WO2013129596A1 - シーリング材及びその製造方法 - Google Patents

シーリング材及びその製造方法 Download PDFInfo

- Publication number

- WO2013129596A1 WO2013129596A1 PCT/JP2013/055479 JP2013055479W WO2013129596A1 WO 2013129596 A1 WO2013129596 A1 WO 2013129596A1 JP 2013055479 W JP2013055479 W JP 2013055479W WO 2013129596 A1 WO2013129596 A1 WO 2013129596A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sealing material

- rubber layer

- foaming

- rubber composition

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/04—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent

- C08J9/06—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent by a chemical blowing agent

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/02—Sealings between relatively-stationary surfaces

- F16J15/021—Sealings between relatively-stationary surfaces with elastic packing

- F16J15/022—Sealings between relatively-stationary surfaces with elastic packing characterised by structure or material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C44/00—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles

- B29C44/02—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles for articles of definite length, i.e. discrete articles

- B29C44/12—Incorporating or moulding on preformed parts, e.g. inserts or reinforcements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/046—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of foam

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/0066—Use of inorganic compounding ingredients

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

- C09K3/10—Materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K3/1006—Materials in mouldable or extrudable form for sealing or packing joints or covers characterised by the chemical nature of one of its constituents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/04—Condition, form or state of moulded material or of the material to be shaped cellular or porous

- B29K2105/046—Condition, form or state of moulded material or of the material to be shaped cellular or porous with closed cells

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2995/00—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds

- B29K2995/0037—Other properties

- B29K2995/0094—Geometrical properties

- B29K2995/0097—Thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/40—Symmetrical or sandwich layers, e.g. ABA, ABCBA, ABCCBA

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2266/00—Composition of foam

- B32B2266/02—Organic

- B32B2266/0207—Materials belonging to B32B25/00

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2266/00—Composition of foam

- B32B2266/02—Organic

- B32B2266/0214—Materials belonging to B32B27/00

- B32B2266/0292—Thermoplastic elastomer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2266/00—Composition of foam

- B32B2266/08—Closed cell foam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/716—Degradable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2581/00—Seals; Sealing equipment; Gaskets

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2201/00—Foams characterised by the foaming process

- C08J2201/02—Foams characterised by the foaming process characterised by mechanical pre- or post-treatments

- C08J2201/026—Crosslinking before of after foaming

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2205/00—Foams characterised by their properties

- C08J2205/04—Foams characterised by their properties characterised by the foam pores

- C08J2205/052—Closed cells, i.e. more than 50% of the pores are closed

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2309/00—Characterised by the use of homopolymers or copolymers of conjugated diene hydrocarbons

- C08J2309/02—Copolymers with acrylonitrile

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2200/00—Chemical nature of materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K2200/06—Macromolecular organic compounds, e.g. prepolymers

- C09K2200/0607—Rubber or rubber derivatives

- C09K2200/0612—Butadiene-acrylonitrile rubber

Definitions

- the present invention relates to a sealing material and a method for producing the same, and more particularly to improvement of sealing performance at a low surface pressure.

- Patent Document 1 discloses a gasket material formed by forming a foamed rubber layer containing microcapsule-like foamed particles heated and expanded with a low-boiling hydrocarbon expander on at least one surface side of a metal plate. Has been.

- the present invention has been made in view of the above problems, and an object of the present invention is to provide a sealing material exhibiting excellent sealing properties at a low surface pressure and a method for producing the same.

- a sealing material according to an embodiment of the present invention for solving the above problems is a sealing material having a metal plate and a foamed rubber layer formed on one or both surfaces of the metal plate, and the foamed rubber layer.

- the closed cell ratio of the foamed rubber layer is 50% or more, and the maximum height Rz of the surface of the foamed rubber layer measured by a method based on JIS B 0601-2001 is 40 ⁇ m or less.

- ADVANTAGE OF THE INVENTION According to this invention, the sealing material which shows the outstanding sealing performance with a low surface pressure can be provided.

- the sealing material may be classified into Category 0, Category 1 or Category 2 after being immersed in water and tested by the cross-cut method according to JIS K5600-5-6.

- the foamed rubber layer may be formed by foaming a rubber composition layer containing a pyrolytic foaming agent. The foamed rubber layer heats the rubber composition layer formed on the one surface or both surfaces of the metal plate at a temperature not lower than the crosslinking temperature and lower than the foaming temperature, and then the rubber composition layer is heated to the foaming temperature. It is good also as what was formed by heating at the above temperature.

- the manufacturing method of the sealing material which concerns on one Embodiment of this invention for solving the said subject is a method of manufacturing the sealing material which has a metal plate and the foaming rubber layer formed in the single side

- the rubber composition layer formed on the one surface or both surfaces of the metal plate is heated at a temperature equal to or higher than the crosslinking temperature and lower than the foaming temperature, and then the rubber composition layer is heated at a temperature equal to or higher than the foaming temperature.

