WO2018056042A1 - フラット電線、フラット電線積層体及びフラット電線の固定構造 - Google Patents

フラット電線、フラット電線積層体及びフラット電線の固定構造 Download PDFInfo

- Publication number

- WO2018056042A1 WO2018056042A1 PCT/JP2017/031860 JP2017031860W WO2018056042A1 WO 2018056042 A1 WO2018056042 A1 WO 2018056042A1 JP 2017031860 W JP2017031860 W JP 2017031860W WO 2018056042 A1 WO2018056042 A1 WO 2018056042A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- electric wire

- flat

- self

- flat electric

- bonding

- Prior art date

Links

- 239000000463 material Substances 0.000 claims abstract description 23

- 239000004020 conductor Substances 0.000 claims abstract description 22

- 230000001747 exhibiting effect Effects 0.000 claims abstract description 11

- 239000010410 layer Substances 0.000 claims description 32

- 239000012790 adhesive layer Substances 0.000 claims description 9

- 239000000853 adhesive Substances 0.000 abstract description 8

- 239000011248 coating agent Substances 0.000 abstract description 5

- 238000000576 coating method Methods 0.000 abstract description 5

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 7

- 230000001070 adhesive effect Effects 0.000 description 7

- 239000011347 resin Substances 0.000 description 7

- 229920005989 resin Polymers 0.000 description 7

- 230000013011 mating Effects 0.000 description 6

- 229910052751 metal Inorganic materials 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 239000011247 coating layer Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 1

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910000881 Cu alloy Inorganic materials 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- MTAZNLWOLGHBHU-UHFFFAOYSA-N butadiene-styrene rubber Chemical class C=CC=C.C=CC1=CC=CC=C1 MTAZNLWOLGHBHU-UHFFFAOYSA-N 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 229920006173 natural rubber latex Polymers 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920006149 polyester-amide block copolymer Polymers 0.000 description 1

- -1 polyethylene methyl acrylate Polymers 0.000 description 1

- 239000005060 rubber Substances 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 229920003048 styrene butadiene rubber Polymers 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 239000005061 synthetic rubber Substances 0.000 description 1

- 150000003505 terpenes Chemical class 0.000 description 1

- 235000007586 terpenes Nutrition 0.000 description 1

- 125000000383 tetramethylene group Chemical group [H]C([H])([*:1])C([H])([H])C([H])([H])C([H])([H])[*:2] 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/08—Flat or ribbon cables

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B1/00—Layered products having a non-planar shape

- B32B1/08—Tubular products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/06—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of natural rubber or synthetic rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

- B32B15/082—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin comprising vinyl resins; comprising acrylic resins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

- B32B15/088—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

- B32B15/09—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin comprising polyesters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/20—Layered products comprising a layer of metal comprising aluminium or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/04—Layered products comprising a layer of natural or synthetic rubber comprising rubber as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B25/042—Layered products comprising a layer of natural or synthetic rubber comprising rubber as the main or only constituent of a layer, which is next to another layer of the same or of a different material of natural rubber or synthetic rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/04—Layered products comprising a layer of natural or synthetic rubber comprising rubber as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B25/08—Layered products comprising a layer of natural or synthetic rubber comprising rubber as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/12—Layered products comprising a layer of natural or synthetic rubber comprising natural rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/16—Layered products comprising a layer of natural or synthetic rubber comprising polydienes homopolymers or poly-halodienes homopolymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/18—Layered products comprising a layer of natural or synthetic rubber comprising butyl or halobutyl rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/34—Layered products comprising a layer of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/36—Layered products comprising a layer of synthetic resin comprising polyesters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/02—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by features of form at particular places, e.g. in edge regions

- B32B3/04—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by features of form at particular places, e.g. in edge regions characterised by at least one layer folded at the edge, e.g. over another layer ; characterised by at least one layer enveloping or enclosing a material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/266—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by an apertured layer, the apertures going through the whole thickness of the layer, e.g. expanded metal, perforated layer, slit layer regular cells B32B3/12

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B17/00—Insulators or insulating bodies characterised by their form

- H01B17/56—Insulating bodies

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/18—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances

- H01B3/30—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/02—Disposition of insulation

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/22—Installations of cables or lines through walls, floors or ceilings, e.g. into buildings

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/30—Installations of cables or lines on walls, floors or ceilings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/02—2 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/04—4 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/06—Coating on the layer surface on metal layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/20—Inorganic coating

- B32B2255/205—Metallic coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2270/00—Resin or rubber layer containing a blend of at least two different polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/20—Properties of the layers or laminate having particular electrical or magnetic properties, e.g. piezoelectric

- B32B2307/202—Conductive

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/08—Flat or ribbon cables

- H01B7/0815—Flat or ribbon cables covered with gluten for wall-fixing

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G5/00—Installations of bus-bars

- H02G5/02—Open installations

- H02G5/025—Supporting structures

Definitions

- This invention relates to a flat electric wire used as a wiring material.

