WO2015186622A1 - 清掃用シート、及びこれを用いた清掃方法 - Google Patents

清掃用シート、及びこれを用いた清掃方法 Download PDFInfo

- Publication number

- WO2015186622A1 WO2015186622A1 PCT/JP2015/065546 JP2015065546W WO2015186622A1 WO 2015186622 A1 WO2015186622 A1 WO 2015186622A1 JP 2015065546 W JP2015065546 W JP 2015065546W WO 2015186622 A1 WO2015186622 A1 WO 2015186622A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- cleaning sheet

- scraping layer

- fiber

- layer

- cleaning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L13/10—Scrubbing; Scouring; Cleaning; Polishing

- A47L13/16—Cloths; Pads; Sponges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/08—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/413—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties containing granules other than absorbent substances

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/425—Cellulose series

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4374—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece using different kinds of webs, e.g. by layering webs

Definitions

- the present invention relates to a cleaning sheet and a cleaning method using the same.

- thermoplastic fiber having a fiber length of 2 to 15 mm and a fineness of 10 to 150 dtex

- cellulosic fiber 10 to 90% by weight of a cellulosic fiber

- thermoplastic fiber 10 to 90% by weight of a cellulosic fiber

- a cleaning sheet having a large number of leading end portions and having an abrasive property or a scraping property against dirt existing on the surface to be cleaned (Patent Document 1).

- Patent Document 1 This cleaning sheet has a feature that it has sufficient abrasiveness or scraping property against dirt.

- Patent Document 2 discloses a polishing comprising a substrate, a water-soluble binder, and a plurality of abrasive particles fixed to the substrate by the water-soluble binder in a peelable manner. Cleaning articles have been proposed. In this abrasive cleaning article, the abrasive particles are peeled off from the substrate when they come into contact with the solvent.

- Patent Document 1 The cleaning sheet described in Patent Document 1 is intended to polish or scrape dirt using the rigidity of a thick thermoplastic fiber, so that it firmly adheres to hard dirt far exceeding its rigidity, for example, a hard surface. It may not be easy to completely remove the dirt.

- the present invention is a cleaning sheet in which a scraping layer and a water absorbing layer containing hydrophilic fibers are laminated,

- the scraping layer is made of an airlaid nonwoven fabric in which fiber intersections of large-diameter fibers are joined, and a plurality of the large-diameter fibers are erected, and the tip portion thereof is present on the surface of the scraping layer,

- the fine fiber has a fineness of 10 dtex or more and 150 dtex or less, and is contained in the scraping layer by 10% by mass or more

- the scraping layer has a space between the large diameter fibers, and abrasive particles are present in the space so as to be removable.

- the large-diameter fiber having a tip portion on the surface of the scraping layer provides a cleaning sheet in which the abrasive particles are not substantially attached to a tip region including the tip portion. .

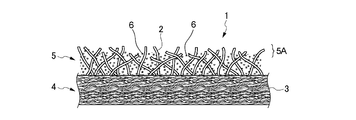

- FIG. 1 is a perspective view schematically showing an embodiment of the cleaning sheet of the present invention.

- FIG. 2 is a schematic diagram showing a cross-sectional structure of the cleaning sheet shown in FIG.

- FIG. 3 is an enlarged schematic view showing the main part of the cross-sectional structure shown in FIG.

- FIG. 4 is a schematic diagram showing a dirt removal mechanism by the cleaning sheet shown in FIG.

- the cleaning sheet 1 of the embodiment shown in FIGS. 1 and 2 is suitably used for cleaning hard surfaces.

- the cleaning sheet 1 is of a dry type and does not substantially contain a liquid component such as a cleaning liquid. “Substantially not contained” means that the ratio of the liquid component in the cleaning sheet 1 is 3% by mass or less.

- the cleaning sheet 1 has a water absorbing layer 4 and a scraping layer 5. That is, the cleaning sheet 1 has a two-layer structure including the water absorption layer 4 and the scraping layer 5. Therefore, no other layer is interposed between the water absorption layer 4 and the scraping layer 5.

- the cleaning sheet 1 Since the cleaning sheet 1 has a two-layer structure composed of the water absorbing layer 4 and the scraping layer 5, the cleaning sheet 1 is composed of one surface of the water absorbing layer 4 and the other surface. The surface is constituted by the surface of the scraping layer 5.

- the structure of the cleaning sheet 1 is not limited to this.

- the cleaning sheet 1 is made of a three-layer structure in which the first and second scraping layers 5 are arranged on each surface of the water absorbing layer 4. It may be configured.

- the cleaning sheet 1 having such a structure has one surface constituted by the surface of the first scraping layer 5 and the other surface constituted by the surface of the second scraping layer 5. .

- irregularities may be formed on the surface of the scraping layer 5.

- the rhombic lattice-shaped recesses 8 may be formed on the surface of the scraping layer 5 by applying a rhombus lattice-shaped heat embossing process.

- a region taken in by the rhombic lattice-shaped recesses 8 is a non-embossed region including the protrusions 9.

- the concave portion 8 is more consolidated than the non-embossed region formed by the convex portion 9 by application of heat and pressure by heat embossing. This heat embossing can be used to join the scraping layer 5 and the water absorbing layer 4 in addition to forming irregularities on the surface of the scraping layer 5.

- the pattern shape of the concave portion 8 is not limited to a rhombus lattice shape, and an arbitrary shape such as a line shape, a dot shape, or a specific pattern can be adopted.

- the total area of the recesses 8 is preferably 5% or more, particularly 10% or more with respect to the area of the cleaning surface of the cleaning sheet 1. Further, it is preferably 50% or less, particularly 40% or less. Specifically, the total area of the recesses 8 is preferably 5% or more and 50% or less, more preferably 10% or more and 40% or less with respect to the area of the cleaning surface of the cleaning sheet 1. This value is referred to as the area ratio of the recess 8). By setting the area ratio of the concave portion 8 within this range, it is possible to successfully achieve both surface strength and cleanability during cleaning.

- the perforation (not shown) may be formed in the cleaning sheet 1.

