WO2016151899A1 - シート - Google Patents

シート Download PDFInfo

- Publication number

- WO2016151899A1 WO2016151899A1 PCT/JP2015/077522 JP2015077522W WO2016151899A1 WO 2016151899 A1 WO2016151899 A1 WO 2016151899A1 JP 2015077522 W JP2015077522 W JP 2015077522W WO 2016151899 A1 WO2016151899 A1 WO 2016151899A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sheet

- layer

- resin

- protective layer

- gloss

- Prior art date

Links

- 238000001514 detection method Methods 0.000 claims abstract description 7

- 239000010410 layer Substances 0.000 claims description 187

- 239000011241 protective layer Substances 0.000 claims description 122

- 229920005989 resin Polymers 0.000 claims description 106

- 239000011347 resin Substances 0.000 claims description 106

- 239000010419 fine particle Substances 0.000 claims description 54

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 38

- 239000000377 silicon dioxide Substances 0.000 claims description 18

- 230000005865 ionizing radiation Effects 0.000 claims description 13

- 239000012508 resin bead Substances 0.000 claims description 13

- 239000000758 substrate Substances 0.000 claims description 5

- 238000009408 flooring Methods 0.000 claims description 4

- 229920005672 polyolefin resin Polymers 0.000 claims description 3

- 238000013461 design Methods 0.000 abstract description 43

- 239000002245 particle Substances 0.000 description 42

- 239000000049 pigment Substances 0.000 description 37

- 238000000034 method Methods 0.000 description 32

- 239000000463 material Substances 0.000 description 30

- -1 polyethylene terephthalate Polymers 0.000 description 28

- 239000004606 Fillers/Extenders Substances 0.000 description 25

- 239000002023 wood Substances 0.000 description 22

- 239000003795 chemical substances by application Substances 0.000 description 16

- 229920002803 thermoplastic polyurethane Polymers 0.000 description 15

- 239000011324 bead Substances 0.000 description 12

- 239000003086 colorant Substances 0.000 description 12

- 238000010894 electron beam technology Methods 0.000 description 12

- 238000012360 testing method Methods 0.000 description 12

- 239000000203 mixture Substances 0.000 description 11

- 239000012790 adhesive layer Substances 0.000 description 10

- 230000000694 effects Effects 0.000 description 10

- 239000002932 luster Substances 0.000 description 10

- 238000007639 printing Methods 0.000 description 10

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 9

- 239000000853 adhesive Substances 0.000 description 9

- 238000000576 coating method Methods 0.000 description 9

- 238000011156 evaluation Methods 0.000 description 9

- 230000001788 irregular Effects 0.000 description 9

- 239000007787 solid Substances 0.000 description 9

- 230000000007 visual effect Effects 0.000 description 9

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 8

- 239000004743 Polypropylene Substances 0.000 description 8

- 239000000654 additive Substances 0.000 description 8

- 229920001155 polypropylene Polymers 0.000 description 8

- 241000272525 Anas platyrhynchos Species 0.000 description 7

- 230000001070 adhesive effect Effects 0.000 description 7

- 239000011342 resin composition Substances 0.000 description 7

- 239000002904 solvent Substances 0.000 description 7

- 229920002554 vinyl polymer Polymers 0.000 description 7

- 230000000996 additive effect Effects 0.000 description 6

- 230000000052 comparative effect Effects 0.000 description 6

- 239000000945 filler Substances 0.000 description 6

- 239000004925 Acrylic resin Substances 0.000 description 5

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 5

- 239000004698 Polyethylene Substances 0.000 description 5

- 229920001577 copolymer Polymers 0.000 description 5

- 239000000975 dye Substances 0.000 description 5

- 239000001023 inorganic pigment Substances 0.000 description 5

- 239000012948 isocyanate Substances 0.000 description 5

- 238000002156 mixing Methods 0.000 description 5

- 229920000573 polyethylene Polymers 0.000 description 5

- 229920000915 polyvinyl chloride Polymers 0.000 description 5

- 239000004800 polyvinyl chloride Substances 0.000 description 5

- 229920001187 thermosetting polymer Polymers 0.000 description 5

- 229920000178 Acrylic resin Polymers 0.000 description 4

- UQSXHKLRYXJYBZ-UHFFFAOYSA-N Iron oxide Chemical compound [Fe]=O UQSXHKLRYXJYBZ-UHFFFAOYSA-N 0.000 description 4

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 4

- TZCXTZWJZNENPQ-UHFFFAOYSA-L barium sulfate Chemical compound [Ba+2].[O-]S([O-])(=O)=O TZCXTZWJZNENPQ-UHFFFAOYSA-L 0.000 description 4

- 229910000019 calcium carbonate Inorganic materials 0.000 description 4

- OSGAYBCDTDRGGQ-UHFFFAOYSA-L calcium sulfate Chemical compound [Ca+2].[O-]S([O-])(=O)=O OSGAYBCDTDRGGQ-UHFFFAOYSA-L 0.000 description 4

- 239000004927 clay Substances 0.000 description 4

- 238000004040 coloring Methods 0.000 description 4

- 238000007646 gravure printing Methods 0.000 description 4

- 239000003999 initiator Substances 0.000 description 4

- 230000003993 interaction Effects 0.000 description 4

- 150000002513 isocyanates Chemical class 0.000 description 4

- 238000010030 laminating Methods 0.000 description 4

- FJQXCDYVZAHXNS-UHFFFAOYSA-N methadone hydrochloride Chemical compound Cl.C=1C=CC=CC=1C(CC(C)N(C)C)(C(=O)CC)C1=CC=CC=C1 FJQXCDYVZAHXNS-UHFFFAOYSA-N 0.000 description 4

- 229920002037 poly(vinyl butyral) polymer Polymers 0.000 description 4

- 239000000047 product Substances 0.000 description 4

- 229920006337 unsaturated polyester resin Polymers 0.000 description 4

- DHKHKXVYLBGOIT-UHFFFAOYSA-N 1,1-Diethoxyethane Chemical compound CCOC(C)OCC DHKHKXVYLBGOIT-UHFFFAOYSA-N 0.000 description 3

- 239000004716 Ethylene/acrylic acid copolymer Substances 0.000 description 3

- 244000043261 Hevea brasiliensis Species 0.000 description 3

- 239000005057 Hexamethylene diisocyanate Substances 0.000 description 3

- 229920000877 Melamine resin Polymers 0.000 description 3

- 239000006096 absorbing agent Substances 0.000 description 3

- 239000003963 antioxidant agent Substances 0.000 description 3

- 239000011230 binding agent Substances 0.000 description 3

- 239000012461 cellulose resin Substances 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 238000003851 corona treatment Methods 0.000 description 3

- 238000001035 drying Methods 0.000 description 3

- 239000003822 epoxy resin Substances 0.000 description 3

- 239000003063 flame retardant Substances 0.000 description 3

- 239000004088 foaming agent Substances 0.000 description 3

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 3

- RRAMGCGOFNQTLD-UHFFFAOYSA-N hexamethylene diisocyanate Chemical compound O=C=NCCCCCCN=C=O RRAMGCGOFNQTLD-UHFFFAOYSA-N 0.000 description 3

