WO2013191226A1 - 歯磨剤用顆粒の製造方法 - Google Patents

歯磨剤用顆粒の製造方法 Download PDFInfo

- Publication number

- WO2013191226A1 WO2013191226A1 PCT/JP2013/066896 JP2013066896W WO2013191226A1 WO 2013191226 A1 WO2013191226 A1 WO 2013191226A1 JP 2013066896 W JP2013066896 W JP 2013066896W WO 2013191226 A1 WO2013191226 A1 WO 2013191226A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- dentifrice

- mass

- less

- water

- granules

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/02—Cosmetics or similar toiletry preparations characterised by special physical form

- A61K8/0216—Solid or semisolid forms

- A61K8/022—Powders; Compacted Powders

- A61K8/0225—Granulated powders

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/19—Cosmetics or similar toiletry preparations characterised by the composition containing inorganic ingredients

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/19—Cosmetics or similar toiletry preparations characterised by the composition containing inorganic ingredients

- A61K8/25—Silicon; Compounds thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/19—Cosmetics or similar toiletry preparations characterised by the composition containing inorganic ingredients

- A61K8/26—Aluminium; Compounds thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q11/00—Preparations for care of the teeth, of the oral cavity or of dentures; Dentifrices, e.g. toothpastes; Mouth rinses

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K2800/00—Properties of cosmetic compositions or active ingredients thereof or formulation aids used therein and process related aspects

- A61K2800/40—Chemical, physico-chemical or functional or structural properties of particular ingredients

- A61K2800/41—Particular ingredients further characterized by their size

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K2800/00—Properties of cosmetic compositions or active ingredients thereof or formulation aids used therein and process related aspects

- A61K2800/40—Chemical, physico-chemical or functional or structural properties of particular ingredients

- A61K2800/41—Particular ingredients further characterized by their size

- A61K2800/412—Microsized, i.e. having sizes between 0.1 and 100 microns

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K2800/00—Properties of cosmetic compositions or active ingredients thereof or formulation aids used therein and process related aspects

- A61K2800/80—Process related aspects concerning the preparation of the cosmetic composition or the storage or application thereof

- A61K2800/805—Corresponding aspects not provided for by any of codes A61K2800/81 - A61K2800/95

Definitions

- the present invention relates to a method for producing a dentifrice granule and a dentifrice granule.

- dentifrices containing granules that can effectively remove dental plaque that causes tooth decay and periodontal disease and are palpable are known. These granules are substantially spherical agglomerated particles and contain functional materials such as drugs, enzymes, and abrasives so as not to damage the enamel and gums on the tooth surface. And there is something that aimed at the visual effect.

- Patent Document 1 discloses a dentifrice containing granules having a certain size and strength obtained by binding a water-insoluble powder material with a water-insoluble inorganic binder and spray drying.

- Patent Document 2 discloses a dentifrice composition containing a granular zeolite having an average particle size of 150 to 800 ⁇ m and an average disintegration strength of 15 to 100 g / piece, modified mint oil, etc.

- Disclosed is a product containing silicic anhydride and titanium oxide and prepared in a granular form by sintering.

- Patent Document 3 discloses a toothpaste comprising granules obtained by drying aggregates of two kinds of water-insoluble fine particle materials which are substantially free of organic and / or inorganic binders and are chemically and / or physically different from each other. Oral compositions are disclosed.

- JP-A-1-299211 JP 2008-266251 A Japanese National Patent Publication No. 10-506885

- the present invention relates to the following [1] to [2].

- [1] A method for producing a dentifrice granule in which a water-insoluble powder material and a silicate are mixed and granulated using a container rotating granulator, and the water-insoluble powder material is obtained using a multi-fluid nozzle.

- a method for producing a dentifrice granule comprising the step of supplying an aqueous solution of the silicate as droplets and granulating.

- [2] Dentifrice granules obtained by the method of [1] above.

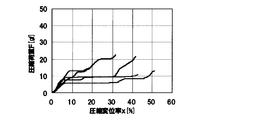

- FIG. 1 It is a schematic diagram of a graph (compression load F-compression displacement rate x diagram) showing the relationship between the compression displacement rate x and the compression load F for the dentifrice granules of the present invention and the conventional dentifrice granules.

- the vertical axis represents the compression load F (gf), and the horizontal axis represents the compression displacement rate x (%).

- 6 is a graph showing the relationship between the compression displacement rate x and the compression load F in the dentifrice granules of Example 31 (compression load F-compression displacement rate x diagram).

- the vertical axis represents the compression load F (gf)

- the horizontal axis represents the compression displacement rate x (%).

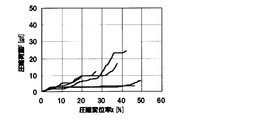

- compression load F-compression displacement rate x figure shows the relationship between the compression displacement rate x and the compression load F in the granule for dentifrice of Example 32.

- the vertical axis represents the compression load F (gf), and the horizontal axis represents the compression displacement rate x (%).

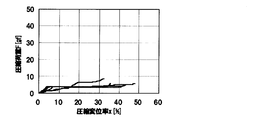

- compression load F-compression displacement rate x figure shows the relationship between the compression displacement rate x and the compression load F in the dentifrice granule of Example 33.

- the vertical axis represents the compression load F (gf)

- the horizontal axis represents the compression displacement rate x (%).

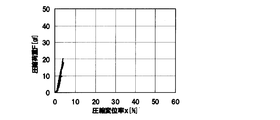

- 14 is a graph showing the relationship between the compression displacement rate x and the compression load F in the dentifrice granules of Comparative Example 11 (compression load F-compression displacement rate x diagram).

- the vertical axis represents the compression load F (gf), and the horizontal axis represents the compression displacement rate x (%).

- 14 is a graph showing the relationship between the compression displacement rate x and the compression load F in the dentifrice granules of Comparative Example 12 (compression load F-compression displacement rate x diagram).

- the vertical axis represents the compression load F (gf)

- the horizontal axis represents the compression displacement rate x (%).

- FIG. 14 is a graph showing the relationship between the compression displacement rate x and the compression load F in the dentifrice granules of Comparative Example 13 (compression load F-compression displacement rate x diagram).

- the vertical axis represents the compression load F (gf), and the horizontal axis represents the compression displacement rate x (%).

- 2 is a cross-sectional photograph of a dentifrice granule of Example 31. It is a cross-sectional photograph of the dentifrice granule of Comparative Example 11.

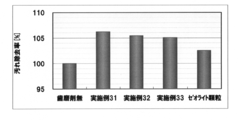

- 6 is a graph showing the results of Test Example 1 using the granules and zeolite granules obtained in Examples 31 to 33. The vertical axis shows the dirt removal rate (%).

- Patent Document 3 describes an example of producing granules by substantially drying agglomerates which are substantially free of binder and aggregated with water in an oven or rotary kiln. However, it is difficult to adjust the disintegration strength of the granules. In addition, the load of the drying operation (processing temperature and / or processing time) for expressing a suitable disintegration strength is large, and it should not be satisfied in terms of freedom of formulation, cost, and productivity.

- the present invention relates to a method for producing a dentifrice granule for obtaining a dentifrice granule having an appropriate disintegration strength and an excellent wet disintegration strength, and to a dentifrice granule obtained by the method.

- the present inventors granulate a water-insoluble powder material and a silicate using a combination of a container rotary granulator and a multi-fluid nozzle, thereby providing a dentifrice having an appropriate disintegration strength and an excellent wet disintegration strength. It has been found that granules for pharmaceutical preparation can be produced with good yield. That is, the present invention relates to the following [1] to [5]. [1] A method for producing a dentifrice granule in which a water-insoluble powder material and a silicate are mixed and granulated using a container rotating granulator, and the water-insoluble powder material is obtained using a multi-fluid nozzle.

- a method for producing a dentifrice granule comprising the step of supplying an aqueous solution of the silicate as droplets and granulating.

- Dentifrice granules obtained by the method of [1] above.

- a dentifrice granule containing a silicate and a water-insoluble material wherein the silicate is one or two selected from sodium silicate and potassium silicate, and the content of the water-insoluble powder material is 40 -97 mass%, silicate (solid content) content is 2-60 mass%, and pore volume of 0.1-1 ⁇ m diameter is 0.1-0.7 cc / g Granules for preparation (Aspect 1).

- Granules for dentifrice with a value of ⁇ F / ⁇ x until reaching the smooth displacement region P of 6.0 or less and a collapse load F max of 30 gf or less (Aspect 2).

