WO2018074274A1 - Power conversion device and air conditioner - Google Patents

Power conversion device and air conditioner Download PDFInfo

- Publication number

- WO2018074274A1 WO2018074274A1 PCT/JP2017/036552 JP2017036552W WO2018074274A1 WO 2018074274 A1 WO2018074274 A1 WO 2018074274A1 JP 2017036552 W JP2017036552 W JP 2017036552W WO 2018074274 A1 WO2018074274 A1 WO 2018074274A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- switching element

- switching

- leg

- control

- current

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/70—Control systems characterised by their outputs; Constructional details thereof

- F24F11/80—Control systems characterised by their outputs; Constructional details thereof for controlling the temperature of the supplied air

- F24F11/86—Control systems characterised by their outputs; Constructional details thereof for controlling the temperature of the supplied air by controlling compressors within refrigeration or heat pump circuits

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M7/00—Conversion of ac power input into dc power output; Conversion of dc power input into ac power output

- H02M7/02—Conversion of ac power input into dc power output without possibility of reversal

- H02M7/04—Conversion of ac power input into dc power output without possibility of reversal by static converters

- H02M7/12—Conversion of ac power input into dc power output without possibility of reversal by static converters using discharge tubes with control electrode or semiconductor devices with control electrode

Definitions

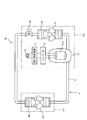

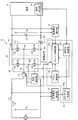

- FIG. 1 is an overall block diagram of a power conversion device 1 according to the first embodiment.

- the power conversion device 1 is a converter that converts an AC power supply voltage Vs applied from an AC power supply G into a DC voltage Vd, and outputs the DC voltage Vd to a load H (an inverter, a motor, etc.).

- the power conversion device 1 has an input side connected to the AC power supply G and an output side connected to the load H.

- the power conversion device 1 includes a bridge circuit 10, a reactor L ⁇ b> 1, a smoothing capacitor C ⁇ b> 1, a current detection unit 11, an AC voltage detection unit 12, a DC voltage detection unit 13, and a load detection unit. 14, a shunt resistor R ⁇ b> 1, and a control unit 15.

- the bridge circuit 10 includes a switching element Q1 (first switching element), a switching element Q2 (second switching element), a switching element Q3 (third switching element), and a switching element Q4 (fourth switching element). I have.

- the bridge circuit 10 has an input side connected to an AC power source G and an output side connected to a load H.

- the switching elements Q1 to Q4 of the bridge circuit 10 are connected in a bridge shape as shown in FIG.

- the switching elements Q1 to Q4 are, for example, MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), and are turned on / off by the control unit 15. Use of MOSFETs as the switching elements Q1 to Q4 has advantages that switching loss can be reduced and switching can be performed at high speed.

- the switching element Q1 has a parasitic diode D1 therein.

- the parasitic diode D1 is a pn junction portion that exists between the source and drain of the switching element Q1.

- the saturation voltage (drain-source voltage in the on state) of the switching element Q1 is preferably lower than the voltage drop in the forward direction of the parasitic diode D1. This is because the voltage drop is smaller when the current is passed through the source / drain of the switching element Q1 than when the current is passed through the parasitic diode D1, thereby reducing the conduction loss. In other words, the conduction loss is smaller when a current is passed through the switching element Q1 in the on state than when a current is passed through the parasitic diode D1 in the switching element Q1 in the off state. The same applies to the other switching elements Q2 to Q4.

- the reverse recovery time (trr) of the parasitic diodes of the switching elements Q1 and Q2 used in this embodiment is relatively shorter than the reverse recovery times of the parasitic diodes of the switching elements Q3 and Q4. This is because the switching elements Q1 and Q2 generate a reverse recovery current in the parasitic diode during the power factor correction operation described later, so that the switching elements Q1 and Q2 are relatively parasitic diodes relative to the switching elements Q3 and Q4. This is because switching loss is reduced by using an element having a short reverse recovery time.

- connection point N2 is connected to the AC power supply G via the wiring hb.

- the wiring hb has one end connected to the AC power supply G and the other end connected to the connection point N2 described above.

- the drain of the switching element Q1 and the drain of the switching element Q3 are connected to each other, and the connection point N3 is connected to the load H through the wiring hc.

- the wiring hc has one end connected to the load H and the other end connected to the connection point N3 described above.

- the source of the switching element Q2 and the source of the switching element Q4 are connected to each other, and the connection point N4 is connected to the load H through the wiring hd.

- the wiring hd has one end connected to the sources of the switching elements Q2 and Q4 and the other end connected to the load H.

- the current detection unit 11 detects the current flowing through the bridge circuit 10 as an effective value (average current), and is provided in the wiring hb.

- a current transformer can be used as the current detection unit 11, for example.

- the AC voltage detector 12 detects an AC power supply voltage vs (instantaneous value) applied from the AC power supply G, and is connected to the wirings ha and hb.

- the DC voltage detector 13 detects the DC voltage Vd of the smoothing capacitor C1, and its positive side is connected to the wiring hc and its negative side is connected to the wiring hd. Note that the detection value of the DC voltage detection unit 13 is used to determine whether or not the voltage value applied to the load H has reached a predetermined target value.

- the zero cross determiner 15a determines whether the polarity of the AC power supply voltage vs has been switched, that is, whether the zero cross timing has been reached. For example, the zero-cross determination unit 15a outputs a signal “1” to the converter control unit 15d while the AC power supply voltage vs is positive, and outputs a signal “1” to the converter control unit 15d while the AC power supply voltage vs is negative. A 0 'signal is output.

- the step-up ratio control unit 15b has a function of setting the step-up ratio of the DC voltage Vd based on the detection value of the current detection unit 11, and outputting the step-up ratio to the gain control unit 15c and the converter control unit 15d. .

- the gain control unit 15c has a function of setting a current control gain based on the effective value of the circuit current is detected by the current detection unit 11 and the step-up ratio of the DC voltage Vd.

- Vcc is a connection terminal for driving power supply voltage of IC1 and IC2.

- HIN is connected to the output ports P1 and P5 of the converter control unit 15d. When a signal is input from the converter control unit 15d, a drive signal for driving the high-side switching elements Q1 and Q3 is output from the HO terminal.

- LIN is connected to the output ports P2 and P6 of the converter control unit 15d, and when a signal is input from the converter control unit 15d, a drive signal for driving the low-side switching elements Q2 and Q4 is output from the LO terminal. Is done.

- the Vs terminals of the drive circuits IC1 and IC2 are connected to the connection points N1 and N2, respectively.

- the GND terminal is connected to the connection point N5 on the wiring hd on the negative electrode side of the smoothing capacitor C1.

- the ITrip terminal is connected to a connection point N6 having the same potential as the drains of the switching elements Q2 and Q4.

- the Fault terminal is connected to the input port P4 of the converter control unit 15d via the connection point N7.

- the shunt resistor R1 is connected to the input port P3 of the converter control unit 15d.

- Diode rectification control is a control mode in which full-wave rectification is performed using four parasitic diodes D1 to D4. The diode rectification control is executed, for example, when the load is relatively small, but is not limited thereto.

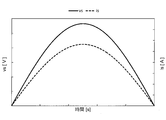

- FIG. 3 is a waveform diagram showing temporal changes in the AC power supply voltage vs, the circuit current is, and the drive pulses of the switching elements Q1 to Q4 in the diode rectification control.

- Waveform W3A is a waveform of AC power supply voltage vs (instantaneous value)

- waveform W3B is a waveform of circuit current is (instantaneous value).

- Waveforms W3C, W3D, W3E, and W3F are waveforms of drive pulses for switching elements Q1 to Q4. As shown by the waveforms W3C, W3D, W3E, and W3F in FIG. 3, the converter control unit 15d maintains all of the switching elements Q1 to Q4 in an off state, so that parasitic diodes D1 to D4 are described as described below. Through the circuit current is.

- the circuit is in the order of AC power supply G ⁇ parasitic diode D3 ⁇ smoothing capacitor C1 ⁇ shunt resistor R1 ⁇ parasitic diode D2 ⁇ reactor L1 ⁇ AC power supply G.

- a current is flows.

- the waveform of the circuit current is as shown by the waveform W3B in FIG.

- FIG. 5 is an explanatory diagram showing a current flow when the AC power supply voltage vs is included in the positive half cycle in the synchronous rectification control.

- the AC power supply G ⁇ reactor L1 ⁇ switching element Q1 ⁇ smoothing capacitor C1 ⁇ shunt resistor R1 ⁇ switching element Q4 ⁇ AC power supply G as shown by the broken line arrow in FIG.

- the circuit current is flows in the current path.

- the current path of the AC power supply G ⁇ switching element Q3 ⁇ smoothing capacitor C1 ⁇ shunt resistor R1 ⁇ switching element Q2 ⁇ reactor L1 ⁇ AC power supply G

- the circuit current is flows in FIG.

