WO2014196333A1 - 電気接続箱 - Google Patents

電気接続箱 Download PDFInfo

- Publication number

- WO2014196333A1 WO2014196333A1 PCT/JP2014/062939 JP2014062939W WO2014196333A1 WO 2014196333 A1 WO2014196333 A1 WO 2014196333A1 JP 2014062939 W JP2014062939 W JP 2014062939W WO 2014196333 A1 WO2014196333 A1 WO 2014196333A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- box body

- wall portion

- cover member

- peripheral wall

- box

- Prior art date

Links

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/02—Details

- H02G3/08—Distribution boxes; Connection or junction boxes

- H02G3/081—Bases, casings or covers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R16/00—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for

- B60R16/02—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for electric constitutive elements

- B60R16/023—Electric or fluid circuits specially adapted for vehicles and not otherwise provided for; Arrangement of elements of electric or fluid circuits specially adapted for vehicles and not otherwise provided for electric constitutive elements for transmission of signals between vehicle parts or subsystems

- B60R16/0238—Electrical distribution centers

Definitions

- the present invention relates to an electrical junction box mounted on an automobile or the like, and more particularly, to an electrical junction box provided with a lock mechanism that detachably attaches a cover member to the box body.

- electrical connection boxes such as relay boxes, fuse boxes, and junction boxes have been used in automobile electrical systems, and a large number of electrical components such as relays and fuses are concentrated in such electrical connection boxes. As a result, the efficiency of electrical wiring and the maintenance such as replacement are improved.

- Such an electrical junction box is composed of a bus bar, a printed circuit board, and the like as described in Japanese Patent Application Laid-Open No. 11-307594 (Patent Document 1) and Japanese Patent Application Laid-Open No. 2012-235654 (Patent Document 2). It has a box body that houses the internal circuit. The upper surface, which is one surface of the box body, is provided with a plurality of component mounting portions on which electrical components are mounted, and the upper surface of the box body is covered by a cover member that is detachably mounted to the box body via a lock mechanism. Is supposed to be covered.

- the peripheral wall portion of the box main body includes a protruding end portion protruding at a predetermined height on the upper surface side of the box main body provided with the component mounting portion, and the front end peripheral wall portion of the peripheral wall portion of the cover member is provided at the protruding end portion.

- the cover member is positioned and arranged with respect to the box body. Then, the cover member can be detached from the box body by fitting a lock mechanism comprising a lock part provided on one of the peripheral wall part of the cover member and the peripheral wall part of the box body and a locked part provided on the other side. It is fixed.

- the locked portion provided on the peripheral wall portion of the box body is located below the protruding end protruding from the top surface of the box body.

- the cover member when attaching the cover member to the box body, confirm the position of the locked part of the box body from above and align the lock part of the cover member with the locked part of the box body from above.

- the cover member is present on the line of sight for confirming the position of the locked portion of the box body, and it is difficult to see, which may lead to a decrease in workability.

- the protruding end provided around the upper surface of the box body is set at the same height position over the entire circumference of the box body. Then, as an electrical component to be mounted on the box body, a relay with a large height of the main body portion protruding from the lead portion inserted into the inside of the component mounting portion to the upper surface side, or a main body protruding from the lead portion to the upper surface side.

- fuses with small height dimensions are mixed, it is inevitable that an electrical component such as a relay with a large height dimension of the main body protrudes upward compared to other electrical components (see Patent Document 2). (See FIG. 1).

- the present invention has been made in the background of the above-mentioned circumstances, and the problem to be solved is that it is possible to achieve both improvement in assembly workability of the lock mechanism and improvement in space efficiency of the electrical junction box.

- An object is to provide an electrical junction box having a novel structure.

- a box body in which a plurality of component mounting portions on which electrical components are mounted is provided on one surface, a cover member that covers the one surface of the box body, and the box body

- a lock mechanism provided on one of the peripheral wall portion of the cover member and the peripheral wall portion of the cover member and a locked portion provided on the other, and a lock mechanism for detachably mounting and fixing the box body and the cover member.

- the electrical connection box wherein the peripheral wall portion of the box body includes a high wall portion and a low wall portion formed by different protruding end positions of the end portion protruding to the one surface side in the circumferential direction.