- the cleaning sheet 1 By cutting the cleaning sheet 1 along the perforations, the cleaning sheet 1 can be subdivided into a size that is easy to use.

- the perforated pattern shape is not particularly limited.

- the scraping layer 5 which is one layer constituting the cleaning sheet 1 includes the thick fiber 2.

- the large-diameter fiber 2 refers to a fiber having a fineness of 10 dtex or more and 150 dtex or less.

- a fiber having such a high fineness has a sufficiently high scraping property against dirt because the rigidity of the fiber is high.

- the fineness of the large-diameter fiber 2 is preferably 10 dtex or more, particularly 20 dtex or more, and particularly preferably 30 dtex or more.

- the fineness of the thick fiber 2 is preferably 10 dtex or more and 150 dtex or less, more preferably 20 dtex or more and 130 dtex or less, and further preferably 30 dtex or more and 120 dtex or less.

- the cleaning sheet 1 becomes more excellent in the scraping property of dirt stuck to, for example, a pot or a frying pan.

- the large diameter fiber 2 is a short fiber.

- the large-diameter fibers 2 are less likely to bend, which also improves the rigidity.

- the scraping layer 5 can be successfully formed by the air array method as described later.

- the fiber length of the large-diameter fiber 2 is preferably 2 mm or more, more preferably 3 mm or more, and further preferably 4 mm or more. Further, it is preferably 15 mm or less, more preferably 8 mm or less, and further preferably 6 mm or less.

- the fiber length of the thick fiber 2 is preferably 2 mm or more and 15 mm or less, more preferably 3 mm or more and 8 mm or less, and further preferably 4 mm or more and 6 mm or less.

- the rigidity of the thick fiber 2 can be sufficiently increased.

- the scraping layer 5 can be successfully formed by the air array method.

- the thick fiber 2 is contained in the scraping layer 5 in an amount of 10% by mass or more (the amount of the thick fiber in the constituent fibers of the scraping layer 5) from the viewpoint of expressing sufficient scraping performance against dirt. .

- the scraping performance is further enhanced when the ratio of the large-diameter fibers 2 in the scraping layer 5 is 30% by mass or more, particularly 50% by mass or more. From this viewpoint, the proportion of the large diameter fibers 2 in the scraping layer 5 may be 100% by mass.

- the scraping layer 5 may contain fibers other than the large-diameter fibers 2. In that case, it is preferable that the ratio of the large diameter fiber 2 to the scraping layer 5 is 90 mass% or less.

- the proportion of the large-diameter fibers 2 in the scraping layer 5 is preferably 10% by mass or more and 100% by mass or less, more preferably 10% by mass or more and 90% by mass or less, and further preferably 30% by mass or more. It is more preferable that it is 90 mass% or less, and it is still more preferable that it is 50 mass% or more and 90 mass% or less.

- the large-diameter fiber 2 examples include polyolefin resins such as polyethylene and polypropylene, polyester resins such as polyethylene terephthalate, acrylic resins such as polyacrylic acid and polymethacrylic acid, vinyl resins such as polyvinyl chloride, and nylon. Fibers made from polyamide resin, various metals, glass, and the like are used.

- the resin hardness is preferably in the range of R40 to R150 in terms of Rockwell hardness. In particular, it is preferable to use R80 to R150 resins from the viewpoint of improving the dirt scraping property.

- a composite fiber (core-sheath type composite fiber or side-by-side type composite fiber) made of a combination of two kinds of resins can be used.

- acrylic fibers, polyester fibers, vinyl chloride fibers, polyamides that do not damage the surface to be cleaned (stainless steel, tiles, tiles, artificial marble, etc.) and have excellent scraping properties Fibers and polyolefin fibers are preferred.

- heat-fusible fibers from the viewpoint of preventing the fibers from falling off.

- heat-fusible fiber for example, a heat-fusible composite fiber composed of a low-melting point resin and a high-melting point fiber having different melting points, and the low-melting point resin forming at least a part of the fiber surface is used.

- Low melting point resin / high melting point resin combinations include high density polyethylene / polypropylene, low density polyethylene / polypropylene, polypropylene / ethylene butene-1 crystalline copolymer, high density polyethylene / polyethylene terephthalate, nylon-6 / nylon- 66, low melting point polyester / polyethylene terephthalate, polypropylene / polyethylene terephthalate, and the like.

- the form of the heat-fusible conjugate fiber is a parallel type, a sheath core type, an eccentric sheath core type, a multilayer type of three or more layers, a hollow parallel type, a middle sheath core type, a deformed sheath core type, a sea island type, etc. Any structure may be used as long as the melting point resin forms at least a part of the fiber surface.

- preferred are low-melting point polyesters such as high-density polyethylene, linear low-density polyethylene, ethylene / butylene-1 crystalline copolymer, and copolymerized polyester of polyethylene terephthalate and polyethylene isophthalate.

- any one thermoplastic resin selected from the above is a low melting point resin and polypropylene or polyethylene terephthalate is a high melting point resin.

- the large-diameter fiber 2 one having crimpability can be used. Thereby, the feeling of thickness (bulkyness) of the cleaning sheet 1 can be improved, and good wiping comfort can be obtained.

- the crimped form there are a spiral type, a zigzag type, a U-shape, and the like, and any of these is preferably used.

- the thick fiber 2 can be used alone or in combination of two or more.

- the cleaning sheet 1 contains two or more kinds of fibers, it is preferable that the large-diameter fibers satisfying the fiber length and fineness are included so as to satisfy the content in total.

- fine fibers having a fineness smaller than that of the large-diameter fibers 2 can be used as the fibers. It is preferable to use a fine fiber having a fineness of 0.5 detex or more, particularly 1 detex or more, provided that the fineness is smaller than that of the large-diameter fiber 2. Further, it is preferable to use a fineness of 5 detex or less, particularly 3 detex or less. Specifically, it is preferable to use fibers having a fineness of 0.5 to 5 detex, particularly 1 to 3 detex.

- the proportion of the small diameter fiber in the scraping layer 5 is preferably 1% by mass or more, particularly preferably 5% by mass or more, It is preferably 50% by mass or less, particularly preferably 30% by mass or less.