- the switching elements Q1 to Q4 are subjected to switching control in synchronization with the polarity of the power supply voltage, so that a current is actively supplied to the portion of the on-resistance having a small loss, and the parasitic diodes D1 to D4 are passed through. , Almost no current flow.

- FIG. 6 is an explanatory diagram showing temporal changes in the AC power supply voltage vs, the circuit current is, the current sh flowing through the shunt resistor R1, and the driving pulses of the switching elements Q1 to Q4 in the synchronous rectification control.

- converter control unit 15d switches on / off switching elements Q1-Q4 in synchronization with circuit current is.

- a description will be given by taking as an example a section in which the AC power supply voltage vs is a positive half cycle.

- the zero cross of the AC power supply voltage is detected by the AC voltage detection unit 12 and the zero cross determination unit 15a.

- the circuit current Is starts to flow after a lapse of a certain time from the zero cross of the AC power supply voltage.

- the circuit current is begins to flow when the AC power supply voltage vs increases and becomes equal to the DC voltage Vd, and then the time dt1 further elapses. Then, after the DC voltage Vd becomes equal to the AC voltage again, the circuit current becomes zero after a further time dt2. That is, a current flows when the DC voltage Vd is larger than the AC power supply voltage vs. On the contrary, when the DC voltage Vd is larger than the AC power supply voltage vs, the circuit current is does not flow.

- time delays dt1 and dt2 occur as described above. These phenomena are caused by a time delay caused by the reactor L1.

- the time dt2 is expressed by the following (Formula 1).

- the converter control unit 15d When the AC power supply voltage vs has a positive polarity, the converter control unit 15d first inputs a drive pulse to the gate of the switching element Q1 at the zero-cross timing to turn on the switching element Q1. Thereafter, the circuit current is> 0, and a drive pulse is input to the gate of the switching element Q4 at a predetermined timing to turn on the switching element Q4. Next, a method for driving the switching element Q4 will be described.

- the timing for turning on / off the switching element Q4 is determined by the detected value of the current ish (hereinafter referred to as shunt current) detected by the shunt resistor R1.

- shunt current the detected value of the current ish

- Two current determination values that is, a determination value a (first determination threshold value) and a determination value b (second determination threshold value) are stored in advance in the converter control unit 15d.

- converter control unit 15d inputs a drive pulse to switching element Q4 at the timing when shunt current ish becomes equal to or greater than determination value a, and turns on switching element Q4. Thereafter, converter control unit 15d turns off switching element Q4 at the timing when the circuit current becomes equal to or less than determination value b.

- the power conversion device 1 of the present embodiment shifts the timing for turning on the switching elements Q1 and Q4 when performing synchronous rectification. That is, when the AC power supply voltage vs has a positive polarity, the switching element Q4 is turned on after a predetermined time has elapsed since the switching element Q1 was turned on. This is to prevent backflow of current from the smoothing capacitor C1, that is, the DC voltage side to the AC power supply.

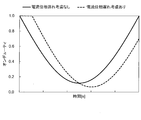

- FIG. 7 is a characteristic diagram showing the relationship between the drain reverse currents of the switching elements Q1 and Q4 and the saturation voltage of the parasitic diode.

- the drain reverse current means a current that flows from the source to the drain of the switching element.

- the parasitic diode saturation voltage means a voltage drop generated in the parasitic diode when a drain reverse current flows through the parasitic diode.

- the reverse recovery time of the parasitic diode D1 of the switching element Q1 is relatively small with respect to the reverse recovery time of the parasitic diode D4 of the switching element Q4.

- the saturation voltages of the respective parasitic diodes have a relationship as shown in FIG.

- the drain reverse current “small” region is a light load region that is not normally used by the device including the power conversion device 1

- the drain reverse current “medium” region is the power conversion device. 1 is a region used by the normal operation operation, and a region where the drain reverse current is “large” means a region used by the device including the power converter 1 in the overload operation.

- the switching element Q ⁇ b> 1 is turned on in the section of time dt ⁇ b> 3 from when the circuit current is starts to flow until the switching element Q ⁇ b> 4 is turned on.

- the circuit current is flows through the on-resistance portion with a small loss.

- the switching element Q4 since the switching element Q4 is turned off, the circuit current is flows through the parasitic diode D4. That is, the loss (area S) generated at time dt3 is the total value of the conduction loss caused by the on-resistance of switching element Q1 and the conduction loss caused by the parasitic diode of switching element Q4.

- the switching element Q4 is turned on first, and the switching element Q1 is turned on when the circuit current is and the shunt current ish reach the judgment value a.

- the loss in the area S is the sum of the conduction loss in the on-resistance portion of the switching element Q4 and the parasitic diode of the switching element Q1.

- the conduction loss of the parasitic diode of the switching element Q1 is larger than the conduction loss of the parasitic diode of the switching element Q4. For this reason, the loss in the area S is increased as compared with the case of switching in the order of the switching elements Q1 ⁇ Q4.

- the switching elements Q3 and Q4 use elements having different characteristics from the switching elements Q1 and Q2.

- the reverse recovery time of the parasitic diodes of the switching elements Q1, Q2 is relatively shorter than the reverse recovery time of the parasitic diodes of the switching elements Q3, Q4.

- the saturation voltage Vf of the parasitic diodes of the switching elements Q1, Q2 is relatively higher than the saturation voltage Vf of the parasitic diodes of the switching elements Q3, Q4.

- the switching elements on the side connected to the reactor L1 after the zero cross detection that is, the element switching elements Q1, Q2 having a high saturation voltage Vf of the parasitic diode are turned on first.

- the switching elements Q3 and Q4 on the side that is not connected to the reactor, that is, the low saturation voltage of the parasitic diode are turned on. .

- the switching elements Q1, Q2 are switched on / off at the zero cross timing at which the AC power supply voltage vs switches from positive to negative.

- a dead time td during which both switching elements Q1 and Q2 are turned off is provided.

- the partial switching control is a control mode in which an operation for short-circuiting the reactor L1 by alternately turning on / off the two switching elements Q1 and Q2 connected to the reactor L1 among the switching elements Q1 to Q4 is performed a predetermined number of times. By such control, it is possible to reduce the harmonic current by improving the power source power factor and boost the DC voltage.

- FIG. 8 is an explanatory diagram showing temporal changes in the AC power supply voltage vs, the circuit current is, the current ish flowing through the shunt resistor R1, and the driving pulses of the switching elements Q1 to Q4 in the partial switching control.

- FIG. 8 shows an example in which the reactor L1 is short-circuited only twice per shot, that is, half a cycle.

- the converter control unit 15d turns on / off the switching elements Q1 and Q2 alternately at a predetermined number of times and with a predetermined pulse width. That is, converter control unit 15d operates to turn on / off switching elements Q1 and Q2 alternately as shown by waveforms W8D and W8E in FIG. 8 immediately after the zero cross timing at which the positive / negative of AC power supply voltage vs is switched. Is performed a predetermined number of times. Further, as shown by waveforms W8F and W8G, converter control unit 15d sets on / off states of switching elements Q3 and Q4 in synchronization with the polarity of AC power supply voltage vs.

- FIG. 9 is an explanatory diagram showing the flow of current when the power factor correction operation is performed in a half cycle in which the AC power supply voltage vs is positive polarity.

- the AC power supply G ⁇ reactor L1 ⁇ switching element Q2 ⁇ switching element Q4 ⁇ AC power supply G is short-circuited, as shown by the dashed arrow in FIG.

- the power factor correction current isp flows. Since the switching element Q4 is assumed to be in a synchronous live operation described later, the short circuit current isp flows through the on-resistance portion, not the parasitic diode D4. At this time, the energy represented by the following (Equation 2) is stored in the reactor L1. Note that I sp shown in (Expression 2) is an effective value of the short-circuit current isp.

- the converter control unit 15d performs the “synchronous rectification operation”. That is, converter control unit 15d switches switching element Q1 from off to on (see waveform W8D in FIG. 8), and switches switching element Q2 from on to off (see waveform W8E in FIG. 8). During this period, the switching element Q3 is maintained in the off state (see waveform W8F in FIG. 8).

- FIG. 8 is a diagram illustrating the case of 2 shots (when the power factor improvement operation is performed twice), but 3 shots (the power factor improvement operation is performed 3 times), 4 shots (power factor improvement operation 4)

- the number of power factor improvement operations may be increased.

- the short-circuit current isp in FIG. 9 also during the power factor correction operation by the switching element Q2.

- the current flows not to the parasitic diode D4 of the switching element Q4 but to the on-resistance portion, high-efficiency operation is possible.

- the converter control unit 15d turns on the switching elements Q1 and Q4 in the section in which the circuit current is flows. Therefore, since the conduction loss between the switching elements Q1 and Q4 can be reduced, high-efficiency operation is possible.

