WO2016024600A1 - Composition de résine colorée pour filtre coloré, filtre coloré et dispositif d'affichage - Google Patents

Composition de résine colorée pour filtre coloré, filtre coloré et dispositif d'affichage Download PDFInfo

- Publication number

- WO2016024600A1 WO2016024600A1 PCT/JP2015/072807 JP2015072807W WO2016024600A1 WO 2016024600 A1 WO2016024600 A1 WO 2016024600A1 JP 2015072807 W JP2015072807 W JP 2015072807W WO 2016024600 A1 WO2016024600 A1 WO 2016024600A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- resin composition

- mass

- colored resin

- color filter

- Prior art date

Links

Images

Classifications

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/09—Photosensitive materials characterised by structural details, e.g. supports, auxiliary layers

- G03F7/105—Photosensitive materials characterised by structural details, e.g. supports, auxiliary layers having substances, e.g. indicators, for forming visible images

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09B—ORGANIC DYES OR CLOSELY-RELATED COMPOUNDS FOR PRODUCING DYES, e.g. PIGMENTS; MORDANTS; LAKES

- C09B63/00—Lakes

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/20—Filters

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/133509—Filters, e.g. light shielding masks

- G02F1/133514—Colour filters

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/0005—Production of optical devices or components in so far as characterised by the lithographic processes or materials used therefor

- G03F7/0007—Filters, e.g. additive colour filters; Components for display devices

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/027—Non-macromolecular photopolymerisable compounds having carbon-to-carbon double bonds, e.g. ethylenic compounds

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/027—Non-macromolecular photopolymerisable compounds having carbon-to-carbon double bonds, e.g. ethylenic compounds

- G03F7/028—Non-macromolecular photopolymerisable compounds having carbon-to-carbon double bonds, e.g. ethylenic compounds with photosensitivity-increasing substances, e.g. photoinitiators

- G03F7/031—Organic compounds not covered by group G03F7/029

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/038—Macromolecular compounds which are rendered insoluble or differentially wettable

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09B—ORGANIC DYES OR CLOSELY-RELATED COMPOUNDS FOR PRODUCING DYES, e.g. PIGMENTS; MORDANTS; LAKES

- C09B11/00—Diaryl- or thriarylmethane dyes

- C09B11/28—Pyronines ; Xanthon, thioxanthon, selenoxanthan, telluroxanthon dyes

Definitions

- the present invention relates to a colored resin composition for a color filter, a color filter, and a display device.

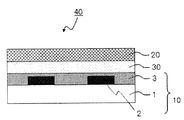

- Color filters are used in these liquid crystal display devices and organic light emitting display devices.

- a backlight is used as a light source, the amount of light is controlled by electrically driving the liquid crystal, and color expression is performed by the light passing through a color filter. Therefore, a color filter must be present in the color representation of a liquid crystal television and plays a major role in determining the performance of the display.

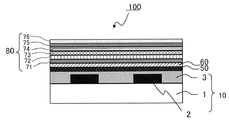

- color adjustment of pixels may be performed using a color filter, or a color image may be formed in the same manner as a liquid crystal display device using a color filter for a white light emitting organic light emitting element.

- An image display device including a color filter affects the design and performance of a mobile terminal in order to be directly linked to the usable time and charging frequency of the mobile terminal.

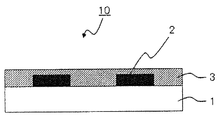

- the color filter is generally formed on a transparent substrate, a transparent layer formed on the transparent substrate, and composed of a colored layer of three primary colors of red, green, and blue, and on the transparent substrate so as to partition each colored pattern. And a light shielding portion formed.

- a pigment dispersion method using a pigment having excellent heat resistance and light resistance as a coloring material has been widely used.

- photosensitive resin compositions for color filters using dyes with high transmittance are being studied, and in order to further improve the heat resistance and light resistance of dyes.

- the use of a rake color material in which a dye is insolubilized has been studied.

- Patent Document 1 discloses a blue pigment for a color filter comprising an anion containing one or more elements selected from tungsten, silicon, and phosphorus as basic elements and oxygen as essential elements. Therefore, it is said that the use of the pigment can provide a liquid crystal display device capable of providing a liquid crystal display with little color change during high-temperature firing and excellent luminance over a long period of time.

- Patent Documents 2 and 3 a heteropolyoxo containing a specific ratio of phosphorus or silicon, molybdenum, and tungsten as a counter anion of a triarylmethane dye cation as a rake colorant having excellent heat resistance and light resistance Lake color materials using metalate anions are described.

- Patent Document 4 includes a specific color filter colored resin composition containing a specific colorant containing a divalent or higher cation in which a plurality of dye skeletons are cross-linked by a crosslinkable group and a divalent or higher anion, A color filter using a color material is disclosed. According to Patent Document 4, it is possible to form a colored layer having high contrast and excellent solvent resistance and electrical reliability by using a colored resin composition for a color filter containing the color material.

- a colored resin composition for forming a colored layer of a color filter usually contains a curable binder component for forming a layer, and in order to improve adhesion to the substrate, a silane coupling agent is used. Widely used (for example, Patent Documents 4 to 6).

- the colored resin composition for a color filter according to the present invention contains a lake color material, a dispersant, an alkali-soluble resin, a polyfunctional monomer, an initiator, and a solvent.

- the alkali-soluble resin is a resin having a hydrocarbon ring and an ethylenic double bond, and an acid value of 80 mgKOH / g or more and 300 mgKOH / g or less,

- the content ratio of the silane coupling agent is 1% by mass or less based on the total solid content in the colored resin composition.

- the lake color material is preferably a lake color material containing a polyacid anion from the viewpoint of excellent heat resistance and light resistance.

- the lake color material includes a lake color material having a triarylmethane dye from the viewpoint of improving the luminance of the color filter.

- the rake color material includes a color material represented by the following general formula (I), whereby a color filter having excellent heat resistance and light resistance and high brightness is obtained. It is preferable from the point which can form.

- A is an a-valent organic group in which the carbon atom directly bonded to N has no ⁇ bond, and the organic group is saturated aliphatic carbonized at least at the terminal directly bonded to N.

- R i to R v each independently represents a hydrogen atom, an optionally substituted alkyl group or an optionally substituted aryl group, and R ii and R iii , R iv and R v may combine to form a ring structure

- Ar 1 represents a divalent aromatic group which may have a substituent

- a plurality of R i to R v and Ar 1 may be the same or different.

- a and c represent an integer of 2 or more

- b and d represent an integer of 1 or more.

- e is 0 or 1, and when e is 0, there is no bond.

- a plurality of e may be the same or different.

- the hydrocarbon ring of the alkali-soluble resin has a cyclopentyl group, a cyclohexyl group, a bornyl group, an isobornyl group, a dicyclopentanyl group, a dicyclopentenyl group, an adamantyl group, And at least one selected from the group consisting of substituents represented by the following chemical formula (A) is excellent in heat resistance and solvent resistance by improving the curability of the colored layer, and suppresses water stain. From the viewpoint of excellent substrate adhesion of the colored layer.

- the alkali-soluble resin is a compound represented by the following general formula (B) to improve the solvent resistance by improving the curability of the colored layer, This is preferable because water stain is improved and the remaining film ratio of the colored layer is increased.

- X represents a group represented by the following general formula (D)

- Y each independently represents a residue of a polyvalent carboxylic acid or its acid anhydride

- R i represents a group represented by the following general formula (C)

- j is an integer of 0 to 4

- k is an integer of 0 to 3

- n is an integer of 1 or more.

- R ii represents a hydrogen atom or a methyl group, and R iii independently represents a hydrogen atom or a methyl group.

- R iv is independently a hydrogen atom, an alkyl group having 1 to 5 carbon atoms, a phenyl group, or a halogen atom, and R v is —O— or —OCH 2 CH. 2 O- is shown.