- 229920000554 ionomer Polymers 0.000 description 3

- 239000004611 light stabiliser Substances 0.000 description 3

- 239000000314 lubricant Substances 0.000 description 3

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 3

- 229910052753 mercury Inorganic materials 0.000 description 3

- 229920003052 natural elastomer Polymers 0.000 description 3

- 229920001194 natural rubber Polymers 0.000 description 3

- 239000005011 phenolic resin Substances 0.000 description 3

- 229920000515 polycarbonate Polymers 0.000 description 3

- 239000004417 polycarbonate Substances 0.000 description 3

- 229920000647 polyepoxide Polymers 0.000 description 3

- 229920000728 polyester Polymers 0.000 description 3

- 229920001225 polyester resin Polymers 0.000 description 3

- 239000004645 polyester resin Substances 0.000 description 3

- 229920005862 polyol Polymers 0.000 description 3

- 229920005749 polyurethane resin Polymers 0.000 description 3

- 229920002689 polyvinyl acetate Polymers 0.000 description 3

- 239000011118 polyvinyl acetate Substances 0.000 description 3

- 229920005992 thermoplastic resin Polymers 0.000 description 3

- VVBLNCFGVYUYGU-UHFFFAOYSA-N 4,4'-Bis(dimethylamino)benzophenone Chemical compound C1=CC(N(C)C)=CC=C1C(=O)C1=CC=C(N(C)C)C=C1 VVBLNCFGVYUYGU-UHFFFAOYSA-N 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 2

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 2

- 229920000742 Cotton Polymers 0.000 description 2

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 2

- 239000004677 Nylon Substances 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- 229920001807 Urea-formaldehyde Polymers 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 2

- 239000011354 acetal resin Substances 0.000 description 2

- AYJRCSIUFZENHW-DEQYMQKBSA-L barium(2+);oxomethanediolate Chemical compound [Ba+2].[O-][14C]([O-])=O AYJRCSIUFZENHW-DEQYMQKBSA-L 0.000 description 2

- ISAOCJYIOMOJEB-UHFFFAOYSA-N benzoin Chemical compound C=1C=CC=CC=1C(O)C(=O)C1=CC=CC=C1 ISAOCJYIOMOJEB-UHFFFAOYSA-N 0.000 description 2

- 229920001400 block copolymer Polymers 0.000 description 2

- QHIWVLPBUQWDMQ-UHFFFAOYSA-N butyl prop-2-enoate;methyl 2-methylprop-2-enoate;prop-2-enoic acid Chemical compound OC(=O)C=C.COC(=O)C(C)=C.CCCCOC(=O)C=C QHIWVLPBUQWDMQ-UHFFFAOYSA-N 0.000 description 2

- 239000006229 carbon black Substances 0.000 description 2

- 239000011093 chipboard Substances 0.000 description 2

- 229910052570 clay Inorganic materials 0.000 description 2

- 238000004132 cross linking Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- GVPWHKZIJBODOX-UHFFFAOYSA-N dibenzyl disulfide Chemical compound C=1C=CC=CC=1CSSCC1=CC=CC=C1 GVPWHKZIJBODOX-UHFFFAOYSA-N 0.000 description 2

- 208000028659 discharge Diseases 0.000 description 2

- 239000002612 dispersion medium Substances 0.000 description 2

- 238000004049 embossing Methods 0.000 description 2

- QHZOMAXECYYXGP-UHFFFAOYSA-N ethene;prop-2-enoic acid Chemical compound C=C.OC(=O)C=C QHZOMAXECYYXGP-UHFFFAOYSA-N 0.000 description 2

- UHESRSKEBRADOO-UHFFFAOYSA-N ethyl carbamate;prop-2-enoic acid Chemical compound OC(=O)C=C.CCOC(N)=O UHESRSKEBRADOO-UHFFFAOYSA-N 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- 239000011094 fiberboard Substances 0.000 description 2

- 238000007756 gravure coating Methods 0.000 description 2

- 238000003475 lamination Methods 0.000 description 2

- ZLNQQNXFFQJAID-UHFFFAOYSA-L magnesium carbonate Chemical compound [Mg+2].[O-]C([O-])=O ZLNQQNXFFQJAID-UHFFFAOYSA-L 0.000 description 2

- 239000001095 magnesium carbonate Substances 0.000 description 2

- 229910000021 magnesium carbonate Inorganic materials 0.000 description 2

- VTHJTEIRLNZDEV-UHFFFAOYSA-L magnesium dihydroxide Chemical compound [OH-].[OH-].[Mg+2] VTHJTEIRLNZDEV-UHFFFAOYSA-L 0.000 description 2

- 239000000347 magnesium hydroxide Substances 0.000 description 2

- 229910001862 magnesium hydroxide Inorganic materials 0.000 description 2

- 239000006224 matting agent Substances 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000002609 medium Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229920001778 nylon Polymers 0.000 description 2

- 239000012860 organic pigment Substances 0.000 description 2

- 239000011120 plywood Substances 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 229920006122 polyamide resin Polymers 0.000 description 2

- 229920001707 polybutylene terephthalate Polymers 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 150000003077 polyols Chemical class 0.000 description 2

- 229920006324 polyoxymethylene Polymers 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 229920002050 silicone resin Polymers 0.000 description 2

- 239000004575 stone Substances 0.000 description 2

- 239000000454 talc Substances 0.000 description 2

- 229910052623 talc Inorganic materials 0.000 description 2

- 235000010215 titanium dioxide Nutrition 0.000 description 2

- DVKJHBMWWAPEIU-UHFFFAOYSA-N toluene 2,4-diisocyanate Chemical compound CC1=CC=C(N=C=O)C=C1N=C=O DVKJHBMWWAPEIU-UHFFFAOYSA-N 0.000 description 2

- 150000003673 urethanes Chemical class 0.000 description 2

- VZXTWGWHSMCWGA-UHFFFAOYSA-N 1,3,5-triazine-2,4-diamine Chemical compound NC1=NC=NC(N)=N1 VZXTWGWHSMCWGA-UHFFFAOYSA-N 0.000 description 1

- FEWSKCAVEJNPBX-UHFFFAOYSA-N 2-(2-hydroxy-2-phenylacetyl)benzenesulfonic acid Chemical compound C=1C=CC=CC=1C(O)C(=O)C1=CC=CC=C1S(O)(=O)=O FEWSKCAVEJNPBX-UHFFFAOYSA-N 0.000 description 1

- AGTPDKIQPDEUOA-UHFFFAOYSA-N 2-(dimethylamino)-3-propan-2-ylbenzoic acid Chemical compound CC(C)C1=CC=CC(C(O)=O)=C1N(C)C AGTPDKIQPDEUOA-UHFFFAOYSA-N 0.000 description 1

- WFUGQJXVXHBTEM-UHFFFAOYSA-N 2-hydroperoxy-2-(2-hydroperoxybutan-2-ylperoxy)butane Chemical compound CCC(C)(OO)OOC(C)(CC)OO WFUGQJXVXHBTEM-UHFFFAOYSA-N 0.000 description 1

- BQZJOQXSCSZQPS-UHFFFAOYSA-N 2-methoxy-1,2-diphenylethanone Chemical compound C=1C=CC=CC=1C(OC)C(=O)C1=CC=CC=C1 BQZJOQXSCSZQPS-UHFFFAOYSA-N 0.000 description 1

- PYSRRFNXTXNWCD-UHFFFAOYSA-N 3-(2-phenylethenyl)furan-2,5-dione Chemical compound O=C1OC(=O)C(C=CC=2C=CC=CC=2)=C1 PYSRRFNXTXNWCD-UHFFFAOYSA-N 0.000 description 1