- FIG. 10 is an explanatory diagram of partial switching control in a half cycle in which the AC power supply voltage vs is positive.

- the horizontal axis in FIG. 10 is time.

- a waveform W10A in FIG. 10 shows the AC power supply voltage vs in the positive half cycle.

- a waveform W10B in FIG. 10 is a circuit current is, a short-circuit current isp, and a sinusoidal ideal current.

- Waveforms W10C, W10D, and W10E in FIG. 10 are drive pulses for the switching elements Q2, Q4, and Q1. As shown in the “ideal current” of the waveform W10B in FIG. 10, it is ideal that the sine wave circuit current is flows in phase with the AC power supply voltage vs.

- the switching element Q2 when the switching element Q2 is off, the synchronous rectification operation is performed with the switching element Q1 in the on state, so that high-efficiency operation is possible.

- the switching element Q4 when the power factor correction operation is not performed as described above, synchronous rectification is performed by turning on the switching element Q4 at a timing when the detection value of the shunt current ish exceeds the determination value a. High-efficiency operation is possible.

- a dead time is provided for a predetermined time in order to prevent a vertical short circuit of the smoothing capacitor C1.

- the switching elements Q1 and Q2 are turned on / off alternately (see waveforms W11D and W11E). Further, in synchronization with the polarity of the AC power supply voltage vs, the switching element Q3 is turned on (see waveform W11F) and the switching element Q4 is turned off (see waveform W11G). Note that the on-duty of the switching elements Q1, Q2 is appropriately set so that the circuit current is approximates a sine wave.

- the circuit current is (instantaneous value) in the power conversion device 1 is expressed by the following (Equation 3).

- Vs is an effective value of the AC power supply voltage vs

- Kp is a current control gain

- Vd is a DC voltage

- ⁇ is an angular frequency.

- circuit current is (instantaneous value) and the circuit current Is (effective value) is expressed by the following (Equation 5).

- the circuit current is (instantaneous value) is detected by the shunt resistor R1

- the circuit current Is (effective value) is detected by the current detector 11.

- the on-duty d (conduction ratio) of the switching element Q2 is expressed by the following (Equation 8). The same applies to the on-duty d of the switching element Q1 in the half cycle in which the AC power supply voltage vs is negative.

- the DC voltage Vd can be boosted to a times the AC power supply voltage Vs (effective value) by controlling Kp ⁇ Is shown in (Equation 7).

- the on-duty d of the switching element Q2 (or the switching element Q1) at that time is given by the above (Formula 8).

- the boost ratio m is set by the boost ratio control unit 15b (see FIG. 9) based on the load detected by the load detection unit 14. For example, the step-up ratio m is set to a larger value as the load is larger.

- FIG. 12 is an explanatory diagram showing the on-duty of the switching elements Q1, Q2 in the high-speed switching control in the half cycle in which the AC power supply voltage vs is positive.

- the horizontal axis in FIG. 12 represents the time in the positive half cycle of the AC power supply voltage vs (the elapsed time from the start of the positive half cycle), and the vertical axis represents the on-duty d_Q1, switching elements Q1, Q2. d_Q2.

- the broken line in FIG. 12 is the on-duty d_Q1 of the switching element Q1 when the dead time dtx is not considered.

- the solid line is the on-duty d_Q1 of the switching element Q1 when the dead time dtx is considered.

- a two-dot chain line is the on-duty d_Q2 of the switching element Q2.

- the on-duty d_Q1 of the switching element Q1 indicated by the broken line is set to be proportional to the AC power supply voltage Vs (effective value), for example.

- the on-duty d_Q2 of the switching element Q2 indicated by the two-dot chain line is set as a value obtained by subtracting the on-duty d_Q1 of the switching element Q1 from 1.0.

- the AC power supply voltage vs and the circuit current is have a sine wave waveform, and the AC power supply voltage vs and the circuit current is are substantially in phase. That is, it can be seen that the power factor is improved by performing high-speed switching control.

- the on-duty d_Q2 of the switching element Q2 is set by the following (Equation 9).

- the on-duty d_Q1 of the switching element Q1 is set by the following (Equation 10).

- FIG. 14 is an explanatory diagram showing the on-duty d_Q2 of the switching element Q2 when the current phase delay due to the reactor L1 is not considered and when the current phase delay is considered in the high-speed switching control.

- the horizontal axis in FIG. 14 is the elapsed time (time) from the start of the positive half cycle of the AC power supply voltage vs, and the vertical axis is the on-duty of the switching element Q2 in the high-speed switching control.

- the solid line is the on-duty of the switching element Q2 when the current phase delay due to the reactor L1 is not taken into consideration.

- a broken line is the on-duty of the switching element Q2 when the delay of the current phase due to the reactor L1 is taken into consideration. As shown by the broken line in FIG. 14, by setting the on-duty of the switching element Q2, a sine-wave circuit current is can flow even when the inductance of the reactor L1 is large.

- FIG. 15 is an explanatory diagram in a case where overcurrent flows when performing synchronous rectification control and protection control is performed.

- a waveform HIN_1 in the figure is a drive pulse for the switching element Q1 output from the converter control unit 15d to the HIN terminal (see FIG. 2) of the drive circuit IC1.

- LIN_1 is a driving pulse for the switching element Q2 output from the converter control unit 15d to the LIN terminal of the driving circuit IC1.

- HIN_2 is a drive pulse of the switching element Q3 output from the converter control unit 15d to the HIN terminal of the drive circuit IC2.

- LIN_2 is a drive pulse of the switching element Q4 output from the converter control unit 15d to the LIN terminal of the drive circuit IC2.

- vs is the waveform of the AC power supply voltage (instantaneous value) and is is the circuit current (instantaneous value).

- Ish is a current waveform flowing through the shunt resistor R1.

- vsh is a voltage waveform generated in the shunt resistor R1.

- vtr is a voltage waveform of the ITrip terminal with reference to the GND terminal of the drive circuit IC1. Actually, a negative voltage such as a dotted line is generated.

- the drive circuit IC1 is not driven in the range of the negative voltage (driven in the range of 0 V to Vcc), the negative voltage such as the dotted line is generated at the ITrip terminal. The voltage is not detected.

- “Fault” is an output voltage waveform of the “Fault” terminal of the drive circuit IC1.

- FIG. 15 is a diagram showing waveforms at various parts when overcurrent protection is performed when synchronous rectification control is being executed.

- a section T1 is an area where the AC power supply voltage vs is a positive half cycle.

- a section T2 is a half-cycle area in which the AC power supply voltage vs is negative.

- FIG. 16 is a diagram showing the flow of the circuit current is in the positive half cycle.

- FIG. 17 is a diagram showing the flow of the circuit current is in the negative half cycle.

- switching elements Q1 and Q4 are turned on in the positive half cycle shown in FIG.

- switching elements Q2 and Q3 are turned on. After that, it becomes the region of the section T3 shown in FIG. 15, and the AC power supply voltage vs again becomes a positive half cycle.

- the circuit current is exceeds the current threshold value tha due to load fluctuation or the like.

- the converter control unit 15d detect this, the converter control unit 15d outputs an off signal (0 V) to the switching elements Q1 to Q4, thereby turning off the switching elements Q1 to Q4.

- a time dt11 shown in FIG. 15 elapses until the switching elements Q1 to Q4 are turned off. This is the time that elapses for calculation in the control unit 15 after detecting the overcurrent.

- the load H such as an inverter or a motor connected to the power conversion device 1 may be stopped.

- FIG. 18 is a diagram illustrating waveforms of respective units when overcurrent protection is performed when partial switching control is performed.

- the sections T1 and T3 are positive half cycles of the AC power supply voltage vs

- the section T2 is a negative half cycle of the AC power supply voltage vs.

- an example in the case of two shots is shown as partial switching control.

- the partial switching control is operating without any particular problem.

- the on-time of the first shot is extended for some reason, and the circuit current is exceeds the current threshold value tha.

- This time period dt12 is a section in which the power factor improving operation is performed in which the switching elements Q2 and Q4 are turned on, so that no current flows through the shunt resistor R1, and current detection by the shunt resistor R1 is performed. This is a section that cannot be performed.

- FIG. 19 is a diagram illustrating the flow of the circuit current is during the power factor correction operation.

- this power factor correction operation is completed and the switching elements Q1 and Q4 are switched to the synchronous rectification operation, the current flows through the shunt resistor R1. Accordingly, it is possible to detect current as an overcurrent. Then, an overcurrent is detected during the period of the synchronous rectification operation, and the switching elements Q1 to Q4 are turned off, so that the synchronous rectification operation and the partial switching control are stopped, and the circuit of each part is protected.

- the time dt13 elapses until the switching elements Q1 to Q4 are turned off.

- the load H such as an inverter or a motor connected to the power conversion device 1 may be stopped.