- Compression displacement rate (%) ⁇ compression displacement d ( ⁇ m) / particle diameter of dentifrice granule before loading compression load F ( ⁇ m) ⁇ ⁇ 100 (1) [5] A dentifrice containing the dentifrice granules according to any one of [2] to [4].

- the granule has an appropriate disintegration strength and an excellent wet disintegration strength (hereinafter, both are also referred to as “disintegration strength”) and is suitable for use in a dentifrice. Can be produced with good yield.

- the dentifrice containing the dentifrice granules of the present invention has an excellent soil removal effect.

- the method for producing a dentifrice granule according to the present invention is a method for producing a dentifrice granule in which a water-insoluble powder material and a silicate are mixed and granulated using a container rotating granulator, and a multi-fluid nozzle And a step of supplying the water-insoluble powder material with an aqueous solution of the silicate as droplets and granulating.

- the granulation method using a container rotating granulator it is possible to make the powder flow uniformly, and further, by the mixing mechanism involving lifting of particles by rotation and sliding and dropping by its own weight, The shear force applied to the powder is suppressed. Therefore, it can be said that the granulation method using the container rotating granulator is a non-consolidated granulation method. Thereby, since the granule for dentifrice obtained by this invention has moderate disintegration strength, it is excellent in a granule feeling.

- the dentifrice granules obtained in the present invention have excellent wet disintegration strength and can maintain strength even in water.

- the dentifrice granule of the present invention is a granulated product obtained by a non-consolidated production method and is porous, so that the aqueous solution of silicate present inside the granule is easily dried, This is probably because the salt dehydrated product has a network structure, which makes the granules stronger. Furthermore, in the method of the present invention, granules having a particle size suitable as a dentifrice granule can be obtained with high yield. This is because, in the present invention, using a multi-fluid nozzle, the silicate is sprayed in advance as droplets of a fine aqueous solution and supplied into the container rotary granulator, thereby forming a large liquid mass formed by coarse particles.

- the production method of the present invention can obtain an excellent dentifrice granule having an appropriate disintegration strength and excellent wet disintegration strength in a high yield.

- each component used for the manufacturing method of this invention, the granule for dentifrice obtained by the manufacturing method of this invention, and the granule for dentifrice is demonstrated one by one.

- Water-insoluble powder material As the water-insoluble powder material used in the method of the present invention, those usually used for tooth abrasives are preferable, and specifically, inorganic materials are preferable.

- water-insoluble means that the amount dissolved in 100 g of water (20 ° C.) is 1 g or less.

- Specific examples of water-insoluble powder materials include light calcium carbonate, heavy calcium carbonate, zeolite, silica, dicalcium phosphate, tricalcium phosphate, insoluble sodium metaphosphate, aluminum hydroxide, magnesium phosphate, calcium pyrophosphate, magnesium carbonate, And one or more selected from titanium oxide and the like. These can be used alone or in combination of two or more.

- the water-insoluble powder material preferably contains one or more selected from light calcium carbonate, heavy calcium carbonate, zeolite, and silica. More preferably, one or two kinds selected from light calcium carbonate and heavy calcium carbonate are contained, and it is more preferred that heavy calcium carbonate is contained.

- the physical properties of the resulting dentifrice granules can be improved, and high dirt removal ability can be achieved even at an early stage where the number of strokes during brushing is small.

- light calcium carbonate, heavy calcium carbonate, zeolite, and 1 type or 2 types or more chosen from silica are preferred, 1 type or 2 sorts chosen from light calcium carbonate and heavy calcium carbonate are more preferred, and heavy calcium carbonate is still more preferred.

- the average particle diameter of the water-insoluble powder material is preferably 0.1 ⁇ m or more, more preferably 0.5 ⁇ m or more, still more preferably 0.8 ⁇ m or more, and even more preferably 1 ⁇ m, from the viewpoint of removing dirt on the teeth after the granule disintegration. That's it.

- the upper limit is preferably 20 ⁇ m or less, more preferably 15 ⁇ m or less, still more preferably 10 ⁇ m or less, still more preferably 7 ⁇ m or less, and even more preferably 5 ⁇ m or less.

- the average particle size of the water-insoluble powder material is preferably 0.1 to 20 ⁇ m, more preferably 0.5 to 15 ⁇ m, still more preferably 0.5 to 10 ⁇ m, still more preferably 0.8 to 7 ⁇ m, and still more preferably.

- the thickness is 0.8 to 5 ⁇ m, and more preferably 1 to 5 ⁇ m.

- the average particle diameter can be measured by the method described in the examples.

- silicate which is a water-soluble inorganic binder is used for imparting appropriate disintegration strength to the granules.

- this silicate also has a function of appropriately increasing the wet disintegration strength of the granules by appropriately drying the granules as necessary.

- the silicate that is a water-soluble inorganic binder preferably has a dissolution amount (20 ° C.) in 100 g of water of preferably 30 g or more, more preferably 50 g or more.

- the silicate preferably contains one or two kinds selected from sodium silicate and potassium silicate, and more preferably contains sodium silicate, from the viewpoint of disintegration strength and wet disintegration strength.

- the total content of sodium silicate and potassium silicate or the content of sodium silicate is preferably 95% by mass or more, more preferably 99% by mass or more, still more preferably 99.5% by mass or more, and still more preferably. Is substantially 100%.

- the water-soluble inorganic binder contained in the dentifrice granules of the present invention preferably contains sodium silicate in order to exhibit the effects of the present invention satisfactorily.

- sodium silicate By containing sodium silicate, voids of various sizes can be scattered in the granules, and the pH of the water in the scattered spaces of various sizes becomes alkaline, so that the plaque is sufficient In addition to being able to be removed, the feeling of slipperiness and the feeling of removing dirt can be improved.

- sodium silicate include sodium metasilicate (Na 2 SiO 3 ), sodium orthosilicate (Na 4 SiO 4 ), sodium disilicate (Na 2 Si 2 O 5 ), sodium tetrasilicate (Na 2 Si 4 O 9 ), and the like. Of the hydrates.

- Sodium silicate is generally represented by the molecular formula Na 2 O.nSiO 2 .mH 2 O.

- the coefficient n molecular ratio of SiO 2 to Na 2 O

- Molar ratio mass ratio (SiO 2 mass% / Na 2 O mass%) ⁇ (Molecular weight of Na 2 O / Molecular weight of SiO 2 )

- water glass having various molar ratios can be used in addition to sodium silicate Nos. 1, 2, and 3 described in JIS K1408.

- the molar ratio is preferably 2.0 to 4.0, more preferably from the viewpoint of compatibility with quasi-drug raw material specifications and the pH of the granules to be obtained. Is 2.4 to 3.5, more preferably 2.8 to 3.5, and still more preferably 3.0 to 3.3.

- the silicate (solid content) in the silicate aqueous solution supplied as droplets is preferably 10% by mass or more from the viewpoint of granulating a water-insoluble powder material as a water-soluble inorganic binder.

- the silicate (solid content) in silicate aqueous solution can be calculated

- the silicate aqueous solution may contain inorganic particles such as fumed silica described later, a polymer, or the like, or may contain a lower alcohol having 1 to 3 carbon atoms.

- the mass ratio of silicate (solid content) to the water-insoluble powder material (silicate (solid content) / water-insoluble powder material) is preferably 1/99. Or more, more preferably 2/98 or more, more preferably 2.5 / 97.5 or more, more preferably 3/97 or more, still more preferably 4/96 or more, and still more preferably 5/95 or more. From the viewpoint of reducing particles and increasing the plaque removal effect and improving the yield, the mass ratio is preferably 60/40 or less, more preferably 50/50 or less, and still more preferably 40/60 or less.

- the mass ratio is preferably 2/98 to 60/40, more preferably 3/97 to 50/50, still more preferably 4/96 to 40/60, and even more preferably 5/95 to 30/30.

- / 70 still more preferably 5/95 to 20/80.

- Fumed silica is hydrophilic silica fine particles obtained by a gas phase method, and is preferably used as a mixed solution mixed with the silicate aqueous solution from the viewpoint of improving wet disintegration strength.

- the aqueous solution and fume of the silicate are added to the water-insoluble powder material using a multi-fluid nozzle.

- Granules for dentifrice can be produced by supplying a mixture liquid with dosilica as droplets and granulating.

- the fumed silicas or fumed silica and silicate dehydrates form a network structure.

- the wet disintegration strength is excellent by acting as a binder for the water-insoluble powder material.

