentyl group, cyclohexyl group, cycloheptyl group can be mentioned.

- the alkyl group as a substituent may be further substituted with a heavy hydrogen atom, an aryl group, an alkoxy group, an aryloxy group, or a halogen atom.

- the "alkenyl group” may be linear, branched or cyclic.

- the number of carbon atoms of the alkenyl group can be, for example, 2 or more and 4 or more. Further, the number of carbon atoms can be 30 or less, 20 or less, 10 or less, 6 or less, and 4 or less.

- Specific examples of the alkenyl group include ethenyl group, n-propenyl group, isopropenyl group, n-butenyl group, isobutenyl group, n-pentenyl group, isopentenyl group, n-hexenyl group, isohexenyl group and 2-ethylhexenyl group. Can be mentioned.

- the alkenyl group as a substituent may be further substituted.

- the "aryl group” and the “heteroaryl group” may be a monocyclic ring or a condensed ring in which two or more rings are condensed. In the case of fused rings, the number of fused rings is preferably 2 to 6, and can be selected from, for example, 2 to 4.

- the ring include a benzene ring, a pyridine ring, a pyrimidine ring, a triazine ring, a naphthalene ring, an anthracene ring, a phenanthrene ring, a triphenylene ring, a quinoline ring, a pyrazine ring, a quinoxaline ring, and a naphthylidine ring.

- arylene group or the heteroarylene group examples include a phenyl group, a 1-naphthyl group, a 2-naphthyl group, a 1-anthrasenyl group, a 2-anthrasenyl group, a 9-anthrasenyl group, a 2-pyridyl group, a 3-pyridyl group, and 4 -Pyridyl groups can be mentioned.

- the alkyl moiety of the "alkoxy group” and the "alkylthio group the above description and specific examples of the alkyl group can be referred to.

- the heterocyclic condensed carbazole-9-yl group preferably has 16 or more atoms other than hydrogen atoms and deuterium atoms, more preferably 20 or more, and may be, for example, 16 or more. Further, it is preferably 80 or less, more preferably 50 or less, and further preferably 30 or less.

- the heterocyclic condensed carbazole-9-yl group may be only D 1 or only D 2 .

- both D 1 and D 2 are heterocyclic condensed carbazole-9-yl groups.

- D 1 and D 2 may have the same structure or may have different heterocyclic condensed carbazole-9-yl groups.

- the other is a donor group other than the heterocyclic condensed carbazole-9-yl group (hereinafter referred to as "another donor group").

- another donor group is a donor group having a negative Hammet's ⁇ p value.

- k is the rate constant of the benzene derivative having no substituent

- k 0 is the rate constant of the benzene derivative substituted with the substituent

- K is the equilibrium constant of the benzene derivative having no substituent

- K 0 is the substituent.

- the equilibrium constant of the benzene derivative substituted with, ⁇ represents the reaction constant determined by the type and conditions of the reaction.

- ⁇ p value refers to the description of ⁇ p value in Hansch, C.et.al., Chem.Rev., 91,165-195 (1991). can. Groups with a negative Hammett ⁇ p value tend to show electron donating properties (donor properties), and groups with positive Hammett ⁇ p values tend to show electron attractor properties (acceptor properties).

- the other donor group in the present invention is preferably a group containing a substituted amino group.

- the substituent bonded to the nitrogen atom of the amino group is preferably a substituted or unsubstituted alkyl group, a substituted or unsubstituted alkenyl group, a substituted or unsubstituted aryl group, or a substituted or unsubstituted heteroaryl group.

- a substituted or unsubstituted aryl group, or a substituted or unsubstituted heteroaryl group is more preferable.

- the substituted amino group is particularly preferably a substituted or unsubstituted diarylamino group or a substituted or unsubstituted diheteroarylamino group.

- the donor group in the present invention may be a group bonded with a nitrogen atom of a substituted amino group or a group bonded with a group to which a substituted amino group is bonded.

- the group to which the substituted amino group is bonded is preferably a ⁇ -conjugated group. More preferred are groups bonded at the nitrogen atom of the substituted amino group.

- the alkyl group, alkenyl group, aryl group and heteroaryl group which are the substituents here the above-mentioned corresponding description regarding the substituent of the aromatic hydrocarbon ring group and the aromatic heterocyclic group can be referred to.

