WO2017200067A1 - バルブ及び蒸気タービン設備 - Google Patents

バルブ及び蒸気タービン設備 Download PDFInfo

- Publication number

- WO2017200067A1 WO2017200067A1 PCT/JP2017/018760 JP2017018760W WO2017200067A1 WO 2017200067 A1 WO2017200067 A1 WO 2017200067A1 JP 2017018760 W JP2017018760 W JP 2017018760W WO 2017200067 A1 WO2017200067 A1 WO 2017200067A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- valve

- valve body

- stem

- seat

- valve stem

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K15/00—Check valves

- F16K15/02—Check valves with guided rigid valve members

- F16K15/06—Check valves with guided rigid valve members with guided stems

- F16K15/063—Check valves with guided rigid valve members with guided stems the valve being loaded by a spring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D17/00—Regulating or controlling by varying flow

- F01D17/10—Final actuators

- F01D17/12—Final actuators arranged in stator parts

- F01D17/14—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits

- F01D17/141—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits by means of shiftable members or valves obturating part of the flow path

- F01D17/145—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits by means of shiftable members or valves obturating part of the flow path by means of valves, e.g. for steam turbines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D17/00—Regulating or controlling by varying flow

- F01D17/10—Final actuators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D25/00—Component parts, details, or accessories, not provided for in, or of interest apart from, other groups

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

- F16K1/34—Cutting-off parts, e.g. valve members, seats

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

- F16K1/34—Cutting-off parts, e.g. valve members, seats

- F16K1/44—Details of seats or valve members of double-seat valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

- F16K1/34—Cutting-off parts, e.g. valve members, seats

- F16K1/36—Valve members

- F16K1/38—Valve members of conical shape

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

- F16K1/34—Cutting-off parts, e.g. valve members, seats

- F16K1/44—Details of seats or valve members of double-seat valves

- F16K1/443—Details of seats or valve members of double-seat valves the seats being in series

Definitions

- the present disclosure relates to a valve and a steam turbine facility including the valve.

- Patent Document 1 discloses a steam valve used for a steam turbine.

- this steam valve when the valve is closed, the seat surface of the valve body is seated on the valve seat, whereby the flow of steam is interrupted, and the valve rod to which the valve body is connected, and the bonnet through which the valve rod is inserted,

- the back seat provided in the enlarged diameter portion of the valve stem comes into contact with the bonnet.

- Patent Document 1 in order to interrupt

- At least one embodiment of the present invention aims to provide a valve and a steam turbine facility capable of reducing fluid leakage.

- a valve includes: A valve stem, A first valve body provided on the tip side of the valve stem and configured to be driven via the valve stem; A first valve seat on which the first valve body can be seated; A sub-seat surface along a direction intersecting the axial direction of the valve stem; A sub seat portion provided on the base end side of the valve stem with respect to the first valve body, and configured to abut on the sub seat surface when the first valve body is closed; A biasing member capable of generating a biasing force along the axial direction of the valve stem, One of the first valve body or the sub seat portion is relatively displaceable in the axial direction with respect to the valve stem, and is directed toward one of the first valve seat or the sub seat surface by the biasing member. Be energized.

- one of the first valve body or the sub seat portion can be displaced relative to the valve stem in the axial direction of the valve stem, and the first valve seat or the sub seat surface can be moved by the biasing member. It is energized towards one side. Accordingly, when the first valve body is closed, the other of the first valve body or the sub seat portion is seated or abutted on the other of the first valve seat or the sub seat surface, and the first valve body or the sub seat portion is One is pressed against the one of the first valve seat and the sub-seat surface by the urging member, so that both the first valve body and the sub-seat portion can be reliably sealed. Thus, fluid leakage in the valve can be reduced.

- the first valve body is relatively displaceable in the axial direction with respect to the valve stem, and the first valve seat is mounted on the first valve seat by the biasing member provided between the first valve body and the valve stem. It is energized towards.

- the first valve body can be displaced relative to the valve stem in the axial direction of the valve stem, and is biased toward the first valve seat by the biasing member.

- the sub seat portion comes into contact with the sub seat surface, and the first valve body is pressed against the first valve seat by the urging member. Therefore, the first valve body and the sub seat portion Both can be reliably sealed. Thus, fluid leakage in the valve can be reduced.

- the valve stem has a valve stem side engaging portion including a convex portion or a concave portion protruding or recessed in the radial direction of the valve stem on the distal end side

- the first valve body has a valve body side engaging portion including a concave portion or a convex portion that is depressed or protruded in the radial direction so as to be engaged with the valve stem side engaging portion

- the valve stem side engaging portion is loosely fitted to the valve body side engaging portion so as to allow relative displacement in the axial direction of the first valve body with respect to the valve stem.

- the valve stem side engaging portion is loosely fitted to the valve body side engaging portion. That is, a gap is formed between the valve stem side engaging portion and the valve body side engaging portion in the axial direction of the valve stem. Therefore, since the relative displacement in the axial direction of the first valve body with respect to the valve stem is allowed, the first valve body can be appropriately pressed against the first valve seat by the urging force of the urging member, and the first valve body and It can be reliably sealed at both sub-sheets.

- the valve stem has the convex portion protruding outward in the radial direction as the valve stem-side engaging portion

- the convex portion as the valve stem side engaging portion is: A first surface facing the first valve body facing the axial valve opening side of the valve stem; A second surface facing the first valve body facing the axial valve closing side of the valve stem; Have A gap is provided between at least one of the first surface and the first valve body, or between the second surface and the first valve body.

- a gap is provided on at least one of the first valve body and the first surface or the second surface of the convex portion as the valve rod side engaging portion. That is, a gap is formed between the convex portion as the valve stem side engaging portion and the first valve body in the axial direction of the valve stem. Therefore, since the axial displacement of the first valve body with respect to the valve stem is allowed, the first valve body can be pressed against the first valve seat by the biasing force of the biasing member, and the first valve body and the sub-seat It can be surely sealed at both parts.