- Patent Document 1 discloses that two electric wires having a self-bonding property in which a thermoplastic insulating coating layer is provided on the outer periphery of a linear conductor are twisted together, and the two electric wires are in contact with each other in the twisted state. Disclosed is a twisted pair electric wire in which insulating coating layers are fixed to each other.

- an object of the present invention is to enable an electric wire used as a wiring material to be easily and firmly fixed to another member.

- the flat electric wire according to the first aspect includes a flat conductor and a covering portion that covers the flat conductor in a flat form and at least one main surface exhibits self-joining properties.

- the second aspect is a flat electric wire according to the first aspect, wherein at least one main surface of the covering portion exhibits self-adhesiveness.

- the third aspect includes a plurality of flat electric wires according to the first or second aspect, and the plurality of flat electric wires are laminated in a state where main surfaces exhibiting self-bonding properties are bonded to each other in the respective covering portions. It is what has been.

- the flat electric wire fixing structure includes the flat electric wire according to the first or second aspect, and an adhesive layer provided on one main surface side, and self-joining of the covering portions on the other main surface side.

- the flat electric wire is fixed to the portion to be fixed in a state where the surface and the self-bonding layer are bonded.

- the main surface exhibiting self-bonding property of the covering portion is fixed to the fixing target portion with a relatively large bonding area with respect to the fixing target portion formed of the same material as this. be able to. For this reason, the flat electric wire used as a wiring material can be easily and firmly fixed to other members.

- the flat electric wire used as a wiring material will be applied to another member. It can be fixed easily and firmly.

- the third aspect it is possible to stack a plurality of flat electric wires in an easily and firmly fixed state.

- the flat electric wire can be easily and firmly fixed to the fixing target portion.

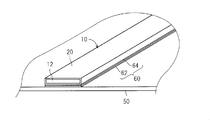

- FIG. 1 is a schematic perspective view showing a flat wire 10 according to the embodiment.

- the flat electric wire 10 includes a flat conductor 12 and a covering portion 20.

- the flat conductor 12 is formed in a long shape, and a cross section in a plane orthogonal to the longitudinal direction thereof is formed in a flat shape (here, a rectangular shape long in one direction).

- the flat conductor 12 is formed of an elongated strip-shaped metal plate.

- the flat conductor 12 is formed of a material such as copper, a copper alloy, aluminum, or an aluminum alloy.

- the flat conductor 12 may be plated with metal such as tin or nickel.

- the covering portion 20 is an insulating member that covers the flat conductor 12 in a flat form.

- the covering portion 20 is formed, for example, by extruding a resin around the flat conductor 12.

- the covering portion 20 covers the periphery of the flat conductor 12 with a uniform thickness, and therefore, when the flat electric wire 10 is observed in a cross section orthogonal to the longitudinal direction, it has a flat shape.

- the main surface on at least one side of the covering portion 20 exhibits self-bonding properties.

- the covering portion 20 itself is formed of a material exhibiting self-bonding properties.

- the self-bonding property refers to the property of being easily bonded to the same material as self.

- the same material is brought into contact (preferably pressed) to become a state in which it is adhered (sometimes referred to as self-adhesion), or melted and integrated.

- the like sometimes referred to as self-bonding property, or may exhibit self-bonding property by heating).

- a synthetic rubber such as a hydrogenated styrene butadiene rubber layer or an olefin elastomer layer, or a natural rubber latex serving as a base resin blended with an adhesion assistant such as a terpene resin, a rosin ester resin, or a petroleum resin

- JP As disclosed in JP-A-2015-15221 and the like, it is known to exhibit self-adhesiveness at room temperature.

- Butylene rubber is a kind of material having a self-fusing property at room temperature

- thermoplastic resins such as EMA (polyethylene methyl acrylate), polyester, and polyamide are a kind of material having a self-fusing property by heating. It is.

- the covering portion 20 itself is formed of a material having self-bonding properties, the entire surface of the covering portion 20 exhibits self-bonding properties.

- the wide width of the covering portion 20 is such that both of the two main surfaces are self-bonding. Exhibits bonding properties.

- the flat electric wire 10 is preferably used as a wiring member of a wattmeter that electrically connects a battery and a DC-DC converter, a starter / generator, an inverter, or the like in a vehicle.

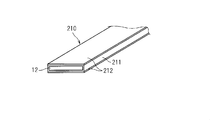

- FIG. 2 is a schematic perspective view showing a flat wire laminate 110 having a plurality of the flat wires 10.