- the proportion of the fine fiber in the scraping layer 5 is preferably 1% by mass or more and 50% by mass or less, and more preferably 5% by mass or more and 30% by mass or less.

- the small-diameter fibers are preferably short fibers like the large-diameter fibers 2.

- the fiber length of the small-diameter fiber is preferably 2 mm or more, more preferably 3 mm or more, and still more preferably 4 mm or more. Further, it is preferably 15 mm or less, more preferably 8 mm or less, and further preferably 6 mm or less.

- the fiber length of the fine fiber is preferably 2 mm or more and 15 mm or less, more preferably 3 mm or more and 8 mm or less, and still more preferably 4 mm or more and 6 mm or less.

- the small diameter fiber is comprised from the same kind or different kind of thermoplastic resin as the large diameter fiber 2.

- FIG. it is preferable that the thin fiber is composed of a heat-fusible fiber.

- the fiber intersections of the large-diameter fibers 2 are joined.

- a plurality of large-diameter fibers 2 are erected, and the tips thereof are present on the surface of the scraping layer 5.

- the longitudinal direction of the large-diameter fiber 2 (direction perpendicular to the cross section of the fiber) assumes that the in-plane direction of the scraping layer 5 is 0 degree (the fiber is lying without inclination).

- the angle formed by the in-plane direction and the longitudinal direction of the large-diameter fiber 2 is preferably 30 degrees or more, more preferably 45 degrees or more.

- the large-diameter fiber 2 When the large-diameter fiber 2 stands, one end of the large-diameter fiber 2 can be seen in plan view from the surface side on the surface of the scraping layer 5.

- the large-diameter fibers 2 included in the scraping layer 5 are preferably 50% or more, more preferably 80% or more.

- the fiber intersections of the large-diameter fibers 2 are joined, and the tip of the large-diameter fibers 2 is present on the surface of the scraping layer 5, so that the scraping layer 5 has sufficient abrasiveness or scraping properties. Is granted. In this case, it is not necessary that the tip portions of all the large-diameter fibers 2 constituting the scraping layer 5 are present on the surface of the scraping layer 5, and a sufficient scraping performance of a target level is exhibited. Any degree is acceptable.

- the scraping layer 5 In order to make the tip of the large-diameter fiber 2 exist on the surface of the scraping layer 5, it is advantageous to form the scraping layer 5 by the air array method. Specifically, a large-diameter fiber 2 made of short fibers is deposited by an air array method to form a web, and the intersection of the large-diameter fibers 2 in this web is joined to scrape the tip of the large-diameter fiber 2 It becomes easy to exist in the surface of the layer 5, ie, an airlaid nonwoven fabric. As a means for joining the intersections of the large-diameter fibers 2, for example, adhesion using an adhesive or heat fusion can be used.

- the basis weight of the scraping layer 5 is preferably 20 g / m 2 or more, particularly preferably 30 g / m 2 or more, more preferably 200 g / m 2 or less, and particularly preferably 150 g / m 2 or less.

- the basis weight of the basis weight of the scraping layer 5 is preferably 20 g / m 2 or more and 200 g / m 2 or less, and more preferably 30 g / m 2 or more and 150 g / m 2 or less.

- the scraping layer 5 has a space between the large-diameter fibers 2 constituting the scraping layer 5. Such a space is easily maintained between the large-diameter fibers 2 because the large-diameter fibers 2 are erected and exist in the scraping layer 5 and the fiber intersections are fixed. As shown in FIG. 3, a plurality of abrasive particles 6 are present in this space. The abrasive particles 6 exist in such a space, and even if the abrasive particles 6 are in contact with the fiber, they are present without being fixed by an adhesive or the like.

- reference numeral 7 indicates an adhesive or a fusion part that bonds the intersection of the large-diameter fibers 2.

- the abrasive particles 6 are used for the purpose of improving the polishing performance of the scraping layer 5 by a synergistic effect with the scraping performance of the large-diameter fiber 2.

- the abrasive particles 6 are present in the space so as to be detachable from the scraping layer 5. That the abrasive particles 6 are detachable means that the cleaning sheet 1 is applied when an external force due to vibration, bending, or the like is applied to the cleaning sheet 1 in a state where the cleaning sheet 1 is not wetted. This means that the abrasive particles 6 are present in the scraping layer 5 in such a manner that at least a part of the abrasive particles 6 falls off from the scraping layer 5.

- the abrasive particles 6 are not in a state of being fixed to the fibers by the bonding agent, unlike the technique described in Patent Document 2 described in the background art section above.

- it is different from the technique described in Patent Document 2 in that the abrasive particles do not fall off only after touching water or an aqueous solution, but easily fall off by an external force such as vibration in a dry state. Specific means for causing the abrasive particles 6 to be present in the scraping layer 5 in such a manner will be described later.

- the degree of removal of the abrasive particles 6 from the scraping layer 5 can be measured by the following method.

- a dry cleaning sheet 1 that is not wet is cut into a 10 cm ⁇ 10 cm square to obtain a test piece.

- This test piece is made into a loop in which the scraping layer faces outward in an environment of 20 ° C. ⁇ 5 ° C.

- the loop is formed so that the approximate center of the test piece draws an arc, and both ends are joined to form a grip.

- the loop is vibrated up and down with the gripping portion up and the loop down and the gripping portion positioned vertically upward.

- the vertical movement stroke is 1 cm, and the cycle is 3 times / second. This vertical movement is performed for 1 minute.

- the substance dropped off by this vertical movement is collected, and its mass (g) is measured.

- the measurement result is multiplied by 100 to obtain the amount of removal of the abrasive particles 6 (g / m 2 ).

- the abrasive particles 6 are preferably present uniformly throughout the entire thickness direction of the scraping layer 5. However, it is advantageous that the abrasive particles 6 are not substantially present in the surface region 5A including the outermost surface of the scraping layer 5.

- the surface area 5 ⁇ / b> A is an area in the surface thickness direction that is configured by an aggregate of the tip portions 2 ⁇ / b> A of the plurality of large-diameter fibers 2 constituting the scraping layer 5.