- the network structure of fumed silica is reversibly divided by the shearing force in the multi-fluid nozzle, the influence on the sprayability can be suppressed.

- the specific surface area of the fumed silica used in the present invention from the viewpoint of improving the wet collapse strength, preferably 50 ⁇ 400m 2 / g, more preferably 100 ⁇ 300m 2 / g.

- the solid content mass ratio of fumed silica to silicate (fumed silica / silicate) is preferably 0.3 / 100 or more, more preferably 0.5 / 100 or more, from the viewpoint of improving wet disintegration strength.

- the ratio is preferably 1/100 or more, and preferably 20/100 or less, more preferably 15/100 or less, and still more preferably 10/100 or less, from the viewpoint of sprayability as a droplet.

- the solid content mass ratio of the fumed silica to the water-insoluble powder material is preferably 0.3 / 100 or more, more preferably 0.5 / 100, from the viewpoint of increasing the wet disintegration strength. From the viewpoint of reducing coarse particles and increasing the plaque removal effect by more preferably 1/100 or more, the mass ratio is preferably 20/100 or less, more preferably 15/100 or less, and still more preferably 10 / 100 or less.

- Zinc oxide In the present invention, it is preferable to use zinc oxide from the viewpoint of imparting a plaque formation inhibitory effect and enhancing the wet disintegration strength by strengthening the network structure of the water-soluble silicate. Usually, to increase the disintegration strength of granules and the stability in dentifrice, it is necessary to increase the amount of binder, but surprisingly the wet disintegration strength of granules is improved by adding zinc oxide. Can be made. Zinc oxide is preferably used together with a water-insoluble powder material. When zinc oxide is used, a dentifrice for mixing and granulating the water-insoluble powder material, silicate and zinc oxide using a container rotating granulator.

- a method for producing a granule for a liquid comprising using a multi-fluid nozzle to drop the silicate into an aqueous solution droplet on the water-insoluble powder material and zinc oxide (preferably a mixture of the water-insoluble powder material and zinc oxide).

- the manufacturing method to supply is preferable.

- the content of zinc oxide in the dentifrice granules (excluding moisture) is preferably 0.3% by mass or more, more preferably 0.5% by mass from the viewpoint of improving the plaque formation inhibitory effect and wet disintegration strength. As mentioned above, More preferably, it is 1 mass% or more, More preferably, it is 1.5 mass% or more.

- the content of zinc oxide is preferably 7% by mass or less, more preferably 6% by mass or less, still more preferably 5% by mass or less, and still more preferably 3%. It is below mass%.

- the content of zinc in the dentifrice granules is preferably 0.3% by mass or more, more preferably 0.5% by mass, from the viewpoint of improving the plaque formation inhibitory effect and wet disintegration strength. % Or more, more preferably 1% by mass or more, and still more preferably 1.5% by mass or more. Further, from the viewpoint of suppressing the astringency and metal taste due to zinc, the zinc content is preferably 7% by mass or less, more preferably 6% by mass or less, still more preferably 5% by mass or less, and still more preferably 3% by mass. % Or less.

- the zinc content in the dentifrice granules can be determined by [Zinc oxide content ⁇ 65.38 (Atom weight of zinc)] / (65.38 + 16).

- the mass ratio of zinc oxide to silicate (solid content) is preferably 0.02 or more, more preferably 0.05 or more, even more preferably from the viewpoint of increasing wet disintegration strength. Is preferably 0.1 or less, and preferably 2 or less, more preferably 1.5 or less, still more preferably 1 or less, still more preferably 0.8 or less, and even more preferably, from the viewpoint of astringency due to zinc and suppression of metallic taste. Is 0.4 or less.

- the mass ratio of zinc to silicate (solid content) is preferably 0.02 or more, more preferably 0.05 or more, and still more preferably from the viewpoint of increasing wet disintegration strength. Is preferably 0.1 or less, and preferably 2 or less, more preferably 1.5 or less, still more preferably 1 or less, still more preferably 0.8 or less, and even more preferably, from the viewpoint of astringency due to zinc and suppression of metallic taste. Is 0.4 or less.

- a water-insoluble inorganic binder other than the water-insoluble powder material (abrasive) and silicate (binder) used in the method of the present invention if necessary, within a range not impairing the object of the present invention, Water-insoluble organic binders, organic fibers, medicinal ingredients, colorants and the like can be blended.

- a silicon-based compound, an aluminum-based compound, a calcium-based compound, a magnesium-based compound, and the like having a hydroxyl group can be used.

- colloidal silica examples include colloidal silica, magnesium aluminate metasilicate, synthetic aluminum silicate, calcium silicate, bentonite, montmorillonite, kaolin, alumina sol, synthetic hydrotalcite, magnesium oxide, and magnesium hydroxide.

- the fats and oils that can be used as the water-insoluble organic binder include higher fatty acids such as wax, paraffin, stearic acid, magnesium stearate, calcium stearate, and salts thereof.

- Polymers and resins that can be used as water-insoluble organic binders include (i) polysaccharides such as xanthan gum, dextrin, gelatin, and derivatives thereof, (ii) rubber latex, (iii) acrylic acid, acrylic ester , Methacrylic acid, methacrylic acid ester, hydroxymethacrylic acid ester, styrene, vinyl acetate, vinyl pyrrolidone, maleic acid ester, methyl vinyl ether, ⁇ -olefin homopolymers, copolymers thereof and the like.

- the organic fiber include cellulose, hemicellulose, lignin, chitin, and the like. Among these, cellulose is particularly preferable from the viewpoint of removing plaque from the granules.

- Medicinal ingredients include caries preventive agents, antimicrobial agents, enzymes, anti-inflammatory agents, etc., specifically sodium fluoride, potassium fluoride, tin fluoride, sodium monofluorophosphate, vitamin E, vitamins C, dextranase, mutanase, sodium chloride and other anti-inflammatory agents; aluminum lactate, azulene, glycyrrhetinic acid, ⁇ -glycyrrhetinic acid, allantochlorohydroxyaluminum, lysozyme chloride, epsilon aminocaproic acid, copper chlorophyllin sodium, copper gluconate, acetic acid Antiperceptive agents such as dl-tocopherol and potassium nitrate; anticalculus agents such as sodium tripolyphosphate and ethanehydroxydiphosphonate; plaque formation inhibitors such as zinc compounds, dihydrcholesterol, chlorhexidine, epidihydrcholesterol, i Propyl-methylphenol,

- colorant examples include titanium oxide and ultramarine blue, and an aesthetic effect can be added by adding these colorants.

- the said other compounding component can be used individually or in combination of 2 or more types.

- a method for producing a dentifrice granule according to the present invention is a method of mixing and granulating a water-insoluble powder material and an aqueous silicate solution using a container rotating granulator, using a multi-fluid nozzle, A method for producing a dentifrice granule, wherein the silicate is supplied as an aqueous solution droplet to the water-insoluble powder material.

- a container rotating granulator is used in order to prevent the granules from being compressed by giving a strong shear during the production of the granules.

- a drum granulator and a bread granulator are preferable.

- the drum granulator is not particularly limited as long as the drum-shaped cylinder rotates and performs processing.

- a horizontal or slightly inclined drum granulator can also be used.

- These apparatuses may be either batch type or continuous type. If the wall friction coefficient between the powder containing the water-insoluble powder material and the inner wall of the container rotary granulator is small, it is difficult to apply sufficient ascending force to the powder. It is preferable to provide a plurality of baffles for assisting. By providing the baffle plate, it is possible to impart an upward movement to the powder, and the powder mixing property and the solid-liquid mixing property are improved.

- the operating conditions of the container rotating granulator are not particularly limited as long as the water-insoluble powder material in the granulator can flow and be stirred as uniformly as possible.

- the fluid number defined by the following formula (2) is preferably 0.005 or more, more preferably 0.01 or more, and 0.05 or more.

- the upper limit is preferably 1.0 or less, more preferably 0.6 or less, and further preferably 0.4 or less. preferable.

- V and R use the values of the main body, and horizontal or vertical type with a main wing or a crushing wing.

- V and R use the value of the crushing blade.

- an aqueous solution of silicate is supplied using a multi-fluid nozzle.

- a multi-fluid nozzle is a nozzle that mixes and atomizes a liquid and atomizing gas (air, nitrogen, etc.) through an independent channel to the vicinity of the nozzle tip. Examples include fluid nozzles.

- the mixing part of the silicate aqueous solution and the atomizing gas may be either an internal mixing type for mixing inside the nozzle tip or an external mixing type for mixing outside the nozzle tip.