- the flat wire laminate 110 includes two flat wires 10.

- the two flat electric wires 10 are overlapped so that one of the two wide main surfaces of the one flat electric wire 10 is brought into surface contact with one of the two wide main surfaces of the other flat electric wire 10. And one main surface and the other main surface of the two flat electric wires 10 are joined, and it has the structure integrated in both lamination

- the said flat electric wire 10 can be manufactured if the two flat electric wires 10 are piled up and force is applied in the direction which unites both.

- two flat electric wires 10 are overlapped, but three or more flat electric wires 10 may be overlapped and joined.

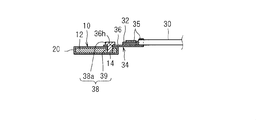

- FIG. 3 and 4 are diagrams showing a configuration example for connecting another electric wire 30 to the flat electric wire 10. That is, in FIG. 3, the hole 14 is formed in the flat electric wire 10. The hole 14 penetrates the flat conductor 12 and the covering portion 20 on the one main surface side thereof. The hole 14 may or may not penetrate the flat electric wire 10.

- the terminal 34 is formed by pressing a metal plate or the like, and includes a crimping part 35 and a mating connection part 36.

- the crimp portion 35 is a portion that is crimped to the end portion of the electric wire 30.

- the mating connection part 36 is a part in which a hole 36h is formed.

- Such a terminal 34 is a terminal called a round terminal.

- the terminal and the core part of the electric wire may be joined by soldering, ultrasonic joining or the like.

- the bolt 38 is screwed and tightened into the hole 14 in a state where the screw part 39 of the bolt 38 is passed through the hole 36h of the mating connection part 36. It is preferable that the tip of the bolt 38 is screwed into only the flat conductor without protruding to the opposite side of the flat electric wire 10. But the front-end

- the mating connection portion 36 of the terminal 34 is sandwiched and fixed between the head 38a of the bolt 38 and the flat electric wire 10.

- the head 38 a and the surrounding portion of the bolt 38 are in contact with the mating connection portion 36 of the terminal 34, and the screw portion 39 is screwed into the hole 36 h and is in contact with the flat conductor 12.

- the core part 32 of the electric wire 30 will be in the state electrically connected to the flat conductor 12 through the volt

- the bolt 38 instead of the bolt 38, a rivet or the like may be used.

- the covering portion 20 may be removed at a portion where the bolt 38 is tightened, and the mating connection portion 36 may be in direct contact with the flat conductor 12.

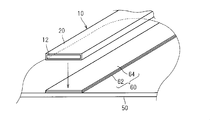

- FIGS. 5 and 6 are explanatory views showing an example of a structure for fixing the flat electric wire 10 to the fixing target portion 50.

- the fixing target portion 50 is assumed to be a metal panel, a resin panel, or the like in a vehicle.

- the adhesive sheet 60 is stuck on the fixing target portion 50 as an intervening layer.

- the adhesive sheet 60 is formed in a band shape.

- the width dimension of the adhesive sheet 60 is the same as the width dimension of the flat electric wire 10, this is not essential.

- the pressure-sensitive adhesive sheet 60 includes a pressure-sensitive adhesive layer 62 on one main surface side, a second main surface side, and a self-bonding layer 64.

- the adhesive layer 62 is a layer that exhibits adhesiveness in the same manner as a general adhesive tape, and is configured to be able to adhere to the fixing target portion 50 made of metal, resin, or the like.

- the self-bonding layer 64 is formed of the same material as the main surface exhibiting self-bonding properties in the covering portion 20. Then, the pressure-sensitive adhesive layer 60 is adhered to the fixation target portion 50 by adhering the adhesive layer 62 to the fixation target portion 50.

- the flat electric wire 10 is fixed to the fixing target portion 50 by bonding one main surface of the covering portion 20 to the self-bonding layer 64 of the adhesive sheet 60. Since the covering portion 20 and the self-bonding layer 64 are formed of the same material having self-bonding properties, the covering portion 20 of the flat electric wire 10 is brought into contact with the self-bonding layer 64 of the pressure-sensitive adhesive sheet 60, and as necessary.

- the flat electric wire 10 can be bonded to the self-bonding layer 64 of the pressure-sensitive adhesive sheet 60 by pressurization, heating (may be heated by energizing the flat conductor 12), or the like. At this time, it is not necessary to form a fixing hole on the fixing target portion 50 side, which is convenient.

- the pressure-sensitive adhesive sheet 60 does not exhibit strong adhesiveness to other peripheral members, and the self-bonding layer 64 of the flat wire 10. A portion that is not joined to the other member does not exhibit strong adhesiveness to other peripheral members. For this reason, it is difficult for other members to stick to the fixing target portion 50 and the flat electric wire 10 unintentionally.