- the initiator is preferably an oxime ester photopolymerization initiator from the viewpoint of suppressing water stain and being excellent in solvent resistance and sensitivity.

- the colored resin composition for a color filter of the present invention preferably further contains at least one selected from a dioxazine-based color material and a xanthene-based color material from the viewpoint that it can be adjusted to a desired color tone.

- the color filter according to the present invention is a color filter comprising at least a transparent substrate and a colored layer provided on the transparent substrate, and at least one of the colored layers is a colored resin composition for a color filter according to the present invention. It has a colored layer formed by curing a product.

- the display device according to the present invention includes the color filter according to the present invention.

- the present invention has been made in view of the above circumstances, and is a colored resin composition for a color filter that can form a colored layer having excellent sensitivity over time, substrate adhesion, heat resistance, and solvent resistance, A color filter formed using the colored resin composition for the color filter and a display device using the color filter can be provided.

- FIG. 1 is a schematic sectional view showing an example of the color filter of the present invention.

- FIG. 2 is a schematic sectional view showing an example of the display device of the present invention.

- FIG. 3 is a schematic cross-sectional view showing another example of the display device of the present invention.

- FIG. 4 is a schematic diagram showing a molecular association state of the coloring material represented by the general formula (I).

- light includes electromagnetic waves having wavelengths in the visible and invisible regions, and further includes radiation, and the radiation includes, for example, microwaves and electron beams. Specifically, it means an electromagnetic wave having a wavelength of 5 ⁇ m or less and an electron beam.

- (meth) acryl represents each of acryl and methacryl

- (meth) acrylate represents each of acrylate and methacrylate.

- the organic group means a group having one or more carbon atoms.

- solid content means all components other than the solvent which comprises a colored resin composition, and even if it is a liquid monomer, it shall be contained in the said solid content.

- the colored resin composition for a color filter according to the present invention contains a rake colorant, a dispersant, an alkali-soluble resin, a polyfunctional monomer, an initiator, and a solvent.

- the alkali-soluble resin is a resin having a hydrocarbon ring and an ethylenic double bond, and an acid value of 80 mgKOH / g or more and 300 mgKOH / g or less,

- the content ratio of the silane coupling agent is 1% by mass or less based on the total solid content in the colored resin composition.

- the colored resin composition for a color filter of the present invention is selected from the rake colorant and the specific alkali-soluble resin, and the content ratio of the silane coupling agent is 1 with respect to the total solid content in the colored resin composition.

- the present inventors prepared a colored resin composition containing a lake colorant and a silane coupling agent and repeatedly used it while being stored. Even when the storage period was short, the colored resin composition was used. It was found that the adhesion of the colored layer formed in this way to the substrate may decrease. As a result of studying this, the resin composition using a combination of the silane coupling agent and the rake colorant was more time-consuming than the resin composition containing no rake colorant. It became clear that the change was remarkable.

- the line width of the patterned colored layer is It has also been clarified that the photosensitive resin composition becomes thinner as the storage period becomes longer.

- the change in the line width was due to a change in the sensitivity of the photosensitive resin composition, and the change in the sensitivity was estimated to be caused by the content ratio of the silane coupling agent.

- the change in sensitivity over time causes a pattern with a different line width to be formed depending on the storage period of the photosensitive resin composition when a patterned colored layer is produced under the same conditions. It becomes a problem that it becomes difficult.

- the reason why the silane coupling agent changes over time due to the above combination is not yet elucidated. It is estimated that hydrolysis of the silyl group is promoted.

- the ionic component generated from the lake color material has a low molecular weight as compared with alkali-soluble resins and the like, and thus is estimated to be close to the silane coupling agent as compared with alkali-soluble resins and the like. It is presumed that the change with time is greatly influenced by the ionic component generated from the rake color material.

- the present inventors have selected and used a hydrocarbon ring and an ethylenic double bond as an alkali-soluble resin, and an acid value of 80 mgKOH / g or more and 300 mgKOH / g or less. Even when not using the said silane coupling agent, the knowledge that it was excellent in adhesiveness with a board

- the alkali-soluble resins or the alkali-soluble resin and the polyfunctional monomer, etc. in the curing step of the resin composition at the time of manufacturing the color filter Can form crosslinks.

- the shrinkage at the time of curing the colored layer is suppressed and the adhesiveness with the substrate is excellent.

- such a crosslinking reaction improves the resistance to an alkaline developer during development.

- the present inventors have found that the use of an alkali-soluble resin having a hydrocarbon ring suppresses the solvent resistance of the obtained colored layer, particularly the swelling of the colored layer.

- the presence of bulky hydrocarbon rings in the colored layer suppresses the movement of molecules in the colored layer and increases the strength of the coating film. It is estimated that From these facts, by controlling the content ratio of the silane coupling agent to 1% by mass or less based on the total solid content in the colored composition, it is possible to suppress changes in adhesiveness and sensitivity over time. In addition, even when the content of the silane coupling agent is 1% by mass or less based on the total solid content in the colored composition, a colored resin composition having excellent adhesion to the substrate can be obtained. it can.

- an alkali-soluble resin having a relatively large number of acidic groups which is a combination of a lake color material and an alkali-soluble resin having an acid value of 80 mgKOH / g or more, is formed on the surface of the fine particles of the lake color material. It is presumed that it is likely to interact with the basic group of the existing dye or lake agent, and as a result, the alkali-soluble resin is likely to be adsorbed on the surface of the lake color material. Since the alkali-soluble resin has a relatively high acid value, once adsorbed, it is less likely to dissociate even during high-temperature heating, can further suppress the decomposition of the coloring material, suppress the decrease in luminance, and significantly improve heat resistance. Estimated.

- the colored resin composition for color filters of the present invention improves the temporal stability of the sensitivity of the colored resin composition even when a rake color material is used, and the colored resin composition is used after long-term storage. In addition, a colored layer having excellent substrate adhesion and excellent colorability can be obtained.

- the colored resin composition for a color filter of the present invention contains at least a lake colorant, a dispersant, an alkali-soluble resin, a polyfunctional monomer, an initiator, and a solvent, and the above-mentioned specific content ratio

- a silane coupling agent may be contained, and other components may be further contained as necessary as long as the effects of the present invention are not impaired.

- each component of the colored resin composition for a color filter of the present invention will be described in detail in order.

- the lake color material of the present invention refers to a color material in which a solvent-soluble color material is insolubilized by salt formation with counter ions.

- the rake color material can be usually obtained by mixing a color material described later and a rake agent described later in a solvent.

- a dye having a high transmittance is preferably used from the viewpoint of increasing the brightness of the color filter.

- the dye may be appropriately selected according to the desired color tone, and may be any basic skeleton (color development site) such as an azo dye, anthraquinone dye, triarylmethane dye, xanthene dye, cyanine dye, or indigo dye. ) May be used.

- the dye may be a dye classified into any of an acidic dye having an anionic substituent and a basic dye having a cationic substituent.

- an acidic dye having an anionic substituent and a basic dye having a cationic substituent.

- triarylmethane dyes, xanthene dyes, cyanine dyes are preferable, and triarylmethane dyes are more preferable.

- Examples of the acid dye include C.I. I. Acid Violet 29, 31, 33, 34, 36, 36: 1, 39, 41, 42, 43, 47, 51, 63, 76, 103, 118, 126, C.I. I. Acid Blue 2, 8, 14, 25, 27, 35, 37, 40, 41, 41: 1, 41: 2, 43, 45, 46, 47, 49, 50, 51, 51, 53, 54, 55, 56, 57, 58, 62, 62: 1, 63, 64, 65, 68, 69, 70, 78, 79, 80, 81, 96, 111, 124, 127, 127: 1, 129, 137, 138, 143,145,150,175,176,183,198,203,204,205,208,215,220,221,225,226,227,230,231,232,233,235,239,245,247, 253, 257, 258, 260, 261, 264, 266, 270, 271, 272, 273, 274, 277,

- Acid violet 9, 30, 102 sulforhodamine G, sulforhodamine B, sulforhodamine 101, xanthene acid dyes such as sulforhodamine 640 and the like.