- the gap (the first valve body) is formed between the first surface facing the valve opening side of the convex portion as the valve rod side engaging portion and the first valve body. 1 gap) is formed, and a gap (second gap) is formed between the first valve body and the second surface facing the valve closing side of the convex portion as the valve rod side engaging portion.

- the first clearance is formed on the valve opening side with respect to the valve rod side engaging portion (convex portion), so that the valve accompanying the stoppage of the flow of fluid (for example, steam) to the valve

- the valve stem contracts due to the temperature drop of the rod, it is possible to prevent the first valve body from being lifted by the valve stem.

- the alignment of the first valve body can be maintained.

- the second valve gap is formed on the valve closing side with respect to the valve rod side engaging portion (convex portion), so that the first valve body and the sub seat portion cannot be seated simultaneously. Even if it is a case, the favorable seal

- valve stem has a valve stem hole extending in the axial direction so as to open on the distal end surface of the valve stem on the distal end side,

- the urging member is a spring provided inside the valve stem hole.

- an axial biasing force can be applied to the first valve body by the spring guided by the valve stem hole extending in the axial direction of the valve stem. Accordingly, the first valve body is appropriately pressed against the first valve seat by the urging member, so that both the first valve body and the sub seat portion can be reliably sealed.

- the valve in the configuration of (6) above, is It is located between the first valve body and the biasing member and transmits the biasing force to the first valve body, and engages with the valve stem hole and is guided in the axial direction by the valve stem hole.

- An urging force receiving portion configured to be further configured.

- the first valve body by applying an urging force along the axial direction to the first valve body through the urging force receiving portion configured to be guided in the axial direction by the valve stem hole, The first valve body can be appropriately pressed by the first valve seat. For this reason, it can seal reliably in both a 1st valve body and a subseat part in a valve

- the urging force receiving portion has a spherical shape at least partially on the first valve body side, and is configured to contact the first valve body at the spherical portion.

- the urging force receiving portion is in contact with the first valve body at the spherical portion, so stress concentration is reduced compared to the case where the urging force receiving portion is in contact with the first valve body at the corner portion. It is possible to improve the life of the urging force receiving portion or the first valve body.

- the urging force receiving portion has a protrusion that engages with a groove formed in the first valve body so as to be recessed in the axial direction of the valve stem.

- the center position of the urging force receiving portion is set to the center of the valve stem by the protrusion engaging with the groove formed in the first valve body so as to be recessed in the axial direction of the valve stem. It can be reliably aligned with the shaft. Thereby, the urging

- a second valve body having an inner wall surface forming the first valve seat, and housing the first valve body in an internal space defined by the inner wall surface;

- a valve casing having a second valve seat on which the second valve body can be seated; With When the second valve body is in the valve opening position away from the second valve seat, one of the valve rod or the first valve body is in the valve opening direction of the first valve body with respect to the second valve body. Configured to be energized.

- the second valve body and the first valve body are seated in stages, so the second valve body and the first valve body are seated integrally.

- the mass of the valve body that collides with the valve seat is reduced compared to (for example, when the second valve body is seated on the second valve seat while the first valve body is seated on the second valve body).

- the second valve body in the configuration of (10), includes a first bush located on the outer peripheral side of the valve stem, for guiding the valve stem in the axial direction of the valve stem, When the second valve body is in the valve open position, a first chamber formed between the first bush and the valve rod is provided in the second valve body in which the first valve body is accommodated. It is comprised so that it may become a low pressure rather than the pressure of internal space.

- the first chamber formed between the first bush and the valve rod via the communication path is The pressure is lower than the pressure in the internal space of the two-valve body. Therefore, the urging force in the valve opening direction of the child valve based on the pressure difference between the first chamber and the internal space of the second valve element acts on the valve stem. Therefore, according to the configuration of (11), when the valve is closed, the second valve body and the first valve body are seated in stages due to the biasing force based on the pressure difference described above. The mass of the valve body that collides with the valve seat is reduced as compared with the case where the single valve body is integrally seated. Thereby, since the impact force which arises in a valve body and a valve seat by the collision of a valve body and a valve seat is reduced, damage to a seat part can be reduced.

- the first chamber is a lift gap for lifting the valve stem and the first valve body relative to the second valve body.

- a chamber can be formed.

- the valve stem has a communication passage extending in the axial direction inside the valve stem, When the second valve body is in the valve open position, the first chamber communicates with the second chamber having a lower pressure than the first chamber via the communication passage. When the second valve body is in the valve closing position, the first chamber and the second chamber are configured not to communicate with each other.

- the pressure in the first chamber is reduced by communicating the first chamber with the second chamber via the communication path.

- the biasing force in the valve opening direction of the first valve body based on the pressure difference between the first chamber and the internal space of the second valve body can be created.

- the first chamber and the second chamber do not communicate with each other, so that the fluid traveling from the first chamber to the second chamber Leakage flow is blocked. Thereby, the leak of the fluid through the space between the valve stem and the first bush from the internal space of the second valve body can be reduced.

- the valve casing has the sub-seat surface along a direction intersecting the axial direction of the valve stem,

- the valve stem includes the sub-seat portion that can come into contact with the sub-seat surface when the second valve body is in the closed position,

- the communication path and the second chamber are configured to be separated by the sub-sheet portion and the contact portion of the sub-sheet surface.

- a steam turbine facility includes: The valve according to any one of (1) to (14); A steam turbine provided downstream of the valve; Is provided.