- the lock part or the locked part provided in the box body protrudes to the one surface side beyond the low wall part, and the box body is interposed via the lock mechanism.

- the peripheral wall portion of the box main body includes the high wall portion and the low wall portion, and is provided on the peripheral wall portion of the box main body. At least a part of the locked part or the locked part protrudes to one surface side beyond the low wall part and is exposed. Therefore, compared with the case where the lock part or the locked part is located below the protruding end part of the peripheral wall part as in the conventional structure, the visibility and the accessibility of the lock part or the locked part are low. The assembly workability is improved and facilitated via the cover member and the lock mechanism of the box body.

- the space between them in the state where the cover member is mounted and fixed to the box main body (the upper end surface of the peripheral wall portion and the cover member) (Opposite distance to the cover surface) can be increased on the low wall side and decreased on the high wall side.

- a relay or other component having a large height dimension of the main body protruding from one side of the box main body is disposed on the low wall portion side.

- the electric parts arranged on the low wall portion side are exposed by the main body portion protruding greatly beyond the upper end surface of the low wall portion. Therefore, the accessibility to the electrical component is improved, and the ease of attaching / detaching the component to / from the electrical component mounting portion can be improved.

- the electrical component arranged on the high wall portion side can be prevented from projecting greatly from the upper end surface of the high wall portion, and the protection of the electrical component by the peripheral wall portion can be improved.

- the specific shapes of the lock part and the locked part constituting the lock mechanism are not particularly limited and can be arbitrarily set. Further, whether the lock portion or the locked portion is provided on the peripheral wall portions of the box body and the cover member can be appropriately selected without any particular limitation.

- the component mounting portion provided on the low wall portion side is mounted with a relay. It has a relay mounting part.

- the component mounting portion on the low wall portion side is a relay mounting portion

- a relay having a large body portion projecting from the component mounting portion to one surface side is advantageously accommodated. be able to.

- the accessibility to the relay main body, which is often gripped with fingers when replacing parts, is improved, workability can be improved at the same time.

- the component mounting portion provided on the high wall portion side of the component mounting portion provided in the box body has a fuse. It has a fuse mounting part to be mounted.

- the fuse mounting portion on the high wall portion side is the fuse mounting portion

- the fuse with a small height dimension of the main body portion protruding from the component mounting portion to the one surface side is used as the cover member. Can be accommodated efficiently without providing a large wasted space between them.

- the main body of the fuse including the fusing part can be covered with the high wall part without greatly exposing the fuse part to the outside, the fuse can be protected by the peripheral wall part.

- the engagement frame according to any one of the first to third aspects, wherein the peripheral wall portion of the box body has an engaging frame projecting from both ends thereof. While the lock portion is provided, the locked portion having an elastic bending piece that is connected to the protruding end portion side of the peripheral wall portion of the cover member and protrudes in a cantilever manner toward the cover surface side. And provided with a deformation restricting protrusion on the peripheral wall portion of the cover member that prevents the deformation of the peripheral wall portion by contacting the engagement frame when the elastic bending piece is deformed. It is.

- the lock portion having the engagement frame is provided on the peripheral wall portion of the box body, the rigidity of the lock portion is ensured while improving the visibility of the engagement frame by the low wall portion.

- an elastic bending piece is provided on the peripheral wall portion of the cover member to secure the ease of bending of the elastic bending piece to reduce the insertion force, and the deformation regulating projection prevents excessive deformation of the peripheral wall portion of the cover member.

- the trajectory of the engagement frame and the elastic bending piece can be maintained in the desired shape to maintain the insertion stability of the elastic bending piece into the engagement frame, and hence the fitting stability of the lock portion and the locked portion. it can.

- the peripheral wall portion of the box body is configured to include a high wall portion and a low wall portion, and at least a part of the lock portion or the locked portion is on one surface side beyond the low wall portion. Protrusively exposed.

- the visibility etc. of a lock part or a to-be-locked part are improved, and the improvement of the assembly

- the facing distance between the upper end surface of the peripheral wall portion and the cover surface of the cover member can be increased on the low wall portion side and decreased on the high wall portion side, components such as relays having a large height can be connected to the low wall portion side.