- FIG. 20 is a first waveform diagram when overcurrent protection is performed when the smoothing capacitor C1, that is, the DC voltage Vd is short-circuited.

- the short-circuit current has a larger current gradient than the overcurrent in the steady state as in the patterns [1] and [2] described above, and an excessive current flows in a shorter time. For this reason, it is preferable to perform protection control more quickly. Therefore, in the power conversion device 1 of the present embodiment, when an overcurrent is detected in the drive circuit IC1 that drives the switching elements Q1 and Q2, the switching elements Q1 and Q2 are forcibly turned off on the circuit. It has a protection function.

- FIG. 21 is a diagram illustrating a current path of the short-circuit current ist when the DC voltage Vd is short-circuited in the comparative example.

- the diodes D5 and D6 transmission elements

- the comparative example shown in FIG. 21 is different in that the diodes D5 and D6 are not provided.

- the short-circuit current ist flows through the shunt resistor R1 in the direction of the arrow.

- the voltage generated in the shunt resistor R1 is a negative voltage at the connection point N5, that is, the GND reference that is the reference potential of the converter control unit 15d, and the detected voltage is regarded as 0 V by the converter control unit 15d. This short-circuit current cannot be detected.

- the converter control part 15d in order to protect each part from the short-circuit current of the DC voltage Vd, the converter control part 15d is used as in the patterns [1] and [2] described above (soft Instead of protecting (in terms of software), the protection function of the drive circuit IC1 is used. In other words, overcurrent protection is performed in hardware. For this reason, as in the processing described above, the time delay until the switching elements Q1 and Q2 are turned off after detecting the overcurrent can be reduced and the switching elements Q1 and Q2 can be quickly turned off. Even when an overcurrent that is fast in time and has a large current value, such as a short-circuit current, can be reliably protected.

- a voltage vtr is generated at the Itrip terminal of the drive circuit IC1 with reference to the GND terminal as shown.

- the protection circuit in the drive circuit IC1 operates to turn off the switching elements Q1 and Q2.

- a voltage of 0 V is output from the fault terminal of the drive circuit IC1.

- a protection circuit such as the drive circuit IC1 is omitted from the drive circuit IC2 that drives the switching elements Q3 and Q4 in order to make the configuration cheaper.

- the switching elements Q3 and Q4 are also quickly turned off, similarly to the switching elements Q1 and Q2.

- the switching elements Q3, Q4 Cannot be given a quick off command. Therefore, as shown in FIG. 20, the switching element Q4 (the switching element Q3 when the AC power supply voltage vs is a negative cycle) operates even after the short-circuit current is passed and the switching elements Q1 and Q2 are turned off. In some cases, the device may be destroyed.

- the diodes D5 and D6 are connected between the fault terminal of the drive circuit IC1 and the HIN terminal and LIN terminal of the drive circuit IC2, thereby short-circuiting. Almost simultaneously with the passage of current to turn off switching elements Q1 and Q2, the switching elements Q3 and Q4 are also turned off.

- FIG. 22 is a diagram illustrating a current path of the short-circuit current ist when the DC voltage Vd is short-circuited in the power conversion device 1 (see FIG. 2) of the present embodiment.

- FIG. 23 is a waveform diagram of each part in the state shown in FIG. 22, that is, the short-circuit state of the DC voltage Vd.

- the switching element Q1 which should be turned off in order to perform the power factor correction operation, is turned on by mistake for some reason, and the short circuit current ist (FIG. 22) occurs.

- the converter control unit 15d cannot detect this short-circuit current by the shunt resistor R1.

- the switching elements Q1 and Q2 can be turned off using the protection circuit in the drive circuit IC1 as described above.

- this protection circuit is activated, the Fault terminal of the drive circuit IC1 outputs 0V almost simultaneously. Therefore, the potentials at the HIN terminal and LIN terminal of the drive circuit IC2 become 0V via the diodes D5 and D6 even if a drive pulse is output from the ports P5 and P6, and the switching elements Q3 and Q4 are forced. Will be off.

- the power conversion device of the present embodiment can perform the protective operation reliably by quickly turning off the switching elements Q1 to Q4. . Further, in addition to turning off the switching elements Q1 to Q4, the load H such as an inverter or a motor connected to the power conversion device 1 may be stopped.

- the power conversion device performs current detection using the shunt resistor R1 for a steady overcurrent with a low speed, and turns off the switching elements Q1 to Q4 by the converter control unit 15d.

- the short-circuit current ist with a fast rising speed is protected by quickly turning off the switching elements Q1 to Q4 in terms of circuit.

- the power conversion device of this embodiment can reliably protect an element from an overcurrent or a short-circuit current. The element can be protected while using an inexpensive drive circuit IC having no protection function like the drive circuit IC2.

- the converter control unit 15d (see FIG. 1) performs, for example, synchronous rectification control in a low load region where the load is relatively small, partial switching control in a rated operation region, and high speed switching control in a high load region where the load is relatively large. I do.

- the diode rectification control may be performed when the load is very small, or the diode rectification may not be performed.

- a waveform W24A in FIG. 24 is a waveform diagram of the AC power supply voltage vs and the circuit current is in the positive half cycle in the partial switching control.

- the peak value is1 shown is the peak value of the circuit current is in the partial switching control.

- a waveform W24B is a waveform diagram of the AC power supply voltage vs and the circuit current is in the positive half cycle in the high-speed switching control.

- a peak value is2 shown in the waveform W24B is a peak value of the circuit current is in the high-speed switching control. As shown by the waveform W24B, the peak value is2 of the circuit current is in the high-speed switching control is smaller than the peak value is1 of the circuit current is in the partial switching control.

- the power factor in the high-speed switching control is higher than the power factor in the partial switching control, so that the DC voltage Vd is boosted excessively in the high-speed switching control.

- the on-duty of the switching elements Q1, Q2 is adjusted so that the peak value is1> the peak value is2. That is, when switching from one of the partial switching control and the high-speed switching control to the other, converter control unit 15d gradually changes the on-duty of switching elements Q1 and Q2 so as to suppress fluctuations in DC voltage Vd of smoothing capacitor C1. Make adjustments. Thereby, when shifting from one of the partial switching control and the high-speed switching control to the other, the fluctuation of the DC voltage Vd is suppressed, and the DC voltage Vd gradually changes.

- the converter control unit 15d switches the control mode at the zero cross timing of the AC power supply voltage vs.

- the converter control unit 15d switches from partial switching control to high-speed switching control at the zero cross timing of the AC power supply voltage vs.

- the control mode is switched, it is possible to prevent the control from becoming unstable and the DC voltage Vd from fluctuating.

- the current is actively supplied to the switching elements Q1 to Q4 by performing the synchronous rectification control at the time of low load.

- loss in the parasitic diodes D1 to D4 can be suppressed, and power conversion can be performed with high efficiency.

- partial switching control is performed at the rated load, and the switching elements Q1 and Q2 are alternately switched a predetermined number of times. Thereby, boosting, power factor improvement, and harmonic suppression can be performed. In addition, switching loss can be reduced because the number of times of switching is small compared to high-speed switching control.

- high-speed switching control is performed at high load so that the switching elements Q1 and Q2 are alternately switched at a predetermined cycle. Thereby, boosting, power factor improvement, and harmonic suppression can be performed.

- the circuit current is has a sine wave shape (see the waveform W11B in FIG. 11), and thus is particularly effective in improving the power factor and suppressing harmonics.

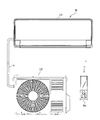

- FIG. 25 is a schematic configuration diagram of an air conditioner W according to the second embodiment.

- the air conditioner W includes an indoor unit U1, an outdoor unit U2, a pipe k that connects the two, and a remote controller Re.

- the air conditioner W is a device that performs air conditioning (cooling operation, heating operation, dehumidifying operation, etc.) by circulating a refrigerant in a known heat pump cycle.

- the remote controller Re transmits / receives predetermined various signals (operation / stop command, change of set temperature, setting of timer, change of operation mode, etc.) to and from the indoor unit U1.

- FIG. 26 is a cooling system diagram of the air conditioner W.

- the indoor unit U1 includes an indoor heat exchanger 44 and an indoor fan F2.

- the outdoor unit U2 includes the power conversion device 1, the inverter 2, the compressor 41 incorporating the motor 41a, the outdoor heat exchanger 42, and the expansion valve 43.

- the indoor unit U1 and the outdoor unit U2 are connected via a pipe k through which a refrigerant flows, and are connected via a communication line (not shown).

- the power conversion device 1 in the outdoor unit U ⁇ b> 2 converts the AC voltage supplied from the AC power supply G into a DC voltage and supplies it to the inverter 2.

- the inverter 2 converts the DC voltage into an AC voltage having an arbitrary frequency by, for example, PWM control (Pulse Width Modulation), and drives the motor 41a to rotate.

- PWM control Pulse Width Modulation

- the compressor 41 compresses the refrigerant when the motor 41a is driven to rotate.