- the large-diameter fibers 2 having a tip portion on the surface of the scraping layer 5 have the abrasive particles 6 substantially in the tip region 2A including the tip portion.

- “Substantially not adhered” means that when the tip region of the large-diameter fiber 2 is enlarged (50 ⁇ 5 times), five large-diameter fibers are selected and the abrasive particles observed at the tip of the large-diameter fiber. It is said that the number of 6 is 10% or less with respect to the number of abrasive particles 6 observed in the selected large-diameter fiber 2 in the central portion of the scraping layer 5 in the thickness direction.

- the central portion in the thickness direction refers to a central portion when the scraping layer 5 is divided into three equal parts in the thickness direction.

- the tip region is defined as a depth region within 5 times the diameter of the thick fiber 2 from the tip.

- the abrasive particles 6 are preferably present in an amount of 150% by mass or more, particularly 200% by mass or more based on the mass of the scraping layer 5. Moreover, it is preferable that it is 900 mass% or less with respect to the mass of the scraping layer 5, especially 750 mass% or less exists. Specifically, the abrasive particles 6 are preferably present in an amount of 150% by mass or more and 900% by mass or less, and more preferably 200% by mass or more and 750% by mass or less, based on the mass of the scraping layer 5. preferable. Since the abrasive particles 6 are present in the scraping layer 5 at a ratio in this range, the polishing performance of the scraping layer 5 is further improved due to a synergistic effect with the scraping property of the large diameter fibers 2.

- the abrasive particles 6 water-insoluble particles are preferably used.

- the abrasive particles 6 preferably have a Mohs hardness of 3 or more and 7 or less from the viewpoint of abrasiveness.

- examples of such abrasive particles 6 include calcium carbonate, zeolite, and silica (silica powder). These abrasive particles 6 can be used alone or in combination of two or more.

- the abrasive particles 6 preferably have an average particle diameter of 5 ⁇ m or more, particularly 10 ⁇ m or more. Moreover, it is preferable that it is 30 micrometers or less, especially 20 micrometers or less.

- the average particle diameter of the abrasive particles 6 is preferably 5 ⁇ m or more and 30 ⁇ m or less.

- the abrasive particles preferably have such an average particle size and have a distribution in the particle size.

- the average particle diameter of the abrasive particles 6 is measured by an electric resistance test method (Coulter counter method).

- the scraping layer 5 may contain other cleaning components in addition to the abrasive particles 6 described above.

- various surfactants can be used for the purpose of enhancing the cleaning effect against dirt.

- an anionic surfactant such as alkylbenzene sulfonic acid or a nonionic surfactant such as polyoxyethylene alkyl ether can be used.

- a polymer of acrylic acid, methacrylic acid, or maleic acid or a salt thereof, a copolymer of maleic acid and another vinyl monomer, or a salt thereof is used. You can also.

- the abrasive particles 6 can be present in the scraping layer 5 by the method described below, for example.

- a cleaning sheet is prepared in a state before the abrasive particles 6 are applied according to a conventional method. Applying means applying so that abrasive particles are present in the scraping layer.

- a specific method for manufacturing the cleaning sheet 1 is described in, for example, US2002 / 0106478A1.

- a slurry containing abrasive particles 6 is prepared. It is convenient to use water as the liquid medium of the slurry. Specific examples of the slurry are described in, for example, JP2006-104264A1 and JP2006-104265A1.

- a small amount of a surfactant may be included in the slurry from the viewpoint of dispersion of the abrasive particles 6.

- the surfactant is preferably contained in an amount of 20% by mass or less, more preferably 10% by mass or less, based on the mass of the slurry.

- the surfactant may be contained in the slurry, but is preferably not contained.

- non-sticking means that the abrasive particles 6 are not fixed to the fiber by adhesion or fusion, and if the vibration is applied without using a solvent such as an aqueous solution, all or a part of the abrasive particles 6 are scraped. Saying to fall off the take-up layer 5.

- the slurry is applied to the scraping layer 5 of the cleaning sheet in a state before the abrasive particles 6 are applied.

- a die coater or a gravure roll coater can be used for the coating.

- a wet coating film containing abrasive particles 6 is formed on the scraping layer 5.

- a member having a smooth surface is pressed against the scraping layer 5.

- the slurry is filled in the space formed by the large-diameter fibers 2 constituting the scraping layer 5 and the slurry is removed from the surface area 5 ⁇ / b> A of the scraping layer 5.

- the abrasive particles 6 are not substantially present in the surface region 5A including the outermost surface of the scraping layer 5. As a result, the abrasive particles 6 are prevented from substantially adhering to the tip region 2A including the tip of the large-diameter fiber 2 having the tip on the surface of the scraping layer 5.

- the tip region is defined as a region within 5 times the diameter of the large-diameter fiber from the tip (region indicated by reference numeral 2A in FIG. 3).

- a synthetic resin film for example, a metal plate, natural fiber yarn, synthetic fiber yarn, or the like is used. Of these, a film made of a synthetic resin is particularly preferable.

- the abrasive particles 6 are substantially not present in the surface region 5A including the outermost surface of the scraping layer 5, and then the coating film is dried. After the coating film is dried, the surface of the scraping layer 5 is wiped with a wiping member. By this wiping, the abrasive particles 6 are prevented from further existing in the surface area 5A including the outermost surface of the scraping layer 5.

- the wiping member for example, fiber sheets such as various nonwoven fabrics and woven fabrics, brushes using synthetic resin fibers, brushes using natural fibers, and the like can be used.

- the water absorption layer 4 is a layer capable of absorbing and holding water.

- the water absorption layer 3 includes the hydrophilic fiber 3.

- a cellulose-based fiber is preferably used. Examples thereof include pulp fiber, cotton fiber, rayon fiber and the like, and it is particularly preferable to use pulp fiber.

- a pulp fiber derived from a conifer as a cellulose-based fiber from the viewpoint of preventing the fiber 3 from falling off and exhibiting an appropriate sheet strength.

- the fiber length of the hydrophilic fiber 3 contained in the water absorbing layer 4 is appropriately selected according to the method for manufacturing the water absorbing layer 4.