- one of the first valve body or the sub-seat portion can be displaced relative to the valve stem in the axial direction of the valve stem, and the first valve seat or the sub-seat surface can be moved by the biasing member. It is energized towards one side. Accordingly, when the first valve body is closed, the other of the first valve body or the sub seat portion is seated or abutted on the other of the first valve seat or the sub seat surface, and the first valve body or the sub seat portion is One is pressed against the one of the first valve seat and the sub-seat surface by the urging member, so that both the first valve body and the sub-seat portion can be reliably sealed. Thus, fluid leakage in the valve can be reduced.

- a valve and a steam turbine facility capable of reducing fluid leakage are provided.

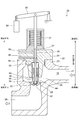

- FIG. 4 is a diagram showing a fully opened state of the valve shown in FIG. 3. It is a figure which shows the state which has shifted the valve shown in FIG. 3 from the valve opening position to the valve closing position.

- valves according to some embodiments are used as steam valves for steam turbine equipment will be described as an example. However, the valves according to some embodiments may be used for applications other than steam turbine equipment. It may be used, and may be used for control of fluids other than steam.

- FIG. 1 is a schematic configuration diagram of a steam turbine facility to which a valve according to an embodiment is applied.

- the steam turbine facility 1 is driven by a boiler 2 for generating steam, a steam turbine 4 that converts the pressure of steam from the boiler 2 into rotational energy, and rotation of the steam turbine 4.

- a generator 8 In the embodiment shown in FIG. 1, the steam turbine 4 includes a high-pressure steam turbine 5, an intermediate-pressure steam turbine 6, and a low-pressure steam turbine 7, and between the high-pressure steam turbine 5 and the intermediate-pressure steam turbine 6.

- a reheater 9 is provided. The steam discharged from the high pressure steam turbine 5 is reheated by the reheater 9 and supplied to the intermediate pressure steam turbine 6. Further, the steam discharged from the intermediate pressure steam turbine 6 is supplied to the low pressure steam turbine 7.

- the boiler 2 and the high-pressure steam turbine 5 are connected via a main steam supply pipe 3, and the main steam supply pipe 3 is provided with a steam valve 10 including a stop valve 11 and an adjusting valve 12.

- a steam valve 10 including a stop valve 11 and an adjusting valve 12.

- the stop valve 11 By closing the stop valve 11, the flow of steam supplied from the boiler 2 to the high pressure steam turbine 5 can be blocked. Further, the flow rate of the steam supplied from the boiler 2 to the high-pressure steam turbine 5 can be adjusted by adjusting the opening degree of the control valve 12.

- a stop valve 13 and an adjusting valve 14 are provided in a pipe connecting the reheater 9 and the intermediate pressure steam turbine 6, and the intermediate pressure steam turbine 6 is supplied by the stop valve 13 and the adjusting valve 14. It is possible to cut off the flow of steam or adjust the flow rate of steam.

- the stop valve 11 is a valve 20 described below.

- the stop valve 13, the control valve 12, or the control valve 14 may be the valve 20 described below.

- valve 20 according to some embodiments will be described with reference to FIGS.

- FIG. 2 is a schematic configuration diagram illustrating an entire valve according to some embodiments.

- the valve 20 accommodates a valve stem 30, a first valve body (child valve) 32 provided on the distal end side of the valve stem 30, and the first valve body 32.

- It is a parent-child valve provided with the 2nd valve body (main valve) 34 which has the interior space 35 to perform, and the valve casing 22 which accommodates the 1st valve body 32 and the 2nd valve body 34.

- An internal space 35 of the second valve body 34 is defined by an inner wall surface 40 of the second valve body 34, and the inner wall surface 40 is a first valve seat (child valve valve seat) 42 on which the first valve body 32 can be seated.

- the valve casing 22 includes a casing main body 23 and a bonnet 24 attached to the casing main body 23, the steam flow path 18 connected from the steam inlet 21 to the steam outlet 29 by the casing main body 23 and the bonnet 24, and the first valve body.

- An accommodation space 25 for the 32 and the second valve body 34 is formed.

- the casing body 23 has a second valve seat (main valve valve seat) 26 on which the second valve body 34 can be seated.

- the bonnet 24 has a through hole 27, and a valve rod 30 is inserted through the through hole 27.

- the second valve body is provided with a passage 44 that communicates the internal space 35 of the second valve body 34 with the steam flow path 18 on the steam inlet 21 side.

- the bonnet 24 is provided with a balance hole 28 for communicating the back side space 46 of the second valve body 34 and the steam flow path 18 on the steam inlet 21 side.

- the bonnet 24 has a first for recovering fluid leaking from the valve body (first valve body 32 and second valve body 34) side to the atmosphere side through the through hole 27 and the valve rod 30.

- a recovery line 48 and a second recovery line 50 are provided.

- the second recovery line 50 is provided at a position farther from the first valve body 32 than the first recovery line 48 and is connected to a fluid reservoir (not shown) having a lower pressure than the first recovery line 48.

- the valve rod 30 is connected to an actuator 38 (for example, a hydraulic actuator) via a lever 36. Further, the valve 20 includes a spring 37 for applying a biasing force in the valve closing direction to the first valve body 32 via the valve rod 30.

- an actuator 38 for example, a hydraulic actuator

- the first valve body 32 and the second valve body 34 are driven via the valve rod 30.

- the first valve body 32 and the second valve body 34 are urged toward the first valve seat 42 and the second valve seat 26 (toward the valve closing direction) by the spring 37. ing.

- the actuator 38 When the valve 20 is opened, the actuator 38 is operated (for example, in the case of a hydraulic actuator, oil is supplied to the hydraulic chamber), and the driving force in the direction opposite to the biasing force of the spring 37 is applied to the valve rod via the lever 36. 30. Then, when the driving force applied to the valve rod 30 by the actuator 38 overcomes the urging force of the spring 37, first, the first valve body 32 moves in the valve opening direction together with the valve rod 30, and the first valve body 32 is moved. Moves away from the first valve seat 42. At this time, the second valve body 34 remains seated on the second valve seat 26. Thereafter, the valve stem side contact surface 72 (see FIG. 3) of the valve stem 30 and the main valve side contact surface 74 (see FIG.