- an internal mixed type two-fluid nozzle made by Spraying Systems Japan Co., Ltd., Kyoritsu Alloy Manufacturing Co., Ltd., Ikeuchi Co., Ltd., etc., made by Spraying Systems Japan Co., Ltd., Kyoritsu Co., Ltd.

- Examples include an external mixing type two-fluid nozzle manufactured by Alloy Seisakusho, manufactured by Atmax Co., Ltd., and an external mixing type four-fluid nozzle manufactured by Fujisaki Electric Co., Ltd.

- the droplet diameter of the silicate aqueous solution can be adjusted to a desired range by adjusting the balance between the flow rate of the silicate aqueous solution and the flow rate of the atomizing gas. That is, in order to reduce the droplet diameter, the flow rate of the atomizing gas may be increased with respect to the silicate aqueous solution having a constant flow rate. What is necessary is just to reduce a flow volume. For example, when a two-fluid nozzle is used, it is easy to adjust the flow rate of the atomizing gas by adjusting the spray pressure of the atomizing gas.

- the atomizing gas spray pressure is preferably 0.1 MPa or more from the viewpoint of liquid dispersion, and preferably 1.0 MPa or less from the viewpoint of equipment load.

- the spray pressure of sodium silicate is not particularly limited, but is preferably 1.0 MPa or less, for example, from the viewpoint of equipment load.

- the average particle diameter of the droplet diameter of the silicate aqueous solution is preferably 210 ⁇ m or less, more preferably 150 ⁇ m or less, and even more preferably 100 ⁇ m or less.

- the lower limit is preferably 1 ⁇ m. More preferably, it is 5 ⁇ m or more, more preferably 10 ⁇ m or more, and still more preferably 20 ⁇ m or more.

- the average particle diameter of the droplet diameter of the silicate aqueous solution is calculated on a volume basis, and is, for example, a value measured using a laser diffraction particle size distribution measuring apparatus (Malburn, Spraytec). is there. Specifically, it can be measured by the method described in the examples.

- the temperature of the silicate aqueous solution when the silicate aqueous solution is supplied using a multi-fluid nozzle is preferably 5 to 50 ° C., more preferably 10 to 30 ° C. from the viewpoint of spray stability.

- the addition rate of the silicate aqueous solution is preferably 35 parts by mass with respect to 100 parts by mass of the water-insoluble powder material from the viewpoint of suppressing the formation of coarse particles and imparting appropriate disintegration strength and excellent wet disintegration strength.

- / Min or less more preferably 20 parts by mass or less, even more preferably 10 parts by mass or less, and the lower limit thereof is preferably 0.2 parts by mass or more, more preferably 0.5 parts by mass / min.

- silicate solid content

- the addition rate of silicate is preferably 19 parts by mass or less, more preferably 11 parts by mass or less, with respect to 100 parts by mass of the water-insoluble powder material, from the same viewpoint as described above. More preferably, it is 5.5 parts by weight or less, and the lower limit thereof is preferably 0.1 parts by weight / minute or more, more preferably 0.3 parts by weight or more, and further preferably 0.6 parts by weight / minute.

- Examples of the drying method include shelf drying, fluidized bed drying, reduced pressure drying, and microwave drying. Among these, from the viewpoint of equipment, shelf drying and fluidized bed drying are preferable. From the viewpoint of suppressing the disintegration of the granules during drying, a drying method that does not give as much shearing force as possible is preferable.

- examples include a method of drying with an electric shelf dryer or a hot air dryer, a method of drying in a batch type fluidized bed, and the continuous type includes a fluidized bed, a rotary dryer, a steam tube dryer, and the like. It is done.

- the drying temperature can be appropriately determined in consideration of the drying speed, but is preferably 60 ° C. or higher, more preferably 70 ° C.

- the upper limit is preferably 200 ° C. or less, more preferably 150 ° C. or less, still more preferably 110 ° C. or less, and still more preferably 90 ° C. or less.

- the drying time varies depending on the effective amount and amount of the silicate aqueous solution used in the production, but is appropriately adjusted so that the wet disintegration strength is within the preferable range of the present invention.

- the drying time is usually about 10 minutes to 24 hours, more preferably about 20 minutes to 20 hours, and further preferably about 30 minutes to 2 hours.

- the water content in the resulting granules is preferably 5% by mass or less, more preferably 3% by mass or less, still more preferably 2% by mass or less, and even more preferably 1% by mass or less, from the viewpoint of increasing wet disintegration strength. From the viewpoint of productivity, it is preferably 0.1% by mass or more, and preferably 0.2% by mass or more.

- the amount of water in the granules can be determined by the method described in the examples. Although the wet disintegration strength depends on the type of the water-insoluble powder material, the wet disintegration strength is higher for the same type when the water content is smaller.

- the granule obtained by the production method of the present invention has the composition and physical properties of Embodiment 1 and / or 2.

- the granule of aspect 1 may have the composition and physical property of the granule of aspect 2, and vice versa.

- the dentifrice granule of the present invention is a dentifrice granule containing a silicate and a water-insoluble material, wherein the content of the water-insoluble powder material is 40 to 97% by mass, and the silicate (solid content) It is preferable that the content is 2 to 60% by mass and the volume of pores having a diameter of 0.1 to 1 ⁇ m is 0.1 to 0.7 cc / g, preferably 0.2 to 0.6 cc / g.

- the dehydrated silicate solution acts as a binder for the water-insoluble powder material and is a granulated granule, but the dehydrated product is considered to be partially condensed.

- the content of the water-insoluble powder material is preferably 40% by mass or more, more preferably 50% by mass or more, from the viewpoint of enhancing the disintegration strength and the polishing power. Preferably, it is 60% by mass or more, more preferably 70% by mass or more, and still more preferably 80% by mass or more.

- the upper limit is preferably 97% by mass or less, more preferably It is 96 mass% or less, More preferably, it is 95 mass% or less.

- the content of the water-insoluble powder material in the dentifrice granule is preferably 40 to 97% by mass, preferably 50 to 96% by mass, more preferably 60 to 95% by mass, and still more preferably 70 to 95% by mass. 80 to 95% by mass is even more preferable.

- required from the compounding quantity at the time of granule manufacture can be used for content and mass ratio of each component in the granule for dentifrice.

- the amount of silicate is the amount of solid content calculated

- the content of silicate is preferably 2% by mass or more, more preferably 3% by mass or more, and still more preferably from the viewpoint of increasing the disintegration strength.

- the upper limit is preferably 60% by mass or less, more preferably 50% by mass or less, still more preferably 40% by mass or less More preferably, it is 30% by mass or less, and still more preferably 20% by mass or less.

- the content of silicate (solid content) is preferably 2 to 60% by mass, more preferably 3 to 50% by mass, further preferably 4 to 40% by mass, and more preferably 5 to 30% by mass. Even more preferred is 5 to 20% by weight.

- the mass ratio of silicate (solid content) to the water-insoluble powder material (silicate (solid content) / water-insoluble powder material) is preferably 1/99 or more, more preferably from the viewpoint of increasing the disintegration strength and wet disintegration strength. 2/98 or more, more preferably 2.5 / 97.5 or more, more preferably 3/97 or more, still more preferably 4/96 or more, still more preferably 5/95 or more, preferably 60/40 or less. More preferably, it is 50/50 or less, further preferably 40/60 or less, still more preferably 30/70 or less, still more preferably 20/80 or less, and still more preferably 15/85 or less.

- the content of the optional binder, medicinal component, and colorant is preferably 0 to 3 parts by mass with respect to 100 parts by mass of the total amount of the solid content of the water-insoluble powder material and silicate, from the viewpoint of disintegration feeling. 0 to 2 parts by mass is more preferable, 0 to 1% by mass is still more preferable, and 0% by mass is even more preferable.

- the dentifrice granule of aspect 1 is preferably obtained by the above production method, but as another production method, for example, the silicate, the water-insoluble powder material, and the oil agent may be obtained by rolling granulation or spray drying. After granulation, a granule having pores or specific disintegration behavior can be obtained by a method such as extracting the oil agent into a solvent and removing it.

- the dentifrice granule of the present invention is a dentifrice granule containing (A) a water-insoluble powder material and (B) a water-soluble inorganic binder containing sodium silicate,

- the compression load F is applied from 0 gf to the collapse load F max at which the granules collapse, and the compression displacement rate x and the compression expressed by the following formula (1)

- the ratio ( ⁇ F / ⁇ x) of the change amount ⁇ F of the compression load F to the change amount ⁇ x of the compression displacement rate x is continuously 0 or more and 0.35 or less.