- the fiber length of the hydrophilic fiber 3 is preferably 0.1 mm or more and 20 mm or less, particularly preferably 0.2 mm or more and 15 mm or less.

- the fiber length of the hydrophilic fiber 3 is preferably 0.1 mm or more and 15 mm or less, and particularly preferably 0.3 mm or more and 10 mm or less.

- the intersections of the fibers are joined by fusion or adhesion.

- any binder can be used. Specific examples of the binder include acrylonitrile-butadiene rubber.

- the ratio of the hydrophilic fibers 3 in the water absorbing layer 4 is preferably 10% by mass or more and 100% by mass or less, and particularly preferably 20% by mass or more and 100% by mass or less from the viewpoint of the absorbability of the dirty liquid.

- the fibers have a fineness of 0.5 dtex or more and 5 dtex or less, particularly 1 dtex or more and 3 dtex or less, and a fiber length of 2 mm or more and 15 mm or less, particularly 3 mm or more and 8 mm or less. These heat-fusible fibers can be used.

- These fibers are preferably contained in the water absorbing layer 4 in an amount of 5% by mass to 90% by mass, particularly 10% by mass to 80% by mass.

- the heat-sealable fiber is contained in the scraping layer 5 from the viewpoint of ensuring the joint integration of the scraping layer 5 and the water absorbing layer 4. It is preferable.

- the heat-fusible fiber include a low-melting polyolefin fiber, a polyester fiber, and a low-melting resin and a high-melting resin as described above, and the low-melting resin forms part of the fiber surface.

- a composite fiber or the like can be used.

- the basis weight of the water absorbing layer 4 is preferably 30 g / m 2 or more, particularly preferably 40 g / m 2 or more, more preferably 100 g / m 2 or less, and particularly preferably 80 g / m 2 or less.

- the basis weight of the basis weight of the water absorbing layer 4 is preferably 30 g / m 2 or more and 100 g / m 2 or less, and more preferably 40 g / m 2 or more and 80 g / m 2 or less.

- the total basis weight of the cleaning sheet 1 including the scraping layer 5 and the water absorbing layer 4 is preferably 50 g / m 2 or more and 300 g / m 2 or less.

- the cleaning sheet 1 is of a dry type before use. In use, it can be left dry or can be used wet.

- the wet surface When the wet surface is used, the surface to be cleaned, for example, the hard surface is wetted with water, the wet hard surface is cleaned with the scraping layer 5, and then the wet hard surface contains moisture, that is, dirt. Cleaning can be performed by the procedure of wiping off the dirty liquid with the water absorbing layer 4.

- the mechanism for removing dirt by the cleaning sheet 1 is, for example, as follows when wetted.

- the hard surface is moistened with water, and the surface on the scraping layer 5 side of the cleaning sheet 1 is pressed against and rubbed against the wet hard surface.

- the abrasive particles 6 are released from the scraping layer 5 and supplied to the surface C to be cleaned, as shown in FIG.

- the released abrasive particles 6 and the tips of the large-diameter fibers 2 present on the surface of the scraping layer 5 polish or scrape the dirt D present on the surface C to be cleaned.

- the dirt D is removed from the surface C to be cleaned.

- the removed dirt D dissolves or disperses in water and is absorbed by the water absorption layer 4 together with water. In this way, the surface C to be cleaned is in a clean state.

- the air permeability T VD in the vertical thickness direction is preferably smaller than the air permeability T MD in the in-plane direction. Further, it is preferable that the air permeability T VD of the water absorbing layer 4 in the vertical thickness direction is smaller than the air permeability T VD of the scraping layer 5 in the vertical thickness direction.

- the air permeability in this manner By controlling the air permeability in this manner, the abrasive grains 6 are prevented from being pulled through, so that the abrasive particles 6 are positioned closer to the back surface side (water absorption layer 4) of the scraping layer 5 in the thickness direction of the cleaning sheet 1. It is preferable that a relatively large amount is present on the front surface side (cleaning surface side) or a relatively small amount is not present.

- the degree of standing of the constituent fibers may be controlled. By erecting the constituent fibers, the air permeability in the vertical direction increases and the air permeability in the in-plane direction decreases.

- the air-laying condition when the scraping layer 5 is formed by the air-laying method, and the length of the large-diameter fiber 2 to be used The fineness and the like are appropriately adjusted, and the degree of standing of the large-diameter fibers 2 in the scraping layer 5 and the fiber density of the large-diameter fibers 2 may be controlled as described above.

- the cleaning sheet 1 can be formed into a laminated body by regularly laminating a plurality of sheets, for example, and the laminated body can be accommodated in a packaging material to form a cleaning sheet packaging body.

- the packaging material preferably includes an opening for taking out the cleaning sheet 1 from the packaging material, and a resealable closing member for closing the opening.

- a plurality of cleaning sheets 1 are regularly stacked such that, for example, the water absorption layer 4 side of the cleaning sheet 1 faces upward. It is preferable to store the laminated body in this state in the packaging material so that the water absorption layer 4 side faces the opening.

- the finger feels a sense of irritation (sensation that the tip of the standing large-diameter fiber 2 stimulates the finger). Since it is reduced, it is preferable.

- the reason for this is that when the cleaning sheet 1 is picked and taken out from the packaging material with the finger, the belly of the finger only comes into contact with the water-absorbing layer 4, and the scraping layer 5 that may give a tingling sensation is provided. This is because it is difficult to touch the belly of the finger. It is preferable to clearly indicate or mark the scraping side so that the water absorption layer side can be easily identified.

- the packaging material is a separate packaging body enclosed in a separate packaging material having an opening or a hook provided at the peripheral edge.

- the opening or hook of the separate package is provided for the purpose of allowing the separate package to be suspended.

- This separate package is advantageous in that it can be easily suspended by an opening or a hook when it is displayed at a store.

- the separate package may be resealable.

- the above-mentioned packaging material may be provided with an opening or a hook directly on the peripheral edge without using another packaging material.

- the packaging material may be resealable.