- the electrical component disposed on the low wall portion side can improve the detachability, while the electrical component disposed on the high wall portion side can improve the protection of the electrical component by the peripheral wall portion.

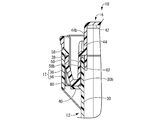

- FIG. 3 is a perspective view of FIG. 2 taken along the section III-III.

- the front view of the electrical-connection box shown in FIG. The front view of the electrical-connection box shown in FIG. FIG. 6 is an enlarged cross-sectional view taken along line VI-VI in FIG. 2.

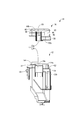

- FIGS. 1 to 6 show a relay box 10 as an electrical connection box according to an embodiment of the present invention.

- the relay box 10 includes a box body 12, a cover member 16 that covers an upper surface 14 that is one surface of the box body 12, and a lock mechanism 17 that detachably mounts and fixes the box body 12 and the cover member 16. It is configured to include.

- the upper surface 14 of the box main body 12 is a surface constituting the upper opening side of the box main body 12 and does not necessarily have to be flat (see FIG. 3).

- “upper” means the upper side in FIG. 1

- “lower” means the lower side in FIG. 1

- front means the left side in FIG. 1

- “rear” means the right side in FIG.

- FIG. 1 shows a relay box 10 as an electrical connection box according to an embodiment of the present invention.

- the relay box 10 includes a box body 12, a cover member 16 that covers an upper surface 14 that is one surface of the box body 12, and a lock mechanism 17 that detachably mounts and fixes the

- the box body 12 has a long rectangular block shape as a whole, and is integrally formed of, for example, a synthetic resin such as polypropylene (PP) or polyamide (PA) by injection molding or the like.

- PP polypropylene

- PA polyamide

- the upper surface 14 of the box body 12 has a plurality of component mounting portions, relay mounting portions 18a and 18b (six in this embodiment) and fuse mounting portions 20 (five in this embodiment). However, an opening is formed upward.

- a plurality of terminal receiving holes are formed in the lower surface of the box body 12 so as to open downward, and crimp terminals and the like crimped to the ends of the electric wires are accommodated in the terminal receiving holes.

- a bus bar or the like constituting the internal circuit is accommodated in the bus bar accommodating groove or the like.

- relays 24a and 24b and the fuses 26 as electrical components are mounted on the relay mounting portions 18a and 18b and the fuse mounting portions 20 from the upper surface 14 side of the box body 12, the relays 24a and 24b and A tab terminal (not shown) protruding from the fuse 26 is connected to the above-described crimp terminal of the end of the electric wire, a bus bar or the like so as to be conductive.

- the projecting end position of the end portion of the peripheral wall portion 30 is configured to include a high wall portion 32 and a low wall portion 34 formed by being different in the circumferential direction.

- the peripheral wall 30 a that faces in the width direction of the box body 12 is configured by a low wall portion 34

- the peripheral wall 30 c is configured by a high wall portion 32.

- the relay mounting portions 18a and 18b are mainly provided on the peripheral wall 30a side, that is, the low wall portion 34 side

- the fuse mounting portion 20 is mainly provided on the peripheral wall 30c side, that is, the high wall portion 32 side.

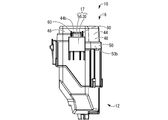

- the peripheral walls 30 b and 30 d that are opposed to each other in the longitudinal direction of the box body 12 are each provided with an engagement frame 36 that is a U-shaped lock portion in a plan view near the upper opening of the box body 12. 36 are projected. More specifically, the engagement frames 36, 36 are structured to protrude from both ends of the peripheral walls 30b, 30d. As shown in FIG. 4, the engaging frame 36 is configured such that a part thereof protrudes toward the upper surface 14 side of the box body 12, that is, upward in the vertical direction, beyond the low wall portion 34. As shown in FIG.

- engagement protrusions 38 and 38 are provided at the upper ends of the engagement frames 36 and 36 so as to protrude inwardly in a substantially triangular cross-sectional shape.

- the peripheral wall 30b (30d) is provided with a stopper 40 that protrudes toward the lower end of the engagement frame 36.