- xanthene acid dyes C.I. I. Acid Red 50, C.I. I. Acid Red 52, C.I. I. Acid Red 289, C.I. I. Acid Violet 9, C.I. I. Acid Violet 30, C.I. I. A rhodamine acid dye such as Acid Blue 19 is preferred.

- Examples of commercially available basic dyes include C.I. I. Basic violet 1, 3, 14, C.I. I. Basic Blue 1, 5, 7, 8, 11, 26, C.I. I.

- Triarylmethane basic dyes such as Basic Green 1, 4; I. Basic Yellow 13, C.I. I. Cyanine basic dyes such as Basic Red 14; C.I. I. Azo basic dyes such as Basic Red 29; I. And xanthene-based basic dyes such as Basic Violet 11.

- Triarylmethane basic dyes are C.I. I. Basic blue 1, 5, 7, 8, 11, 26 are preferred.

- the dye which has the cation of the coloring material represented by general formula (I ') mentioned later is also mentioned as a suitable thing. These dyes can be used alone or in combination of two or more.

- the counter ion differs depending on the type of the dye, the counter ion of the acid dye is a cation, and the counter ion of the basic dye is an anion. Therefore, the rake agent is appropriately selected and used depending on the dye. That is, when the acid dye is insolubilized, a compound that generates a counter cation of the dye is used as a rake agent. When the basic dye is insolubilized, a counter anion of the dye is generated as a rake agent. A compound is used.

- Examples of the counter cation of the acid dye include an ammonium cation, a metal cation, and an inorganic polymer.

- a rake agent that generates ammonium ions for example, primary amine compounds, secondary amine compounds, tertiary amine compounds, and the like are preferable. Among them, secondary amines are preferred because of their excellent heat resistance and light resistance. It is preferable to use an amine compound or a tertiary amine compound.

- what is necessary is just to select suitably from the metal salt which has a desired metal ion as a lake agent which generate

- the counter cation of the acid dye can be used alone or in combination of two or more.

- the rake color material containing an acid dye is preferably a rake color material containing a xanthene-based dye from the viewpoint that high luminance can be achieved.

- the xanthene acid dye in the lake color material it is preferable to have a compound represented by the following general formula (VI), that is, a rhodamine acid dye.

- R 10 to R 13 each independently represents a hydrogen atom, an alkyl group, an aryl group, or a heteroaryl group, and R 10 and R 12 , R 11 and R 13 are bonded to each other.

- R 14 represents an acidic group

- X represents a halogen atom

- m represents an integer of 0 to 5.

- the general formula (VI) has one or more acidic groups.

- N is an integer of 0 or more.

- the alkyl group in R 10 to R 13 is not particularly limited. Examples thereof include a linear or branched alkyl group having 1 to 20 carbon atoms which may have a substituent. Among them, a linear or branched alkyl group having 1 to 8 carbon atoms is preferable. More preferably, it is a linear or branched alkyl group having 1 to 5 carbon atoms.

- the substituent that the alkyl group may have is not particularly limited, and examples thereof include an aryl group, a halogen atom, a hydroxyl group, and the like, and the substituted alkyl group includes a benzyl group, and further, a substituent. May have a halogen atom or an acidic group.

- the aryl group in R 10 to R 13 is not particularly limited.

- an aryl group which may have a substituent having 6 to 20 carbon atoms is exemplified, and among them, a group having a phenyl group, a naphthyl group or the like is preferable.

- the heteroaryl group in R 10 to R 13 include heteroaryl groups which may have a substituent having 5 to 20 carbon atoms, and those containing a nitrogen atom, an oxygen atom or a sulfur atom as the heteroatom are preferable .

- Examples of the substituent that the aryl group or heteroaryl group may have include an alkyl group having 1 to 5 carbon atoms, a halogen atom, an acidic group, a hydroxyl group, an alkoxy group, a carbamoyl group, and a carboxylic acid ester group.

- R 10 to R 13 may be the same or different.

- the acidic group or a salt thereof include a carboxy group (—COOH), a carboxylate group (—COO ⁇ ), a carboxylate group (—COOM, where M represents a metal atom), a sulfonate group (—SOO). 3 -), a sulfo group (-SO 3 H), sulfonate (-SO 3 M, wherein M represents a metal atom), and among them, a sulfonato group (-SO 3 -.), a sulfo group It is preferable to have at least one of (—SO 3 H) or a sulfonate group (—SO 3 M).

- the metal atom M include a sodium atom and a potassium atom.

- Acid Red 50, Acid Red 52, Acid Red 289, Acid Violet 9, Acid Violet 30, Acid Blue 19 and the like are preferable from the viewpoint of increasing brightness.

- the metal lake color material of the xanthene acid dye includes a metal atom-containing material as a lake agent.

- a rake agent containing a metal atom By using a rake agent containing a metal atom, the heat resistance of the coloring material is increased.

- a rake agent containing a metal atom that becomes a divalent or higher valent metal cation is preferable.

- the counter anion of the basic dye may be an organic anion or an inorganic anion.

- organic anion include organic compounds having an anionic group as a substituent.

- the lake color material is an acid dye and a basic dye present as an ion pair.

- rake agents that generate these organic anions include alkali metal salts and alkaline earth metal salts of the above organic anions.

- the inorganic anion for example, an anion of oxo acid (phosphate ion, sulfate ion, chromate ion, tungstate ion (WO 4 2 ⁇ ), molybdate ion (MoO 4 2 ⁇ ), etc.) Mention may be made of inorganic anions such as polyacid anions condensed with oxo acids and mixtures thereof.

- the polyacid may be an isopolyacid anion (M m O n ) c- or a heteropoly acid anion (X l M m O n ) c- .

- M represents a poly atom

- X represents a hetero atom

- m represents a composition ratio of poly atoms

- n represents a composition ratio of oxygen atoms.

- the poly atom M include Mo, W, V, Ti, and Nb.

- the hetero atom X include Si, P, As, S, Fe, and Co.

- a polyacid anion containing at least one of molybdenum (Mo) and tungsten (W) is preferable, and a c-valent polyacid anion containing at least tungsten is more preferable.

- rake agents that generate inorganic anions include alkali salts and alkali metal salts of the above inorganic anions.

- the counter anion of the basic dye in the lake color material can be used alone or in combination of two or more.

- the rake color material is preferably a rake color material composed of a basic dye and an inorganic anion, more preferably a basic dye and a polyacid anion, from the viewpoint of heat resistance and light resistance. .

- the silane coupling agent is easily changed over time, but in the present invention, the content of the silane coupling agent is the total solid content in the colored resin composition.

- the influence of the change with time is small, while the heat resistance and light resistance are high.

- the lake color material includes a lake color material having a triarylmethane dye from the viewpoint that the brightness of the color filter can be improved.

- the rake color material is excellent in heat resistance and light resistance and achieves high brightness of the color filter, among others, the color material represented by the following general formula (I) and the following general formula ( It is preferable that the color material is one or more selected from the color materials represented by II), and that the color material represented by the following general formula (I) forms a molecular association state and is more excellent It is preferable at the point which shows heat resistance.

- A is an a-valent organic group in which the carbon atom directly bonded to N has no ⁇ bond, and the organic group is saturated aliphatic carbonized at least at the terminal directly bonded to N.