- the flat electric wire 10 configured as described above, if the main surface exhibiting self-bonding property of the covering portion 20 is brought into contact with the surface of the portion to be fixed formed of the same material as this, a relatively large joint is obtained.

- the flat electric wire 10 can be fixed to the fixing target portion 50 in terms of area. For this reason, the flat electric wire 10 used as a wiring material can be easily and firmly fixed to other members.

- the covering portion 20 has self-adhesiveness, if the covering portion 20 is pressed against the surface of the fixing target portion formed of the same material as this, the flat wire 10 can be fixed with a relatively large joint area. It can be fixed to the portion 50 easily and firmly.

- a certain flat electric wire 10 is laminated on another flat electric wire 10 that is a fixing target portion, and the main surfaces of the covering portions 20 are joined to each other, so that a plurality of flat electric wires 10 can be easily and easily provided.

- the layers can be laminated in a firmly fixed state.

- a certain flat electric wire 10 can be easily and firmly fixed to a fixing target portion 50 such as a vehicle body via an adhesive sheet 60 having an adhesive layer 62 and a self-bonding layer 64.

- the entire covering portion 20 is described as being formed of a material having self-bonding properties.

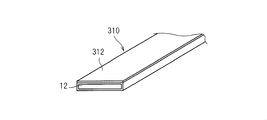

- a configuration in which a self-bonding layer 212 or a self-bonding layer 312 made of a material having self-bonding properties is formed around the covering main body 211 formed of vinyl or the like may be used.

- the self-bonding layer 212 or the self-bonding layer 312 may be formed by coating or the like with respect to the covering main body 211, or may be separately adhered through an adhesive layer.

- the self-bonding layer 212 or the self-bonding layer 312 is formed on at least one of the two main surfaces that are wide among the four surfaces around the covering main body 211.

- the self-bonding layer 212 is formed on both main surfaces of the covering main body 211.

- a self-bonding layer 212 is formed on both main surfaces of the covering main body 211.

- the flat electric wires 210 and 310 can be fixed in a state where the relatively wide main surface is in contact with the portion to be fixed.

- a laminate of the flat electric wires 10 may be fixed to the fixing target portion 50 via the adhesive sheet 60.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Insulated Conductors (AREA)

- Mechanical Engineering (AREA)

- Installation Of Indoor Wiring (AREA)

Abstract

配線材として用いられる電線を他の部材に対して容易かつ強固に固定できるようにすることを目的とする。フラット電線は、扁平導体と、扁平導体を扁平な形態で覆うと共に、少なくとも一方側の主面が自己接合性を呈する被覆部とを備える。被覆部の少なくとも一方側の主面は自己粘着性を呈する。複数のフラット電線が、それぞれの被覆部のうち自己接合性を呈する主面同士が接合された状態で、積層されて、フラット電線積層体が製造される。

Description

この発明は、配線材として用いられるフラット電線に関する。

特許文献1は、線状の導体の外周に熱可塑性の絶縁被覆層を設けた自己融着性を有する2本の電線が撚り合わせられ、該撚り合わせ状態で、前記2本の電線の互いに接触する絶縁被覆層同士が固着しているツイストペア電線を開示している。

しかしながら、特許文献1によると、2本の電線の互いに接触する絶縁被覆層同士が自己融着性によって固着された構成とされている。2本の電線それぞれは、断面円形状であるため、それらの接触面積は小さい。このため、2つの電線の固着力は小さい。

そこで、本発明は、配線材として用いられる電線を他の部材に対して容易かつ強固に固定できるようにすることを目的とする。

上記課題を解決するため、第1の態様に係るフラット電線は、扁平導体と、前記扁平導体を扁平な形態で覆うと共に、少なくとも一方側の主面が自己接合性を呈する被覆部とを備える。

第2の態様は、第1の態様に係るフラット電線であって、前記被覆部の少なくとも一方側の主面は自己粘着性を呈するものである。

第3の態様は、第1又は第2の態様に係るフラット電線を複数備え、前記複数のフラット電線が、それぞれの被覆部のうち自己接合性を呈する主面同士が接合された状態で、積層されているものである。

第4の態様に係るフラット電線の固定構造は、第1又は第2の態様に係るフラット電線と、一方主面側に粘着層が設けられると共に、他方主面側に前記被覆部のうち自己接合性を呈する主面と同じ材料で形成された自己接合層が設けられ、前記粘着層が固定対象部分に粘着された介在層とを備え、前記フラット電線の被覆部のうち自己接合性を呈する主面と、前記自己接合層とが接合された状態で、前記フラット電線が前記固定対象部分に固定されているものである。