- UPMLOUAZCHDJJD-UHFFFAOYSA-N 4,4'-Diphenylmethane Diisocyanate Chemical compound C1=CC(N=C=O)=CC=C1CC1=CC=C(N=C=O)C=C1 UPMLOUAZCHDJJD-UHFFFAOYSA-N 0.000 description 1

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 1

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 1

- 238000012935 Averaging Methods 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 241000218645 Cedrus Species 0.000 description 1

- 229920002284 Cellulose triacetate Polymers 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 239000004641 Diallyl-phthalate Substances 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- 239000005058 Isophorone diisocyanate Substances 0.000 description 1

- 235000008331 Pinus X rigitaeda Nutrition 0.000 description 1

- 235000011613 Pinus brutia Nutrition 0.000 description 1

- 241000018646 Pinus brutia Species 0.000 description 1

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 1

- 239000005062 Polybutadiene Substances 0.000 description 1

- 239000004721 Polyphenylene oxide Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- NBBJYMSMWIIQGU-UHFFFAOYSA-N Propionic aldehyde Chemical compound CCC=O NBBJYMSMWIIQGU-UHFFFAOYSA-N 0.000 description 1

- NRCMAYZCPIVABH-UHFFFAOYSA-N Quinacridone Chemical compound N1C2=CC=CC=C2C(=O)C2=C1C=C1C(=O)C3=CC=CC=C3NC1=C2 NRCMAYZCPIVABH-UHFFFAOYSA-N 0.000 description 1

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 description 1

- 244000028419 Styrax benzoin Species 0.000 description 1

- 235000000126 Styrax benzoin Nutrition 0.000 description 1

- 229920000147 Styrene maleic anhydride Polymers 0.000 description 1

- 235000008411 Sumatra benzointree Nutrition 0.000 description 1

- 240000002871 Tectona grandis Species 0.000 description 1

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 1

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 1

- 229920002433 Vinyl chloride-vinyl acetate copolymer Polymers 0.000 description 1

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 1

- NNLVGZFZQQXQNW-ADJNRHBOSA-N [(2r,3r,4s,5r,6s)-4,5-diacetyloxy-3-[(2s,3r,4s,5r,6r)-3,4,5-triacetyloxy-6-(acetyloxymethyl)oxan-2-yl]oxy-6-[(2r,3r,4s,5r,6s)-4,5,6-triacetyloxy-2-(acetyloxymethyl)oxan-3-yl]oxyoxan-2-yl]methyl acetate Chemical compound O([C@@H]1O[C@@H]([C@H]([C@H](OC(C)=O)[C@H]1OC(C)=O)O[C@H]1[C@@H]([C@@H](OC(C)=O)[C@H](OC(C)=O)[C@@H](COC(C)=O)O1)OC(C)=O)COC(=O)C)[C@@H]1[C@@H](COC(C)=O)O[C@@H](OC(C)=O)[C@H](OC(C)=O)[C@H]1OC(C)=O NNLVGZFZQQXQNW-ADJNRHBOSA-N 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 238000006359 acetalization reaction Methods 0.000 description 1

- 150000001241 acetals Chemical class 0.000 description 1

- 150000008062 acetophenones Chemical class 0.000 description 1

- 125000005396 acrylic acid ester group Chemical group 0.000 description 1

- 150000001299 aldehydes Chemical class 0.000 description 1

- GZCGUPFRVQAUEE-SLPGGIOYSA-N aldehydo-D-glucose Chemical compound OC[C@@H](O)[C@@H](O)[C@H](O)[C@@H](O)C=O GZCGUPFRVQAUEE-SLPGGIOYSA-N 0.000 description 1

- 125000001931 aliphatic group Chemical group 0.000 description 1

- 229920000180 alkyd Polymers 0.000 description 1

- 125000000217 alkyl group Chemical group 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 150000001413 amino acids Chemical class 0.000 description 1

- PYKYMHQGRFAEBM-UHFFFAOYSA-N anthraquinone Natural products CCC(=O)c1c(O)c2C(=O)C3C(C=CC=C3O)C(=O)c2cc1CC(=O)OC PYKYMHQGRFAEBM-UHFFFAOYSA-N 0.000 description 1

- 150000004056 anthraquinones Chemical class 0.000 description 1

- 239000002518 antifoaming agent Substances 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 239000010426 asphalt Substances 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- CHIHQLCVLOXUJW-UHFFFAOYSA-N benzoic anhydride Chemical compound C=1C=CC=CC=1C(=O)OC(=O)C1=CC=CC=C1 CHIHQLCVLOXUJW-UHFFFAOYSA-N 0.000 description 1

- 229960002130 benzoin Drugs 0.000 description 1

- 239000012965 benzophenone Substances 0.000 description 1

- 150000008366 benzophenones Chemical class 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- QUDWYFHPNIMBFC-UHFFFAOYSA-N bis(prop-2-enyl) benzene-1,2-dicarboxylate Chemical compound C=CCOC(=O)C1=CC=CC=C1C(=O)OCC=C QUDWYFHPNIMBFC-UHFFFAOYSA-N 0.000 description 1

- GLQBXSIPUULYOG-UHFFFAOYSA-M bismuth oxychloride Chemical compound Cl[Bi]=O GLQBXSIPUULYOG-UHFFFAOYSA-M 0.000 description 1

- 229910052793 cadmium Inorganic materials 0.000 description 1

- BDOSMKKIYDKNTQ-UHFFFAOYSA-N cadmium atom Chemical compound [Cd] BDOSMKKIYDKNTQ-UHFFFAOYSA-N 0.000 description 1

- 239000004202 carbamide Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 235000019241 carbon black Nutrition 0.000 description 1

- 125000002091 cationic group Chemical group 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000004581 coalescence Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- XCJYREBRNVKWGJ-UHFFFAOYSA-N copper(II) phthalocyanine Chemical compound [Cu+2].C12=CC=CC=C2C(N=C2[N-]C(C3=CC=CC=C32)=N2)=NC1=NC([C]1C=CC=CC1=1)=NC=1N=C1[C]3C=CC=CC3=C2[N-]1 XCJYREBRNVKWGJ-UHFFFAOYSA-N 0.000 description 1

- 239000003431 cross linking reagent Substances 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 239000012954 diazonium Substances 0.000 description 1

- PPSZHCXTGRHULJ-UHFFFAOYSA-N dioxazine Chemical compound O1ON=CC=C1 PPSZHCXTGRHULJ-UHFFFAOYSA-N 0.000 description 1

- LTYMSROWYAPPGB-UHFFFAOYSA-N diphenyl sulfide Chemical compound C=1C=CC=CC=1SC1=CC=CC=C1 LTYMSROWYAPPGB-UHFFFAOYSA-N 0.000 description 1

- KPUWHANPEXNPJT-UHFFFAOYSA-N disiloxane Chemical class [SiH3]O[SiH3] KPUWHANPEXNPJT-UHFFFAOYSA-N 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 238000010828 elution Methods 0.000 description 1

- 125000003700 epoxy group Chemical group 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 150000004676 glycans Chemical class 0.000 description 1

- 239000010438 granite Substances 0.000 description 1

- 235000019382 gum benzoic Nutrition 0.000 description 1

- 125000004051 hexyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 239000010954 inorganic particle Substances 0.000 description 1

- 238000010884 ion-beam technique Methods 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- PXZQEOJJUGGUIB-UHFFFAOYSA-N isoindolin-1-one Chemical compound C1=CC=C2C(=O)NCC2=C1 PXZQEOJJUGGUIB-UHFFFAOYSA-N 0.000 description 1