- the outdoor heat exchanger 42 performs heat exchange between the indoor air sent from the outdoor fan F1 and the refrigerant.

- the expansion valve 43 expands and depressurizes the refrigerant flowing from the outdoor heat exchanger 42 or the indoor heat exchanger 44.

- the indoor heat exchanger 44 performs heat exchange between the indoor air sent from the indoor fan F2 and the refrigerant.

- the compressor 41, the outdoor heat exchanger 42, the expansion valve 43, the indoor heat exchanger 44, and the pipe k are connected in a ring shape so as to circulate the refrigerant in a heat pump cycle. Therefore, these are collectively referred to as “refrigerant circuit 4”.

- the air conditioner W may be for cooling or for heating. Moreover, you may provide the four-way valve (not shown) which switches the direction through which a refrigerant

- the control unit 15 includes the circuit current Is (effective value) detected by the current detection unit 11 (see FIG. 1), and predetermined threshold values I1 (first threshold value) and I2 (second threshold value). Is different from the first embodiment in that the control mode of the power converter 1 is switched according to the result. A process for switching the control mode will be described.

- FIG. 27 is a diagram illustrating a relationship between the magnitude of the load, the control mode, and the operation region of the device in the second embodiment.

- a region where the circuit current Is is less than the threshold value I1 is a region where the magnitude of the load (that is, the circuit current Is which is an effective value) is relatively small.

- the control unit 15 selects “synchronous rectification control” as the control mode so as to achieve high efficiency.

- the region where the circuit current Is is greater than or equal to the threshold value I1 and less than the threshold value I2 has a larger load than the intermediate operation region, and is a region where the motor 41a of the compressor 41 (that is, the load H shown in FIG. 1) can be rated. It is. In the air conditioner W, this region is referred to as a “rated operation region”. In this region, the control unit 15 selects “partial switching control” as the control mode, and realizes boosting, power factor improvement, and suppression of harmonic current.

- the region where the circuit current Is is equal to or greater than the threshold value I2 is a region where the load is relatively large.

- the operation region corresponds to the case where the heating operation is performed when the outside air temperature is very low, or the case where the cooling operation is performed when the outside air temperature is very high.

- this region is referred to as a “low temperature heating / high load region”.

- a part of “low temperature heating / high load region” overlaps with “rated operation region”.

- the control unit 15 selects “high-speed switching control” as the control mode, selects “synchronous rectification control”, and performs step-up, power factor improvement, and harmonic suppression. I am doing so.

- the magnitudes of the threshold values I1 and I2 described above may be set as appropriate based on prior experiments and simulations.

- FIG. 28 is a flowchart of a control program executed by the control unit 15 of the power conversion device 1. It is assumed that the motor 41a (see FIG. 26) is driven at the time of “START” in FIG.

- the control unit 15 reads the circuit current Is (effective value) detected by the current detection unit 11.

- the control unit 15 determines whether or not the circuit current Is read in step S101 is less than a threshold value I1 (first threshold value). That is, the control unit 15 determines whether or not the circuit current Is is included in the “intermediate operation region” (see FIG. 27).

- a threshold value I1 first threshold value

- step S102 When the circuit current Is is less than the threshold value I1 (S102: Yes), the process of the control unit 15 proceeds to step S103, and the control unit 15 executes synchronous rectification control.

- the control unit 15 executes synchronous rectification control.

- step S104 the control unit 15 determines whether or not the circuit current Is is less than the threshold value I2 (second threshold value). That is, the control unit 15 determines whether or not the circuit current Is is included in the “rated operation region” (see FIG. 27). As described above, the threshold value I2 is larger than the threshold value I1.

- step S105 the control unit 15 performs partial switching control. As described above, by performing the partial switching control in the rated operation region, it is possible to perform boosting, power factor improvement, and harmonic suppression as described in the first embodiment.

- step S104 the process of the control unit 15 proceeds to step S106.

- step S106 the control unit 15 executes high-speed switching control. As a result, even if a large circuit current is flows in the high load operation region, the power factor can be improved and harmonics can be suppressed.

- the process of the control unit 15 returns to “START” (RETURN).

- the diode rectification control see FIGS. 3 and 4) described in the first embodiment may be performed.

- the present invention is not limited to the above-described embodiments, and various modifications can be made.

- the above-described embodiments are illustrated for easy understanding of the present invention, and are not necessarily limited to those having all the configurations described.

- a part of the configuration of an embodiment can be replaced with the configuration of another embodiment, and the configuration of another embodiment can be added to the configuration of an embodiment.

- the control lines and information lines shown in the figure are those that are considered necessary for the explanation, and not all the control lines and information lines that are necessary on the product are shown. Actually, it may be considered that almost all the components are connected to each other. Examples of possible modifications to the above embodiment are as follows.

- FIG. 29 is a block diagram of a power converter 1A according to the first modification.

- a power conversion device 1A shown in FIG. 29 has a configuration in which a reactor L2 is added between the current detection unit 11 and the AC power supply G in the power conversion device 1 (see FIG. 1) of the first embodiment.

- Reactor L2 is provided on wiring hb that connects connection point N2 and AC power supply G.

- FIG. 30 is a block diagram of a power conversion device 1B according to a second modification.

- the power conversion device 1B shown in FIG. 30 uses IGBTs (Insulated-Gate-Bipolar-Transistors) instead of MOSFETs as the switching elements Q1, Q2 connected to the reactor L1 via the connection point N1. This is different from the first embodiment (see FIG. 1). As described above, even when the IGBT is used as the switching elements Q1 and Q2, the same effect as that of the first embodiment is obtained.

- IGBTs Insulated-Gate-Bipolar-Transistors

- FRD Flust-Recovery-Diode

- SiC-SBD Silicon-Carbide-Schokky Barrier-Diodes

- a super junction MOSFET having a low on-resistance may be used as the switching elements Q1 to Q4.

- SJMOSFET super junction MOSFET

- trr time during which the reverse recovery current flows

- reverse recovery current is the moment when the voltage applied to the parasitic diodes D1 to D4 is switched from the forward voltage to the reverse voltage. It is a flowing current.

- SJMOSFET having a reverse recovery time of 300 nsec or less as switching elements Q1 to Q4

- loss can be reduced and further efficiency can be improved.

- switching elements Q1 to Q4 having an on-resistance of 0.2 ⁇ or less. This can reduce conduction loss in switching elements Q1-Q4.

- the reverse recovery time of the switching elements Q1, Q2 is preferably shorter than that of the switching elements Q3, Q4.

- the switching elements Q1 and Q2 are turned on / off a predetermined number of times every half cycle of the AC power supply voltage vs. Therefore, by using switching elements Q1 and Q2 having a short reverse recovery time, the reverse recovery current is reduced, so that the switching loss can be reduced.

- reverse recovery current does not occur during the power factor correction operation, and therefore, the reverse recovery time is relatively long and the on-resistance is relatively small with respect to switching elements Q1 and Q2. Also good.

- switching elements Q1 to Q4 for example, SiC (Silicon Carbide) -MOSFET or gallium nitride (GaN) element may be used. Thereby, the energy loss of the power converter device 1 can be further reduced, and high efficiency can be achieved.

- SiC Silicon Carbide

- GaN gallium nitride

- FIG. 31 is a block diagram of a power conversion device 1C according to a third modification.

- a power conversion device 1C illustrated in FIG. 31 has a configuration in which a current sensor CT is newly added to the wiring ha in the power conversion device 1 according to the first embodiment illustrated in FIG.

- a current transformer or a Hall element may be used for the current sensor CT.

- the synchronous rectification control of the switching elements Q3 and Q4 is performed using the current value detected by the shunt resistor R1 so that no backflow current is generated.

- the current since the current during the power factor correction operation cannot be detected, the current is detected when the power factor correction operation is off. Therefore, as described above, in order to prevent the backflow of the current to the AC power supply side, the current is detected by the shunt resistor, and the state where the circuit current is surely detected is detected, and then the synchronous live flow of the switching element Q3 or Q4 Was moving. Therefore, synchronous rectification is not performed for the first shot.

- FIG. 32 shows AC power supply voltage vs, circuit current is, power factor correction current isp, shunt current ish, and drive pulses of switching elements Q1 to Q4 when partial switching control (two shots) is performed in the circuit configuration of FIG.

- FIG. 6 is a waveform diagram showing temporal changes (waveforms W32A to W32G).

- FIG. 33 is a block diagram of a control system and the like of the power conversion device according to the fourth modification.

- transistors Tr1 and Tr2 are applied instead of the diodes D5 and D6 which are transfer elements.

- the transistors Tr1 and Tr2 are turned on when the output voltage waveform “Fault” output from the drive circuit IC1 becomes 0V, and a voltage of 0V is applied to the HIN terminal and the LIN terminal of the drive circuit IC2.