- R i to R v each independently represents a hydrogen atom, an optionally substituted alkyl group or an optionally substituted aryl group, and R ii and R iii , R iv and R v may combine to form a ring structure

- Ar 1 represents a divalent aromatic group which may have a substituent

- a plurality of R i to R v and Ar 1 may be the same or different.

- a and c represent an integer of 2 or more

- b and d represent an integer of 1 or more.

- e is 0 or 1, and when e is 0, there is no bond.

- a plurality of e may be the same or different.

- R I , R II , R III , R IV , R V and R VI each independently represent a hydrogen atom, an alkyl group having 1 to 3 carbon atoms, or a phenyl group

- the color material represented by the general formula (I) includes a divalent or higher valent anion 202 and a divalent or higher cation 201. It is presumed that the cation and the cation are not simply ion-bonded by one molecule to one molecule but form a molecular aggregate 210 in which a plurality of molecules are associated through the ion bond 203. Therefore, the apparent molecular weight of the color material represented by the general formula (I) is remarkably increased as compared with the molecular weight of the conventional lake color material. It is presumed that the formation of such molecular aggregates increases the cohesive force in the solid state, lowers the thermal motion, suppresses dissociation of ion pairs and decomposition of the cation part, and improves heat resistance.

- a in the general formula (I) is an a-valent organic group in which the carbon atom directly bonded to N (nitrogen atom) does not have a ⁇ bond, and the organic group is saturated at least at the terminal directly bonded to N.

- A preferably does not have a siloxane bond, and more preferably does not have Si (silicon atom).

- an aliphatic hydrocarbon group having a saturated aliphatic hydrocarbon group at the terminal directly bonded to N is linear, branched or cyclic unless the terminal carbon atom directly bonded to N has a ⁇ bond.

- the carbon atom other than the terminal may have an unsaturated bond, may have a substituent, and the carbon chain contains O, S, and N. Also good.

- a carbonyl group, a carboxyl group, an oxycarbonyl group, an amide group or the like may be contained, and a hydrogen atom may be further substituted with a halogen atom or the like.

- the aromatic group having an aliphatic hydrocarbon group in A is a monocyclic or polycyclic aromatic group having an aliphatic hydrocarbon group having a saturated aliphatic hydrocarbon group at the terminal directly bonded to N. And may have a substituent, and may be a heterocyclic ring containing O, S, and N. Especially, it is preferable that A contains a cyclic

- the cyclic aliphatic hydrocarbon groups a bridged alicyclic hydrocarbon group is preferable from the viewpoint of skeleton fastness.

- the bridged alicyclic hydrocarbon group means a polycyclic aliphatic hydrocarbon group having a bridged structure in the aliphatic ring and having a polycyclic structure, for example, norbornane, bicyclo [2,2,2]. Examples include octane and adamantane.

- norbornane is preferable.

- the group containing a benzene ring and a naphthalene ring is mentioned, for example, Among these, the group containing a benzene ring is preferable.

- A is a divalent organic group, a linear, branched or cyclic alkylene group having 1 to 20 carbon atoms, or an aromatic group substituted with two alkylene groups having 1 to 20 carbon atoms such as a xylylene group Etc.

- the valence a in the general formula (I) is the number of chromogenic cation sites constituting the cation, and a is an integer of 2 or more. In the color material of the present invention, since the valence a of the cation is 2 or more, it has excellent heat resistance.

- the upper limit of a is not particularly limited, but a is preferably 4 or less, and more preferably 3 or less, from the viewpoint of ease of production.

- the alkyl group for R i to R v is not particularly limited. Examples thereof include straight-chain or branched alkyl groups having 1 to 20 carbon atoms. Among them, straight-chain or branched alkyl groups having 1 to 8 carbon atoms are preferable, and straight chain having 1 to 5 carbon atoms. A chain or branched alkyl group is more preferable from the viewpoint of luminance and heat resistance. Of these, the alkyl group in R i to R v is particularly preferably an ethyl group or a methyl group.

- the substituent that the alkyl group may have is not particularly limited, and examples thereof include an aryl group, a halogen atom, and a hydroxyl group, and examples of the substituted alkyl group include a benzyl group.

- the aryl group in R i to R v is not particularly limited. For example, a phenyl group, a naphthyl group, etc. are mentioned. Examples of the substituent that the aryl group may have include an alkyl group and a halogen atom.

- R i to R v are each independently a hydrogen atom, an alkyl group having 1 to 5 carbon atoms, a phenyl group, or R ii and R iii , or R iv and R v.

- R i to R v are each independently a hydrogen atom, an alkyl group having 1 to 5 carbon atoms, a phenyl group, or R ii and R iii , or R iv and R v.

- R i to R v can each independently have the above-described structure, and among these, R i is preferably a hydrogen atom from the viewpoint of color purity, and R ii to R ii from the viewpoint of ease of production and raw material procurement. More preferably, R v are all the same.

- the divalent aromatic group in Ar 1 is not particularly limited.

- the aromatic group for Ar 1 the same aromatic groups as those described for the aromatic group for A can be used.

- Ar 1 is preferably an aromatic group having 6 to 20 carbon atoms, more preferably an aromatic group composed of a condensed polycyclic carbocycle having 10 to 14 carbon atoms. Among these, a phenylene group or a naphthylene group is more preferable because the structure is simple and the raw material is inexpensive.

- a plurality of R i to R v and Ar 1 in one molecule may be the same or different.

- the combination of R i to R v and Ar 1 can be adjusted to a desired color.

- the anion portion (B c ⁇ ) represents a c-valent polyacid anion containing at least tungsten and optionally containing molybdenum.

- the polyacid anion in the colorant represented by the general formula (I) can be used alone or in combination of two or more of the above-mentioned anions.

- the overall ratio of tungsten to molybdenum is preferably 90:10 to 100: 0 from the viewpoint of heat resistance and light resistance.

- b represents the number of cations

- d represents the number of anions in the molecular aggregate

- b and d represent an integer of 1 or more.

- a plurality of cations in the molecular aggregate may be one kind alone, or two or more kinds may be combined.

- the anion present in the molecular aggregate may be a single anion or a combination of two or more, and an organic anion and an inorganic anion may be used in combination. .

- E in the general formula (I) is an integer of 0 or 1.

- a plurality of e may be the same or different. That is, for example, it may be a cation moiety having only a triarylmethane skeleton or a plurality of xanthene skeletons, or may be a cation moiety containing both a triarylmethane skeleton and a xanthene skeleton in one molecule. From the viewpoint of color purity, an anion portion having only the same skeleton is preferable.

- the color material represented by the general formula (I) can be adjusted to a desired color by using a cation portion including both a triarylmethane skeleton and a xanthene skeleton.

- e in the color material represented by the general formula (I) is 0, that is, the use of the color material represented by the following general formula (I ′) is easy to adjust to a desired color. More preferred.

- the color material represented by the general formula (I) has a xanthene skeleton, it may be included in a xanthene dye described later, but as long as the color material represented by the general formula (I) is applicable, the present invention. In this case, it is assumed that it corresponds to the color material represented by the general formula (I).

- the method for producing the color material represented by the general formula (I) is not particularly limited. For example, it can be obtained by the production method described in International Publication No. 2012/144520 pamphlet.

- the color material represented by the general formula (II) is a color material obtained by rake formation of a triarylmethane dye, and therefore is suitable for increasing the brightness as in the case of conventional dyes. Furthermore, since the specific heteropolyoxometalate anion is used, it is excellent in heat resistance and light resistance as compared with conventional color materials.

- Examples of the alkyl group having 1 to 3 carbon atoms of R I to R VI in the general formula (II) include a methyl group, an ethyl group, an n-propyl group, and an iso-propyl group.