- NIMLQBUJDJZYEJ-UHFFFAOYSA-N isophorone diisocyanate Chemical compound CC1(C)CC(N=C=O)CC(C)(CN=C=O)C1 NIMLQBUJDJZYEJ-UHFFFAOYSA-N 0.000 description 1

- 239000010985 leather Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 1

- 150000007974 melamines Chemical class 0.000 description 1

- 229910001507 metal halide Inorganic materials 0.000 description 1

- 150000005309 metal halides Chemical class 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 125000005397 methacrylic acid ester group Chemical group 0.000 description 1

- 125000005395 methacrylic acid group Chemical group 0.000 description 1

- 239000010445 mica Substances 0.000 description 1

- 229910052618 mica group Inorganic materials 0.000 description 1

- 239000011859 microparticle Substances 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 229920005615 natural polymer Polymers 0.000 description 1

- 230000003472 neutralizing effect Effects 0.000 description 1

- 150000002825 nitriles Chemical class 0.000 description 1

- 238000007645 offset printing Methods 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 239000011146 organic particle Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 150000002978 peroxides Chemical class 0.000 description 1

- 229920001568 phenolic resin Polymers 0.000 description 1

- IEQIEDJGQAUEQZ-UHFFFAOYSA-N phthalocyanine Chemical compound N1C(N=C2C3=CC=CC=C3C(N=C3C4=CC=CC=C4C(=N4)N3)=N2)=C(C=CC=C2)C2=C1N=C1C2=CC=CC=C2C4=N1 IEQIEDJGQAUEQZ-UHFFFAOYSA-N 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 229920000191 poly(N-vinyl pyrrolidone) Polymers 0.000 description 1

- 229920001084 poly(chloroprene) Polymers 0.000 description 1

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 1

- 229920002401 polyacrylamide Polymers 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920002857 polybutadiene Polymers 0.000 description 1

- 229920005906 polyester polyol Polymers 0.000 description 1

- 229920000570 polyether Polymers 0.000 description 1

- 239000011112 polyethylene naphthalate Substances 0.000 description 1

- 239000003505 polymerization initiator Substances 0.000 description 1

- 229920000306 polymethylpentene Polymers 0.000 description 1

- 239000011116 polymethylpentene Substances 0.000 description 1

- 102000040430 polynucleotide Human genes 0.000 description 1

- 108091033319 polynucleotide Proteins 0.000 description 1

- 239000002157 polynucleotide Substances 0.000 description 1

- 229920001184 polypeptide Polymers 0.000 description 1

- 229920001282 polysaccharide Polymers 0.000 description 1

- 239000005017 polysaccharide Substances 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920005553 polystyrene-acrylate Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000012805 post-processing Methods 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 125000002924 primary amino group Chemical group [H]N([H])* 0.000 description 1

- 102000004196 processed proteins & peptides Human genes 0.000 description 1

- 108090000765 processed proteins & peptides Proteins 0.000 description 1

- KCTAWXVAICEBSD-UHFFFAOYSA-N prop-2-enoyloxy prop-2-eneperoxoate Chemical compound C=CC(=O)OOOC(=O)C=C KCTAWXVAICEBSD-UHFFFAOYSA-N 0.000 description 1

- 150000003254 radicals Chemical class 0.000 description 1

- 238000002310 reflectometry Methods 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 239000005060 rubber Substances 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 230000035807 sensation Effects 0.000 description 1

- 229920001909 styrene-acrylic polymer Polymers 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 150000003871 sulfonates Chemical class 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 239000005061 synthetic rubber Substances 0.000 description 1

- 239000013008 thixotropic agent Substances 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 229920006186 water-soluble synthetic resin Polymers 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

- 239000011787 zinc oxide Substances 0.000 description 1

- 235000014692 zinc oxide Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/20—Layered products comprising a layer of synthetic resin characterised by the use of special additives using fillers, pigments, thixotroping agents

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/042—Coating with two or more layers, where at least one layer of a composition contains a polymer binder

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/043—Improving the adhesiveness of the coatings per se, e.g. forming primers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/046—Forming abrasion-resistant coatings; Forming surface-hardening coatings

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F15/00—Flooring

- E04F15/16—Flooring, e.g. parquet on flexible web, laid as flexible webs; Webs specially adapted for use as flooring; Parquet on flexible web

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/10—Coating on the layer surface on synthetic resin layer or on natural or synthetic rubber layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/26—Polymeric coating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2255/00—Coating on the layer surface

- B32B2255/28—Multiple coating on one surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/02—Synthetic macromolecular particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/10—Inorganic particles

- B32B2264/102—Oxide or hydroxide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/406—Bright, glossy, shiny surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/412—Transparent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/416—Reflective

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/538—Roughness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/732—Dimensional properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2310/00—Treatment by energy or chemical effects

- B32B2310/08—Treatment by energy or chemical effects by wave energy or particle radiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2363/00—Epoxy resins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2367/00—Polyesters, e.g. PET, i.e. polyethylene terephthalate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2471/00—Floor coverings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2607/00—Walls, panels

- B32B2607/02—Wall papers, wall coverings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24893—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] including particulate material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24942—Structurally defined web or sheet [e.g., overall dimension, etc.] including components having same physical characteristic in differing degree

Definitions

- the present invention relates to a sheet.

- sheets have been laminated on the surface of various articles in order to impart design properties.

- a decorative sheet on which a pattern such as a wood grain pattern is printed is laminated and used on the surface of an interior material such as a wall covering material used for a wall surface of a building or a floor decorative material used on a floor surface.

- Such interior materials are used as an alternative to natural wood interior materials.

- the sheet laminated on the surface of the article as described above is required to suppress the gloss of the surface in order to improve the design. If the surface has a high gloss, the light from a lighting fixture such as a fluorescent lamp is reflected to deteriorate the texture, and the reflected light appears to shine white.

- Such a decorative sheet is also a sheet that is excellent in low gloss and excellent in suppressing light reflection, there is room for study on suppression of light reflection on the surface, and further design is required.

- a sheet is laminated on a flat adherend, when oblique light is incident on the flat surface from a lighting fixture or the like, the light is diffusely reflected, and when viewed from an oblique direction, it appears to shine white, and a sheet such as a pattern

- the design expressed by is difficult to visually recognize and the design properties are lowered.

- the present invention is excellent in low gloss, suppresses irregular reflection of light even when oblique light is incident on the surface, the surface is difficult to look white when viewed from an oblique direction, and the design to be expressed is visible. It aims at providing the sheet

- the present inventors set the arithmetic average roughness Ra (JIS B0633: 2001) of the surface of the sheet to a specific range, and the incident light with an incident angle of 75 ° is applied to the surface by a goniophotometer.

- the above object can be achieved by setting the reflectance at the detection angle of regular reflection angle + 5 ° and the reflectance at the detection angle of regular reflection angle ⁇ 5 °, which are measured when irradiated, within a specific range.

- the headline and the present invention were completed.

- the present invention relates to the following sheets.

- the arithmetic average roughness Ra (JIS B0633: 2001) of the surface is 0.7 ⁇ m or less

- the reflectance at the detection angle of the regular reflection angle ⁇ 5 ° measured when the surface is irradiated with incident light with an incident angle of 75 ° by a variable angle photometer is 50% or less of the reflectance at the regular reflection angle.

- Is A sheet characterized by that. 2.

- Item 2 The sheet according to Item 1, wherein the outermost surface has a surface protective layer containing an ionizing radiation curable resin. 3.