- the stopper 40 can advantageously prevent an elastic bending piece 56 described later from being excessively inserted into the engagement frame 36 in a state where the cover member 16 is mounted and fixed to the box body 12.

- the cover member 16 has a bottomed box shape that opens downward (see FIG. 1), and is formed in a substantially rectangular shape that is substantially the same as the upper surface 14 of the box body 12 in plan view. It is integrally formed by injection molding or the like with a synthetic resin such as polypropylene (PP) or polyamide (PA).

- PP polypropylene

- PA polyamide

- a peripheral wall portion 44 that protrudes downward in the vertical direction is provided on the peripheral edge portion of the cover surface 42 of the cover member 16 over the entire circumference. As shown in FIG. 4, the protruding end of the end portion of the peripheral wall portion 44 is provided.

- a high wall portion 46 and a low wall portion 48 formed by different positions in the circumferential direction are included.

- the high wall portion 46 and the low wall portion 48 are provided at positions facing the high wall portion 32 and the low wall portion 34 of the box body 12, respectively.

- a tip peripheral wall portion 50 that protrudes in an inverted L shape is provided over the entire circumference. As shown in FIG. 3, the protruding end portion of the tip peripheral wall portion 50 is a peripheral wall. It protrudes below the protruding end of the portion 44.

- the cover surface 42 of the cover member 16 is a flat surface. Therefore, as shown in FIG. 3, with the cover member 16 attached and fixed to the box body 12 via the lock mechanism 17, the cover surface 42 of the cover member 16 and the upper end surface 52 of the lower wall portion 34 of the box body 12.

- the facing distance L1 is made larger than the facing distance L2 between the cover surface 42 of the cover member 16 and the upper end surface 54 of the high wall portion 32 of the box body 12.

- the peripheral walls 44b and 44d opposed to each other in the longitudinal direction of the cover member 16 are opposed to the engagement frames 36 and 36 which are the lock portions of the box body 12 in the vicinity of the lower opening of the cover member 16 as shown in FIG.

- the elastic bending pieces 56 and 56 which are to-be-locked parts are provided in the position to perform.

- a substantially rectangular engagement hole 58 is provided above the central portion of the elastic bending piece 56.

- the elastic bending piece 56 is connected to the protruding end portion side of the tip peripheral wall portion 50 in the peripheral wall portion 44 of the cover member 16 and is cantilevered toward the cover surface 42 side, that is, substantially upward in the vertical direction. It is projecting to.

- the front peripheral walls 50b and 50d of the peripheral walls 44b and 44d opposed to each other in the longitudinal direction of the cover member 16 are provided with engaging frames 36 and 36 when assembled to the box body 12, as shown in FIGS.

- Deformation restricting projections 60, 60 are formed over substantially the entire gap formed between the elastic deflecting pieces 56, 56.

- the protrusion height of the deformation restricting protrusion 60 is configured to be opposed to the engagement frame 36 with a substantially constant slight gap when assembled to the box body 12.

- the outer surfaces of the peripheral walls 44a and 44c (including the tip peripheral walls 50a and 50c) facing each other in the width direction of the cover member 16 are flat surfaces on which nothing protrudes.

- the deformation restricting projections 60, 60 projecting from the front peripheral walls 50b, 50d are arranged to face the engaging frames 36, 36 with a substantially constant small gap. Therefore, the deformation restricting projections 60, 60 come into contact with the engaging frames 36, 36, and the deformation of the distal peripheral walls 50b, 50d, that is, the peripheral wall portion 44 is prevented.

- the cover member 16 is locked in the mounted state in the upper opening of the box body 12.

- the engagement frames 36 and 36 provided on the opposed peripheral walls 30b and 30d of the box body 12 and the elasticity provided on the distal peripheral walls 50b and 50d of the opposed peripheral walls 44b and 44d of the cover member 16 are provided.

- a pair of locking mechanisms 17 for detachably mounting and fixing the box main body 12 and the cover member 16 is configured by the bending pieces 56 and 56.

- the peripheral wall portion 30 of the box body 12 has the high wall portion 32 and the low wall portion on the upper surface 14 side of the box body 12 to which the cover member 16 is attached. 34, and an engagement frame 36 serving as a lock portion provided on the peripheral wall portion 30 of the box body 12 protrudes upward beyond the low wall portion 34 and is exposed (FIGS. 1 and 4). reference).