第1の態様によると、被覆部のうち自己接合性を呈する主面を、これと同じ材料で形成された固定対象部分に対して、比較的大きい接合面積でフラット電線を固定対象部分に固定することができる。このため、配線材として用いられるフラット電線を他の部材に対して容易かつ強固に固定できる。

第2の態様によると、被覆部のうち自己粘着性を呈する主面を、これと同じ材料で形成された固定対象部分の表面に押付ければ、配線材として用いられるフラット電線を他の部材に対して容易かつ強固に固定できる。

第3の態様によると、複数のフラット電線を、容易かつ強固に固定した状態で、積層することができる。

第4の態様によると、フラット電線を容易かつ強固に固定対象部分に固定できる。

以下、実施形態に係るフラット電線について説明する。図1は実施形態に係るフラット電線10を示す概略斜視図である。

フラット電線10は、扁平導体12と、被覆部20とを備える。

扁平導体12は、長尺形状に形成されており、その長手方向に対して直交する面における横断面が扁平形状(ここでは、一方向に長い長方形状)に形成されている。扁平導体12は、細長い帯状の金属板によって形成されている。扁平導体12は、銅、銅合金、アルミニウム、アルミニウム合金などの材料によって形成される。扁平導体12には、スズやニッケルなどの金属めっきが施されていても良い。

被覆部20は、上記扁平導体12を扁平な形態で覆う絶縁部材である。被覆部20は、例えば、扁平導体12の周囲に樹脂を押出被覆すること等によって形成される。被覆部20は、扁平導体12の周囲を均一な厚み寸法で覆っており、従って、フラット電線10を、その長手方向に対して直交する横断面で観察すると、扁平形状を呈する。

被覆部20の少なくとも一方側の主面は、自己接合性を呈する。ここでは、被覆部20自体が自己接合性を呈する材料により形成されている。ここで、自己接合性とは、自己と同じ材料に対して接合し易い性質をいう。かかる自己接合性としては、例えば、同じ材料同士が接触(好ましくは押圧)されることによって、粘着されたような状態となる性質(自己粘着性と呼ばれることもある)、或いは、融けて一体化する性質(自己融着性と呼ばれることがある、加熱によって自己融着性を呈するものであってもよい)等が挙げられる。例えば、水素添加スチレンブタジエンゴム層或いはオレフィンエラストマー層等の合成ゴム、ベース樹脂となる天然ゴムラテックスにテルペン系樹脂、ロジンエステル系樹脂、石油系樹脂等の粘着助剤を配合したものは、特開2015-15221号公報等に開示されているように、常温にて自己粘着性を呈するものとして知られている。また、ブチレンゴムは、常温にて自己融着性を持つ材料の一種であり、また、EMA(ポリエチレンメチルアクリレート)、ポリエステル、ポリアミド等の熱可塑性樹脂は、加熱によって自己融着性を持つ材料の一種である。

被覆部20自体が自己接合性を有する材料により形成されているため、被覆部20の表面全体が、自己接合性を呈し、特に、被覆部20のうち幅広は、2つの主面の両方が自己接合性を呈する。

上記フラット電線10は、例えば、車両においてバッテリと、DC-DCコンバータ、スタータ・ジェネレータ又はインバータ等とを電気的につなぐ電力計の配線部材として用いられることが好ましい。

図2は上記フラット電線10を複数備えるフラット電線積層体110を示す概略斜視図である。

ここでは、フラット電線積層体110は、2つのフラット電線10を備える。そして、一方のフラット電線10の2つの幅広な主面の一方を、他方のフラット電線10の2つの幅広な主面の一方に面接触させるように、両フラット電線10が重ね合わされている。そして、2つのフラット電線10の一方の主面と他方の主面とが接合されて、両者積層状態で一体化された構成となっている。上記フラット電線10は、2つのフラット電線10を重ね合せ、両者を合体させる方向に力を加えれば、製造することができる。

ここでは、2つのフラット電線10が重ね合わされているが、3つ以上のフラット電線10が重ね合わされて接合されていてもよい。

図3及び図4はフラット電線10に他の電線30を接続するための構成例を示す図である。すなわち、図3では、上記フラット電線10に孔14を形成する。孔14は、扁平導体12及びその一方主面側の被覆部20を貫通している。孔14は、フラット電線10を貫通していてもよいし、していなくてもよい。

また、電線30の端部では、芯線部32が露出しており、端子34が圧着されている。端子34は、金属板をプレス加工等することによって形成されており、圧着部35と相手側接続部36とを備える。圧着部35は、電線30の端部に圧着される部分である。相手側接続部36は、孔36hが形成された部分である。かかる端子34は、丸形端子と呼ばれる端子である。端子と電線の芯線部とは、半田付、超音波接合等によって接合されていてもよい。