- a dentifrice granule having a ⁇ F / ⁇ x value of 6.0 or less until reaching the smooth displacement region P and a collapse load F max of 30 gf or less is preferable.

- Compression displacement rate (%) ⁇ compression displacement d ( ⁇ m) / particle diameter of dentifrice granule before loading compression load F ( ⁇ m) ⁇ ⁇ 100 (1)

- the content of the water-insoluble powder material (A) is preferably 40% by mass in the dry state in the dentifrice granule of the present invention from the viewpoint of realizing stepwise disintegration behavior and enhancing the polishing power.

- the content of the water-insoluble powder material (A) is preferably 40 to 99% by mass, more preferably 50 to 98.5% by mass, and still more preferably 60% in the dry state in the dentifrice granules of the present invention. It is -98 mass%, More preferably, it is 85-97.5 mass%.

- the sodium silicate (pure component) in the water-soluble inorganic binder (B) contained in the dentifrice granules of the present invention is preferably 10 mass from the viewpoint of granulating a water-insoluble powder material as a water-soluble inorganic binder. % Or more, more preferably 20% by mass or more, and still more preferably 30% by mass or more. From the viewpoints of handling properties and spraying as droplets, suppressing coarse particles, and increasing the wet disintegration strength of granules, preferably 60%. It is not more than mass%, more preferably not more than 50 mass%, still more preferably not more than 40 mass%.

- the sodium silicate (pure component) in the water-soluble inorganic binder (B) is preferably 10 to 60% by mass, more preferably 20 to 50% by mass, and further preferably 30 to 40% by mass. It is.

- the sodium silicate (pure part) in a water-soluble inorganic binder (B) is based on a manufacturer's prescribed value.

- the sodium silicate (solid content) in the water-soluble inorganic binder (B) contained in the dentifrice granules of the present invention is preferably 20 mass from the viewpoint of granulating a water-insoluble powder material as a water-soluble inorganic binder. % Or more, more preferably 30% by mass or more, and still more preferably 40% by mass or more. From the viewpoint of handling properties and spraying as droplets, suppressing coarse particles, and increasing wet disintegration strength of granules, preferably 80%. It is 70 mass% or less, More preferably, it is 60 mass% or less more preferably 70 mass% or less.

- the sodium silicate (solid content) in the water-soluble inorganic binder (B) is preferably 20 to 80% by mass, more preferably 30 to 70% by mass, and further preferably 40 to 60% by mass. It is.

- the silicate (solid content) in silicate aqueous solution can be calculated

- the content of sodium silicate (solid content) in the dentifrice granule of the present invention realizes the dry state and disintegration strength of the granule in water, stability in dentifrice, and stepwise disintegration behavior. From the viewpoint, it is preferably 0.5% by mass or more, more preferably 1% by mass or more, further preferably 1.5% by mass or more, and still more preferably 2% by mass or more in a dry state. Moreover, from a viewpoint of improving a yield, Preferably it is 30 mass% or less, More preferably, it is 20 mass% or less, More preferably, it is 15 mass% or less, More preferably, it is 10 mass% or less.

- the content of sodium silicate in the dentifrice granules of the present invention is preferably 0.5 to 30% by mass, more preferably 1 to 20% by mass, still more preferably 1.5 to 15% by mass, and still more.

- the content is preferably 2 to 10% by mass.

- the mass ratio of the component (B) sodium silicate (solid content) to the water-insoluble powder material (A) (sodium silicate (solid content) / water-insoluble powder material (A)) is water-insoluble.

- it is preferably 1/99 or more, more preferably 2/98 or more, and further preferably 2.5 / 97.5. More preferably, it is 3/97 or more, more preferably 4/96 or more, and still more preferably 5/95 or more.

- the mass ratio is preferably 60/40 or less, more preferably 50/50 or less, still more preferably 40/60 or less, and still more preferably 30. / 70 or less, still more preferably 20/80 or less, and still more preferably 15/85 or less.

- the mass ratio is preferably 1/99 to 60/40, more preferably 2/98 to 50/50, still more preferably 2.5 / 97.5 to 40/60, More preferably, it is 3/97 to 30/70, and still more preferably 3/97 to 15/85.

- the granule for dentifrice of the present invention is a water-insoluble inorganic binder, water-insoluble organic binder, organic fiber, medicinal component, coloring agent, etc. in addition to the above components, as long as the effects of the present invention are not impaired Can be contained.

- Other components other than the above components may be used alone or in combination of two or more.

- about aspect 2 it is also preferable to obtain with the following manufacturing methods. That is, in the dentifrice granule according to the second aspect of the present invention, the water-soluble inorganic binder containing sodium silicate as the component (B) is used as an aqueous solution (hereinafter referred to as a water-soluble inorganic binder aqueous solution) as necessary.

- a water-soluble inorganic binder aqueous solution is added to component (A) to form granules.

- the water-soluble inorganic binder aqueous solution may be prepared by diluting a water-soluble inorganic binder containing sodium silicate as the component (B) with 3 times or less of water.

- a water-soluble inorganic binder aqueous solution may be added to component (A) to form granules.

- the water-soluble inorganic binder aqueous solution is desirably added to the water-insoluble powder material of the component (A) at a moderate rate from the viewpoint of agglomerating and forming granules while effectively forming voids.

- the addition rate of the water-soluble inorganic binder aqueous solution is preferably 35 parts by mass or less, more preferably 20 parts by mass / min with respect to 100 parts by mass of the water-insoluble powder material (A).

- Min. Or less more preferably 10 parts by mass / min or less, preferably 0.5 parts by mass / min or more, more preferably 0.8 parts by mass / min or more, and further preferably 1 part by mass / min or more. is there.

- the above range is suitable when using sodium silicate No. 1, 2 or 3 described in JIS K1408.

- the addition rate of the water-soluble inorganic binder aqueous solution is preferably 0.5 to 35 parts by mass / min, more preferably 0.8 to 100 parts by mass with respect to 100 parts by mass of the water-insoluble powder material (A). It is 20% by mass, more preferably 1 to 10% by mass.

- the addition rate of sodium silicate (solid content) is preferably 19 parts by mass or less, more preferably 11 parts by mass with respect to 100 parts by mass of the water-insoluble powder material (A) from the same viewpoint as described above.

- Part / minute or less more preferably 5.5 parts by weight or less, preferably 0.1 parts by weight or more, more preferably 0.2 parts by weight or more, and further preferably 0.3 parts by weight. / Min or more.

- the addition rate of the sodium silicate (solid content) is preferably 0.1 to 19 parts by mass / min, more preferably 0.2 to 11% by mass with respect to 100 parts by mass of the water-insoluble powder material. More preferably, it is 0.3 to 5.5% by mass.

- a rolling granulation method is preferable.

- the container rotating granulator include a drum granulator and a bread granulator.

- the drum granulator is not particularly limited as long as the drum-shaped cylinder rotates and performs processing.

- a conical drum granulator, a multi-stage conical drum granulator, or the like can be used. These apparatuses may be either batch type or continuous type.

- a multi-fluid nozzle is a nozzle that mixes and atomizes a liquid and atomizing gas (air, nitrogen, etc.) through an independent channel to the vicinity of the nozzle tip.

- a nozzle, a three-fluid nozzle, a four-fluid nozzle, etc. can be mentioned.

- the temperature of the water-soluble inorganic binder aqueous solution when supplying the water-soluble inorganic binder aqueous solution using a multi-fluid nozzle is preferably 5 ° C.

- the temperature of the water-soluble inorganic binder aqueous solution when supplying the water-soluble inorganic binder aqueous solution using a multi-fluid nozzle is preferably 5 to 50 ° C., more preferably 10 to 30 ° C.

- the obtained granules are preferably further dried from the viewpoint of ensuring stability when blended with a dentifrice.

- Specific examples of such drying include shelf drying, fluidized bed drying, reduced pressure drying, and microwave drying. Of these, shelf drying and fluidized bed drying are preferable from the viewpoint of equipment.

- the drying temperature is preferably 60 ° C. or higher, more preferably 70 ° C. or higher, and further preferably 80 ° C. or higher from the viewpoint of heat load. Further, it is preferably 200 ° C. or lower, more preferably 150 ° C. or lower, still more preferably 110 ° C., and still more preferably 90 ° C. or lower.