- valve 20 when the valve 20 is opened, if the first valve body 32 moves away from the first valve seat 42 in the state in which the second valve body 34 is seated on the second valve seat 26, the second valve body 34 moves.

- the steam flow path 18 and the back side space 46 of the second valve body 34 communicate with each other via a passage 44 provided in the body 34 and a balance hole 28 provided in the bonnet 24.

- the pressure difference before and behind the 2nd valve body 34 becomes small, and the 2nd valve body 34 can be opened, without giving big driving force with the actuator 38 grade

- the actuator 38 is operated (for example, in the case of a hydraulic actuator, oil is discharged from the hydraulic chamber), and the driving force in the valve opening direction applied to the valve rod by the actuator 38 via the lever 36. Decrease. Then, the first valve body 32 and the second valve body 34 move toward the first valve seat 42 and the second valve seat 26 by the urging force of the spring 37 and the like, and are seated. In this way, the valve 20 is closed.

- 3 and 4 are each a configuration diagram illustrating a main part of the valve according to the embodiment.

- 3 and 4 are views showing a fully closed state of the valve (that is, a state where both the first valve body 32 and the second valve body 34 are in the valve closing position).

- 5 is a view showing a fully opened state of the valve shown in FIG. 3 (that is, a state where both the first valve body 32 and the second valve body 34 are in the valve open position)

- FIG. 6 is a view shown in FIG. It is a figure which shows the state which has moved to the valve closing position from the valve opening position. 3 to 6, the illustration of the balance hole is omitted.

- the first recovery line 48 and the second recovery line 50 are not shown.

- the second valve body 34 includes a first bush 86 that is located on the outer peripheral side of the valve stem 30 and guides the valve stem 30 in the axial direction of the valve stem 30.

- the first bush 86 is provided separately from the second valve body 34 and attached to the second valve body.

- the first bush 86 may be provided integrally with the second valve body 34.

- the bonnet 24 (valve casing 22) includes a second bush 92 that is positioned on the outer peripheral side of the valve stem 30 and guides the valve stem 30 in the axial direction of the valve stem 30.

- the bonnet 24 is located on the outer peripheral side of the second valve body 34, and on the outer peripheral side of the valve stem 30, a sleeve 76 for guiding the sliding of the second valve body 34 in the axial direction (valve opening / closing direction). And a sleeve 78 for guiding the valve stem 30 in the axial direction.

- the valve 20 is provided on the proximal end side with respect to the distal side on which the secondary valve surfaces 98A and 98B along the direction intersecting the axial direction of the valve stem 30 and the first valve body 32 are provided.

- the auxiliary seat portions 33A and 33B and an urging member capable of generating an urging force along the axial direction of the valve rod 30 are provided.

- the sub seat portions 33A and 33B are configured to contact the sub seat surfaces 98A and 33B when the first valve body 32 is opened.

- One of the first valve body 32 or the sub seat portions 33A and 33B can be displaced relative to the valve stem 30 in the axial direction of the valve stem 30, and the first valve seat 42 or the sub seat surface by the urging member. It is biased toward one of 98A and 33B.

- the end surface on the proximal end side of the valve stem 30 of the second bush 92 forms the sub seat surface 98 ⁇ / b> A, and is integrated with the valve stem 30 on the outer peripheral side of the valve stem 30.

- the distal end side end surface of the enlarged diameter portion 31 provided so as to move in a straight line forms a sub-sheet portion 33A.

- a spring 62 ⁇ / b> A as an urging member is provided between the first valve body 32 and the valve rod 30.

- a valve stem hole 60 extending in the axial direction of the valve stem 30 is provided on the distal end side of the valve stem 30 so as to open to the distal end surface 70 of the valve stem 30, and the spring 62 ⁇ / b> A is connected to the valve stem hole 60.

- the first valve body 32 can be displaced relative to the valve stem 30 in the axial direction of the valve stem 30, and a first valve seat is provided by a spring 62 ⁇ / b> A provided between the first valve body 32 and the valve stem 30. It is biased toward 42.

- the enlarged diameter portion 31 may be provided integrally with the valve stem 30. Alternatively, the enlarged diameter portion 31 provided separately from the valve stem 30 may be attached to the outer peripheral side of the valve stem 30.

- the first valve body 32 can be displaced relative to the valve stem 30 in the axial direction of the valve stem 30 and is biased toward the first valve seat 42 by the spring 62A.

- the sub seat portion 33A comes into contact with the sub seat surface 98A, and the first valve body 32 is pressed against the first valve seat 42 by the spring 62A.

- both the first valve body 32 and the sub-seat portion 33A can be surely sealed, and in the valve 20, the leakage of fluid to the atmosphere side through the gap between the through hole 27 and the valve rod 30 can be reduced. it can.

- the bonnet 24 (valve casing 22) has a shaft extending in the axial direction on the proximal side of the valve stem 30 from the second bush 92.

- Directional holes 85 are provided.

- a movable piece 82 that is movable along the axial direction of the valve rod 30 inside the axial hole 85 is provided inside the axial hole 85.

- a concave portion 83 extending along the axial direction is provided on the inner peripheral side of the movable piece 82.