- the manufacturing method of the sealing material which shows the outstanding sealing performance with low surface pressure can be provided.

- the rubber composition layer may contain a pyrolytic foaming agent.

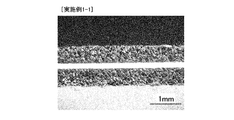

- Example 1 which concerns on one Embodiment of this invention, it is explanatory drawing which shows an example of the result of having observed the cross section of the sealing material.

- Example 1 which concerns on one Embodiment of this invention, it is explanatory drawing which shows the other example of the result of having observed the cross section of the sealing material.

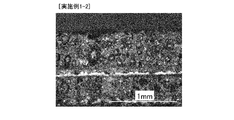

- Example 1 which concerns on one Embodiment of this invention, it is explanatory drawing which shows the other example of the result of having observed the cross section of the sealing material.

- Example 1 which concerns on one Embodiment of this invention, it is explanatory drawing which shows the other example of the result of having observed the cross section of the sealing material.

- Example 2 which concerns on one Embodiment of this invention, it is explanatory drawing which shows an example of the result of having observed the cross section of the sealing material.

- Example 2 which concerns on one Embodiment of this invention, it is explanatory drawing which shows the other example of the result of having observed the cross section of the sealing material.

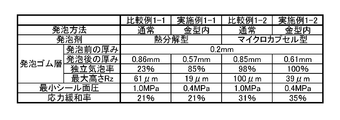

- Example 2 which concerns on one Embodiment of this invention, it is explanatory drawing which shows an example of the result of having evaluated the characteristic of the sealing material.

- FIG. 1 is an explanatory view schematically showing a part of a cross section of a sealing material 1 according to the present embodiment.

- the sealing material 1 includes a metal plate 10 and a foamed rubber layer 20 formed on both surfaces 11 of the metal plate 10. More specifically, in the example shown in FIG. 1, the sealing material 1 includes a metal plate 10 and a foamed rubber layer 20.

- the sealing material 1 is not restricted to the example shown in FIG. 1, It is good also as having the metal plate 10 and the foamed rubber layer 20 formed only in the one surface 11 of the said metal plate 10.

- FIG. 1 is an explanatory view schematically showing a part of a cross section of a sealing material 1 according to the present embodiment.

- the sealing material 1 includes a metal plate 10 and a foamed rubber layer 20 formed on both surfaces 11 of the metal plate 10. More specifically, in the example shown in FIG. 1, the sealing material 1 includes a metal plate 10 and a foamed rubber layer 20.

- the sealing material 1 is not restricted to the example shown in FIG.

- the kind of metal which comprises the metal plate 10 is not specifically limited, For example, steel plates, such as a stainless steel plate, a cold rolled steel plate (SPCC), an aluminum steel plate, can be used preferably.

- the thickness of the metal plate 10 is not particularly limited, but may be, for example, 0.1 to 0.3 mm. When the thickness of the metal plate 10 is less than 0.1 mm, since the sealing material 1 has low rigidity, handling properties such as carrying and assembling properties may be lowered. When the thickness of the metal plate 10 is more than 0.3 mm, the weight and cost of the sealing material 1 are increased, which may not be suitable for downsizing and weight reduction of, for example, a hybrid vehicle and an electric vehicle.

- the sealing material 1 has the metal plate 10, for example, when used for sealing a flange, the sealing material 1 can be punched in accordance with the shape of the flange, and has excellent handling properties.

- the sealing material 1 includes the metal plate 10, thereby providing a small width (for example, 2 mm) corresponding to the seal surface. ) Can be punched.

- the foamed rubber layer 20 is formed by applying a rubber composition containing a rubber polymer, a crosslinking agent and a foaming agent to the surface 11 of the metal plate 10 and foaming.

- a rubber polymer contained in the foamed rubber layer 20 is not particularly limited, for example, a synthetic rubber polymer can be preferably used.

- the synthetic rubber include nitrile rubber (NBR), hydrogenated nitrile rubber (H-NBR), butadiene rubber (BR), styrene butadiene rubber (SBR), ethylene propylene rubber (EPM, EPDM), and fluorine rubber (FKM, One or more selected from the group consisting of FFKM) can be preferably used.

- the amount of the rubber polymer contained in the foamed rubber layer 20 is not particularly limited as long as the foamed rubber layer 20 has a desired rubber elasticity, but the foamed rubber layer 20 is, for example, 20% by weight or more of rubber.

- a polymer may be included, or 30% by weight or more of a rubber polymer may be included.

- the upper limit of the content of the rubber polymer in the foamed rubber layer 20 is not particularly limited, but the foamed rubber layer 20 may include, for example, 90% by weight or less of a rubber polymer. That is, the foamed rubber layer 20 may include, for example, 20 to 90% by weight of rubber polymer, or may include 30 to 90% by weight of rubber polymer. Further, the foamed rubber layer 20 may contain, for example, 20 to 80% by weight of rubber polymer, or 30 to 80% by weight of rubber polymer.