- other switching elements such as IGBTs and MOSFETs may be applied. Even in such a configuration, it is possible to quickly protect each part against a short-circuit current generated in the smoothing capacitor C1.

- FIG. 34 is an explanatory diagram regarding switching of the control mode of the power conversion device according to other various modifications.

- Control methods X1 to X8 in the figure show control mode selection methods in other various modifications.

- the hardware configuration of the power conversion device in these modified examples is the same as that of the first and second embodiments.

- synchronous rectification means that “synchronous rectification control” is selected as the control mode.

- synchronous rectification + partial SW means that the partial switching control includes the above-described synchronous rectification control (that is, the power factor correction operation and the synchronous rectification control are alternately performed).

- Synchronous rectification + high-speed SW means that high-speed switching control includes synchronous rectification control.

- diode rectification + partial SW means that diode rectification control is included in the partial switching control.

- the “diode rectification control” is an operation of flowing the circuit current is through the parasitic diode D1 and the like. That is, “diode rectification + partial SW” means that partial switching control is performed by alternately performing power factor correction operation and diode rectification control.

- “Diode rectification + high-speed SW” means that diode rectification control is included in high-speed switching control.

- control method X1 when the load (for example, the circuit current Is detected by the current detection unit 11) is equal to or greater than the threshold value I1, partial switching control including synchronous rectification control is performed, and the load is set to the threshold value I1. If it is less, synchronous rectification control may be performed.

- the control method X2 when the load is equal to or higher than the threshold value I1, high-speed switching control including synchronous rectification control is performed, and when the load is less than the threshold value I1, synchronous rectification control is performed. You may do it.

- the control method X3 shown in FIG. 34 is the same as the control method described in the second embodiment (see FIGS. 27 and 28). Further, for example, as shown in the control method X4, when the load is greater than or equal to the threshold value I1, partial switching control including diode rectification control is performed, and when the load is less than the threshold value I1, synchronous rectification control is performed. You may do it. By performing diode rectification control in this way, only one switching element is required to be turned on in a half cycle of the AC power supply voltage vs. Therefore, control can be simplified.

- control method X5 to X8 shown in FIG. 34 is omitted, but the control method may be appropriately set in consideration of efficiency, suppression of harmonics, boosting, and the like. For example, if the main objectives are high efficiency, suppression of harmonic current, and boosting, any one of the control methods X1 to X3 may be selected. Further, when the main purpose is not to increase the efficiency but to suppress and boost the harmonic current, the control methods X4 to X6 may be selected.

- the current value of the inverter 2 (see FIG. 26) connected to the output side of the smoothing capacitor C1 (see FIG. 1), the rotation speed of the motor 41a (see FIG. 26) connected to the inverter 2, and the motor voltage

- the control mode may be switched based on a modulation rate that is a ratio with the voltage applied to the inverter.

- the current (rotational speed and modulation factor of the motor 41a) flowing through the inverter 2 also increases. Therefore, the relationship between the load region divided by a plurality of threshold values and the current flowing through the inverter 2 (the rotational speed and modulation factor of the motor 41a) is the same as that in FIG.

- each embodiment demonstrated the structure which detects the circuit current is by shunt resistor R1 (refer FIG. 1), it is not restricted to this.

- a high-speed current transformer may be used instead of the shunt resistor R1.

- a rectifier diode (not shown) may be connected in antiparallel to each of the switching elements Q1 to Q4.

- each embodiment demonstrated the structure which the power converter device 1 is a 2 level converter it is applicable also to a 3 level or 5 level converter, for example.

- the motor 41a of the compressor 41 (see FIG. 26) described in the second embodiment may be driven by performing power conversion using any one of the control methods X1 to X8 (see FIG. 34). Good.

- the apparatus which can apply the power converter device 1 is not restricted to this.

- the power conversion device 1 may be mounted on a vehicle such as a train or an automobile, a refrigerator, a water heater, a washing machine, a vehicle such as a ship or an aircraft, or a charging facility for a battery.

- each of the above-described configurations, functions, processing units, processing means, etc. may be partially or entirely realized by hardware such as an integrated circuit.

- Each of the above-described configurations, functions, and the like may be realized by software by the processor interpreting and executing a program that realizes each function.

- Information such as programs, tables, and files for realizing each function may be recorded on a recording device such as a memory or a hard disk, or a recording medium such as a flash memory card or a DVD (Digital Versatile Disk).

Abstract

In order to provide a power conversion device that is inexpensive and that prevents damage to elements, the present invention is provided with: a first drive circuit (IC1) that drives a first and a second switch element (Q1, Q2), detects overcurrent in a current flowing in a bridge circuit, and has an output terminal (Fault terminal) that outputs a prescribed voltage signal (0V) when overcurrent is detected; a second drive circuit (IC2) that drives a third and a fourth switch element (Q3, Q4); and transmission elements (D5, D6) that are connected between the output terminal (Fault terminal) of the first drive circuit (IC1) and an input terminals (LIN, HIN) of the second drive circuit (IC2), and transmit the voltage signal (0V) to the input terminals (LIN, HIN).

Description

本発明は、電力変換装置および空気調和機に関する。

The present invention relates to a power conversion device and an air conditioner.

電車、自動車、空気調和機等には、交流電圧を直流電圧に変換する電力変換装置(直流電源装置、コンバータ)が搭載されている。そして、電力変換装置から出力される直流電圧をインバータによって所定周波数の交流電圧に変換し、この交流電圧をモータ等の負荷に印加するようになっている。このような電力変換装置において、高調波電流規制に準拠して高調波を抑制し、また、電力変換効率を高めて省エネルギ化を図ることが求められている。

例えば、下記特許文献1の要約書には、「コンバータ回路(2)のブリッジ回路(2a)の2つのダイオード(D1,D2)には、SiC素子を用いたMOS-FETのスイッチング素子(T1,T2)が並列接続されている。そして、スイッチング素子(T1,T2)に商用電源(5)の逆電圧が作用するタイミングで該スイッチング素子(T1,T2)がオンされる。これにより、確実に同期整流が行われる」と記載されている。 Trains, automobiles, air conditioners, and the like are equipped with a power conversion device (DC power supply device, converter) that converts AC voltage into DC voltage. And the direct-current voltage output from a power converter device is converted into the alternating voltage of a predetermined frequency with an inverter, and this alternating voltage is applied to loads, such as a motor. In such a power conversion device, it is required to suppress harmonics in accordance with the harmonic current regulation, and to improve power conversion efficiency to save energy.

For example, the abstract of the followingPatent Document 1 states that “the two diodes (D1, D2) of the bridge circuit (2a) of the converter circuit (2) are MOS-FET switching elements (T1, T2) using SiC elements. T2) are connected in parallel, and the switching elements (T1, T2) are turned on at the timing when the reverse voltage of the commercial power supply (5) acts on the switching elements (T1, T2). Synchronous rectification is performed ".

例えば、下記特許文献1の要約書には、「コンバータ回路(2)のブリッジ回路(2a)の2つのダイオード(D1,D2)には、SiC素子を用いたMOS-FETのスイッチング素子(T1,T2)が並列接続されている。そして、スイッチング素子(T1,T2)に商用電源(5)の逆電圧が作用するタイミングで該スイッチング素子(T1,T2)がオンされる。これにより、確実に同期整流が行われる」と記載されている。 Trains, automobiles, air conditioners, and the like are equipped with a power conversion device (DC power supply device, converter) that converts AC voltage into DC voltage. And the direct-current voltage output from a power converter device is converted into the alternating voltage of a predetermined frequency with an inverter, and this alternating voltage is applied to loads, such as a motor. In such a power conversion device, it is required to suppress harmonics in accordance with the harmonic current regulation, and to improve power conversion efficiency to save energy.

For example, the abstract of the following

ところで、特許文献1のようにダイオードによる整流回路ではなく、スイッチング素子を回路に含んだ回路構成においては、過電流や短絡電流による素子の破壊を確実に防ぐため保護制御を行うことが好ましい。しかし、保護制御を行うことはコストアップにつながる。

この発明は上述した事情に鑑みてなされたものであり、安価でありながら素子の破壊を防止できる電力変換装置および空気調和機を提供することを目的とする。 By the way, in a circuit configuration in which a switching element is included in a circuit instead of a rectifier circuit using a diode as inPatent Document 1, it is preferable to perform protection control in order to reliably prevent element destruction due to overcurrent or short-circuit current. However, performing protection control leads to an increase in cost.

This invention is made | formed in view of the situation mentioned above, and it aims at providing the power converter device and air conditioner which can prevent destruction of an element, although it is cheap.

この発明は上述した事情に鑑みてなされたものであり、安価でありながら素子の破壊を防止できる電力変換装置および空気調和機を提供することを目的とする。 By the way, in a circuit configuration in which a switching element is included in a circuit instead of a rectifier circuit using a diode as in

This invention is made | formed in view of the situation mentioned above, and it aims at providing the power converter device and air conditioner which can prevent destruction of an element, although it is cheap.