- Item 5. The sheet according to any one of Items 1 to 4, which has a pattern layer. 6).

- Item 6. The sheet according to Item 5, wherein at least the pattern layer, the transparent resin layer, and the surface protective layer are laminated in this order on a substrate sheet. 7).

- Item 7. The sheet according to any one of Items 1 to 6, wherein the sheet has a thickness of 50 to 600 ⁇ m. 8).

- Item 8. The sheet according to any one of Items 1 to 7, which is a decorative sheet for flooring.

- the sheet of the present invention has a surface arithmetic average roughness Ra (JIS B 0633: 2001) of 0.7 ⁇ m or less, and is measured when incident light with an incident angle of 75 ° is irradiated on the surface by a goniophotometer.

- the reflectance at the detection angle of regular reflection angle ⁇ 5 ° (hereinafter also simply referred to as “reflectance at regular reflection angle ⁇ 5 °”) is 50% or less of the reflectance at the regular reflection angle.

- the incident angle and the regular reflection angle are angles of incident light and reflected light with respect to the normal of the surface of the sheet.

- the surface of the sheet of the present invention Since the surface of the sheet of the present invention has the above-described configuration, it is excellent in low gloss, and even when oblique light is incident on the surface, irregular reflection of light on the sheet surface is suppressed when viewed from an oblique direction. Even if the sheet normally has a low gloss feeling, light is diffusely reflected when viewed from an oblique direction, and a specific portion of the sheet surface appears white, and the design originally expressed by the sheet cannot be visually recognized.

- the sheet according to the present invention has an arithmetic mean roughness Ra of 0.7 ⁇ m or less, and is measured when the surface is irradiated with incident light having an incident angle of 75 °.

- the reflectance at 5 ° is configured to be 50% or less of the reflectance at the regular reflection angle, irregular reflection of incident light on the sheet surface is suppressed, and the surface of the sheet of the present invention is A design expressed by a sheet such as a pattern can be visually recognized only by looking at a slight deviation of about ⁇ 5 ° from the regular reflection angle of incident light. For this reason, the sheet

- the surface is a so-called “front surface” and is opposite to the surface in contact with the adherend when the sheet of the present invention is used by being laminated on the adherend.

- This is a side surface that is visible after lamination.

- the direction of the surface of the sheet of the present invention may be referred to as “front” or “up”, and the opposite side may be referred to as “back” or “down”.

- the sheet according to the present invention has an arithmetic average roughness Ra of 0.7 ⁇ m or less as measured according to JIS B0633: 2001.

- Ra arithmetic average roughness

- incident light easily diffuses on the sheet surface, and it is difficult to adjust the reflectance at the regular reflection angle ⁇ 5 ° to 50% or less of the reflectance at the regular reflection angle.

- the Ra is preferably 0.6 ⁇ m or less.

- the method of making the surface shape the above-mentioned uneven shape is not particularly limited, for example, a method of containing extender pigments such as silica in the outermost layer, or arithmetic average roughness on the sheet surface Examples thereof include a method of forming an uneven shape such that Ra (JIS B0633: 2001) is 0.7 ⁇ m or less with an embossed plate.

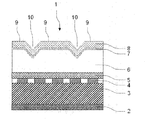

- FIG. 1 is a cross-sectional view showing an example of the sheet of the present invention.

- the sheet 1 of the present invention illustrated in FIG. 1 includes a flat portion 9 having a concavo-convex shape formed by the above-described extender pigment on the surface, and a wood grain plate conduit groove 10 is formed between the flat portions 9. ing.

- the other embossed shapes are not limited to the wood grain plate conduit grooves, and examples thereof include stone plate surface irregularities (such as granite cleaved surfaces), cloth surface textures, satin texture, sand texture, hairlines, and ridges.

- the sheet of the present invention has a reflectivity at a regular reflection angle of ⁇ 5 °, measured when the surface is irradiated with incident light having an incident angle of 75 ° by a goniophotometer. 50% or less.

- the reflectance at the regular reflection angle of ⁇ 5 ° is preferably 40% or less of the reflectance at the regular reflection angle.

- the lower limit of the ratio of the reflectance at the regular reflection angle ⁇ 5 ° to the reflectance at the regular reflection angle is not particularly limited, and it is preferably as small as possible.

- the surface 60 ° gloss of the sheet of the present invention is preferably 10 or less, and more preferably 7 or less.

- the 60 ° gloss is a value measured using a gloss measuring device (trade name: GMX-202, manufactured by Murakami Color Research Laboratory Co., Ltd.) according to a method in accordance with JIS Z-8741. It is.

- the thickness of the sheet of the present invention is preferably 50 to 600 ⁇ m, and more preferably 100 to 250 ⁇ m. By setting the thickness within the above-described range, the sheet of the present invention is more excellent in design properties and can be provided with scratch resistance.

- the specific structure will not be limited.

- the sheet of the present invention is a decorative sheet, a sheet formed by sequentially laminating a pattern layer, a transparent adhesive layer, a transparent resin layer, a primer layer, and a surface protective layer on the base sheet is exemplified. .

- the base sheet is a layer in which a pattern layer or the like is sequentially laminated on the surface (front surface).

- a sheet (film) formed of a thermoplastic resin is suitable.

- a thermoplastic resin Specifically, polyvinyl chloride, polyethylene terephthalate, polybutylene terephthalate, polyamide, polyethylene, polypropylene, polycarbonate, polyethylene naphthalate, ethylene / vinyl acetate copolymer, ethylene / acrylic acid copolymer, ethylene / acrylic acid ester copolymer Examples include polymers, ionomers, acrylic esters, and methacrylic esters.

- the said base material sheet is formed by using these resin individually or in combination of 2 or more types.

- the base sheet may be colored.

- a coloring material pigment or dye

- a coloring material for coloring

- the colorant for example, inorganic pigments such as titanium dioxide, carbon black and iron oxide, organic pigments such as phthalocyanine blue, and various dyes can be used. These can be selected from one or more known or commercially available ones. Further, the addition amount of the colorant may be appropriately set according to the desired color tone.

- the base sheet contains various additives such as fillers, matting agents, foaming agents, flame retardants, lubricants, antistatic agents, antioxidants, UV absorbers, and light stabilizers as necessary. It may be.

- the thickness of the substrate sheet can be appropriately set depending on the use of the final product, the method of use, etc., but generally 20 to 300 ⁇ m is preferable.

- the base sheet may be subjected to corona discharge treatment on the surface (front surface) as necessary in order to enhance the adhesion of the ink for forming the pattern layer.

- corona discharge treatment on the surface (front surface) as necessary in order to enhance the adhesion of the ink for forming the pattern layer.

- What is necessary is just to implement the method and conditions of a corona discharge process according to a well-known method.

- Pattern pattern layer is a layer that imparts a desired pattern (design) to the sheet, and the type of pattern is not limited. For example, a wood grain pattern, a leather pattern, a stone pattern, a grain pattern, a tiled pattern, a brickwork pattern, a cloth pattern, a geometric figure, a character, a symbol, an abstract pattern, and the like can be given.

- the method for forming the pattern layer is not particularly limited.

- an ink obtained by dissolving (or dispersing) a known colorant (dye or pigment) in a solvent (or dispersion medium) together with a binder resin is used. What is necessary is just to form on the base-material sheet

- an aqueous composition can be used from the viewpoint of reducing the VOC of the sheet.