そして、ボルト38のネジ部39を相手側接続部36の孔36hに通した状態で、ボルト38を孔14に螺合締付けする。ボルト38の先端部は、フラット電線10の反対側に突出せずに、扁平導体のみに螺合していることが好ましい。もっとも、ボルト38の先端部がフラット電線10の反対側に突出し、この部分が別途ナットに螺合していてもよい。

上記端子34の相手側接続部36が、ボルト38の頭部38aとフラット電線10との間に挟込まれて固定される。また、ボルト38のうち頭部38a及びその周囲部が端子34の相手側接続部36に接触した状態になると共に、ネジ部39が孔36hにねじ込まれ、扁平導体12と接触した状態になる。このため、電線30の芯線部32は、ボルト38を通じて扁平導体12に電気的に接続された状態となり、もって、電線30がフラット電線10に接続される。

上記ボルト38に代えて、リベット等を用いてもよい。また、ボルト38を締付ける部分で、被覆部20が除去され、相手側接続部36が直接扁平導体12に接触するようにしてもよい。

図5及び図6はフラット電線10を、固定対象部分50に固定する構造例を示す説明図である。固定対象部分50としては、車両における金属パネル、樹脂パネル等であることが想定される。

固定対象部分50には、介在層として粘着シート60が貼付けられる。粘着シート60は、帯状に形成されている。好ましくは、粘着シート60の幅寸法は、フラット電線10の幅寸法と同じであるが、これは必須ではない。粘着シート60は、一方主面側の粘着層62と、他方主面側と自己接合層64とを備える。粘着層62は、一般的な粘着テープと同様に粘着性を呈する層であり、金属又は樹脂等で構成される固定対象部分50に粘着可能に構成されている。自己接合層64は、上記被覆部20のうち自己接合性を呈する主面と同じ材料で形成されている。そして、上記粘着層62を固定対象部分50に粘着させることによって、本粘着シート60が固定対象部分50に粘着されている。

フラット電線10は、その被覆部20の一方主面を、粘着シート60の自己接合層64に接合させることによって、固定対象部分50に固定されている。被覆部20と自己接合層64とは自己接合性を有する同じ材料で形成されているため、フラット電線10の被覆部20を、粘着シート60の自己接合層64に接触させて、必要に応じて加圧、加熱(扁平導体12に対する通電によって加熱するとよい)等することによって、フラット電線10を粘着シート60の自己接合層64に接合させることができる。この際、固定対象部分50側に固定用の孔を形成しなくてもよいため、好都合である。

粘着シート60の自己接合層64にフラット電線10を接合する前の状態では、粘着シート60は他の周辺部材に対して強い粘着性等を呈さず、また、フラット電線10のうち自己接合層64に接合されない部分も他の周辺部材に対して強い粘着性を呈さない。このため、固定対象部分50及びフラット電線10に、意図せず他の部材がくっついてしまい難い。

上記したいずれの例においても、両面テープ等を用いる場合とは異なり、剥離紙の剥離作業、剥離した剥離紙の処分作業等は不要であり、この点でも、便利である。

以上のように構成されたフラット電線10によると、被覆部20のうち自己接合性を呈する主面を、これと同じ材料で形成された固定対象部分の表面に接触させれば、比較的大きい接合面積で、フラット電線10を固定対象部分50に固定できる。このため、配線材として用いられるフラット電線10を、他の部材に対して容易かつ強固に固定できる。

特に、被覆部20は、自己粘着性を有するため、被覆部20を、これと同じ材料で形成された固定対象部分の表面に押しつければ、比較的大きい接合面積で、フラット電線10を固定対象部分50に容易かつ強固に固定できる。

上記例では、あるフラット電線10を、固定対象部分である他のフラット電線10に積層させた状態とし、それらの被覆部20の主面同士を接合することで、複数備えるフラット電線10を容易かつ強固に固定した状態で、積層することができる。

また、他の例では、あるフラット電線10を、粘着層62及び自己接合層64を有する粘着シート60を介して、車両ボディ等の固定対象部分50に容易かつ強固に固定できる。

なお、上記実施形態では、被覆部20の全体が自己接合性を有する材料で形成されている例で説明したが、図7に示すフラット電線210又は図8に示すフラット電線310のように、塩化ビニル等で形成された被覆本体部211の周囲に自己接合性を有する材料による自己接合層212又は自己接合層312が形成された構成であってもよい。自己接合層212又は自己接合層312は、被覆本体部211に対して、塗布等によって形成されてもよいし、別途粘着層を解して粘着されていてもよい。