- the cleaning sheet 1 As another packaging mode of the cleaning sheet 1, there is an individual package of cleaning sheets in which one cleaning sheet 1 is housed in a packaging material and individually packaged. In this individual package, a cut line or a perforation may be included for easy opening. It is preferable that an opening or a hook is provided on the peripheral edge of the individual packaging material. The opening or the hook is provided for the purpose of allowing the individual package to be suspended.

- This individual package is advantageous in that it can be easily hung by an opening or a hook when it is displayed over the counter.

- a plurality of individual packages can be arranged in a row so that the first individual package can be hung with an opening or a hook, and after the second, 5 to 10 can be separated by joints or perforations. In a state where it is possible, it can be sold by hanging it in a store and separating it.

- the cleaning sheet 1 described so far has been of a dry type, but instead of this, the cleaning sheet 1 is impregnated with water or an aqueous cleaning agent containing water and a surfactant. It may be a wet type.

- the member when the abrasive particles 6 are applied to the scraping layer 5, a member having a smooth surface is used, the member is pressed against the coating film of the slurry containing the abrasive particles 6, and then dried. Although the operation of wiping the coating film with the fiber sheet was performed, the operation of wiping with the fiber sheet may not be performed.

- a cleaning sheet in which a scraping layer and a water absorbing layer containing hydrophilic fibers are laminated The scraping layer is made of an airlaid nonwoven fabric in which fiber intersections of large-diameter fibers are joined, and a plurality of the large-diameter fibers are erected, and the tip portion thereof is present on the surface of the scraping layer,

- the fine fiber has a fineness of 10 dtex or more and 150 dtex or less, and is contained in the scraping layer by 10% by mass or more

- the scraping layer has a space between the large diameter fibers, and abrasive particles are present in the space so as to be removable.

- the cleaning fiber, wherein the large-diameter fiber having a tip portion on the surface of the scraping layer is substantially free of the abrasive particles attached to a tip region including the tip portion.

- ⁇ 2> The cleaning sheet according to ⁇ 1>, wherein the scraping layer contains the large diameter fiber and a small diameter fiber having a fineness smaller than that of the large diameter fiber.

- ⁇ 3> The cleaning sheet according to ⁇ 1> or ⁇ 2>, wherein the large-diameter fibers contained in the scraping layer are heat-fusible fibers.

- ⁇ 4> The cleaning sheet according to any one of ⁇ 1> to ⁇ 3>, wherein unevenness is formed on a surface of the scraping layer.

- ⁇ 5> The total area of the said recessed part is a cleaning sheet as described in said ⁇ 4> which is 5% or more with respect to the area of the cleaning surface of the cleaning sheet.

- ⁇ 6> The cleaning sheet according to any one of ⁇ 1> to ⁇ 5>, wherein perforations are formed.

- the cleaning sheet is for cleaning a hard surface, the cleaning sheet is of a dry type, and does not contain a liquid component such as a cleaning liquid, according to any one of ⁇ 1> to ⁇ 6>.

- ⁇ 8> The cleaning sheet according to ⁇ 7>, wherein a ratio of the liquid component in the cleaning sheet is 3% by mass or less.

- ⁇ 9> The cleaning sheet according to any one of ⁇ 1> to ⁇ 8>, wherein the surface of the scraping layer is subjected to rhomboid heat embossing.

- ⁇ 11> The cleaning sheet according to any one of ⁇ 1> to ⁇ 10>, wherein the large-diameter fiber is a short fiber, and the fiber length is 2 mm or more.

- the ratio of the large diameter fiber is 30% by mass or more, and when a fiber other than the large diameter fiber is contained, the ratio of the large diameter fiber is 90% by mass or less.

- the said large diameter fiber uses the thing which has a crimping

- the scraping layer when fibers other than the large-diameter fibers are included, as the fibers, small-diameter fibers having a fineness smaller than that of the large-diameter fibers are used,

- the fine fiber has a fineness smaller than that of the thick fiber and a fineness of 0.5 detex or more, preferably a fineness of 5 detex or less, more preferably 3 detex or less,

- the cleaning sheet according to any one of ⁇ 1> to ⁇ 13>, wherein a ratio of the small-diameter fibers in the scraping layer is 1% by mass or more.

- the scraping layer when fibers other than the large-diameter fibers are included, as the fibers, small-diameter fibers having a fineness smaller than that of the large-diameter fibers are used,

- the fine fiber is a short fiber, the fiber length of the fine fiber is 2 mm or more,

- the thin fiber is the cleaning sheet according to any one of ⁇ 1> to ⁇ 14>, wherein the thin fiber is composed of a heat-fusible fiber.

- a basis weight of the scraping layer is 20 g / m 2 or more.

- the large-diameter fiber having a tip portion on the surface of the scraping layer is substantially free from abrasive particles attached to the tip region including the tip portion, and the tip of the large-diameter fiber.

- the number of abrasive particles observed when the area is enlarged is 10% or less with respect to the number of abrasive particles observed in the large-diameter fiber at the center in the thickness direction of the scraping layer.

- abrasive particles according to any one of ⁇ 1> to ⁇ 17>, wherein the abrasive particles are present in an amount of 150% by mass or more based on the mass of the scraping layer and are present in an amount of 900% by mass or less based on the mass of the scraping layer.

- Cleaning sheet. ⁇ 19> Water-insoluble particles are used as the abrasive particles, the Mohs hardness of the particles is 3 or more and 7 or less, the abrasive particles are calcium carbonate, zeolite, or silica, and these abrasive particles are used alone or in combination of two or more.

- the hydrophilic layer is included in the water absorption layer, and the fiber length of the hydrophilic fiber is 0.1 mm or more and 20 mm or less when the water absorption layer is manufactured by a wet papermaking method, and the water absorption layer is manufactured by the air lay method.

- the ratio of the hydrophilic fiber in the water absorption layer is 10% by mass or more and 100% by mass or less.

- the heat-fusible fiber having a fineness of 0.5 dtex or more and 5 detex or less and a fiber length of 2 mm or more and 15 mm or less is used, and these fibers are contained in the water absorption layer in an amount of 5% by mass to 90% by mass.