- the drying temperature is preferably 60 to 200 ° C., more preferably 70 to 150 ° C., still more preferably 80 to 110 ° C., and still more preferably 80 to 90 ° C.

- the drying time is preferably 10 minutes or more, more preferably 20 minutes or more, still more preferably 30 minutes or more, preferably 24 hours or less, more preferably 20 hours or less, and even more preferably 5 hours or less.

- the drying time is preferably 10 minutes to 24 hours, more preferably 20 minutes to 20 hours, and even more preferably 30 minutes to 5 hours.

- the characteristics of the granule of the above-described embodiment 1 and embodiment 2 will be described. It is preferable that the granules obtained by the production method of the present invention have the characteristics of Embodiment 1 and / or Embodiment 2. Moreover, the granule of aspect 1 may have the characteristic of the granule of aspect 2, and vice versa.

- the average disintegration strength of the dentifrice granules of the present invention is such that when used in a dentifrice, the granules in the mouth can be palpated, and from the viewpoint of plaque removal effect, preferably 3 g weight or more (pieces) From the viewpoint of not damaging the tooth enamel and hardly feeling a foreign body feeling, more preferably 4 g weight / piece, more preferably 5 g weight / piece or more.

- the weight is preferably 30 g weight or less, more preferably 20 g weight or less, and even more preferably 15 g weight or less.

- the average disintegration strength can be increased by adjusting the content of silicate (solid content) or appropriately selecting the type of water-insoluble powder material.

- the average wet disintegration strength of the dentifrice granule is preferably 10% or more, more preferably 15 from the viewpoint of plaque removal effect, because the granule in the mouth can be palpated when used in a dentifrice. % Or more, more preferably 20% or more, still more preferably 31% or more, and preferably 90% or less, more preferably 80% or less, from the viewpoint of hardly feeling a foreign matter.

- the average wet disintegration strength of the dentifrice granules is preferably 10 to 90%, more preferably 15 to 90%, still more preferably 20 to 80%, and still more preferably 31 to 80%.

- the average wet disintegration strength can be increased by increasing the content of silicate (solid content), decreasing the amount of water in the granules, or appropriately selecting the type of water-insoluble powder material.

- the pore volume of the dentifrice granule is preferably 0.1 cc / g or more from the viewpoint of increasing the average wet disintegration strength when the pore volume is 0.1 to 1 ⁇ m when used in a dentifrice. More preferably, it is 0.2 cc / g or more, More preferably, it is 0.3 cc / g or more, From a viewpoint of productivity, Preferably it is 0.7 cc / g or less, More preferably, it is 0.6 cc / g or less, More preferably Is 0.5 cc / g or less.

- the volume of the pores having a diameter of 0.1 to 1 ⁇ m can be increased by reducing the droplet diameter to the container rotating granulator or decreasing the fluid number of the container rotating granulator.

- average disintegration strength, average wet disintegration strength, and pore volume are measured by the method as described in an Example.

- the average particle size of the dentifrice granules of the present invention is preferably 50 ⁇ m or more, more preferably 75 ⁇ m or more, and even more preferably 100 ⁇ m or more from the viewpoint of having sufficient polishing power, and suppresses the feeling of foreign matter in the oral cavity. From the viewpoint, it is preferably 500 ⁇ m or less, more preferably 400 ⁇ m or less, still more preferably 400 ⁇ m, more preferably 350 ⁇ m or less, still more preferably 300 ⁇ m or less.

- the average particle size of the dentifrice granules is preferably 50 to 500 ⁇ m, more preferably 75 to 350 ⁇ m, and still more preferably 100 to 300 ⁇ m. In addition, an average particle diameter can be measured by the method as described in an Example.

- Granules having the above average particle diameter, disintegration strength, and the like can be produced by appropriately changing the type, blending amount, and production conditions of the silicate.

- the characteristic of the granule of aspect 2> The dentifrice granule of the present invention is obtained by applying a compression load F from 0 gf to a collapse load F max at which the granule disintegrates by lowering the indenter at a constant speed using a micro compression tester.

- the ratio ( ⁇ F / ⁇ x) of the change amount ⁇ F of the compression load F to the change amount ⁇ x of the compression displacement rate x is continuously 0.

- Compression displacement rate (%) ⁇ compression displacement d ( ⁇ m) / particle diameter of dentifrice granules before loading compression load F ( ⁇ m) ⁇ ⁇ 100 (1)

- the granule for dentifrice of the present invention has the above-mentioned characteristics, and exhibits a stepwise disintegration behavior when a load is applied with a toothbrush or the like in the oral cavity as in the case of using a micro compression tester. .

- the dentifrice granule of the present invention will be finely divided while gradually changing the form of the granule during the brushing time without collapsing at once due to the load of the toothbrush, They effectively transmit the load from the toothbrush while intruding into a narrow area such as the gap between teeth, and can exhibit high dirt removal capability even at an early stage with a small number of strokes during brushing, removing plaque or dirt Performance can be fully exerted, and a feeling of smoothness and dirt can be improved.

- the indenter is lowered at a constant speed using a micro-compression tester to start applying a load to the granule, and the compressive load F

- the compression displacement rate x (%) is obtained by measuring the compression displacement d ( ⁇ m) while increasing the value from 0 gf, and the point where the granules eventually collapse and the compression load F becomes maximum, that is, the collapse load F max (gf )

- the collapse load F max gf

- An example of a micro-compression tester used for measurement is MCT-W500 (manufactured by Shimadzu Corporation).

- one granule is placed on the test table of a micro-compression tester, and the indenter provided in the tester is vertically lowered at a constant speed so as to be sandwiched between the indenter and the test table.

- the granules are loaded with a compressive load F and gradually increased from 0 gf until the granules collapse and reach the collapse load F max .

- the indenter is preferably lowered while keeping the speed constant within a range of 0.1 to 0.2 gf / min, for example.

- the compression load F is plotted on the vertical axis and the compression displacement rate x is plotted on the horizontal axis. It is preferable to use a load F-compression displacement rate x diagram.

- the particle diameter r ( ⁇ m) of the dentifrice granule before applying the compression load F is obtained by measuring the particle diameter of the granule on two sides with a micro compressor and calculating the average value.

- the dentifrice granule of the present invention has a ratio ( ⁇ F / ⁇ x) of the change amount ⁇ F of the compression load F to the change amount ⁇ x of the compression displacement rate x.

- the smooth displacement region P in which the value of ⁇ F / ⁇ x is continuously 0 or more and 0.35 or less means that there are various sizes of voids in the granule even though the compressive load F is continuously applied to the granule.

- the smooth displacement region P has a larger variation width in the horizontal axis direction (compression displacement rate x) than a variation width in the vertical axis direction (compression load F).

- compression load F-compression displacement rate x diagram it is shown as a smooth region in the horizontal axis direction.

- the change amount ⁇ x p in the compression displacement rate x is preferably 2% or more, more preferably 5% or more, preferably 70% or less, more preferably 50% or less. It is. Further, it is preferably 2 to 70%, more preferably 5 to 50%.

- the amount of change ⁇ x p in the compression displacement rate x means the difference (change amount) between the compression displacement rate x at the start point and the compression displacement rate x at the end point in the smooth displacement region P region.

- the change amount ⁇ x p of the compression displacement rate x in the smooth displacement region P is shown as the width of the smooth displacement region P in the direction of the compression displacement rate x.

- one or more smooth displacement regions P exist, preferably two or more, from when the compressive load F is applied from 0 gf until the collapse load F max is reached. More preferably, there are 3 or more.

- the load is increased while increasing the compression displacement d ( ⁇ m) due to the air gaps scattered in the granules.

- the curve A in FIG. 1 schematically illustrates the case where there are two smooth displacement regions P, such as the smooth displacement region P 1 and the smooth displacement region P 2 .

- the value of ⁇ F / ⁇ x until reaching the first smooth displacement region P is 6.0 or less. Whether there is only one smooth displacement region P or two or more smooth displacement regions P, the value of ⁇ F / ⁇ x until reaching the first smooth displacement region P is 6.0 or less. It means that. For example, in the curve A in FIG. 1, this corresponds to the value of ⁇ F / ⁇ x until the start point of the smooth displacement region P 1 that appears first after the displacement from the origin O is reached.

- the compressive load F has a characteristic to relax or absorb the load from when it starts to increase from 0 gf, and is high even at an early stage where the number of strokes during brushing is small, coupled with the stepwise collapse behavior.