- the valve stem 30 is provided with a convex portion 80 in the concave portion 83 so as to protrude in the radial direction of the valve stem 30, and the convex portion 80 engages with the concave portion 83 and is opposed to the movable piece 82. It is slidable in the axial direction. Since the convex portion 80 is slidable in the axial direction with respect to the movable piece 82, the convex portion 80 moves the movable piece 82 when the first valve body 32 and the second valve body 34 move in the valve opening direction. By pushing up in the axial direction and compressing the spring 62B, the sheet of the sub-sheet portion 33B is released.

- the end surface of the second bush 92 on the base end side of the valve stem 30 forms a sub seat surface 98B

- the end surface of the movable piece 82 on the front end side of the valve stem 30 forms a sub seat portion 33B.

- a spring 62 ⁇ / b> B as an urging member is provided on the proximal side of the valve rod 30 with respect to the movable piece 82 inside the axial hole 85.

- the sub seat portion 33B can be displaced relative to the valve stem 30 in the axial direction of the valve stem 30, and is biased toward the sub seat surface 98B by the spring 62B.

- the secondary seat portion 33B can be displaced relative to the valve stem 30 in the axial direction of the valve stem 30 and is biased toward the secondary seat surface 98B by the spring 62B.

- the first valve body 32 is closed, the first valve body 32 is seated on the first valve seat 42, and the sub seat portion 33B is pressed against the sub seat surface 98B by the spring 62B. Therefore, both the first valve body 32 and the sub-seat portion 33B can be reliably sealed, and in the valve 20, fluid leakage to the atmosphere side through the gap between the through hole 27 and the valve rod 30 can be reduced. it can.

- the valve stem 30 has a valve stem side engaging portion including a convex portion or a concave portion protruding or recessed in the radial direction of the valve stem 30 on the distal end side of the valve stem 30 and the first valve.

- the body 32 has a valve body side engaging portion including a concave portion or a convex portion that is depressed or protruded in the radial direction so as to engage with the valve rod side engaging portion, and the valve rod side engaging portion is a first portion.

- the valve body 32 is loosely fitted to the valve body side engaging portion so as to allow relative displacement in the axial direction of the valve body 30 with respect to the valve body 30.

- the valve stem 30 has a convex portion 52 (valve stem side engaging portion) protruding in the radial direction of the valve stem 30 on the distal end side of the valve stem 30, and the first valve

- the body 32 has a concave portion 58 (valve element side engaging portion) that is recessed in the radial direction of the valve stem 30 so as to engage with the convex portion 52.

- the convex portion 52 (valve stem side engaging portion) is loosely fitted to the concave portion 58 (valve side engaging portion) so as to allow relative displacement in the axial direction of the first valve body 32 with respect to the valve stem 30.

- the convex portion 52 (valve stem side engaging portion) faces the valve opening side (valve opening direction) in the axial direction of the valve stem 30, and the first valve body 32.

- a second surface 56 facing the first valve body 32 facing the valve closing side (valve closing direction) in the axial direction of the valve rod 30.

- a gap (55 or 57) is provided between at least one of the first surface 54 and the first valve body 32 or between the second surface 56 and the first valve body 32.

- the convex portion 52 (valve stem side engaging portion) is loosely fitted to the concave portion 58 (valve body side engaging portion), and the convex portion 52 (valve stem side engaging portion) in the axial direction of the valve stem 30.

- a gap is formed between the joint portion) and the recess 58 (valve element side engaging portion)

- relative displacement in the axial direction of the first valve element 32 with respect to the valve stem 30 is allowed. Therefore, the first valve body 32 can be appropriately pressed against the first valve seat 42 by the urging force of the spring 62A that is the urging member, and the first valve body 32 and the sub seat portion 33A can be reliably sealed.

- a first gap 55 is provided between the first valve body 32 and a second gap 57 is provided between the second surface 56 and the first valve body 32.

- a first gap 55 is formed between the first surface 54 facing the valve opening side of the convex portion (valve rod side engaging portion) and the first valve body 32.

- a second gap 57 is formed between the second surface 56 facing the valve closing side of the convex portion (valve stem side engaging portion) and the first valve body 32.

- the second gap 57 is formed on the valve closing side with respect to the convex portion (valve rod side engaging portion), so that the first valve body 32 and the sub seat portion 33A are formed. Even when the seats cannot be seated at the same time, a good seal can be realized in both the first valve body 32 and the sub-seat portion 33A. Further, the second gap 57 can absorb a difference in thermal elongation between various components including the valve stem 30 and the first valve body 32.

- the spring 62 ⁇ / b> A as the biasing member is inside the valve stem hole 60 that extends in the axial direction of the valve stem 30 so as to open to the distal end surface 70 of the valve stem 30.

- an axial biasing force can be applied to the first valve body 32 by the spring 62A guided by the valve stem hole 60 extending in the axial direction of the valve stem 30.

- the valve 20 further includes a biasing force receiving portion 64 that is located between the first valve body 32 and the spring 62 ⁇ / b> A and transmits the biasing force of the spring 62 ⁇ / b> A to the first valve body 32.

- the urging force receiving portion 64 is engaged with the valve stem hole 60, and is guided in the axial direction of the valve stem 30 by the valve stem hole 60. In this way, by applying an urging force along the axial direction to the first valve body 32 via the urging force receiving portion 64 configured to be guided in the axial direction by the valve stem hole 60, the first valve The body 32 can be appropriately pressed by the first valve seat 42.

- the urging force receiving portion 64 has a spherical shape portion 66 at least partially on the first valve body 32 side, and is configured to contact the first valve body 32 at the spherical shape portion 66.

- the stress concentration can be relaxed, and the life of the biasing force receiving portion 64 or the first valve body 32 can be improved.

- the urging force receiving portion 64 has a protrusion 68 that engages with a groove 69 formed in the first valve body 32 so as to be recessed in the axial direction of the valve rod 30.

- the groove 69 and the protrusion 68 are provided so as to pass through the axial center of the valve stem 30.