- the structure of the cation moiety having a triarylmethane skeleton may be appropriately selected depending on the desired chromaticity and the like. Among these, from the viewpoint of easily achieving high brightness and high contrast, it is preferable to have the same structure as the cation portion of a conventionally known triarylmethane dye.

- Basic Blue 7 in which R I to R V are ethyl groups and R VI is a hydrogen atom, R I to R IV are methyl groups, R V is a phenyl group

- Basic Blue 26 in which R VI is a hydrogen atom, R I to R IV are methyl groups

- R V is an ethyl group

- Basic Blue 11 in which R VI is a hydrogen atom, R I to R V are methyl groups

- R VI is phenyl

- Examples thereof include a cation portion such as basic blue 8 and the like, and it is preferable to have a cation portion structure similar to that of basic blue 7 from the viewpoint of easily achieving high luminance and high contrast.

- X ⁇ in the colorant represented by the above general formula (I) is only one of (SiMoW 11 O 40 ) 4- / 4 or P 2 Mo y W 18-y O 62 ) 6- / 6 Or (SiMoW 11 O 40 ) 4- / 4 and P 2 Mo y W 18-y O 62 ) 6- / 6 may be used in combination.

- the heteropolyoxometalate anion represented by (SiMoW 11 O 40 ) 4- / 4 is used as a corresponding heteropolyacid or a corresponding heteropolyoxometalate alkali metal salt, for example, Journal of American Chemical Society, 104 (1982). It can be obtained according to the method described in p3194. More specifically, a heteropolyacid can be obtained by mixing and stirring a nitric acid aqueous solution and an alkali metal molybdate aqueous solution, adding K 8 ( ⁇ -type SiW 11 O 39 ) thereto, and stirring for 2 to 6 hours. Furthermore, a heteropolyoxometalate alkali metal salt can be obtained by reacting the obtained heteropolyacid with an alkali metal chloride.

- the heteropolyoxometalate anion represented by (P 2 Mo y W 18-y O 62 ) 6- / 6 is used as a corresponding heteropolyacid or a corresponding heteropolyoxometalate alkali metal salt, for example, Inorganic Chemistry , vol 47, p3679.

- a heteropolyacid can be obtained by dissolving an alkali metal tungstate and an alkali metal molybdate in water, adding phosphoric acid thereto, and heating to reflux for 5 to 10 hours with heating and stirring. it can.

- a heteropolyoxometalate alkali metal salt can be obtained by reacting the obtained heteropolyacid with an alkali metal salt compound.

- the number y of molybdenum in the heteropolyoxometalate anion can be adjusted in the range of 1 to 3 by appropriately adjusting the amounts of the alkali metal tungstate and alkali metal molybdate.

- an alkali metal molybdate salt is dissolved in water, hydrochloric acid is added thereto, and then an ⁇ 2-type deficient Dawson-type phosphotungstic acid alkali metal salt such as K 10 ( ⁇ 2-type P 2 W 17 O 61 ) is added.

- K 10 ⁇ 2-type P 2 W 17 O 61

- P 2 Mo 1 W 17 O 62 having no y distribution can be obtained by stirring at 10 to 30 ° C. for 30 minutes to 2 hours.

- heteropolyoxometalate alkali metal salt examples include K 4 (SiMoW 11 O 40 ), K 6 (P 2 MoW 17 O 62 ), K 6 (P 2 Mo 2 W 16 O 62 ), and K 6 (P 2 ). Mo 3 W 15 O 62 ) and the like.

- the colorant represented by the above general formula (II) is obtained by salt-substituting a heteropolyacid or heteropolyoxometalate alkali metal salt corresponding to the obtained heteropolyoxometalate anion with a dye having a desired structure. Can be obtained. From the viewpoint of high reaction yield of salt substitution, it is preferable to use a heteropolyoxometalate alkali metal salt rather than a heteropolyacid.

- the color material represented by the general formula (II) may be a hydrate having crystal water or an anhydride. Moreover, you may use the color material represented by the said general formula (II) individually by 1 type or in combination of 2 or more types.

- the rake colorant can be used alone or in combination of two or more.

- the colored resin composition for a color filter of the present invention may further contain another color material for the purpose of controlling the color tone within a range not impairing the effects of the present invention.

- Other pigments include known pigments and dyes, and one or more can be used.

- dioxazine-based color materials and xanthene-based color materials as other color materials from the viewpoint of obtaining a desired color tone.

- preferable dioxazine pigments include Pigment Violet 23 and the like.

- preferable xanthene color materials include Acid Red 51, 52, 87, 92, 94, 289, 388, C.I. I. Acid Violet 9, 30, 102, sulforhodamine G, sulforhodamine B, sulforhodamine 101, sulforhodamine 640, etc., as well as JP2010-32999, JP2010-211198, and Japanese Patent No. 4492760 And the xanthene dyes described.

- Acid Red 289 or xanthene color materials represented by the following general formula (III) is preferably used from the viewpoint of heat resistance and light resistance.

- R 21 and R 22 are each independently an alkyl group or an aryl group, and R 23 and R 24 are each independently an aryl group or a heteroaryl group.

- the alkyl group in R 21 and R 22 is not particularly limited. Examples thereof include a linear or branched alkyl group having 1 to 20 carbon atoms which may have a substituent. Among them, a linear or branched alkyl group having 1 to 8 carbon atoms is preferable. More preferably, it is a linear or branched alkyl group having 1 to 5 carbon atoms.

- the substituent that the alkyl group may have is not particularly limited, and examples thereof include an aryl group, a halogen atom, a hydroxyl group, and the like, and the substituted alkyl group includes a benzyl group, and further, a substituent. May have a halogen atom.

- the aryl group in R 21 to R 24 is not particularly limited.

- an aryl group which may have a substituent having 6 to 20 carbon atoms is exemplified, and among them, a group having a phenyl group, a naphthyl group or the like is preferable.

- the heteroaryl group in R 23 and R 24 include heteroaryl groups which may have a substituent having 5 to 20 carbon atoms, and those containing a nitrogen atom, an oxygen atom or a sulfur atom as a heteroatom are preferable. .

- the substituent that the aryl group or heteroaryl group may have include an alkyl group having 1 to 5 carbon atoms, a halogen atom, a hydroxyl group, an alkoxy group, a carbamoyl group, and a carboxylic acid ester group.

- R 21 to R 24 do not have an acidic group from the viewpoint of light resistance.

- the substitution position of the sulfonate group (—SO 3 ⁇ ) of the benzene ring that substitutes the xanthene skeleton is not particularly limited, but is preferably in the ortho or para position with respect to the xanthene skeleton. From the viewpoint of light resistance, the sulfonate group is preferably substituted in the ortho position relative to the xanthene skeleton.

- the compound represented by the general formula (III) has one sulfonate group and does not have a metal ion or a halogen atom.

- R 21 to R 24 are not hydrogen atoms, and R 23 and R 24 are either aryl groups or heteroaryl groups.

- the method for producing the compound represented by the general formula (III) is not particularly limited, and can be obtained by referring to, for example, JP2010-211198A.

- the blending ratio of the color material may be appropriately adjusted so as to obtain a desired color tone.

- the rake color material is 30 to 100 parts by mass with respect to 100 parts by mass of the total amount of the color material including the rake color material and other color materials.

- the amount is 60 to 99 parts by mass, and more preferably 70 to 98 parts by mass.

- the lake color material is used by being dispersed in a solvent with a dispersant.

- the dispersant can be appropriately selected from conventionally known dispersants.

- the dispersant that can be used include cationic, anionic, nonionic, amphoteric, silicone, and fluorine surfactants.

- the surfactants a polymer dispersant is preferable because it can be uniformly and finely dispersed.