上記課題を解決するため本発明の電力変換装置にあっては、第1スイッチング素子と、前記第1スイッチング素子に直列に接続され前記第1スイッチング素子とともに第1レグを構成する第2スイッチング素子と、第3スイッチング素子と、前記第3スイッチング素子に直列に接続され前記第3スイッチング素子とともに第2レグを構成する第4スイッチング素子と、を有し、前記第1レグと前記第2レグとを並列接続したブリッジ回路と、交流電源と前記第1レグ間に設けられたリアクトルと、前記ブリッジ回路に接続され、前記ブリッジ回路から印加される電圧を平滑化し、直流電圧として出力する平滑コンデンサと、前記第1ないし第4スイッチング素子を制御する制御部と、前記平滑コンデンサの負極と前記第2スイッチング素子との間に設けられた電流センサと、前記第1および第2スイッチング素子を駆動するとともに、前記ブリッジ回路に流れる電流における過電流の有無を検出し、前記過電流を検出した場合に所定の電圧信号を出力する出力端子を有する第1の駆動回路と、前記第3および第4スイッチング素子を駆動する第2の駆動回路と、前記第1の駆動回路の前記出力端子と、前記第2の駆動回路の入力端子との間に接続され、前記電圧信号を前記入力端子に伝達する伝達素子と、を有することを特徴とする。

In order to solve the above problems, in the power conversion device of the present invention, a first switching element and a second switching element connected in series to the first switching element and constituting a first leg together with the first switching element; A third switching element, and a fourth switching element connected in series to the third switching element and forming a second leg together with the third switching element, wherein the first leg and the second leg A bridge circuit connected in parallel, a reactor provided between an AC power supply and the first leg, a smoothing capacitor connected to the bridge circuit, smoothing a voltage applied from the bridge circuit, and outputting as a DC voltage; A control unit that controls the first to fourth switching elements, a negative electrode of the smoothing capacitor, and the second switching element; Driving a first current sensor and a second switching element, detecting the presence or absence of overcurrent in the current flowing through the bridge circuit, and detecting the overcurrent, a predetermined voltage signal A first drive circuit having an output terminal for outputting the second drive circuit, a second drive circuit for driving the third and fourth switching elements, the output terminal of the first drive circuit, and the second drive circuit And a transmission element connected to the input terminal for transmitting the voltage signal to the input terminal.

本発明によれば、安価でありながら素子の破壊を防止できる。

According to the present invention, it is possible to prevent element destruction while being inexpensive.

[第1実施形態]

<電力変換装置の構成>

図1は、第1実施形態による電力変換装置1の全体ブロック図である。

電力変換装置1は、交流電源Gから印加される交流電源電圧Vsを直流電圧Vdに変換し、この直流電圧Vdを負荷H(インバータ、モータ等)に出力するコンバータである。電力変換装置1は、その入力側が交流電源Gに接続され、出力側が負荷Hに接続されている。 [First Embodiment]

<Configuration of power converter>

FIG. 1 is an overall block diagram of apower conversion device 1 according to the first embodiment.

Thepower conversion device 1 is a converter that converts an AC power supply voltage Vs applied from an AC power supply G into a DC voltage Vd, and outputs the DC voltage Vd to a load H (an inverter, a motor, etc.). The power conversion device 1 has an input side connected to the AC power supply G and an output side connected to the load H.

<電力変換装置の構成>

図1は、第1実施形態による電力変換装置1の全体ブロック図である。

電力変換装置1は、交流電源Gから印加される交流電源電圧Vsを直流電圧Vdに変換し、この直流電圧Vdを負荷H(インバータ、モータ等)に出力するコンバータである。電力変換装置1は、その入力側が交流電源Gに接続され、出力側が負荷Hに接続されている。 [First Embodiment]

<Configuration of power converter>

FIG. 1 is an overall block diagram of a

The

図1に示すように、電力変換装置1は、ブリッジ回路10と、リアクトルL1と、平滑コンデンサC1と、電流検出部11と、交流電圧検出部12と、直流電圧検出部13と、負荷検出部14と、シャント抵抗器R1と、制御部15と、を備えている。

As shown in FIG. 1, the power conversion device 1 includes a bridge circuit 10, a reactor L <b> 1, a smoothing capacitor C <b> 1, a current detection unit 11, an AC voltage detection unit 12, a DC voltage detection unit 13, and a load detection unit. 14, a shunt resistor R <b> 1, and a control unit 15.

ブリッジ回路10は、スイッチング素子Q1(第1スイッチング素子)と、スイッチング素子Q2(第2スイッチング素子)と、スイッチング素子Q3(第3スイッチング素子)と、スイッチング素子Q4(第4スイッチング素子)と、を備えている。

ブリッジ回路10は、その入力側が交流電源Gに接続され、出力側が負荷Hに接続されている。また、ブリッジ回路10のスイッチング素子Q1~Q4は、図1に示すように、ブリッジ形に接続されている。 Thebridge circuit 10 includes a switching element Q1 (first switching element), a switching element Q2 (second switching element), a switching element Q3 (third switching element), and a switching element Q4 (fourth switching element). I have.

Thebridge circuit 10 has an input side connected to an AC power source G and an output side connected to a load H. The switching elements Q1 to Q4 of the bridge circuit 10 are connected in a bridge shape as shown in FIG.

ブリッジ回路10は、その入力側が交流電源Gに接続され、出力側が負荷Hに接続されている。また、ブリッジ回路10のスイッチング素子Q1~Q4は、図1に示すように、ブリッジ形に接続されている。 The

The

スイッチング素子Q1~Q4は、例えば、MOSFET(Metal-Oxide-Semiconductor Field-Effect Transistor)であり、制御部15によってオン/オフが制御される。なお、スイッチング素子Q1~Q4としてMOSFETを用いることで、スイッチング損失を低減できるとともに、スイッチングを高速で行えるという利点がある。

また、スイッチング素子Q1は、その内部に寄生ダイオードD1を有している。寄生ダイオードD1は、スイッチング素子Q1のソースとドレインとの間に存在するpn接合の部分である。 The switching elements Q1 to Q4 are, for example, MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), and are turned on / off by thecontrol unit 15. Use of MOSFETs as the switching elements Q1 to Q4 has advantages that switching loss can be reduced and switching can be performed at high speed.

The switching element Q1 has a parasitic diode D1 therein. The parasitic diode D1 is a pn junction portion that exists between the source and drain of the switching element Q1.

また、スイッチング素子Q1は、その内部に寄生ダイオードD1を有している。寄生ダイオードD1は、スイッチング素子Q1のソースとドレインとの間に存在するpn接合の部分である。 The switching elements Q1 to Q4 are, for example, MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), and are turned on / off by the

The switching element Q1 has a parasitic diode D1 therein. The parasitic diode D1 is a pn junction portion that exists between the source and drain of the switching element Q1.

なお、スイッチング素子Q1の飽和電圧(オン状態におけるドレイン・ソース間電圧)は、寄生ダイオードD1の順方向の電圧降下よりも低いことが好ましい。これによって、寄生ダイオードD1に電流を流すよりも、スイッチング素子Q1のソース・ドレインに電流を流すほうが電圧降下は小さくなり、ひいては、導通損失を低減できるからである。換言すると、オフ状態のスイッチング素子Q1において寄生ダイオードD1に電流を流すよりも、オン状態のスイッチング素子Q1に電流を流すほうが導通損失は小さくなるようにしている。なお、他のスイッチング素子Q2~Q4についても同様のことがいえる。

Note that the saturation voltage (drain-source voltage in the on state) of the switching element Q1 is preferably lower than the voltage drop in the forward direction of the parasitic diode D1. This is because the voltage drop is smaller when the current is passed through the source / drain of the switching element Q1 than when the current is passed through the parasitic diode D1, thereby reducing the conduction loss. In other words, the conduction loss is smaller when a current is passed through the switching element Q1 in the on state than when a current is passed through the parasitic diode D1 in the switching element Q1 in the off state. The same applies to the other switching elements Q2 to Q4.

本実施形態で使用しているスイッチング素子Q1とスイッチング素子Q2の寄生ダイオードの逆回復時間(trr)は、スイッチング素子Q3とスイッチング素子Q4の寄生ダイオードの逆回復時間よりも相対的に小さい。これは、スイッチング素子Q1とスイッチング素子Q2は後述する力率改善動作時に寄生ダイオードに逆回復電流が発生してしまうため、スイッチング素子Q1とQ2はスイッチング素子Q3とQ4に対して相対的に寄生ダイオードの逆回復時間の小さい素子を使用することでスイッチング損失を低減するためである。

The reverse recovery time (trr) of the parasitic diodes of the switching elements Q1 and Q2 used in this embodiment is relatively shorter than the reverse recovery times of the parasitic diodes of the switching elements Q3 and Q4. This is because the switching elements Q1 and Q2 generate a reverse recovery current in the parasitic diode during the power factor correction operation described later, so that the switching elements Q1 and Q2 are relatively parasitic diodes relative to the switching elements Q3 and Q4. This is because switching loss is reduced by using an element having a short reverse recovery time.