- the projection 68 that engages with the groove 69 formed in the first valve body 32 so as to be recessed in the axial direction of the valve stem 30 ensures that the center position of the biasing force receiving portion 64 is aligned with the central axis of the valve stem 30. Can be matched.

- valve body 34 when the second valve body 34 is in the valve opening position away from the second valve seat 26, one of the valve stem 30 or the first valve body 32 is in the valve opening direction of the first valve body 32.

- the second valve body 34 is configured to be biased.

- “when the valve body is in the valve open position” may mean that the valve body is at an arbitrary position away from the valve seat. It may mean that it is in a specific position apart. That is, “when the valve body is in the valve open position” means that the valve body is in at least one position among the positions away from the valve seat.

- the second valve body 34 is formed between the first bush 86 provided on the second valve body 34 and the valve stem 30 when the second valve body 34 is in the valve open position (see FIG. 5).

- the first chamber 88 is configured to have a pressure lower than the pressure in the internal space 35 of the second valve body 34 in which the first valve body 32 is accommodated.

- valve stem 30 has a communication passage 90 extending in the axial direction inside the valve stem 30, and when the second valve body 34 is in the valve open position (see FIG. 5), The first chamber 88 and the second chamber 89 having a lower pressure than the first chamber 88 communicate with each other through the passage 90.

- the second chamber 89 has a first recovery line 48 for recovering leaked fluid through the gap between the second bush 92 provided in the valve casing 22 and the valve stem 30. Formed by.

- the valve stem 30 includes a pair of communication holes (94, 96) connected to both ends of the communication passage 90 and extending in the radial direction of the valve stem 30.

- the pair of communication holes are a first communication hole 94 located on the first valve body 32 side of these communication holes, and a first position located on the opposite side of the first valve body 32 (the base end side of the valve rod 30).

- 2 communication holes 96 are a first communication hole 94 located on the first valve body 32 side of these communication holes, and a first position located on the opposite side of the first valve body 32 (the base end side of the valve rod 30).

- 2 communication holes 96 are a first communication hole 94 located on the first valve body 32 side of these communication holes, and a first position located on the opposite side of the first valve body 32 (the base end side of the valve rod 30).

- 2 communication holes 96 are a first communication hole 94 located on the first valve body 32 side of these communication holes, and a first position located on the opposite side of the first valve body 32 (the base end

- FIG. 5 when the second valve element 34 is in the valve open position away from the second valve seat 26, the first communication hole 94 of the communication passage 90 provided inside the valve rod 30 is the first communication hole 94. While communicating with the first chamber 88, the second communication hole 96 communicates with the first recovery line 48 that is the second chamber 89. Thereby, the first chamber 88 formed on the back side of the first valve body 32 is connected to the first recovery line 48 which is the second chamber 89 having a lower pressure than the internal space 35 via the communication passage 90. The first chamber 88 has a lower pressure than the pressure in the internal space 35 of the second valve body 34.

- the urging force in the valve opening direction of the first valve body 32 based on the pressure difference between the first chamber 88 and the internal space 35 of the second valve body 34 acts on the valve rod 30.

- the first communication hole 94 opens to the valve rod 30 on the valve opening direction side of the valve rod side contact surface 72 and communicates with the first chamber 88.

- the second valve body 34 While being held on the valve opening direction side of the valve body 32, the second valve body 34 moves in the valve closing direction together with the second valve body 34 (a process of transition from the state of FIG. 5 to the state of FIG. 6). Then, as shown in FIG. 6, after the second valve body 34 is seated on the second valve seat 26, the valve rod 30 is further moved in the valve closing direction, and the first valve body 32 is seated on the first valve seat 42 ( (The state shown in FIG. 3 is obtained).

- the second valve body 34 and the first valve body 32 are seated in stages when the valve is closed, the second valve body 34 and the first valve body 32 are seated integrally (for example, the first valve body 32).

- the mass of the valve body that collides with the valve seat is reduced.

- the first chamber 88 is a lift gap for lifting the valve rod 30 and the first valve body 32 relative to the second valve body 34.

- a part of the lift gap is defined by the valve stem side contact surface 72 of the valve stem 30 and the first bush 86.

- the lift gap for lifting the valve rod 30 and the first valve body 32 relative to the second valve body 34 is used to make the first pressure lower than the internal space 35 of the second valve body 34.

- a chamber 88 can be formed.

- the first chamber 88 and the first recovery line 48 which is the second chamber 89, are configured not to communicate with each other when the second valve body 34 is in the valve closing position. That is, the communication path 90 and the first collection line 48 that is the second chamber 89 are separated from each other by the contact portion formed by the contact between the sub-sheet portion 33A and the sub-sheet surface 98A. Yes.

- the second recovery line 50 is provided in the valve casing 22 at a position farther from the first valve body 32 than the first recovery line 48.

- the recovery line 50 is connected to a fluid reservoir (not shown) having a lower pressure than the first recovery line 48.

- the valve 20 when the valve 20 includes the second recovery line 50 in addition to the first recovery line 48, the leaked fluid through the gap between the second bush 92 and the valve stem 30 can be recovered by the first recovery line 48. Even if not, the leaked fluid can be recovered through the second recovery line 50 without being released to the atmosphere.

- the valve stem 30 when the valve stem 30 starts to move in the valve opening direction in the fully closed state of the valve (that is, in a state where both the first valve body 32 and the second valve body 34 are in the closed position).

- the first chamber 88 and the second chamber 89 having a lower pressure than the first chamber 88 communicate with each other through the communication passage 90, and the first chamber 88 has a lower pressure than the pressure in the internal space 35 of the second valve body 34. .

- the inflow of leak fluid from the internal space 35 is promoted between the first bush 86 and the valve stem 30, the slidability between the first bush 86 and the valve stem 30 is improved, and the valve stem 30 is compared. It can be moved with a small driving force.