- Particularly preferred as the other donor group in the present invention is a substituted or unsubstituted carbazole-9-yl group.

- the carbazole-9-yl group may be further condensed with a benzene ring or a heterocycle (excluding the benzofuran ring, the benzothiophene ring, the indole ring, the indene ring, and the sirainden ring).

- the substituent of the carbazole-9-yl group includes an alkyl group, an alkenyl group, an aryl group, a heteroaryl group, an alkoxy group, an alkylthio group, an aryloxy group, an arylthio group, a heteroaryloxy group, a heteroarylthio group and a substituted amino.

- a group can be mentioned, and preferred substituents include an alkyl group, an aryl group, and a substituted amino group.

- the substituted amino group referred to here includes a substituted or unsubstituted carbazolyl group, for example, a substituted or unsubstituted carbazole-3-yl group and a substituted or unsubstituted carbazole-9-yl group.

- the other donor group in the present invention preferably has 8 or more atoms other than hydrogen atoms and deuterium atoms, more preferably 12 or more, and may be, for example, 16 or more. Further, it is preferably 80 or less, more preferably 60 or less, and further preferably 40 or less.

- D13 to D78, D84 to D119, D150 to D161, D168 to D209, D215 to D268, D270 to D324 are specific examples of the heterocyclic condensed carbazole-9-yl group, and D1 to D12, D79 to 83, D120 to 149.

- D162-D167, D210-D214, D269 are specific examples of other donor groups.

- Ph represents a phenyl group and * represents a bond position.

- R in the general formula (1) is a hydrogen atom, a deuterium atom, a substituted or unsubstituted aryl group, or a substituted or unsubstituted heteroaryl group bonded with a carbon atom.

- R is a hydrogen atom or a deuterium atom.

- R is a substituted or unsubstituted aryl group or an embodiment in which R is a substituted or unsubstituted heteroaryl group bonded at a carbon atom.

- R is an aryl group, it is preferably a substituted aryl group.

- R is a heteroaryl group, it is preferably a substituted heteroaryl group.

- Ar in the general formula (1) is a substituted or unsubstituted aryl group, or a substituted or unsubstituted heteroaryl group bonded at a carbon atom.

- Ar is a substituted or unsubstituted aryl group.

- an embodiment in which Ar is a substituted or unsubstituted heteroaryl group can also be adopted.

- the description and preferable range of the aryl group and the heteroaryl group that can be taken by R and Ar the description of the aryl group and the heteroaryl group in the substituent of the heterocyclic condensed carbazole-9-yl group can be referred to.

- the heteroaryl group is a heteroaryl group bonded at a carbon atom.

- Aryl group substituents and heteroaryl group substituents include alkyl groups, alkenyl groups, aryl groups, heteroaryl groups, alkoxy groups, alkylthio groups, aryloxy groups, arylthio groups, heteroaryloxy groups, and heteroarylthio groups.

- Cyano groups can be mentioned. These substituents may be substituted with yet another substituent.

- Preferred groups of substituents include an alkyl group, an aryl group, an alkoxy group, an alkylthio group and a cyano group.

- R is a hydrogen atom or a deuterium atom and Ar is a substituted or unsubstituted phenyl group (the phenyl group is selected from a benzene ring, a pyridine ring, a furan ring, a thiophene ring and a pyrrole ring. One or more rings may be condensed).

- R is a hydrogen atom or a deuterium atom and Ar is a substituted or unsubstituted pyridyl group (the pyridyl group is composed of a benzene ring, a pyridine ring, a furan ring, a thiophene ring and a pyrrole ring. One or more rings selected may be fused).

- R is a hydrogen atom or a deuterium atom and Ar is a substituted phenyl group (the phenyl group is selected from a substituted or unsubstituted phenyl group and a substituted or unsubstituted pyridyl group.

- R is a hydrogen atom or a deuterium atom and Ar is a substituted pyridyl group (the pyridyl group is selected from a substituted or unsubstituted phenyl group and a substituted or unsubstituted pyridyl group.

- One or more groups are substituted).

- the compound represented by the general formula (1) may be a compound composed of only an atom selected from the group consisting of a carbon atom, a hydrogen atom, a heavy hydrogen atom, a nitrogen atom, an oxygen atom and a sulfur atom.