図1に示すように、ブリッジ回路10は、スイッチング素子Q1,Q2が直列接続されてなる第1レグJ1と、スイッチング素子Q3,Q4が直列接続されてなる第2レグJ2と、が並列接続された構成になっている。

第1レグJ1において、スイッチング素子Q1のソースと、スイッチング素子Q2のドレインと、が接続され、その接続点N1は、配線haを介して交流電源Gに接続されている。なお、配線haは、その一端が交流電源Gに接続され、他端が前述した接続点N1に接続されている。 As shown in FIG. 1, thebridge circuit 10 includes a first leg J1 in which switching elements Q1 and Q2 are connected in series and a second leg J2 in which switching elements Q3 and Q4 are connected in series. It has a configuration.

In the first leg J1, the source of the switching element Q1 and the drain of the switching element Q2 are connected, and the connection point N1 is connected to the AC power supply G via the wiring ha. Note that the wiring ha has one end connected to the AC power supply G and the other end connected to the connection point N1 described above.

第1レグJ1において、スイッチング素子Q1のソースと、スイッチング素子Q2のドレインと、が接続され、その接続点N1は、配線haを介して交流電源Gに接続されている。なお、配線haは、その一端が交流電源Gに接続され、他端が前述した接続点N1に接続されている。 As shown in FIG. 1, the

In the first leg J1, the source of the switching element Q1 and the drain of the switching element Q2 are connected, and the connection point N1 is connected to the AC power supply G via the wiring ha. Note that the wiring ha has one end connected to the AC power supply G and the other end connected to the connection point N1 described above.

第2レグJ2において、スイッチング素子Q3のソースと、スイッチング素子Q4のドレインとが接続され、その接続点N2は、配線hbを介して交流電源Gに接続されている。なお、配線hbは、その一端が交流電源Gに接続され、他端が前述した接続点N2に接続されている。

In the second leg J2, the source of the switching element Q3 and the drain of the switching element Q4 are connected, and the connection point N2 is connected to the AC power supply G via the wiring hb. The wiring hb has one end connected to the AC power supply G and the other end connected to the connection point N2 described above.

スイッチング素子Q1のドレインと、スイッチング素子Q3のドレインと、は互いに接続され、その接続点N3は、配線hcを介して負荷Hに接続されている。なお、配線hcは、その一端が負荷Hに接続され、他端が前述した接続点N3に接続されている。

スイッチング素子Q2のソースと、スイッチング素子Q4のソースと、は互いに接続され、その接続点N4は、配線hdを介して負荷Hに接続されている。なお、配線hdは、その一端がスイッチング素子Q2,Q4のソースに接続され、他端が負荷Hに接続されている。 The drain of the switching element Q1 and the drain of the switching element Q3 are connected to each other, and the connection point N3 is connected to the load H through the wiring hc. Note that the wiring hc has one end connected to the load H and the other end connected to the connection point N3 described above.

The source of the switching element Q2 and the source of the switching element Q4 are connected to each other, and the connection point N4 is connected to the load H through the wiring hd. Note that the wiring hd has one end connected to the sources of the switching elements Q2 and Q4 and the other end connected to the load H.

スイッチング素子Q2のソースと、スイッチング素子Q4のソースと、は互いに接続され、その接続点N4は、配線hdを介して負荷Hに接続されている。なお、配線hdは、その一端がスイッチング素子Q2,Q4のソースに接続され、他端が負荷Hに接続されている。 The drain of the switching element Q1 and the drain of the switching element Q3 are connected to each other, and the connection point N3 is connected to the load H through the wiring hc. Note that the wiring hc has one end connected to the load H and the other end connected to the connection point N3 described above.

The source of the switching element Q2 and the source of the switching element Q4 are connected to each other, and the connection point N4 is connected to the load H through the wiring hd. Note that the wiring hd has one end connected to the sources of the switching elements Q2 and Q4 and the other end connected to the load H.

リアクトルL1は、交流電源Gから供給される電力をエネルギとして蓄え、このエネルギを放出することで昇圧や力率の改善を行うものである。リアクトルL1は、交流電源Gとブリッジ回路10とを接続する配線haに設けられている。

平滑コンデンサC1は、ブリッジ回路10から印加される電圧を平滑化して直流電圧にするものであり、配線hc,hdを介してブリッジ回路10の出力側に接続されている。また、平滑コンデンサC1は、その正極が配線hcを介してスイッチング素子Q1,Q3のドレインに接続され、負極が配線hdを介してスイッチング素子Q2,Q4のソースに接続されている。 The reactor L1 stores the electric power supplied from the AC power source G as energy, and releases the energy to increase the pressure and improve the power factor. The reactor L <b> 1 is provided on the wiring ha that connects the AC power supply G and thebridge circuit 10.

The smoothing capacitor C1 smoothes the voltage applied from thebridge circuit 10 into a DC voltage, and is connected to the output side of the bridge circuit 10 via the wirings hc and hd. The smoothing capacitor C1 has a positive electrode connected to the drains of the switching elements Q1 and Q3 via the wiring hc and a negative electrode connected to the sources of the switching elements Q2 and Q4 via the wiring hd.

平滑コンデンサC1は、ブリッジ回路10から印加される電圧を平滑化して直流電圧にするものであり、配線hc,hdを介してブリッジ回路10の出力側に接続されている。また、平滑コンデンサC1は、その正極が配線hcを介してスイッチング素子Q1,Q3のドレインに接続され、負極が配線hdを介してスイッチング素子Q2,Q4のソースに接続されている。 The reactor L1 stores the electric power supplied from the AC power source G as energy, and releases the energy to increase the pressure and improve the power factor. The reactor L <b> 1 is provided on the wiring ha that connects the AC power supply G and the

The smoothing capacitor C1 smoothes the voltage applied from the

電流検出部11は、ブリッジ回路10に流れる電流を実効値(平均電流)として検出するものであり、配線hbに設けられている。電流検出部11として、例えば、カレントトランスを用いることができる。交流電圧検出部12は、交流電源Gから印加される交流電源電圧vs(瞬時値)を検出するものであり、配線ha,hbに接続されている。

直流電圧検出部13は、平滑コンデンサC1の直流電圧Vdを検出するものであり、その正側が配線hcに接続され、負側が配線hdに接続されている。なお、直流電圧検出部13の検出値は、負荷Hに印加される電圧値が所定の目標値に達しているか否かの判定に用いられる。 Thecurrent detection unit 11 detects the current flowing through the bridge circuit 10 as an effective value (average current), and is provided in the wiring hb. As the current detection unit 11, for example, a current transformer can be used. The AC voltage detector 12 detects an AC power supply voltage vs (instantaneous value) applied from the AC power supply G, and is connected to the wirings ha and hb.

TheDC voltage detector 13 detects the DC voltage Vd of the smoothing capacitor C1, and its positive side is connected to the wiring hc and its negative side is connected to the wiring hd. Note that the detection value of the DC voltage detection unit 13 is used to determine whether or not the voltage value applied to the load H has reached a predetermined target value.

直流電圧検出部13は、平滑コンデンサC1の直流電圧Vdを検出するものであり、その正側が配線hcに接続され、負側が配線hdに接続されている。なお、直流電圧検出部13の検出値は、負荷Hに印加される電圧値が所定の目標値に達しているか否かの判定に用いられる。 The

The

負荷検出部14は、負荷Hに供給される電流すなわち負荷電流を検出するものであり、この負荷Hに設置されている。負荷検出部14として、例えば、シャント抵抗器を用いることができる。なお、負荷Hがモータである場合、負荷検出部14によってモータ電流を検出し、回転速度を推定するようにしてもよい。

シャント抵抗器R1は、配線hdを介して回路を流れる電流の瞬時値(瞬時電流)を検出するものであり、この配線hdに設けられている。 Theload detection unit 14 detects a current supplied to the load H, that is, a load current, and is installed in the load H. For example, a shunt resistor can be used as the load detection unit 14. When the load H is a motor, the load detection unit 14 may detect the motor current and estimate the rotational speed.

The shunt resistor R1 detects an instantaneous value (instantaneous current) of the current flowing through the circuit through the wiring hd, and is provided in the wiring hd.

シャント抵抗器R1は、配線hdを介して回路を流れる電流の瞬時値(瞬時電流)を検出するものであり、この配線hdに設けられている。 The

The shunt resistor R1 detects an instantaneous value (instantaneous current) of the current flowing through the circuit through the wiring hd, and is provided in the wiring hd.