- the cleaning sheet according to any one of ⁇ 1> to ⁇ 20>.

- the basis weight of the water absorbing layer is the cleaning sheet according to any one of ⁇ 1> to ⁇ 21>, wherein the basis weight is 30 g / m 2 or more.

- the total basis weight of the cleaning sheet comprising the scraping layer and the water absorbing layer is the cleaning sheet according to any one of ⁇ 1> to ⁇ 22>, wherein the total basis weight is 50 g / m 2 or more and 300 g / m 2 or less.

- the abrasive particles are present in a relatively large amount at a position near the back surface side (water absorbing layer) of the scraping layer, and are relatively small or not present on the front surface side (cleaning surface side).

- the cleaning sheet according to any one of 1> to ⁇ 24>.

- the cleaning sheet according to any one of the above ⁇ 1> to ⁇ 25> is used as a dry type in a state before use, and is used in a dry state or wetted before use.

- the surface to be cleaned is moistened with water, the wet surface to be cleaned is cleaned with a scraping layer, and then the soiled water-containing soil containing dirt is contained. Wipe with a water-absorbing layer, cleaning method.

- the surface to be cleaned is moistened with water, and the surface on the scraping layer side of the cleaning sheet according to any one of ⁇ 1> to ⁇ 25> is pressed against the wet hard surface.

- the abrasive particles are released from the scraping layer and supplied to the surface C to be cleaned.

- the dirt existing on the surface to be cleaned is polished or scraped, and the dirt is removed from the surface to be cleaned.

- the cleaning method according to ⁇ 26> wherein the removed dirt is dissolved or dispersed in water and absorbed into the water absorption layer together with water, and thus the surface to be cleaned is in a clean state.

- a plurality of cleaning sheets according to any one of the above ⁇ 1> to ⁇ 25> are stacked, and the cleaning sheet package is housed in a packaging material

- the packaging material includes an opening for taking out the cleaning sheet, and a resealable closing member for closing the opening

- the cleaning sheet packaging body wherein the cleaning sheet is laminated in the packaging material such that the water absorption layer side faces the opening.

- ⁇ 31> The method for producing a cleaning sheet according to any one of ⁇ 1> to ⁇ 25>, To the scraping layer in the cleaning sheet before the abrasive particles are applied, a slurry containing abrasive particles is applied to form a coating film, The manufacturing method of the sheet

- seat for cleaning as described in said ⁇ 31> which further has the process of wiping off the surface area of a scraping layer with the wiping member which consists of fibers.

- Example 1 Manufacture of scraping layer A raw material was prepared by mixing large diameter fibers (45 g / m 2 ) and small diameter fibers (15 g / m 2 ).

- a heat-sealable composite fiber (hereinafter referred to as “PET / PET”) having a core-sheath structure having a core made of polyethylene terephthalate (PET) and a sheath made of low melting point polyethylene terephthalate (PET) was used as a large diameter fiber.

- PET / PET heat-sealable composite fiber having a core-sheath structure having a core made of polyethylene terephthalate (PET) and a sheath made of low melting point polyethylene terephthalate (PET) was used as a large diameter fiber.

- PET polyethylene terephthalate

- PET low melting point polyethylene terephthalate

- PET heat-sealable composite fiber

- PET polyethylene terephthalate

- PET low melting point polyethylene terephthalate

- This fine fiber had a fineness of 2.2 dtex and a fiber length of 5 mm.

- a web having a basis weight of 45 g / m 2 was formed from this fiber raw material by the air array method. The crossing points of the constituent fibers in this web were bonded by thermal fusion to obtain an airlaid nonwoven fabric for the scraping layer.

- a web formed by an air array method including a scraping layer fiber is laminated on one side of a web formed by an air array method including a water absorbing layer fiber, and the constituent fibers of each web The intersection and the webs are fused or bonded together with a binder to form an airlaid nonwoven fabric for the water absorbing layer and an airlaid nonwoven fabric for the scraping layer, and the airlaid nonwoven fabric for the water absorbing layer and the airlaid nonwoven fabric for the scraping layer are integrated.

- Heat embossing was used as a means for integration. The heat embossing pattern was as shown in FIG. The area ratio of the recesses was 12%.

- a slurry containing abrasive particles was applied to the scraping layer of the laminated sheet thus obtained.

- the slurry contained 50% abrasive particles (calcium carbonate) and 10% surfactant, and the balance was water.

- the amount of slurry applied was such that the solid content after drying had the values shown in Table 1 below.

- the abrasive particles had an average particle size of 20 ⁇ m. While the coating film formed by applying the slurry was wet, the surface of the scraping layer was scraped off with a film made of polyethylene terephthalate.

- the surface of the scraping layer was wiped with a pulp nonwoven fabric having a basis weight of 40 g / m 2 .

- the intended cleaning sheet was obtained.

- abrasive particles were not substantially present in the surface area of the scraping layer.

- Examples 2 to 4 and Comparative Examples 1 to 3 A cleaning sheet was obtained in the same manner as in Example 1 except that the conditions shown in Table 1 below were adopted. However, the slurry of Comparative Example 3 used 30% abrasive particles (calcium carbonate: average particle size 20 ⁇ m) by mass ratio, and 30% of the surfactant was made of water.

- abrasive particles calcium carbonate: average particle size 20 ⁇ m

- the cleaning sheet of each example has a higher detergency than that of the comparative cleaning sheet and is superior in the sense of dirt scraping.

- the performance is inferior without the abrasive particles falling off from the obtained sheet. This is because in Comparative Example 3, the abrasive particles adhered firmly to the fibers because the ratio of the surfactant in the slurry used when adhering the abrasive particles to the fibers was increased. .

- Examples 5 to 10 and Comparative Example 4 A cleaning sheet was obtained in the same manner as in Example 1 except that the conditions shown in Table 2 below were adopted. Comparative Example 4 did not apply slurry (does not include abrasive particles). About the obtained sheet

- the cleaning sheet of each example has a higher detergency than that of the comparative cleaning sheet, excellent scratching feeling, and good foaming properties. It turns out that it is.