- an expression representing a relative or absolute arrangement such as “in a certain direction”, “along a certain direction”, “parallel”, “orthogonal”, “center”, “concentric” or “coaxial”. Represents not only such an arrangement strictly but also a state of relative displacement with tolerance or an angle or a distance to obtain the same function.

- an expression indicating that things such as “identical”, “equal”, and “homogeneous” are in an equal state not only represents an exactly equal state, but also has a tolerance or a difference that can provide the same function. It also represents the existing state.

- expressions representing shapes such as quadrangular shapes and cylindrical shapes not only represent shapes such as quadrangular shapes and cylindrical shapes in a strict geometric sense, but also within a range where the same effects can be obtained.

- a shape including an uneven portion or a chamfered portion is also expressed.

- the expression “comprising”, “including”, or “having” one constituent element is not an exclusive expression for excluding the existence of another constituent element.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Lift Valve (AREA)

- Control Of Turbines (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201780028554.4A CN109073094B (zh) | 2016-05-20 | 2017-05-19 | 蒸汽阀、阀及蒸汽轮机设备 |

| DE112017002592.3T DE112017002592T5 (de) | 2016-05-20 | 2017-05-19 | Ventil und Dampfturbinenanlage |

| US16/099,350 US10941865B2 (en) | 2016-05-20 | 2017-05-19 | Steam valve, valve and steam turbine facility |

| KR1020187032328A KR102091505B1 (ko) | 2016-05-20 | 2017-05-19 | 증기 밸브, 밸브 및 증기 터빈 설비 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016101334A JP6718306B2 (ja) | 2016-05-20 | 2016-05-20 | バルブ及び蒸気タービン設備 |

| JP2016-101334 | 2016-05-20 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017200067A1 true WO2017200067A1 (ja) | 2017-11-23 |

Family

ID=60325959

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/018760 Ceased WO2017200067A1 (ja) | 2016-05-20 | 2017-05-19 | バルブ及び蒸気タービン設備 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10941865B2 (enExample) |

| JP (1) | JP6718306B2 (enExample) |

| KR (1) | KR102091505B1 (enExample) |

| CN (1) | CN109073094B (enExample) |

| DE (1) | DE112017002592T5 (enExample) |

| WO (1) | WO2017200067A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020056664A (ja) * | 2018-10-01 | 2020-04-09 | 東北発電工業株式会社 | 測定方法、及び、測定補助具 |

| WO2023149088A1 (ja) * | 2022-02-01 | 2023-08-10 | 三菱重工業株式会社 | 蒸気弁、及び発電システム |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7051398B2 (ja) * | 2017-11-30 | 2022-04-11 | 三菱重工業株式会社 | 開閉弁及び蒸気タービンシステム |

| JP7207999B2 (ja) * | 2018-12-28 | 2023-01-18 | 三菱重工業株式会社 | 蒸気弁、発電システム、及び蒸気弁の検査方法 |

| JP7232043B2 (ja) | 2018-12-28 | 2023-03-02 | 三菱重工業株式会社 | 蒸気弁、及び発電システム |

| JP7236272B2 (ja) * | 2018-12-28 | 2023-03-09 | 三菱重工業株式会社 | 蒸気弁、及び発電システム |

| JP7458168B2 (ja) * | 2019-11-14 | 2024-03-29 | 三菱重工業株式会社 | 蒸気弁及び蒸気タービン設備並びに蒸気弁の組立て方法 |

| CN114059318B (zh) * | 2020-08-04 | 2025-06-20 | 青岛海尔滚筒洗衣机有限公司 | 一种阀芯结构及离心阀及洗衣机 |

| US11585449B2 (en) * | 2020-10-21 | 2023-02-21 | Caterpillar Inc. | Pilot operated bypass valve with reverse check |

| DE102022109609B3 (de) * | 2022-04-21 | 2023-08-03 | Otto Egelhof Gmbh & Co. Kg | Ventil zur Steuerung eines Mediums in einem Kälte- oder Wärmekreislauf |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5037027A (enExample) * | 1973-06-22 | 1975-04-07 | ||

| JPS57144354A (en) * | 1981-02-27 | 1982-09-06 | Toshiba Corp | Valve mechanism for low temperature |

| JPS58134284A (ja) * | 1982-02-03 | 1983-08-10 | Ishikawajima Harima Heavy Ind Co Ltd | 高温流体遮断弁 |

| JPH02125285U (enExample) * | 1989-03-28 | 1990-10-16 | ||

| JPH05965U (ja) * | 1991-06-26 | 1993-01-08 | 株式会社アツギユニシア | 流量制御バルブ |

| JP2003329158A (ja) * | 2002-05-15 | 2003-11-19 | Saginomiya Seisakusho Inc | 電動弁 |

| JP2012021568A (ja) * | 2010-07-14 | 2012-02-02 | Mitsubishi Heavy Ind Ltd | 水平弁 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US433543A (en) * | 1890-08-05 | Automatic relief-valve | ||

| US2666452A (en) * | 1951-12-29 | 1954-01-19 | Gen Electric | Valve actuating mechanism |

| US3459212A (en) * | 1967-05-15 | 1969-08-05 | Donald C Campion Sr | Vented fluid valve |

| US3529630A (en) * | 1968-04-11 | 1970-09-22 | Westinghouse Electric Corp | Combined stop and control valve |

| BR7604063A (pt) * | 1975-08-13 | 1977-06-28 | Kraftwerk Union Ag | Instalacao de reator nuclear |