- the compound represented by the general formula (1) is composed only of an atom selected from the group consisting of a carbon atom, a hydrogen atom, a deuterium atom, a nitrogen atom and an oxygen atom.

- the compound represented by the general formula (1) may be a compound composed of only an atom selected from the group consisting of a carbon atom, a hydrogen atom, a heavy hydrogen atom, a nitrogen atom and a sulfur atom.

- the compound represented by the general formula (1) may be a compound composed of only atoms selected from the group consisting of carbon atoms, hydrogen atoms and nitrogen atoms. Further, the compound represented by the general formula (1) may be a compound containing a deuterium atom without containing a hydrogen atom. For example, the compound represented by the general formula (1) may be a compound composed of only an atom selected from the group consisting of a carbon atom, a heavy hydrogen atom, a nitrogen atom, an oxygen atom and a sulfur atom. In one aspect of the present invention, the compound represented by the general formula (1) has a symmetrical structure.

- the compound represented by the general formula (1) has a structure represented by the following general formula (2).

- the compound represented by the general formula (1) has a structure represented by the following general formula (3).

- R 1 to R 4 of the following general formula for each compound corresponds to R 1 of the following general formula

- D 1 of the general formula (1) corresponds to R 2 of the following general formula. If a rotational isomer is present among the following compounds, the mixture of the rotational isomer and each separated rotational isomer are also disclosed in the present specification.

- the compounds in which H of R 1 is substituted with D in the compounds 1 to 6300 are disclosed here as compounds 6301 to 12600 in order.

- Compounds 1 to 6300 in which R 1 and R 4 are exchanged to form R 4 and R 1 are disclosed herein as compounds 12601 to 18900.

- the compounds in which H of R 2 is substituted with D in the compounds 12601 to 18900 are disclosed here as compounds 18901 to 25200 in order.

- Compounds 1 to 6300 in which R 1 , R 2 , R 3 , and R 4 are designated as R 3 , R 1 , R 4 , and R 2 in that order are disclosed here as compounds 25201 to 31500.

- the compounds of the H of R 3 was replaced to D in compounds 25201-31500, disclosed herein as compounds 31501-37800 sequentially.

- the compounds in which R 1 , R 2 , R 3 , and R 4 in compounds 1 to 6300 are designated as R 4 , R 1 , R 2 , and R 3 in this order are disclosed here as compounds 37801 to 44100.

- Compounds 1 to 6300 in which R 1 , R 3 , and R 4 are replaced to form R 3 , R 4 , and R 1 are disclosed here as compounds 50401 to 56700.

- the compounds of the H of R 3 was replaced to D in compounds 50401-56700, disclosed herein as compounds 56701-63000 sequentially.

- Compounds 1 to 6300 in which R 3 and R 4 are replaced to form R 4 and R 3 are disclosed herein as compounds 63001 to 69300.

- the compounds in which H of R 1 is substituted with D in the compounds 63001 to 69300 are disclosed herein as compounds 69301 to 75600 in order.

- Each structure of the above compounds 901 to 75600 is individually specified, and each is described as a specific compound in the present specification.

- the molecular weight of the compound represented by the general formula (1) is, for example, 1500 or less when the organic layer containing the compound represented by the general formula (1) is intended to be formed into a film by a vapor deposition method. It is preferably 1200 or less, more preferably 1000 or less, and even more preferably 900 or less.

- the lower limit of the molecular weight is the molecular weight of the smallest compound represented by the general formula (1). It is preferably 624 or more.

- the compound represented by the general formula (1) may be formed into a film by a coating method regardless of the molecular weight. By using the coating method, it is possible to form a film even if the compound has a relatively large molecular weight.

- the compound represented by the general formula (1) has an advantage that it is easily dissolved in an organic solvent among the cyanobenzene compounds. Therefore, the compound represented by the general formula (1) is easy to apply the coating method and is easy to purify to increase the purity.

- a compound containing a plurality of structures represented by the general formula (1) in the molecule as a light emitting material.

- a polymer obtained by pre-existing a polymerizable group in the structure represented by the general formula (1) and polymerizing the polymerizable group as a light emitting material.