自己接合層212又は自己接合層312は、被覆本体部211の周囲の4つの面のうち幅広となる2つの主面の少なくとも一方に形成される。ここでは、フラット電線210に対しては、被覆本体部211の両方の主面に自己接合層212が形成されている。また、フラット電線310に対しては、被覆本体部211の両方の主面に自己接合層212が形成されている。

このため、フラット電線210、310を、比較的幅広な主面を固定対象部分に接触させた状態で、固定することができる。

なお、上記実施形態及び各変形例で説明した各構成は、相互に矛盾しない限り適宜組合わせることができる。例えば、フラット電線10を積層したものが、粘着シート60を介して、固定対象部分50に固定されていてもよい。

以上のようにこの発明は詳細に説明されたが、上記した説明は、すべての局面において、例示であって、この発明がそれに限定されるものではない。例示されていない無数の変形例が、この発明の範囲から外れることなく想定され得るものと解される。

10、210、310 フラット電線

12 扁平導体

20 被覆部

50 固定対象部分

60 粘着シート

62 粘着層

64 自己接合層

110 フラット電線積層体

211 被覆本体部

212、312 自己接合層

12 扁平導体

20 被覆部

50 固定対象部分

60 粘着シート

62 粘着層

64 自己接合層

110 フラット電線積層体

211 被覆本体部

212、312 自己接合層

Claims (4)

- 扁平導体と、

前記扁平導体を扁平な形態で覆うと共に、少なくとも一方側の主面が自己接合性を呈する被覆部と、

を備えるフラット電線。 - 請求項1記載のフラット電線であって、

前記被覆部の少なくとも一方側の主面は自己粘着性を呈する、

を備えるフラット電線。 - 請求項1又は請求項2に記載のフラット電線を複数備え、

前記複数のフラット電線が、それぞれの被覆部のうち自己接合性を呈する主面同士が接合された状態で、積層されている、フラット電線積層体。 - 請求項1又は請求項2に記載のフラット電線と、

一方主面側に粘着層が設けられると共に、他方主面側に前記被覆部のうち自己接合性を呈する主面と同じ材料で形成された自己接合層が設けられ、前記粘着層が固定対象部分に粘着された介在層と、

を備え、

前記フラット電線の被覆部のうち自己接合性を呈する主面と、前記自己接合層とが接合された状態で、前記フラット電線が前記固定対象部分に固定されている、フラット電線の固定構造。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/335,051 US20190279787A1 (en) | 2016-09-26 | 2017-09-05 | Flat wire, flat wire multilayer body, and fixing structure for flat wire |

| CN201780058358.1A CN109791818B (zh) | 2016-09-26 | 2017-09-05 | 扁平电线、扁平电线层积体以及扁平电线的固定结构 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016-186725 | 2016-09-26 | ||

| JP2016186725A JP6747212B2 (ja) | 2016-09-26 | 2016-09-26 | フラット電線の固定構造 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018056042A1 true WO2018056042A1 (ja) | 2018-03-29 |

Family

ID=61690366

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/031860 WO2018056042A1 (ja) | 2016-09-26 | 2017-09-05 | フラット電線、フラット電線積層体及びフラット電線の固定構造 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20190279787A1 (ja) |

| JP (1) | JP6747212B2 (ja) |

| CN (1) | CN109791818B (ja) |

| WO (1) | WO2018056042A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019202191A1 (es) * | 2018-04-17 | 2019-10-24 | Representacions Jerg, S.L. | Cable conductor de cinta plana mejorado |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020066071A1 (ja) * | 2018-09-28 | 2020-04-02 | 住友電気工業株式会社 | ワイヤーハーネス |

| US10639737B1 (en) * | 2018-10-19 | 2020-05-05 | Aptiv Technologies Limited | Welding system and method |

| JP7318486B2 (ja) * | 2019-10-28 | 2023-08-01 | 株式会社オートネットワーク技術研究所 | 配線部材の固定構造及び接合部材付き配線部材 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5328475U (ja) * | 1976-08-18 | 1978-03-10 | ||

| JP2013127866A (ja) * | 2011-12-16 | 2013-06-27 | Yazaki Corp | ワイヤハーネス用シート及びワイヤハーネス並びにワイヤハーネスの製造方法 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3217245A (en) * | 1962-03-27 | 1965-11-09 | Whitney Blake Co | Method of testing a packaged insulated cable wound on an annular core |

| US3237136A (en) * | 1964-11-19 | 1966-02-22 | Westinghouse Electric Corp | Coils for inductive apparatus |

| US3504104A (en) * | 1968-12-13 | 1970-03-31 | Matsushita Electric Ind Co Ltd | Self-bonding,surface-insulated foil conductors |