| JPS58134284U (ja) * | 1982-03-01 | 1983-09-09 | 松下電器産業株式会社 | 真空封止治具 |

| JP2005321061A (ja) | 2004-05-11 | 2005-11-17 | Kubota Corp | 高温用弁 |

| JP6037684B2 (ja) * | 2012-07-02 | 2016-12-07 | 三菱日立パワーシステムズ株式会社 | 蒸気タービン設備 |

| WO2014098073A1 (ja) * | 2012-12-21 | 2014-06-26 | 三菱重工業株式会社 | 蒸気弁及び蒸気タービン |

| US9670794B2 (en) * | 2014-02-19 | 2017-06-06 | Mitsubishi Heavy Industries Compressor Corporation | Steam valve and steam turbine |

| JP6382556B2 (ja) * | 2014-04-08 | 2018-08-29 | 株式会社東芝 | 蒸気弁 |

| JP6557577B2 (ja) * | 2015-10-30 | 2019-08-07 | 三菱日立パワーシステムズ株式会社 | 蒸気弁及び蒸気タービンシステム |

| JP6606407B2 (ja) * | 2015-11-12 | 2019-11-13 | 三菱日立パワーシステムズ株式会社 | 蒸気弁及び蒸気タービンシステム |

| JP6855846B2 (ja) * | 2017-03-06 | 2021-04-07 | セイコーエプソン株式会社 | ペースト及び三次元造形物の製造方法 |

-

2016

- 2016-05-20 JP JP2016101334A patent/JP6718306B2/ja active Active

-

2017

- 2017-05-19 DE DE112017002592.3T patent/DE112017002592T5/de active Pending

- 2017-05-19 KR KR1020187032328A patent/KR102091505B1/ko active Active

- 2017-05-19 WO PCT/JP2017/018760 patent/WO2017200067A1/ja not_active Ceased

- 2017-05-19 US US16/099,350 patent/US10941865B2/en active Active

- 2017-05-19 CN CN201780028554.4A patent/CN109073094B/zh active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5037027A (enExample) * | 1973-06-22 | 1975-04-07 | ||

| JPS57144354A (en) * | 1981-02-27 | 1982-09-06 | Toshiba Corp | Valve mechanism for low temperature |

| JPS58134284A (ja) * | 1982-02-03 | 1983-08-10 | Ishikawajima Harima Heavy Ind Co Ltd | 高温流体遮断弁 |

| JPH02125285U (enExample) * | 1989-03-28 | 1990-10-16 | ||

| JPH05965U (ja) * | 1991-06-26 | 1993-01-08 | 株式会社アツギユニシア | 流量制御バルブ |

| JP2003329158A (ja) * | 2002-05-15 | 2003-11-19 | Saginomiya Seisakusho Inc | 電動弁 |

| JP2012021568A (ja) * | 2010-07-14 | 2012-02-02 | Mitsubishi Heavy Ind Ltd | 水平弁 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020056664A (ja) * | 2018-10-01 | 2020-04-09 | 東北発電工業株式会社 | 測定方法、及び、測定補助具 |

| WO2023149088A1 (ja) * | 2022-02-01 | 2023-08-10 | 三菱重工業株式会社 | 蒸気弁、及び発電システム |

| JPWO2023149088A1 (enExample) * | 2022-02-01 | 2023-08-10 | ||

| JP7654120B2 (ja) | 2022-02-01 | 2025-03-31 | 三菱重工業株式会社 | 蒸気弁、及び発電システム |

Also Published As

| Publication number | Publication date |

|---|---|

| KR102091505B1 (ko) | 2020-03-20 |

| DE112017002592T5 (de) | 2019-04-25 |

| KR20180127499A (ko) | 2018-11-28 |

| JP2017207174A (ja) | 2017-11-24 |

| CN109073094B (zh) | 2021-03-12 |

| US20190178388A1 (en) | 2019-06-13 |

| CN109073094A (zh) | 2018-12-21 |

| JP6718306B2 (ja) | 2020-07-08 |

| US10941865B2 (en) | 2021-03-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017200067A1 (ja) | バルブ及び蒸気タービン設備 | |

| EP3040588B1 (en) | Double piston effect lip seal seating assemblies | |

| EP2492559B1 (en) | Solenoid valve | |

| JP2006097900A5 (enExample) | ||

| CN1746542B (zh) | 蒸汽阀 | |

| JP2017207174A5 (enExample) | ||

| JP6713826B2 (ja) | 親子弁及びその閉弁方法並びに蒸気タービン設備 | |

| JP2016534289A (ja) | ターボ機械のための弁 | |

| JP5982703B2 (ja) | 減圧弁 | |

| JP6773469B2 (ja) | ガス弁装置 | |

| KR20190133550A (ko) | 노즐 체크밸브용 디스크의 최적 운동속도 가변 조절장치 | |

| JP2019100243A (ja) | 蒸気弁および蒸気タービン | |

| JP2010266000A (ja) | 過流防止弁 | |

| JP5722164B2 (ja) | 減圧装置 | |

| JP7458168B2 (ja) | 蒸気弁及び蒸気タービン設備並びに蒸気弁の組立て方法 | |

| US20240328538A1 (en) | Steam valve and power generation system | |

| JP6218233B2 (ja) | 減圧弁 | |

| KR101741482B1 (ko) | 닫힘 상태에서 조작력 완화구조를 가지는 플로팅 타입 볼 밸브 | |

| JP6367078B2 (ja) | バタフライ弁の止水構造 | |

| JP5712092B2 (ja) | パイロット機能付き弁 | |

| JP2012172519A (ja) | フラップバルブ | |

| JP5430104B2 (ja) | バルブ付き管継手 | |

| JP2018146103A (ja) | 電磁弁装置 | |

| RU2591382C1 (ru) | Клапан | |

| JP6268593B2 (ja) | 2部材の連結構造 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 20187032328 Country of ref document: KR Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17799491 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 17799491 Country of ref document: EP Kind code of ref document: A1 |