- a monomer containing a polymerizable functional group is prepared in any of Ar, D 1 , and D 2 of the general formula (1), and this is polymerized alone or copolymerized with another monomer. Therefore, it is conceivable to obtain a polymer having a repeating unit and use the polymer as a light emitting material.

- dimers and trimers by coupling compounds having a structure represented by the general formula (1) to each other and use them as a light emitting material.

- a polymer having a repeating unit containing a structure represented by the general formula (1) a polymer containing a structure represented by the following general formula (4) or (5) can be mentioned.

- Q represents a group containing the structure represented by the general formula (1)

- L 1 and L 2 represent a linking group.

- the carbon number of the linking group is preferably 0 to 20, more preferably 1 to 15, and even more preferably 2 to 10.

- X 11 represents an oxygen atom or a sulfur atom, and is preferably an oxygen atom.

- L 11 represents a linking group, preferably a substituted or unsubstituted alkylene group, or a substituted or unsubstituted arylene group, and is a substituted or unsubstituted alkylene group having 1 to 10 carbon atoms, or a substituted or unsubstituted alkylene group. It is more preferably a phenylene group.

- R 101 , R 102 , R 103 and R 104 each independently represent a substituent.

- the linking group represented by L 1 and L 2 can be bonded to any of Ar, D 1 , and D 2 of the general formula (1) constituting Q. Two or more linking groups may be linked to one Q to form a crosslinked structure or a network structure.

- a hydroxy group is introduced into any of Ar, D 1 and D 2 of the general formula (1), and the polymer is used as a linker as described below. It can be synthesized by reacting a compound to introduce a polymerizable group and polymerizing the polymerizable group.

- the polymer containing the structure represented by the general formula (1) in the molecule may be a polymer consisting only of repeating units having the structure represented by the general formula (1), or may have other structures. It may be a polymer containing a repeating unit having. Further, the repeating unit having the structure represented by the general formula (1) contained in the polymer may be a single type or two or more types. Examples of the repeating unit having no structure represented by the general formula (1) include those derived from a monomer used for ordinary copolymerization. For example, a repeating unit derived from a monomer having an ethylenically unsaturated bond such as ethylene and styrene can be mentioned.

- the compound represented by the general formula (1) is a light emitting material. In certain embodiments, the compound represented by the general formula (1) is a compound capable of emitting delayed fluorescence. In one embodiment of the present disclosure, the compound represented by the general formula (1) is in the UV region, the blue, green, yellow, orange, red region of the visible spectrum when excited by thermal or electronic means. It can emit light (eg, about 420 nm to about 500 nm, about 500 nm to about 600 nm or about 600 nm to about 700 nm) or in the near infrared region.

- the compound of the general formula (1) when excited by thermal or electronic means, is in the red or orange region of the visible spectrum (eg, from about 620 nm to about 780 nm, about 780 nm). It can emit light at 650 nm). In certain embodiments of the present disclosure, the compound of the general formula (1), when excited by thermal or electronic means, has an orange or yellow region of the visible spectrum (eg, from about 570 nm to about 620 nm, about 620 nm). It can emit light at 590 nm (about 570 nm).

- the compound of the general formula (1) when excited by thermal or electronic means, is in the green region of the visible spectrum (eg, from about 490 nm to about 575 nm, about 510 nm). Can emit light. In certain embodiments of the present disclosure, the compound of the general formula (1), when excited by thermal or electronic means, is in the blue region of the visible spectrum (eg, from about 400 nm to about 490 nm, about 475 nm). Can emit light. In certain embodiments of the present disclosure, the compound represented by the general formula (1) can emit light in the ultraviolet spectral region (eg, 280-400 nm) when excited by thermal or electronic means. In one embodiment of the present disclosure, the compound represented by the general formula (1) can emit light in the infrared spectral region (eg, 780 nm to 2 ⁇ m) when excited by thermal or electronic means.

- the ultraviolet spectral region eg, 280-400 nm

- the electronic properties of small molecule chemical libraries can be calculated using known ab initio quantum chemistry calculations.

- TD-DFT / B3LYP / 6-31G * can be analyzed and screened for molecular fragments (partial) having HOMO above a specific threshold and LUMO below a specific threshold.

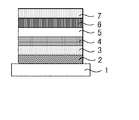

- HOMO energy for example, ionization potential