- polymer dispersant examples include (co) polymers of unsaturated carboxylic acid esters such as polyacrylic acid esters; (partial) amine salts of (co) polymers of unsaturated carboxylic acid such as polyacrylic acid; (Partial) ammonium salts and (partial) alkylamine salts; (co) polymers of hydroxyl group-containing unsaturated carboxylic acid esters such as hydroxyl group-containing polyacrylates and their modified products; polyurethanes; unsaturated polyamides; polysiloxanes Long chain polyaminoamide phosphates; polyethylenimine derivatives (amides and their bases obtained by reaction of poly (lower alkylene imines) with free carboxyl group-containing polyesters); polyallylamine derivatives (polyallylamine and free carboxyls) Polyester, polyamide, or ester and amide co-condensation Object reaction product obtained by reacting one or more compound selected from among the three compounds of (polyester amide)), and the

- a polymer dispersant containing a nitrogen atom in the main chain or side chain and having an amine value is preferable from the viewpoint that the rake colorant can be suitably dispersed and the dispersion stability is good.

- it is a polymer dispersant made of a polymer containing a repeating unit having a tertiary amine, because the dispersibility is good, no foreign matter is deposited at the time of coating film formation, and the resolvability in a solvent is excellent.

- a polymer containing a repeating unit having a tertiary amine as a dispersant, the dispersibility and dispersion stability of the lake color material are improved.

- the repeating unit having a tertiary amine is a site having an affinity for the lake colorant.

- the polymer dispersant made of a polymer containing a repeating unit having a tertiary amine usually contains a repeating unit that becomes a site having an affinity for a solvent.

- a polymer containing a repeating unit having a tertiary amine a block copolymer having a block part composed of a repeating unit having a tertiary amine and a block part having a solvent affinity is particularly preferable. It is preferable at the point which can form the coating film which is excellent in it and becomes high-intensity.

- the repeating unit having a tertiary amine only needs to have a tertiary amine, and the tertiary amine may be contained in the side chain of the block polymer or may constitute the main chain.

- a repeating unit having a tertiary amine in the side chain is preferable, and among them, the structure represented by the following general formula (IV) is preferable because the main chain skeleton is hardly thermally decomposed and has high heat resistance. Is more preferable.

- R 1 is a hydrogen atom or a methyl group

- Q is a divalent linking group

- R 2 is an alkylene group having 1 to 8 carbon atoms, — [CH (R 5 ) —CH

- R 3 And R 4 each independently represents an optionally substituted chain or cyclic hydrocarbon group, or R 3 and R 4 are bonded to each other to form a cyclic structure

- R 5 and R 6 are Each independently represents a hydrogen atom or a methyl group.

- x represents an integer of 1 to 18, y represents an integer of 1 to 5, and z represents an integer of 1 to 18.

- Examples of the divalent linking group Q in the general formula (IV) include, for example, an alkylene group having 1 to 10 carbon atoms, an arylene group, a —CONH— group, a —COO— group, an ether group having a carbon number of 1 to 10 (— R′—OR ′′ —: R ′ and R ′′ are each independently an alkylene group) and combinations thereof.

- Q is a —COO— group because of the heat resistance of the polymer obtained, solubility in propylene glycol monomethyl ether acetate (PGMEA) suitably used as a solvent, and a relatively inexpensive material. preferable.

- the divalent organic group R 2 in the general formula (IV) is an alkylene group having 1 to 8 carbon atoms, — [CH (R 5 ) —CH (R 6 ) —O] x —CH (R 5 ) —CH (R 6 ) — or — [(CH 2 ) y —O] z — (CH 2 ) y —.

- the alkylene group having 1 to 8 carbon atoms may be linear or branched. For example, methylene group, ethylene group, trimethylene group, propylene group, various butylene groups, various pentylene groups, various hexylenes. Groups, various octylene groups and the like.

- R 5 and R 6 are each independently a hydrogen atom or a methyl group.

- R 2 is preferably an alkylene group having 1 to 8 carbon atoms from the viewpoint of dispersibility. Among them, R 2 is more preferably a methylene group, an ethylene group, a propylene group, or a butylene group. Groups are more preferred.

- Examples of the cyclic structure formed by combining R 3 and R 4 in the general formula (IV) include a 5- to 7-membered nitrogen-containing heterocyclic monocycle or a condensed ring formed by condensing two of these. It is done.

- the nitrogen-containing heterocycle preferably has no aromaticity, more preferably a saturated ring.

- repeating unit represented by the general formula (IV) examples include (meth) acryloyloxypropyldimethylamine, (meth) acryloyloxyethyldimethylamine, (meth) acryloyloxypropyldiethylamine, (meth) acryloyloxyethyldiethylamine, and the like. Examples include, but are not limited to, derived repeating units.

- the block part having solvent affinity in the copolymer from the viewpoint of improving solvent affinity and improving dispersibility, the block unit does not have the structural unit represented by the general formula (IV), and the general formula It has a solvent affinity block part having a structural unit copolymerizable with (IV).

- the arrangement of each block of the block copolymer is not particularly limited, and for example, an AB block copolymer, an ABA block copolymer, a BAB block copolymer, and the like can be used.

- the constitutional unit copolymerizable with the general formula (IV) is a constitutional unit represented by the following general formula (V) from the viewpoint of improving heat resistance while improving dispersibility and dispersion stability of the rake colorant. Preferably it is a unit.

- R 7 is a hydrogen atom or a methyl group

- A is a direct bond or a divalent linking group

- R 8 is an alkyl group having 1 to 18 carbon atoms, or an alkenyl group having 2 to 18 carbon atoms.

- R 9 and R 10 are each independently a hydrogen atom or a methyl group

- R 11 is a hydrogen atom, an alkyl group having 1 to 18 carbon atoms, an alkenyl group having 2 to 18 carbon atoms, an aralkyl group

- m represents an integer of 3 to 200

- n represents an integer of 10 to

- the divalent linking group A of the general formula (V) can be the same as Q in the general formula (IV), and propylene glycol which is suitably used as the heat resistance and solvent of the obtained polymer.

- A is preferably a —COO— group.

- the alkyl group having 1 to 18 carbon atoms may be linear, branched or cyclic, for example, methyl group, ethyl group, n-propyl group, isopropyl group, n-butyl.

- the alkenyl group having 2 to 18 carbon atoms may be linear, branched or cyclic.

- alkenyl groups include vinyl groups, allyl groups, propenyl groups, various butenyl groups, various hexenyl groups, various octenyl groups, various decenyl groups, various dodecenyl groups, various tetradecenyl groups, various hexadecenyl groups, various octadecenyl groups, A cyclopentenyl group, a cyclohexenyl group, a cyclooctenyl group, etc. can be mentioned.

- R 8 is preferably a methyl group, various butyl groups, various hexyl groups, benzyl groups, cyclohexyl groups, or hydroxyethyl groups from the viewpoint of dispersibility and substrate adhesion.

- Examples of the aryl group which may have a substituent include a phenyl group, a biphenyl group, a naphthyl group, a tolyl group, and a xylyl group.

- the aryl group preferably has 6 to 24 carbon atoms, more preferably 6 to 12 carbon atoms.

- Examples of the aralkyl group which may have a substituent include a benzyl group, a phenethyl group, a naphthylmethyl group, and a biphenylmethyl group.

- the aralkyl group preferably has 7 to 20 carbon atoms, more preferably 7 to 14 carbon atoms.

- Examples of the substituent of the aromatic ring such as an aryl group and an aralkyl group include an alkenyl group, a nitro group, and a halogen atom in addition to a linear or branched alkyl group having 1 to 4 carbon atoms.

- R 11 may have a hydrogen atom or a substituent, an alkyl group having 1 to 18 carbon atoms, an alkenyl group having 2 to 18 carbon atoms, an aralkyl group, an aryl group, —CHO, —CH 2 CHO, or A monovalent group represented by —CH 2 COOR 12 , wherein R 12 is a hydrogen atom or a linear, branched or cyclic alkyl group having 1 to 5 carbon atoms;

- examples of the substituent that may be included include linear, branched or cyclic alkyl groups having 1 to 4 carbon atoms, and halogen atoms such as F, Cl, and Br. And so on.