- the colorant examples include inorganic pigments such as carbon black, titanium white, zinc white, dial, bitumen, and cadmium red; azo pigments, lake pigments, anthraquinone pigments, quinacridone pigments, phthalocyanine pigments, isoindolinone pigments, dioxazine pigments.

- Organic pigments such as aluminum powder, metal powder pigments such as bronze powder, pearlescent pigments such as titanium oxide-coated mica and bismuth oxide chloride; fluorescent pigments; These colorants can be used alone or in admixture of two or more. These colorants may be used together with fillers such as silica, extender pigments such as organic beads, neutralizing agents, surfactants and the like.

- binder resin in addition to polyester-based urethane resin treated with hydrophilicity, polyester, polyacrylate, polyvinyl acetate, polybutadiene, polyvinyl chloride, chlorinated polypropylene, polyethylene, polystyrene, polystyrene-acrylate copolymer, rosin derivative

- an alcohol adduct of styrene-maleic anhydride copolymer, cellulose resin and the like can be used in combination. More specifically, for example, polyacrylamide resins, poly (meth) acrylic resins, polyethylene oxide resins, poly N-vinyl pyrrolidone resins, water-soluble polyester resins, water-soluble polyamide resins, water-soluble amino acids.

- water-based resins water-soluble phenolic resins, other water-soluble synthetic resins; water-soluble natural polymers such as polynucleotides, polypeptides, polysaccharides, and the like.

- water-soluble natural polymers such as polynucleotides, polypeptides, polysaccharides, and the like.

- natural rubber, synthetic rubber, polyvinyl acetate resin, (meth) acrylic resin, polyvinyl chloride resin, polyurethane-polyacrylic resin, etc. modified or a mixture of natural rubber, etc. Resin can also be used.

- the said binder resin can be used individually or in combination of 2 or more types.

- the thickness of the pattern layer is not particularly limited and can be appropriately set according to the product characteristics.

- the layer thickness at the time of coating is about 1 to 15 ⁇ m, and the layer thickness after drying is about 0.1 to 10 ⁇ m.

- seat of this invention is a structure which does not have a pattern pattern layer

- seat of this invention is made transparent, the pattern of adherends, such as a wooden base material, will be visible through the said sheet

- the pattern of the adherend can be used as a design as it is.

- the design expressed by the pattern of the adherend is excellent in low gloss by the sheet of the present invention, and the irregular reflection of light on the surface of the sheet is suppressed even when viewed from an oblique direction. Is visible and can exhibit excellent design properties.

- an adhesive layer may be formed on the design pattern layer.

- the adhesive layer is preferably a transparent adhesive layer, and the transparent adhesive layer includes any of colorless and transparent, colored and transparent, and translucent.

- the adhesive is not particularly limited, and an adhesive known in the field of decorative sheets can be used.

- known adhesives in the field of decorative sheets include thermoplastic resins such as polyamide resins, acrylic resins and vinyl acetate resins, and thermosetting resins such as urethane resins. These adhesives can be used individually by 1 type or in combination of 2 or more types. Further, a two-component curable polyurethane resin or polyester resin using isocyanate as a curing agent can also be applied.

- the thickness of the adhesive layer is not particularly limited, but the thickness after drying is about 0.1 to 30 ⁇ m, preferably about 1 to 20 ⁇ m.

- the transparent resin layer is not particularly limited as long as it is transparent, and includes any of colorless and transparent, colored and transparent, and translucent.

- the resin constituting the transparent resin layer include polyethylene terephthalate, polybutylene terephthalate, polyamide, polyethylene, polypropylene, ethylene / vinyl acetate copolymer, ethylene / acrylic acid copolymer, and ethylene / acrylic acid ester copolymer.

- Examples thereof include coalescence, ionomer, polymethylpentene, acrylic acid ester, methacrylic acid ester, polycarbonate, and cellulose triacetate. These resins can be used alone or in combination of two or more.

- a polyolefin resin typified by polypropylene resin is used. Therefore, when using polyolefin-type resin as a transparent resin layer, the various polyolefin-type resin quoted as what comprises a base material sheet can be used.

- the transparent resin layer may be colored as long as it has transparency, but it is particularly desirable not to add a colorant.

- the thickness of the transparent resin layer is usually about 20 to 200 ⁇ m, but may exceed the above range depending on the use of the sheet.

- the transparent resin layer is the outermost layer of the sheet, and the uneven shape of the sheet of the present invention is formed on the surface of the transparent resin layer. It is preferable.

- the method for forming the uneven shape of the sheet of the present invention on the surface of the transparent resin layer include a method of forming the above uneven shape on the surface of the transparent resin layer with an embossed plate.

- a primer layer may be provided on the primer layer transparent resin layer.

- the primer layer can be formed by applying a known primer agent to the surface of the transparent resin layer.

- the primer agent include a urethane resin primer agent made of an acrylic-modified urethane resin (acrylic urethane resin), a urethane-cellulose resin (for example, a resin obtained by adding hexamethylene diisocyanate to a mixture of urethane and nitrified cotton) ), A resinous primer agent made of a block copolymer of acrylic and urethane, and the like. You may mix

- the additive examples include fillers such as calcium carbonate and clay, flame retardants such as magnesium hydroxide, antioxidants, lubricants, foaming agents, ultraviolet absorbers, and light stabilizers.

- the blending amount of the additive can be appropriately set according to the product characteristics.

- the application amount of the primer agent is not particularly limited, but is usually 0.1 to 100 g / m 2 , preferably about 0.1 to 50 g / m 2 .

- the thickness of the primer layer is not particularly limited, but is usually about 0.01 to 10 ⁇ m, preferably about 0.1 to 1 ⁇ m.

- the resin constituting the surface protective layer is preferably a curable resin such as a thermosetting resin or an ionizing radiation curable resin (for example, an electron beam curable resin).

- a curable resin such as a thermosetting resin or an ionizing radiation curable resin (for example, an electron beam curable resin).

- ionizing radiation curable resins are preferable from the viewpoint of high surface hardness, productivity, and the like.

- thermosetting resins include unsaturated polyester resins, polyurethane resins (including two-component curable polyurethane), epoxy resins, amino alkyd resins, phenol resins, urea resins, diallyl phthalate resins, melamine resins, guanamine resins, and melamines.

- unsaturated polyester resins polyurethane resins (including two-component curable polyurethane)

- epoxy resins include epoxy resins, amino alkyd resins, phenol resins, urea resins, diallyl phthalate resins, melamine resins, guanamine resins, and melamines.

- -Urea cocondensation resin silicon resin, polysiloxane resin and the like.

- a curing agent such as a crosslinking agent and a polymerization initiator and a polymerization accelerator can be added to the resin.

- curing agents isocyanates, organic sulfonates, etc. can be added to unsaturated polyester resins, polyurethane resins, etc., organic amines, etc. can be added to epoxy resins, peroxides such as methyl ethyl ketone peroxide, azoisobutyl nitrile, etc.

- a radical initiator can be added to the unsaturated polyester resin.

- Examples of the method of forming the surface protective layer with a thermosetting resin include a method in which a solution of a thermosetting resin is applied by a coating method such as a roll coating method or a gravure coating method, followed by drying and curing.

- the ionizing radiation curable resin is not limited as long as it is a resin that undergoes a crosslinking polymerization reaction upon irradiation with ionizing radiation and changes to a three-dimensional polymer structure.

- one or more prepolymers, oligomers, and monomers having a polymerizable unsaturated bond or epoxy group that can be cross-linked by irradiation with ionizing radiation in the molecule can be used.