- the abrasive particles are released quickly and in large quantities on the surface to be cleaned, so that it is possible to easily remove the dirt quickly and reliably. it can. Moreover, according to the cleaning sheet of the present invention, abrasive particles can be released even when the surface to be cleaned is in a dry state.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Mechanical Engineering (AREA)

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Laminated Bodies (AREA)

- Nonwoven Fabrics (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201580023432.7A CN106455893B (zh) | 2014-06-06 | 2015-05-29 | 清扫用片材、及使用其的清扫方法 |

| SG11201609175RA SG11201609175RA (en) | 2014-06-06 | 2015-05-29 | Cleaning sheet and cleaning method in which same is used |

| MYPI2016704424A MY174231A (en) | 2014-06-06 | 2015-05-29 | Cleaning sheet and cleaning method in which same is used |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014-117379 | 2014-06-06 | ||

| JP2014117379A JP6118290B2 (ja) | 2014-06-06 | 2014-06-06 | 清掃用シートの製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015186622A1 true WO2015186622A1 (ja) | 2015-12-10 |

Family

ID=54766695

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/065546 Ceased WO2015186622A1 (ja) | 2014-06-06 | 2015-05-29 | 清掃用シート、及びこれを用いた清掃方法 |

Country Status (6)

| Country | Link |

|---|---|

| JP (1) | JP6118290B2 (enExample) |

| CN (1) | CN106455893B (enExample) |

| MY (1) | MY174231A (enExample) |

| SG (1) | SG11201609175RA (enExample) |

| TW (1) | TW201602436A (enExample) |

| WO (1) | WO2015186622A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6928446B2 (ja) * | 2016-12-22 | 2021-09-01 | 王子ホールディングス株式会社 | 清掃用シート |

| JP2019137419A (ja) * | 2018-02-08 | 2019-08-22 | 花王株式会社 | 収納容器 |

| CN108442033A (zh) * | 2018-04-16 | 2018-08-24 | 许大鹏 | 功能性非织造布及其制作方法 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5877655U (ja) * | 1981-11-20 | 1983-05-25 | 岩田 秋雄 | 仕上用特殊ふきん |

| JPH04372440A (ja) * | 1991-06-19 | 1992-12-25 | Ishihara Chem Co Ltd | 車両用の洗浄シート |

| JPH10245756A (ja) * | 1997-03-03 | 1998-09-14 | Lion Corp | 掃除用材料およびこれを用いた掃除用製品 |

| JP2005312711A (ja) * | 2004-04-30 | 2005-11-10 | Kao Corp | 人工大理石用清掃物品 |

| JP2006015011A (ja) * | 2004-07-02 | 2006-01-19 | Kao Corp | 清掃用シート |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| MY125395A (en) * | 1999-07-08 | 2006-07-31 | Kao Corp | Personal cleansing sheet |

| EP1211342B1 (en) * | 2000-12-01 | 2011-07-06 | Kao Corporation | Cleaning sheet |

| JP2005185429A (ja) * | 2003-12-25 | 2005-07-14 | Kao Corp | 清掃用不織布 |

| JP4406584B2 (ja) * | 2004-07-02 | 2010-01-27 | 高志 秋廣 | 口唇器具 |

| WO2009084500A1 (ja) * | 2007-12-27 | 2009-07-09 | Kao Corporation | 清掃用シート |

-

2014

- 2014-06-06 JP JP2014117379A patent/JP6118290B2/ja active Active

-

2015

- 2015-05-29 CN CN201580023432.7A patent/CN106455893B/zh active Active

- 2015-05-29 MY MYPI2016704424A patent/MY174231A/en unknown

- 2015-05-29 WO PCT/JP2015/065546 patent/WO2015186622A1/ja not_active Ceased

- 2015-05-29 SG SG11201609175RA patent/SG11201609175RA/en unknown

- 2015-06-03 TW TW104118001A patent/TW201602436A/zh unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5877655U (ja) * | 1981-11-20 | 1983-05-25 | 岩田 秋雄 | 仕上用特殊ふきん |

| JPH04372440A (ja) * | 1991-06-19 | 1992-12-25 | Ishihara Chem Co Ltd | 車両用の洗浄シート |

| JPH10245756A (ja) * | 1997-03-03 | 1998-09-14 | Lion Corp | 掃除用材料およびこれを用いた掃除用製品 |

| JP2005312711A (ja) * | 2004-04-30 | 2005-11-10 | Kao Corp | 人工大理石用清掃物品 |

| JP2006015011A (ja) * | 2004-07-02 | 2006-01-19 | Kao Corp | 清掃用シート |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6118290B2 (ja) | 2017-04-19 |

| CN106455893A (zh) | 2017-02-22 |

| CN106455893B (zh) | 2019-10-15 |

| SG11201609175RA (en) | 2016-12-29 |

| TW201602436A (zh) | 2016-01-16 |

| JP2015229041A (ja) | 2015-12-21 |

| MY174231A (en) | 2020-04-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2006526463A (ja) | クリーニングパッド | |

| CN101309627A (zh) | 改善的清洁基底 | |

| JP3912753B2 (ja) | 改良クリーニングパッド | |

| JP6198803B2 (ja) | 清掃用シート | |

| JP2023100937A (ja) | 異なるピッチのトウ房を有する掃除用品 | |

| JP2004513728A (ja) | 改良クリーニング器具 | |

| JP6118290B2 (ja) | 清掃用シートの製造方法 | |

| JP2022106901A (ja) | 不規則に離間したトウ房を有する掃除用品 | |

| US10730081B2 (en) | Method of making a cleaning article having cutouts | |

| CN101111184A (zh) | 具有可变举升工作表面的清洁擦 | |

| JP2017131676A (ja) | 清掃用シート | |

| HK1230047B (zh) | 清扫用片材、及使用其的清扫方法 | |

| HK1230047A1 (en) | Cleaning sheet and cleaning method in which same is used | |

| CA3071720C (en) | Method of making a cleaning article having cutouts | |

| JP2005185429A (ja) | 清掃用不織布 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15803176 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 15803176 Country of ref document: EP Kind code of ref document: A1 |