- the alkyl group having 1 to 18 carbon atoms and the alkenyl group, aralkyl group and aryl group having 2 to 18 carbon atoms in R 11 are as described for R 8 above.

- R 8 x, y and z are the same as R 2 in the general formula (IV).

- the glass transition temperature (Tg) of the solvent-compatible block part of the block copolymer may be appropriately selected.

- the glass transition temperature (Tg) of the solvent-compatible block part is preferably 80 ° C. or higher, and more preferably 100 ° C. or higher.

- the glass transition temperature (Tg) of the solvent-affinity block part in the present invention can be calculated by the following formula.

- Tgi is the glass transition temperature (absolute temperature) of the homopolymer of the i-th monomer.

- Tgi the value of the homopolymer glass transition temperature of each monomer

- the number of structural units constituting the solvent-affinity block part may be appropriately adjusted within a range where the amine value of the dispersant is 70 mgKOH / g or more and 160 mgKOH / g.

- the number of structural units constituting the solvent-affinity block part is 10 to 200 from the viewpoint that the solvent-affinity part and the colorant affinity part act effectively and improve the dispersibility of the colorant. It is preferably 10 to 100, more preferably 10 to 70.

- the solvent-affinity block part may be selected so as to function as a solvent-affinity site, and the repeating unit constituting the solvent-affinity block part may be composed of one kind, or two or more kinds.

- the repeating unit may be included.

- the ratio between the number m of the structural unit represented by the general formula (IV) and the number n of other structural units constituting the solvent-affinity block unit m / n is preferably in the range of 0.01 to 1, and more preferably in the range of 0.05 to 0.7 from the viewpoint of dispersibility and dispersion stability of the color material.

- a dispersant having an amine value of 70 mgKOH / g or more and 160 mgKOH / g or less is selected and used.

- the amine value is within the above range, the viscosity is excellent in stability over time and heat resistance, and is also excellent in alkali developability and solvent resolubility.

- the amine value of the dispersant is preferably 80 mgKOH / g or more, more preferably 90 mgKOH / g or more, from the viewpoint of dispersibility and dispersion stability.

- the amine value of the dispersant is preferably 120 mgKOH / g or less, and more preferably 105 mgKOH / g or less.

- the amine value refers to the number of mg of potassium hydroxide equivalent to perchloric acid required to neutralize the amine component contained in 1 g of a sample, and can be measured by the method defined in JIS-K7237. When measured by this method, since the organic acid compound usually dissociates in the amino group that forms a salt with the organic acid compound in the dispersant, the amine value of the block copolymer itself used as the dispersant is Can be measured.

- the acid value of the dispersant used in the present invention is preferably 1 mg KOH / g or more as a lower limit from the viewpoint that a development residue suppressing effect is exhibited.

- the acid value of the dispersant is more preferably 2 mgKOH / g or more from the viewpoint of more excellent development residue suppression effect.

- the acid value of the dispersant used in the present invention is preferably 18 mgKOH / g or less as the upper limit from the viewpoint of preventing the deterioration of the development adhesion and the solvent resolubility.

- the acid value of the dispersant is more preferably 16 mgKOH / g or less, and even more preferably 14 mgKOH / g or less, from the viewpoint of improving the development adhesion and the solvent resolubility.

- the acid value of the block copolymer before salt formation is preferably 1 mgKOH / g or more, and more preferably 2 mgKOH / g or more. This is because the effect of suppressing the development residue is improved.

- the upper limit of the acid value of the block copolymer before salt formation is preferably 18 mgKOH / g or less, more preferably 16 mgKOH / g or less, and even more preferably 14 mgKOH / g or less.

- the development adhesiveness and the solvent resolubility are improved.

- the colorant concentration is increased and the dispersant content is increased, the amount of the binder is relatively decreased. Therefore, the colored resin layer is easily peeled off from the base substrate during development.

- the dispersant contains a B block containing a structural unit derived from a carboxy group-containing monomer and has the specific acid value and glass transition temperature, the development adhesion is improved. If the acid value is too high, the developability is excellent, but it is presumed that the polarity is too high and peeling easily occurs during development.

- the glass transition temperature of a dispersing agent is 30 degreeC or more from the point which image development adhesiveness improves. That is, whether the dispersant is a block copolymer before salt formation or a salt block copolymer, the glass transition temperature is preferably 30 ° C. or higher.

- the glass transition temperature of the dispersant is low, it is particularly close to the developer temperature (usually about 23 ° C.), and the development adhesion may be lowered. This is presumably because when the glass transition temperature is close to the developer temperature, the movement of the dispersant increases during development, resulting in poor development adhesion.

- the glass transition temperature is 30 ° C.

- the glass transition temperature of the dispersant is preferably 32 ° C. or higher, more preferably 35 ° C. or higher, from the viewpoint of development adhesion. On the other hand, the temperature is preferably 200 ° C. or lower from the viewpoint of operability during use, such as easy precision weighing.

- the glass transition temperature of the dispersant in the present invention can be determined by measuring by differential scanning calorimetry (DSC) according to JIS K7121.

- the dispersant has an acid value of 1 mgKOH / g or more and 18 mgKOH / g or less and a glass transition temperature of 30 ° C. or more. Furthermore, it is preferable from the viewpoint of excellent solvent resolubility and further high development adhesiveness while suppressing generation of development residues.

- the colorant concentration is increased and the dispersant content is increased, the amount of the binder is relatively decreased. Therefore, the colored resin layer is easily peeled off from the base substrate during development.

- the dispersant contains a B block containing a structural unit derived from a carboxy group-containing monomer and has the specific acid value and glass transition temperature, the development adhesion is improved.

- the acid value is too high, it is presumed that although the developability is excellent, the polarity is too high and peeling easily occurs during development.

- the carboxy group-containing monomer a monomer that can be copolymerized with a monomer having a structural unit represented by the general formula (II) and contains an unsaturated double bond and a carboxy group can be used.

- monomers include (meth) acrylic acid, vinyl benzoic acid, maleic acid, maleic acid monoalkyl ester, fumaric acid, itaconic acid, crotonic acid, cinnamic acid, acrylic acid dimer, and the like.

- an addition reaction product of a monomer having a hydroxyl group such as 2-hydroxyethyl (meth) acrylate and a cyclic anhydride such as maleic anhydride, phthalic anhydride, or cyclohexanedicarboxylic anhydride, ⁇ -carboxy-polycaprolactone Mono (meth) acrylates can also be used.

- a cyclic anhydride such as maleic anhydride, phthalic anhydride, or cyclohexanedicarboxylic anhydride, ⁇ -carboxy-polycaprolactone Mono (meth) acrylates

- acid anhydride group containing monomers such as maleic anhydride, itaconic anhydride, and citraconic anhydride, as a precursor of a carboxy group.

- (meth) acrylic acid is particularly preferable from the viewpoints of copolymerizability, cost, solubility, glass transition temperature, and the like.

- the content ratio of the structural unit derived from the carboxy group-containing monomer may be appropriately set so that the acid value of the block copolymer is within the range of the specific acid value. Although not limited, it is preferably 0.05 to 4.5% by mass and more preferably 0.07 to 3.7% by mass with respect to the total mass of all the structural units of the block copolymer. Since the content ratio of the structural unit derived from the carboxy group-containing monomer is not less than the lower limit value, the effect of suppressing the development residue is expressed, and since it is not more than the upper limit value, the development adhesiveness is deteriorated and the solvent resolubility is reduced. Deterioration can be prevented. In addition, the structural unit derived from a carboxy group containing monomer should just become said specific acid value, may consist of 1 type, and may contain 2 or more types of structural units.