- an engagement frame 36 serving as a lock portion provided on the peripheral wall portion 30 of the box body 12 protrudes upward beyond the low wall portion 34 and is exposed (FIGS. 1 and 4). reference).

- the visibility and ease of access of the engagement frame 36 are improved as compared with the conventional case where the engagement frame is positioned below the protruding end portion of the peripheral wall portion.

- the workability of the assembly through the lock mechanism 17 of the box body 12 is improved and facilitated.

- the opposing distances L1 and L2 between the upper end surfaces 52 and 54 of the peripheral wall portion 30 of the box body 12 and the cover surface 42 of the cover member 16 are set as the box body 12. It is large on the low wall portion 34 side and small on the high wall portion 32 side (L1> L2 in FIG. 3).

- the relays 24a and 24b can be advantageously accommodated by disposing the relays 24a and 24b having a large height of the main body on the low wall portion 34 side of the box main body 12.

- workability can be improved at the same time.

- the fuse 26 having a small height of the main body is disposed on the high wall portion 32 side of the box main body 12 so that it can be efficiently accommodated without providing a large waste space with the cover member 16. Can do.

- the main body portion of the fuse 26 including the fusing portion can be covered with the high wall portion 32 without greatly exposing to the outside, the fuse wall 26 can be protected by the peripheral wall portion 30.

- the elastic member 56 is provided on the peripheral wall portion 44 of the cover member 16 to secure the ease of bending of the elastic member 56 to reduce the insertion force, and the cover member 16 is deformed by the deformation restriction protrusion 60.

- the excessive deformation of the peripheral wall portion 44 is prevented, and the locus of the engagement frame 36 and the elastic bending piece 56 is maintained in an intended shape, and the insertion stability of the elastic bending piece 56 into the engagement frame 36 is extended.

- the fitting stability between the engagement frame 36 and the elastic bending piece 56 can be maintained.

- relay box 10 has been described as an example of the electrical connection box of the present invention, but the present invention can of course be applied to a fuse box or a junction box.

- the specific shapes of the lock part and the locked part constituting the lock mechanism are not particularly limited and can be arbitrarily set.

- the twelve low wall portions 34 may be exposed and exposed.

- Relay box (electric connection box), 12: Box body, 14: Upper surface (one surface), 16: Cover member, 17: Lock mechanism, 18a, b: Relay mounting part (component mounting part), 20: Fuse Mounting part (part mounting part), 24a, b: relay (electrical part), 26: fuse (electrical part), 30: peripheral wall part, 32: high wall part, 34: low wall part, 36: engagement frame (locking) Part), 42: cover surface, 44: peripheral wall part, 52: upper end face, 54: upper end face, 56: elastic bending piece (locked part), 60: deformation regulating projection

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mechanical Engineering (AREA)

- Connection Or Junction Boxes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-117451 | 2013-06-04 | ||

| JP2013117451A JP6004189B2 (ja) | 2013-06-04 | 2013-06-04 | 電気接続箱 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014196333A1 true WO2014196333A1 (ja) | 2014-12-11 |

Family

ID=52007986

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/062939 WO2014196333A1 (ja) | 2013-06-04 | 2014-05-15 | 電気接続箱 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6004189B2 (ru) |

| WO (1) | WO2014196333A1 (ru) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3578419A1 (en) * | 2018-06-07 | 2019-12-11 | Yazaki Corporation | Lock structure, electric connection box and wire harness |

| GB2603021A (en) * | 2020-08-28 | 2022-07-27 | Sumitomo Wiring Systems | Housing |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6277110B2 (ja) * | 2014-11-14 | 2018-02-07 | 住友電装株式会社 | 電気接続箱 |