- examples thereof include acrylate resins such as urethane acrylate, polyester acrylate, and epoxy acrylate; silicon resins such as siloxane; polyester resins; epoxy resins and the like.

- Ionizing radiation includes visible light, ultraviolet light (near ultraviolet light, vacuum ultraviolet light, etc.), X-rays, electron beams, ion beams, etc. Among them, ultraviolet light and / or electron beams are desirable.

- an ultra-high pressure mercury lamp As the ultraviolet light source, an ultra-high pressure mercury lamp, a high pressure mercury lamp, a low pressure mercury lamp, a carbon arc lamp, a black light fluorescent lamp, or a metal halide lamp can be used.

- the wavelength of ultraviolet light is about 190 to 380 nm.

- the electron beam source for example, various electron beam accelerators such as a cockcroft-wald type, a bandegraft type, a resonant transformer type, an insulating core transformer type, a linear type, a dynamitron type, and a high frequency type can be used.

- the energy of the electron beam is preferably about 100 to 1000 keV, more preferably about 100 to 300 keV.

- the irradiation amount of the electron beam is preferably about 2 to 15 Mrad.

- the ionizing radiation curable resin is sufficiently cured when irradiated with an electron beam, but it is preferable to add a photopolymerization initiator (sensitizer) when cured by irradiation with ultraviolet rays.

- a photopolymerization initiator sensitizer

- Photopolymerization initiators in the case of resin systems having radically polymerizable unsaturated groups include, for example, acetophenones, benzophenones, thioxanthones, benzoin, benzoin methyl ether, Michler benzoylbenzoate, Michler ketone, diphenyl sulfide, dibenzyl disulfide , Diethyl oxide, triphenylbiimidazole, isopropyl-N, N-dimethylaminobenzoate and the like can be used.

- a resin system having a cationic polymerizable functional group for example, at least one kind such as an aromatic diazonium salt, an aromatic sulfonium salt, a metallocene compound, a benzoin sulfonic acid ester, and a freeloxysulfoxonium diallyl iodosyl salt.

- an aromatic diazonium salt an aromatic sulfonium salt, a metallocene compound, a benzoin sulfonic acid ester, and a freeloxysulfoxonium diallyl iodosyl salt.

- the addition amount of the photopolymerization initiator is not particularly limited, but is generally about 0.1 to 10 parts by mass with respect to 100 parts by mass of the ionizing radiation curable resin.

- a solution of an ionizing radiation curable resin may be applied by a coating method such as a gravure coating method or a roll coating method.

- the thickness of the surface protective layer is usually about 0.1 to 50 ⁇ m, preferably about 1 to 20 ⁇ m.

- additives such as solvents, dyes, extender pigments, fillers such as extenders, antifoaming agents, leveling agents, and thixotropic agents can be added to the surface protective layer as necessary.

- the extender pigment added to the surface protective layer is not particularly limited as long as it does not impair the design properties expressed by the sheet of the present invention, and known or commercially available pigments can be used.

- inorganic fine particles such as silica fine particles, silicone resin, talc, clay, barium sulfate, barium carbonate, calcium sulfate, calcium carbonate, and magnesium carbonate can be used.

- silica fine particles are preferable from the viewpoint of excellent scratch resistance.

- the amount of the extender added to the surface protective layer is preferably 5 to 50 parts by mass, more preferably 10 to 30 parts by mass with respect to 100 parts by mass of the resin solid content of the resin forming the surface protective layer.

- the average particle size of the extender pigment is preferably 0.5 to 35 ⁇ m, more preferably 2 to 14 ⁇ m.

- the surface of the surface protective layer can be formed into an uneven shape with which the sheet of the present invention is provided, and the surface of the surface protective layer has a low gloss feeling. And can have the stain resistance and scratch resistance required for the surface of the sheet.

- the average particle diameter of the extender pigment is preferably smaller than the thickness of the surface protective layer.

- the surface protective layer may further contain resin beads.

- the surface protective layer contains resin beads, white turbidity of the surface protective layer due to the inclusion of the extender pigment or the like can be suppressed.

- the resin beads are not particularly limited, and examples thereof include acrylic beads, urethane beads, polyethylene beads, polypropylene beads, polycarbonate beads, polyvinyl chloride beads, melamine beads, nylon beads, and styrene-acrylic copolymer beads. Among these, acrylic beads are preferable in terms of excellent transparency.

- the amount of the resin beads added to the surface protective layer is preferably 2 to 40 parts by mass, more preferably 4 to 30 parts by mass with respect to 100 parts by mass of the resin solid content of the resin forming the surface protective layer.

- the average particle diameter of the resin beads is preferably 0.5 to 20 ⁇ m, more preferably 2 to 14 ⁇ m. By setting the average particle diameter of the resin beads within such a range, the cloudiness of the surface protective layer can be further suppressed.

- the average particle diameter of the resin beads is preferably smaller than the thickness of the surface protective layer.

- the surface shape of the sheet of the present invention may be changed to the above-described uneven shape by a method of forming the above-described uneven shape with an embossed plate on the sheet surface. .

- seat of this invention as the above-mentioned uneven

- the surface protective layer is preferably formed adjacent to the gloss adjusting layer.

- the back surface and / or side surface of the surface protective layer is preferably adjacent to the gloss adjusting layer.

- a surface protective layer is transparent.

- the surface protective layer preferably contains fine particles A having a particle diameter equal to or smaller than the thickness of the surface protective layer and fine particles B having a particle diameter larger than the thickness of the surface protective layer as extender pigments.

- the fact that the particle diameter of the fine particles A is equal to or smaller than the thickness of the surface protective layer and that the particle diameter of the fine particles B is larger than the thickness of the surface protective layer are determined by SEM (scanning electron microscope). For example, it can be confirmed by cutting the sheet in a direction perpendicular to the surface and observing the portion of the surface protective layer of the obtained cross section using an SEM (scanning electron microscope).

- the particle diameter of the fine particles A is not particularly limited as long as it is not more than the thickness of the surface protective layer. If the particle diameter of the fine particles A exceeds the thickness of the surface protective layer, the matting effect may not be sufficient, and the fine particles A will cue from the surface protective layer, and the cue from the surface protective layer of the fine particles A will occur.

- the rubbed part may be rubbed and scraped, the gloss of the rubbed part may increase and become noticeable, and the scratch resistance may not be sufficient.

- the particle size of the fine particles A is preferably 3 to 15 ⁇ m, more preferably 8 to 12 ⁇ m. If the particle diameter of the fine particles A is too small, the matting effect may not be sufficient.

- the content of the fine particles A is preferably 5 to 30 parts by mass with respect to 100 parts by mass of the resin component of the surface protective layer. If the content of the fine particles A is too large, the fine particles A cued from the surface protective layer increase, and when the crushed portion is rubbed and scraped off, the gloss of the rubbed portions increases and becomes conspicuous. May not be enough. Further, if the content of the fine particles A is too small, the matting effect may not be sufficient.

- the content of the fine particles A is preferably 10 to 20 parts by mass with respect to 100 parts by mass of the resin component of the surface protective layer.

- the particle diameter of the fine particles B is not particularly limited as long as it is larger than the thickness of the surface protective layer.

- the surface protective layer may not have sufficient scratch resistance.

- the particle diameter of the fine particles B is preferably 8 to 33 ⁇ m, and more preferably 8 to 20 ⁇ m. If the particle diameter of the fine particles B is too large, the fine particles B may be easily detached from the surface protective layer.