- the monomer whose glass transition temperature (Tgi) of the homopolymer of the monomer is 10 ° C. or higher from the viewpoint that the glass transition temperature of the dispersant used in the present invention is a specific value or higher and development adhesion is improved.

- Tgi glass transition temperature of the homopolymer of the monomer

- the ratio m / n of the unit number m of the structural unit of the A block and the unit number n of the structural unit of the B block is in the range of 0.05 to 1.5.

- the range of 0.1 to 1.0 is more preferable from the viewpoint of the dispersibility and dispersion stability of the color material.

- the weight average molecular weight Mw of the block copolymer is not particularly limited, but is preferably 1000 to 20000, and preferably 2000 to 15000 from the viewpoint of good colorant dispersibility and dispersion stability. More preferably, it is more preferably 3000 to 12000.

- the weight average molecular weight is determined as a standard polystyrene conversion value by (Mw) and gel permeation chromatography (GPC).

- Mw polystyrene conversion value by

- GPC gel permeation chromatography

- the method for producing the block copolymer is not particularly limited. Although a block copolymer can be produced by a known method, it is preferable to produce it by a living polymerization method. This is because chain transfer and deactivation are unlikely to occur, a copolymer having a uniform molecular weight can be produced, and dispersibility and the like can be improved.

- the living polymerization method include a living anionic polymerization method such as a living radical polymerization method and a group transfer polymerization method, and a living cation polymerization method.

- a copolymer can be produced by sequentially polymerizing monomers by these methods.

- a block copolymer can be produced by first producing the A block and polymerizing the structural units constituting the B block into the A block.

- the order of polymerization of the A block and the B block can be reversed.

- the A block and the B block can be manufactured separately, and then the A block and the B block can be coupled.

- a block copolymer having a block part composed of a repeating unit having a tertiary amine and a block part having a solvent affinity for example, a block copolymer described in Japanese Patent No. 4911253 is used. It can be mentioned as a suitable thing.

- the repeating unit having the tertiary amine is included with respect to 100 parts by mass of the lake color material.

- the content of the polymer is preferably 15 to 300 parts by mass, and more preferably 20 to 250 parts by mass. Within the above range, the dispersibility and dispersion stability are excellent.

- the third grade from the viewpoint of dispersibility and dispersion stability of the rake color material, in particular, the color material represented by the general formula (I) and the color material represented by the general formula (II), the third grade.

- a dispersant a salt in which at least a part of an amino group in a polymer containing a repeating unit having an amine and an organic acid compound form a salt (hereinafter, such a polymer is Sometimes referred to as a salt-type polymer).

- a salt-type polymer By using the salt polymer, the dispersibility and dispersion stability of the color material represented by the general formula (I) and the color material represented by the general formula (II) are improved.

- the rake colorant particularly the general formula (I)

- the polymer containing a repeating unit having a tertiary amine is a block copolymer

- the organic acid compound is an acidic organic phosphorus compound. From the viewpoint of excellent dispersibility and dispersion stability of the coloring material and the coloring material represented by the general formula (II).

- the organic acid compound is not particularly limited as long as it is a compound having one or more carbon atoms and an acidic group.

- the acidic group possessed by the organic acid compound include a carboxy group, a sulfo group, and a phosphoric acid group.

- the acidic group is a sulfo group or a phosphoric acid group. Is preferred.

- the number of acidic groups contained in one molecule of the organic acid compound is not particularly limited.

- the number of acidic groups in one molecule may be 1 to 3. Preferably, it is 1 to 2 and more preferably.

- the valence of the acidic group is not particularly limited, but is preferably a monovalent to trivalent acid from the viewpoint of dispersion stability, heat resistance, and developability, and more preferably a monovalent to divalent acid. preferable.

- the organic acid compound preferably has a molecular weight of 5000 or less, more preferably 100 or more and 1000 or less, and more preferably 150 or more and 500 or less from the viewpoint of easily forming a salt with the amino group of the dispersant. Is more preferable.

- the organic acid compound is at least one selected from the group consisting of the following general formula (VI) and the following general formula (VII): dispersibility, dispersion stability, heat resistance and alkali developability From the point which is excellent in it.

- R a and R a ′ are each independently a hydrogen atom, a hydroxyl group, an alkyl group having 1 to 18 carbon atoms, an alkenyl group having 2 to 18 carbon atoms, an aralkyl group, or an aryl group. 1 represented by the group, — [CH (R c ) —CH (R d ) —O] s —R e , — [(CH 2 ) t —O] u —R e , or —O—R a ′′.

- R a and R a ′ each contain a carbon atom.

- R a ′′ is an alkyl group having 1 to 18 carbon atoms, an alkenyl group having 2 to 18 carbon atoms, an aralkyl group, or an aryl group. , — [CH (R c ) —CH (R d ) —O] s —R e , — [(CH 2 ) t —O] u —R e .

- R b represents an alkyl group having 1 to 18 carbon atoms, an alkenyl group having 2 to 18 carbon atoms, an aralkyl group, an aryl group, — [CH (R c ) —CH (R d ) —O] s —R e , — A monovalent group represented by [(CH 2 ) t —O] u —R e or —O—R b ′ .

- R b ′ is an alkyl group having 1 to 18 carbon atoms, an alkenyl group having 2 to 18 carbon atoms, an aralkyl group, an aryl group, — [CH (R c ) —CH (R d ) —O] s —R e , Or, it is a monovalent group represented by — [(CH 2 ) t —O] u —R e .

- R c and R d are each independently a hydrogen atom or a methyl group

- R e is a hydrogen atom, an alkyl group having 1 to 18 carbon atoms, an alkenyl group having 2 to 18 carbon atoms, an aralkyl group, an aryl group, —CHO, —CH 2 CHO, —CO—CH ⁇ CH 2 , —CO—C (CH 3 ) ⁇ CH 2 or a monovalent group represented by —CH 2 COOR f

- R f is a hydrogen atom or carbon

- each of the alkyl group, alkenyl group, aralkyl group, and aryl group may have a substituent.

- s represents an integer of 1 to 18, t represents an integer of 1 to 5, and u represents an integer of 1 to 18.

- R a and R a ′ have an aromatic ring

- an appropriate substituent for example, a linear or branched alkyl group having 1 to 4 carbon atoms, is provided on the aromatic ring. You may have.

- the alkyl group having 1 to 18 carbon atoms, the aralkyl group, and the aryl group may be the same as R 8 in the dispersant.

- R a and / or R a ′ is —O—R a ′′ , it is an acidic phosphate ester.

- R a ′′ has an aromatic ring, it may have an appropriate substituent on the aromatic ring, for example, a linear or branched alkyl group having 1 to 4 carbon atoms.

- R e In the monovalent group represented by R e, Examples of the substituent which may have, for example, C 1-4 straight, branched or cyclic alkyl group, F, Cl, halogen atom such as Br And so on.

- R e the alkyl group having 1 to 18 carbon atoms is as shown in the above R 8

- the alkenyl group having 2 to 18 carbon atoms is as shown in the above R a and R a ′.

- s is an integer of 1 to 18

- t is an integer of 1 to 5

- u is an integer of 1 to 18.

- s is preferably an integer of 1 to 4, and more Preferably, it is an integer of 1 to 2, and t is preferably an integer of 1 to 4, more preferably 2 or 3. u is preferably an integer of 1 to 4, more preferably an integer of 1 to 2. is there.

- R b when R b has an aromatic ring, it may have an appropriate substituent on the aromatic ring, for example, a linear or branched alkyl group having 1 to 4 carbon atoms. Good.

- R b When R b is —O—R b ′, it is an acidic sulfate ester.