| JP6508951B2 (ja) * | 2015-01-27 | 2019-05-08 | 三笠産業株式会社 | ヒンジキャップ |

| JP6232014B2 (ja) * | 2015-07-16 | 2017-11-15 | 矢崎総業株式会社 | 電気接続箱及びワイヤハーネス |

| KR101872832B1 (ko) * | 2016-12-30 | 2018-06-29 | 주식회사 유라코퍼레이션 | 배터리 단자 커버 구조 |

| KR102085980B1 (ko) * | 2018-11-08 | 2020-03-06 | 현대자동차(주) | 도난 방지용 파워커넥터 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1051931A (ja) * | 1996-07-29 | 1998-02-20 | Yazaki Corp | 電気接続箱のカバーロック構造 |

| JP2001244660A (ja) * | 2000-03-01 | 2001-09-07 | Sumitomo Wiring Syst Ltd | 電気接続箱 |

| US20050020106A1 (en) * | 2003-07-23 | 2005-01-27 | Sumitomo Wiring Systems, Ltd. | Electrical connection box |

-

2013

- 2013-06-04 JP JP2013117451A patent/JP6004189B2/ja active Active

-

2014

- 2014-05-15 WO PCT/JP2014/062939 patent/WO2014196333A1/ja active Application Filing

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1051931A (ja) * | 1996-07-29 | 1998-02-20 | Yazaki Corp | 電気接続箱のカバーロック構造 |

| JP2001244660A (ja) * | 2000-03-01 | 2001-09-07 | Sumitomo Wiring Syst Ltd | 電気接続箱 |

| US20050020106A1 (en) * | 2003-07-23 | 2005-01-27 | Sumitomo Wiring Systems, Ltd. | Electrical connection box |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3578419A1 (en) * | 2018-06-07 | 2019-12-11 | Yazaki Corporation | Lock structure, electric connection box and wire harness |

| CN110581468A (zh) * | 2018-06-07 | 2019-12-17 | 矢崎总业株式会社 | 锁定构造、电气连接箱以及线束 |

| CN110581468B (zh) * | 2018-06-07 | 2020-11-24 | 矢崎总业株式会社 | 锁定构造、电气连接箱以及线束 |

| US11329465B2 (en) | 2018-06-07 | 2022-05-10 | Yazaki Corporation | Water-proof lock structure, electric connection box, and apparatus |

| GB2603021A (en) * | 2020-08-28 | 2022-07-27 | Sumitomo Wiring Systems | Housing |

| GB2603021B (en) * | 2020-08-28 | 2024-08-21 | Sumitomo Wiring Systems | Housing |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014236609A (ja) | 2014-12-15 |

| JP6004189B2 (ja) | 2016-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6004189B2 (ja) | 電気接続箱 | |

| JP6441112B2 (ja) | 電子部品ユニット、及び、ワイヤハーネス | |

| US11757271B2 (en) | Electrical connection box | |

| US10136539B2 (en) | Electronic component assembly structure and electronic component | |

| JP6432866B2 (ja) | 付設ボックス付電気接続箱 | |

| US10903634B2 (en) | Electrical junction box | |

| US9941678B2 (en) | Electrical connection box | |

| US9509079B2 (en) | Assembling structure of electronic component, electrical junction box, and electronic component | |

| JP6211483B2 (ja) | リーク遮断構造、電子部品、及び、電子部品ユニット | |

| WO2015098482A1 (ja) | 電気回路装置 | |

| JP2016096674A (ja) | 電気接続箱 | |

| JP6238873B2 (ja) | 電気接続箱 | |

| JP6277110B2 (ja) | 電気接続箱 | |

| JP7226190B2 (ja) | 電気接続箱 | |

| JP2014087221A (ja) | バスバーおよび該バスバーを備えた電気接続箱 | |

| US20200168423A1 (en) | Attachment structure between cover and housing, and fusible link unit | |

| JP5360581B2 (ja) | 電気接続箱 | |

| JP6210437B2 (ja) | 電気接続箱 | |

| JP6513959B2 (ja) | ヒューズユニット | |

| WO2021020255A1 (ja) | 電子モジュール | |

| US20240186777A1 (en) | Electrical junction box | |

| JP6195128B2 (ja) | 電気接続箱 | |

| JP2014023322A (ja) | 電気接続箱 | |

| JP2024047353A (ja) | 電力供給システム | |

| KR20230100038A (ko) | 전원분배 정선블록 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14808318 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 14808318 Country of ref document: EP Kind code of ref document: A1 |