- the content of the fine particles B is preferably 5 to 30 parts by mass with respect to 100 parts by mass of the resin component of the surface protective layer.

- the content of the fine particles B is preferably 10 to 20 parts by mass with respect to 100 parts by mass of the resin component of the surface protective layer.

- the particle diameters of the fine particles A and B can be measured by SEM (scanning electron microscope). For example, a decorative sheet is cut in a direction perpendicular to the surface, and the surface of the obtained cross section is obtained. An arbitrary portion of the protective layer can be photographed using an SEM (scanning electron microscope) and measured by averaging the particle diameter of the fine particles A and the particle diameter (diameter) of the fine particles B. Average particle size.

- the total content of the fine particles A and the fine particles B is preferably 15 to 35 parts by mass with respect to 100 parts by mass of the resin component of the surface protective layer. If the total content of the fine particles A and the content of the fine particles B is too small, the surface protective layer may be inferior in scratch resistance and design properties (low glossiness). If the total content is too large, the fine particles When the portions A and B are cueing increase and the portions are rubbed and scraped, the gloss of the rubbed portion is increased and noticeable, and the scratch resistance may not be sufficient.

- the total content of the fine particles A and the fine particles B is preferably 20 to 35 parts by mass with respect to 100 parts by mass of the resin component of the surface protective layer.

- the fine particles A and B are not particularly limited as long as they can improve the scratch resistance of the surface protective layer according to the particle diameter and can improve the matting effect, and conventionally known ones can be used.

- the fine particles A and B include inorganic particles such as silica fine particles and silicone resins; organic particles such as crosslinked alkyl, crosslinked styrene, inzoguanamine resin, urea-formaldehyde resin, phenol resin, polyethylene, and nylon. .

- silica fine particles are preferable.

- Gloss control layer A gloss control layer may be formed on the sheet of the present invention.

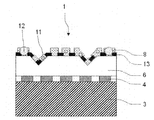

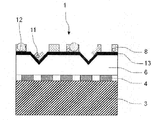

- Examples of the form of the sheet on which the gloss adjusting layer is formed include the forms shown in FIGS. 2 to 4, in the sheet 1 of the present invention, a pattern layer 4, a transparent resin layer 6, a gloss adjusting layer 13, and a surface protective layer 8 are laminated on a base sheet 3.

- the surface protective layer 8 contains fine particles A11 having a particle diameter equal to or smaller than the thickness of the surface protective layer 8 and fine particles B12 having a particle diameter larger than the thickness of the surface protective layer 8.

- the gloss adjusting layer is preferably formed on the transparent resin layer so as to be adjacent to the surface protective layer. More specifically, the back surface of the gloss adjusting layer is adjacent to the front surface of the transparent resin layer (or the primer layer when the sheet of the present invention has the primer layer), and The front surface and / or the side surface of the gloss adjusting layer is adjacent to the surface protective layer.

- the gloss adjustment layer may be formed on a part of the surface on the front surface side (the surface side that is visually recognized after the application of the sheet (decorative sheet) or the decorative plate) from the viewpoint of design, (2) It may be formed on the entire front surface (the entire surface). That is, the gloss adjustment layer may be (1) partially formed with respect to the front surface, and (2) formed over the entire surface with reference to the front surface. May be.

- the surface protective layer When the (1) gloss adjustment layer is formed on a part of the front side surface, (a) the surface protective layer may be formed on a part of the front side surface, (B) The surface protective layer may be formed on the entire front surface side.

- the surface protective layer is formed by the gloss adjusting layer. It is formed so as to fill a region that has not been formed (region that does not exist).

- the gloss adjusting layer is formed on a part of the surface on the front surface side, and the surface protective layer is formed on the entire surface on the front surface side ((1) ( b)).

- the gloss adjusting layer is formed on a part of the surface on the front surface side, and the surface protective layer is formed on a part of the surface on the front surface side ((1) above) (Form of (a)).

- the surface protective layer is formed on a part of the front surface.

- the gloss adjusting layer is formed on the entire front surface side, and the surface protective layer is formed on a part of the front surface side (form (2) above. ).

- the gloss value of the gloss adjusting layer is G A

- the gloss value of the surface protective layer is GP .

- the relationship between the gloss values G A luster control layer and the luster value G P of the aforementioned surface protective layer is preferably a G P ⁇ G A.

- the G A and the G P in the present specification is a value measured according to Japanese Industrial Standard JIS Z8741.

- the gloss value is also referred to as a gloss value or a gloss value.

- the gloss adjustment layer is formed on a part of the front side surface or (2) the gloss adjustment layer is formed on the entire front side. Even on the surface visually recognized after the construction of the sheet (decorative sheet) or the decorative plate, both the gloss adjusting layer and the surface protective layer are visible, and each of the gloss adjusting layer and the surface protective layer is visible. It is preferred relationship gloss value is G P ⁇ G a. In this case, when the sheet (decorative sheet) of the present invention is adhered to an adherend, the influence of the uneven shape (duck) generated on the sheet surface is further suppressed, and the design of the sheet or decorative plate is improved. Therefore, the sheet

- the gloss adjusting layer is formed on a part of the surface on the front side (simply referred to as the case (1) above)

- the area ratio of the area where the gloss adjusting layer occupies per 1 cm 2 of the front surface area of the sheet (decorative sheet) or the decorative board is 20 to 80%. preferable.

- the gloss adjusting layer is formed so that the front surface (surface to be visually recognized) side of the gloss adjusting layer has a pattern shape.

- the gloss adjustment layer has a pattern shape and the ratio of the area is 20 to 80%, so that the gloss difference between the gloss adjustment layer and the surface protective layer becomes clearer, and as a result, the design is further improved, and Further, it is possible to further suppress the influence of the uneven shape (duck).

- the type of the pattern is not particularly limited. Specific examples of the pattern include those similar to the various patterns exemplified in the pattern pattern layer described above.

- the ratio of the area of the area (area where the gloss adjusting layer is present) where the gloss adjusting layer occupies per 1 cm 2 of the area of the front surface of the sheet (decorating sheet) or the decorative board is expressed as gloss. It may be referred to as the occupation area ratio of the adjustment layer.

- the occupation area ratio of the gloss adjusting layer is calculated from plate making data at the stage of producing a plate for forming the gloss adjusting layer.

- the area occupied by the gloss adjusting layer can also be calculated from the shape of the plate.

- the relationship between the G A and the G P is G A ⁇ G P Is preferred. More preferably, G A ⁇ GP and G A ⁇ 5.

- the mechanism by which the sheet of the present invention can exhibit excellent design properties has not yet been fully elucidated, but it is provided on the surface of the gloss adjusting layer in the case of (1) above.

- an uncured material such as a curable resin of the surface protective layer

- the resin component of the gloss adjusting layer and the uncured material of the surface protective layer are selected depending on the combination of materials and application conditions. Is presumed to be due to the development of some interactions such as elution, dispersion, and mixing. That is, the resin component in the uncured product such as the curable resin forming the surface protective layer and the ink of the gloss adjusting layer in the case of (1) is not completely compatible in a short time.

- the suspended state is present on or near the gloss adjusting layer, and the suspended portion scatters light to form a low gloss region.

- the surface protective layer is formed by crosslinking and curing while maintaining this suspended state, the region on the gloss adjusting layer in the case (1) in the surface protective layer is at least a low gloss region, By the illusion, it is presumed that the region is visually recognized as if it were a concave portion (hereinafter also referred to as “visual concave portion”).