| US4348548A (en) * | 1979-09-11 | 1982-09-07 | Thomas & Betts Corporation | Insulator for covering electrical cables |

| JPS58108640A (ja) * | 1981-08-08 | 1983-06-28 | Fujitsu Ltd | 電子ビ−ム露光装置の偏向コイル |

| JPS5845275A (ja) * | 1981-09-10 | 1983-03-16 | Daikin Ind Ltd | アクリル系粘着剤 |

| US4473716A (en) * | 1981-11-12 | 1984-09-25 | New England Electric Wire Corporation | Compacted fine wire cable and method for producing same |

| US4447797A (en) * | 1982-10-12 | 1984-05-08 | Westinghouse Electric Corp. | Insulated conductor having adhesive overcoat |

| CN2111264U (zh) * | 1991-11-13 | 1992-07-29 | 福建省将乐县印刷厂 | 自粘胶信封 |

| JP2003100156A (ja) * | 2001-09-26 | 2003-04-04 | Canon Inc | ケーブル及び電子機器 |

| US7223919B2 (en) * | 2004-05-11 | 2007-05-29 | Gagne Norman P | Flat flexible cable with integrated stiffener |

| JP2007227266A (ja) * | 2006-02-24 | 2007-09-06 | Mitsubishi Cable Ind Ltd | 集合導体 |

| JP6007857B2 (ja) * | 2013-05-10 | 2016-10-12 | 日立金属株式会社 | フラット配線部材およびその製造方法 |

-

2016

- 2016-09-26 JP JP2016186725A patent/JP6747212B2/ja not_active Expired - Fee Related

-

2017

- 2017-09-05 WO PCT/JP2017/031860 patent/WO2018056042A1/ja active Application Filing

- 2017-09-05 US US16/335,051 patent/US20190279787A1/en not_active Abandoned

- 2017-09-05 CN CN201780058358.1A patent/CN109791818B/zh not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5328475U (ja) * | 1976-08-18 | 1978-03-10 | ||

| JP2013127866A (ja) * | 2011-12-16 | 2013-06-27 | Yazaki Corp | ワイヤハーネス用シート及びワイヤハーネス並びにワイヤハーネスの製造方法 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019202191A1 (es) * | 2018-04-17 | 2019-10-24 | Representacions Jerg, S.L. | Cable conductor de cinta plana mejorado |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109791818B (zh) | 2021-01-29 |

| US20190279787A1 (en) | 2019-09-12 |

| JP6747212B2 (ja) | 2020-08-26 |

| JP2018055778A (ja) | 2018-04-05 |

| CN109791818A (zh) | 2019-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2018056042A1 (ja) | フラット電線、フラット電線積層体及びフラット電線の固定構造 | |

| US20180354231A1 (en) | Different-material joining structure | |

| CN111033641A (zh) | 线束 | |

| US11167702B2 (en) | Wiring module, composite wiring module, and fixing target member equipped with wiring module | |

| JP7513140B2 (ja) | 配線部材 | |

| JPH10334972A (ja) | 端子の組み付け構造及び組み付け方法 | |

| JP6663463B2 (ja) | プリント配線板の製造方法に用いられるシート状積層体 | |

| WO2018207641A1 (ja) | 配線モジュール、複合配線モジュール及び配線モジュール付固定対象部材 | |

| WO2020080092A1 (ja) | 電線の接続構造、および、電線の接続方法 | |

| CN103379743A (zh) | 电子组件和将金属体连接于柔性载体的导电线路上的方法 | |

| JP4917119B2 (ja) | 配線基板の表裏導通方法 | |

| JP6556513B2 (ja) | 接続構造、及び、ワイヤハーネス | |

| JP4492186B2 (ja) | 発熱体 | |

| CN103098574A (zh) | 导电接地垫 | |

| JP4560185B2 (ja) | 電線付き導体薄膜シートと電線付き導体薄膜シートの製造方法 | |

| JP2014235777A (ja) | 電線と端子の接合構造及び接合方法 | |

| JP3203763U (ja) | 極板とそれを含む電池 | |

| JP2016030021A (ja) | 生体用電極具 | |

| WO2008056449A1 (fr) | Structure servant à accoupler des éléments | |

| WO2021210383A1 (ja) | 配線部材 | |

| JP6972448B1 (ja) | 液晶調光フィルム | |

| JP2018041548A (ja) | 配線モジュール及び配線接続装置 | |

| CN108058657B (zh) | 导电部件固定结构 | |

| WO2021039496A1 (ja) | 配線部材の固定構造及び配線部材 | |

| JP2021138125A (ja) | テープ及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17852819 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 17852819 Country of ref document: EP Kind code of ref document: A1 |