- the ability to remove dirt can be exhibited, the ability to remove plaque or dirt can be enhanced, and the feeling of slipperiness and the feeling of removing dirt can be improved.

- the value of ⁇ F / ⁇ x until reaching the first smooth displacement region P is preferably 6.0 or less, more preferably 5 0.5 or less, preferably 0.4 or more, and more preferably 0.5 or more.

- the disintegration load F max which is a compressive load at the disintegration point Q is 30 gf or less, preferably less than 25 gf, more preferably less than 20 gf, still more preferably less than 15 gf. Yes, preferably 0.2 gf or more, more preferably 0.5 gf or more, still more preferably 1 gf or more, and even more preferably 3 gf or more.

- the collapse load F max that is the compression load at the collapse point Q is preferably 0.2 to 30 gf, more preferably 0.5 gf to 25 gf, still more preferably 1 gf to 20 gf, and still more preferably. 3 to 15 gf.

- the compression displacement rate x at the disintegration point Q of the dentifrice granules of the present invention is preferably 20% or more, more preferably 22% or more, further preferably 25% or more, 90% Or less, more preferably 85% or less, and still more preferably 80% or less.

- the compression displacement rate x at the disintegration point Q of the dentifrice granule of the present invention is preferably 20 to 90%, more preferably 22 to 85%, and further preferably 25 to 80%.

- Such a granule can exhibit various forms over a long period of time without collapsing at a time when a load is applied, and exhibits a high compressive displacement rate until reaching the collapse load F max and is high. The stepwise collapse behavior that can exert the effect can be shown more remarkably.

- the average particle diameter d ave ( ⁇ m) of the granule for dentifrice of the present invention is preferably 50 ⁇ m or more, more preferably 75 ⁇ m or more, still more preferably 100 ⁇ m or more, from the viewpoint of having sufficient polishing power. From the viewpoint of suppressing the sensation of foreign matter in the oral cavity, it is preferably 500 ⁇ m or less, more preferably 450 ⁇ m or less, still more preferably 400 ⁇ m or less, more preferably 350 ⁇ m or less, and even more preferably 300 ⁇ m or less.

- the average particle diameter d ave ( ⁇ m) of the dentifrice granules is preferably 50 to 500 ⁇ m, more preferably 75 to 450 ⁇ m, and still more preferably 100 to 400 ⁇ m.

- the average particle diameter dave of a granule can be measured by the method as described in an Example.

- the dentifrice containing the granule obtained by the production method of the present invention contains the said granule for dentifrice, and also contains surfactant.

- the dentifrice granule, preferably the dentifrice granule exhibiting a stepwise disintegration behavior, is contained together with a surfactant to provide good foaming and to a narrow region such as a gap between teeth.

- the smooth touch means that when the tooth surface is touched with the tongue, it is possible to smoothly slide the tongue on the surface of the tooth without obtaining a touch of plaque or dirt. Say the touch.

- the content of the dentifrice granule is preferably in the dentifrice of the present invention from the viewpoint of sufficiently exerting the disintegration behavior of the granule to enhance the effect of removing plaque or dirt and improve the feeling of use. 1 mass% or more, More preferably, it is 3 mass% or more, More preferably, it is 5 mass% or more.

- the content of the dentifrice granule is preferably 50% by mass in the dentifrice of the present invention from the viewpoint of exerting the plaque or dirt removing effect without feeling a foreign body and without damaging the tooth enamel. Hereinafter, it is more preferably 30% by mass or less, and still more preferably 20% by mass or less.

- the content of the dentifrice granule is preferably 1 to 50% by mass, more preferably 3 to 30% by mass, and further preferably 5 to 20% by mass in the dentifrice of the present invention.

- anionic surfactants one or more selected from anionic surfactants, nonionic surfactants, and zwitterionic surfactants can be used.

- anionic surfactant include alkyl sulfates such as sodium lauryl sulfate and sodium myristyl sulfate; N-acyl sarcosine salts such as sodium N-lauroyl sarcosine and sodium N-myristoyl sarcosine; N-palmitoyl glutamic acid.

- N-acyl glutamates such as sodium, sodium N-methyl-N-acyl taurate, sodium N-methyl-N-acylalanine, sodium olefin sulfonate, sodium dioctyl sulfosuccinate and the like.

- Nonionic surfactants include sugar fatty acid esters such as sucrose fatty acid esters; sugar alcohol fatty acid esters such as maltitol fatty acid esters and lactitol fatty acid esters; polyoxyethylene sorbitan monolaurate, polyoxyethylene sorbitan monostearate Oxyethylene sorbitan fatty acid ester; fatty acid diethanolamide such as lauric acid mono- or ethanolamide, myristic acid mono- or diethanolamide; sorbitan fatty acid ester, fatty acid monoglyceride, polyoxyethylene higher alcohol ether, polyoxyethylene polyoxypropylene copolymer, etc. Can be mentioned.

- zwitterionic surfactants include N-alkyldiaminoethylglycine such as N-lauryldiaminoethylglycine and N-myristyldiaminoethylglycine, N-alkyl-N-carboxymethylammonium betaine, and 2-alkyl-1-hydroxyethylimidazoline. Betaine sodium or the like is used.

- the content of the surfactant is preferably 0.2% by mass or more in the dentifrice of the present invention from the viewpoint of providing a good flavor while ensuring good foaming and enhancing the cleaning effect and feeling of use. Preferably it is 0.3 mass% or more, More preferably, it is 0.5 mass% or more. Further, the content of the surfactant is preferably 2.0% by mass or less, more preferably 1.7% by mass or less, and still more preferably in the dentifrice of the present invention from the viewpoint of suppressing the loss of flavor.

- the content of the surfactant in the dentifrice of the present invention is preferably 0.2 to 2.0% by mass, more preferably 0.3 to 1.7% by mass, and still more preferably 0.5 to 1.5% by mass.

- the content ratio of dentifrice granules and surfactant in the dentifrice of the present invention is preferably 0.5 to 250, more preferably 2 to 100, It is preferably 4 to 40.

- the dentifrice of the present invention may further contain a binder.

- a binder one or more selected from sodium carboxymethyl cellulose, sodium polyacrylate, hydroxyethyl cellulose, thickening silica, montmorillonite, carrageenan, sodium alginate, guar gum, and pectin are used.

- the content of the binder in the dentifrice of the present invention is such that the above-mentioned granule for dentifrice and the surfactant are effectively diffused in the oral cavity, and preferably the plaque or dirt removal effect by the granule that disintegrates stepwise In the dentifrice of the present invention, it is preferably 0.1% by mass or more, more preferably 0.5%, from the viewpoint of effectively exhibiting the effect of improving the smoothness and the feeling of removing dirt. It is at least mass%, more preferably at least 0.7 mass%, preferably at most 5 mass%, more preferably at most 3 mass%, still more preferably at most 2 mass%.

- the content of the binder in the dentifrice of the present invention is preferably 0.1 to 5% by mass, more preferably 0.5 to 3% by mass, and still more preferably 0.7 to 3% in the dentifrice of the present invention. 2% by mass.

- the content ratio of the dentifrice granules and the binder in the dentifrice of the present invention effectively diffuses the dentifrice granules in the oral cavity, and preferably the step From the viewpoint of effectively exhibiting the plaque or dirt removal effect by the automatically disintegrating granules, improving the smooth feeling and the feeling of dirt removal, and preferably providing 0.2 to 500, more preferably Is from 1 to 60, more preferably from 2.5 to 30.

- the dentifrice of the present invention may further contain a wetting agent.

- the wetting agent include sorbit, glycerin, propylene glycol, 1,3 butylene glycol, ethylene glycol, polyethylene glycol, polypropylene glycol, xylitol, maltite, lactit, erythritol and the like. These may be used alone or in combination of two or more.

- the content of the wetting agent in the dentifrice of the present invention is such that the dentifrice granules and the surfactant are effectively diffused in the oral cavity while dissolving or dispersing, preferably removing granules or dirt by granules that gradually disintegrate.

- the dentifrice of the present invention is preferably 5% by mass or more, more preferably 10% by mass or more, further preferably 15% by mass or more, preferably It is 70 mass% or less, More preferably, it is 60 mass% or less, More preferably, it is 50 mass% or less.

- the content of the wetting agent in the dentifrice of the present invention is preferably 5 to 70% by mass, more preferably 10 to 60% by mass, and still more preferably 15 to 50% by mass in the dentifrice of the present invention. .

- the dentifrice of the present invention may further contain water.

- the content of water in the dentifrice of the present invention is the effect of removing plaque or dirt by the granules that effectively diffuse in the oral cavity while dissolving or dispersing the abrasive granules and the surfactant, and preferably gradually disintegrate.

- it is preferably 3% by mass or more, more preferably 5% from the viewpoint of effectively exhibiting a high level of dirt removal ability even at an early stage where the number of strokes during brushing is small. It is at least 7 mass%, more preferably at least 7 mass%, preferably at most 50 mass%, more preferably at most 45 mass%, still more preferably at most 40 mass%.

- the water content in the dentifrice of the present invention is preferably 3 to 50% by mass in the dentifrice of the present invention from the viewpoint of providing good solubility and dispersibility, and plaque or dirt removal ability. More preferably, it is 5 to 45% by mass, and still more preferably 7 to 40% by mass.

- this moisture content can also be calculated by calculation from the mix

- a trace moisture measuring device Hiranuma Sangyo Co., Ltd.

- the content ratio of dentifrice granules and water is from the viewpoint of providing good solubility and dispersibility, and plaque or dirt removal ability. It is preferably 0.02 to 15, more preferably 0.1 to 6, and still more preferably 0.2 to 5.

- the dentifrice of the present invention can contain components other than those described above, such as abrasives, excipients, sweeteners, preservatives, fragrances, medicinal ingredients, colorants, and other commonly used ingredients.

- the other components described above may be used alone or in combination of two or more.

- the dentifrice of this invention can be manufactured by a conventional method using the said component.

- the present invention further discloses the following method for producing dentifrice granules and dentifrice granules obtained by the method.

- a method for producing a dentifrice granule comprising a step of supplying an aqueous solution of the silicate as droplets to the water-insoluble powder material and granulating.

- the silicate (solid content) in the silicate aqueous solution is preferably 10% by mass or more, more preferably 20% by mass or more, still more preferably 30% by mass or more, and still more preferably 35% by mass or more. Preferably, it is 65 mass% or less, More preferably, it is 60 mass% or less, More preferably, it is 58 mass% or less, The manufacturing method of the granule for dentifrice as described in said ⁇ 1> or ⁇ 2>.

- the average particle diameter of the droplets of the silicate aqueous solution is preferably 210 ⁇ m or less, more preferably 150 ⁇ m or less, still more preferably 100 ⁇ m or less, preferably 1 ⁇ m or more, more preferably 5 ⁇ m or more, and even more preferably 10 ⁇ m or more. More preferably, the method for producing a dentifrice granule according to any one of the above ⁇ 1> to ⁇ 3>, which is 20 ⁇ m or more.

- Water-insoluble powder material is preferably light calcium carbonate, heavy calcium carbonate, zeolite, silica, dicalcium phosphate, tricalcium phosphate, insoluble sodium metaphosphate, aluminum hydroxide, magnesium phosphate, calcium pyrophosphate, magnesium carbonate And one or more selected from titanium oxide and the like, more preferably light calcium carbonate, heavy calcium carbonate, zeolite, silica, dicalcium phosphate, tricalcium phosphate, insoluble sodium metaphosphate, aluminum hydroxide, One or more selected from magnesium phosphate, calcium pyrophosphate, and magnesium carbonate, more preferably one or more selected from light calcium carbonate, heavy calcium carbonate, zeolite, and silica.

- the average particle size of the water-insoluble powder material is preferably 0.1 ⁇ m or more, more preferably 0.5 ⁇ m or more, still more preferably 0.8 ⁇ m or more, preferably 20 ⁇ m or less, more preferably 15 ⁇ m or less,

- Mass ratio of silicate to water-insoluble powder material is preferably 1/99 or more, more preferably 2/98 or more, more preferably 2.5 / 97.5 or more, more preferably 3/97 or more, still more preferably 4/96 or more, still more preferably 5/95 or more, preferably 60/40 or less, more preferably 50/50 or less, still more preferably 40/60 or less, more preferably 30/70 or less, even more preferably 20/80 or less, and still more preferably 15/85 or less, according to any one of ⁇ 1> to ⁇ 7> above A method for producing dentifrice granules.

- the addition rate of the ⁇ 9> silicate aqueous solution is preferably 35 parts by mass / min or less, more preferably 20 parts by mass or less, and still more preferably 10 parts by mass / min with respect to 100 parts by mass of the water-insoluble powder material.

- Min. Or less preferably 0.2 parts by mass / min or more, more preferably 0.5 parts by mass / min or more, more preferably 1 part by mass / min or more, still more preferably 1.5 parts by mass / min or more.

- the addition rate of ⁇ 10> silicate (solid content) is preferably 19 parts by mass or less, more preferably 11 parts by mass or less, and further preferably 5.5 with respect to 100 parts by mass of the water-insoluble powder material. Parts by weight or less, preferably 0.1 parts by weight or more, more preferably 0.3 parts by weight or more, more preferably 0.6 parts by weight or more, and even more preferably 0.8 parts by weight.

- ⁇ 11> Granules for dentifrice according to any one of ⁇ 1> to ⁇ 10>, wherein the water-insoluble powder material, silicate, and further zinc oxide are mixed and granulated using a container rotating granulator. Manufacturing method.

- Mass ratio of zinc oxide to silicate (solid content) is preferably 0.02 or more, more preferably 0.05 or more, and still more preferably 0.1 or more.

- the dentifrice according to ⁇ 11> which is preferably 2 or less, more preferably 1.5 or less, still more preferably 1 or less, still more preferably 0.8 or less, and even more preferably 0.4 or less.

- the fluid number defined by the following formula (2) is preferably 0.005 or more, more preferably 0.01 or more, still more preferably 0.05 or more.

- Fluid number: Fr V 2 / (R ⁇ g) (2)

- V peripheral speed [m / s]

- R radius from the center of rotation to the circumference of the rotating object [m]

- g Gravity acceleration [m / s 2 ]

- ⁇ 14> The method for producing a dentifrice granule according to any one of ⁇ 1> to ⁇ 13>, wherein a liquid mixture obtained by mixing the aqueous silicate solution and fumed silica is supplied as droplets.

- the solid content mass ratio (fumed silica / silicate) of fumed silica to silicate is preferably 0.3 / 100 or more, more preferably 0.5 / 100 or more, and even more preferably 1/100 or more.

- the method for producing a dentifrice granule according to ⁇ 14> preferably 20/100 or less, more preferably 15/100 or less, and still more preferably 10/100 or less.

- the solids mass ratio of fumed silica to the water-insoluble powder material is preferably 0.3 / 100 or more, more preferably 0.5 / 100 or more, and still more preferably. It is 1/100 or more, Preferably it is 20/100 or less, More preferably, it is 15/100 or less, More preferably, it is 10/100 or less, The manufacturing method of the granule for dentifrice as described in said ⁇ 14> or ⁇ 15> .

- ⁇ 17> The method for producing a dentifrice granule according to any one of ⁇ 1> to ⁇ 16>, wherein the obtained granulated product is further dried.

- the drying temperature is preferably 60 ° C. or higher, more preferably 70 ° C. or higher, further preferably 80 ° C. or higher, preferably 200 ° C. or lower, more preferably 150 ° C. or lower, still more preferably 110 ° C. or lower, and more. More preferably, it is 90 degrees C or less,

- a dentifrice granule containing a silicate and a water-insoluble material wherein the silicate contains one or two types selected from sodium silicate and potassium silicate, and the content of the water-insoluble powder material is 40.

- the content of silicate (solid content) is 2 to 60 mass%, and the volume of pores having a diameter of 0.1 to 1 ⁇ m is preferably 0.1 to 0.7 cc / g, Granules for dentifrices, more preferably 0.2 to 0.6 cc / g, still more preferably 0.3 to 0.5 cc / g.

- the content of the water-insoluble powder material is preferably 40% by mass or more, more preferably 50% by mass or more, still more preferably 60% by mass or more, and still more preferably 70% by mass or more. More preferably, it is 80% by mass or more, preferably 97% by mass or less, more preferably 96% by mass or less, and still more preferably 95% by mass or less, according to either ⁇ 19> or ⁇ 20>. Dentifrice granules.

- the content of silicate is preferably 2% by mass or more, more preferably 3% by mass or more, still more preferably 4% by mass or more, and still more preferably 5% by mass.

- the above is preferably 60% by mass or less, more preferably 50% by mass or less, still more preferably 40% by mass or less, still more preferably 30% by mass or less, and even more preferably 20% by mass or less.