- the foamed rubber layer 20 may further include other components in addition to the rubber polymer. That is, the foamed rubber layer 20 may include a filler, for example.

- the filler is not particularly limited as long as it improves the properties (for example, compressibility, sag resistance, and foamability) of the sealing material 1, and includes, for example, carbon black, calcium carbonate, silica, clay, and talc. One or more selected from the group can be preferably used.

- the foamed rubber layer 20 may contain one or more additives selected from the group consisting of a tackifier, an anti-aging agent and a wax.

- the thickness of the foam rubber layer 20 is not particularly limited, but may be, for example, 0.1 to 1.0 mm, or 0.1 to 0.6 mm. When the thickness of the foamed rubber layer 20 is too small, the compression elasticity of the foamed rubber layer 20 is not sufficient, so that the conformability of the sealing material 1 to the surface to be sealed (for example, the flange surface) is inferior, and the sealing performance is low. When the thickness is too large, the strength of the foamed rubber layer 20 may not be sufficient.

- the foamed rubber layer 20 is formed as a single layer on the surface 11 of the metal plate 10. That is, for example, the foamed rubber layer 20 formed on one surface 11 of the metal plate 10 is formed by applying a rubber composition to the surface 11 to form a single rubber composition layer. It is a single layer formed by foaming. Therefore, in the example shown in FIG. 1, the surface of the foam rubber layer 20 on the metal plate 10 side adheres to the surface 11 of the metal plate 10, and the surface 21 of the foam rubber layer 20 opposite to the metal plate 10 is It is the outermost surface of the sealing material 1.

- the sealing material 1 having such a metal plate 10 and the foamed rubber layer 20 is preferably used for various applications such as a gasket. That is, the sealing material 1 is good also as being the raw material for gaskets which comprises a part of gasket, for example.

- the closed cell ratio of the foamed rubber layer 20 is 50% or more, and the maximum height Rz of the surface 21 of the foamed rubber layer 20 measured by a method according to JIS B 0601-2001 is 40 ⁇ m or less.

- the closed cell ratio of the foamed rubber layer 20 is preferably 60% or more, more preferably 70% or more, and particularly preferably 80% or more.

- the surface 21 of the foamed rubber layer 20 When the maximum height Rz of the surface 21 of the foamed rubber layer 20 is 40 ⁇ m or less, the surface 21 can be effectively adhered to a portion to be sealed (for example, a flange surface). Therefore, even when the sealing material 1 is used at a relatively low tightening surface pressure (for example, 0.2 MPa to 2 MPa), it can exhibit excellent sealing performance.

- the sealing material 1 may be classified into Category 0, Category 1 or Category 2 after being immersed in water and tested by the cross-cut method in accordance with JIS K5600-5-6.

- the sealing material 1 is immersed in water. As a result, water in an amount corresponding to the closed cell ratio of the foamed rubber layer 20 penetrates into the foamed rubber layer 20 of the sealing material 1.

- the adhesion between the metal plate 10 of the sealing material 1 taken out of water and the foamed rubber layer 20 is tested by the cross-cut method defined in JIS K5600-5-6.

- the test results correspond to classification 0, classification 1 or classification 2 among the six classifications (classification 0 to 5) shown in Table 1 of JIS K5600-5-6.

- a sample for example, 25 mm ⁇ 100 mm

- the sample is immersed in water at a predetermined temperature (for example, 90 ° C.) for a predetermined time (for example, 24 hours).

- a predetermined cutting tool (cutter) is used so that a predetermined number (for example, 100) of grids of a predetermined size (for example, 2 mm square) is formed on the surface 21 of the foamed rubber layer 20 of the sample after the water immersion.

- a cut is formed in the foamed rubber layer 20 from the surface 21 to the surface 11 of the metal plate 10.

- a predetermined transparent pressure-sensitive adhesive tape is affixed to a portion (cross cut portion) in which the notch of the surface 21 of the foam rubber layer 20 is formed. Thereafter, the adhesive tape is peeled off from the surface 21 of the foam rubber layer 20. And the state of the crosscut part of the surface 21 of the foamed rubber layer 20 after peeling an adhesive tape is observed visually.

- the observation result (that is, the test result by the cross-cut method) is as follows, as defined in JIS K5600-5-6, in the case where “the edge of the cut is completely smooth and there is no peeling on the eyes of any lattice” If it falls under “Category 0" and “It is not clearly exceeding 5% that it is affected by the crosscut part”, it falls under “Category 1” and “It is affected by the crosscut part. Clearly exceeds 5% but never exceeds 15%, it falls under "Category 2".

- the adhesion between the metal plate 10 and the foamed rubber layer 20 is such that the test result by the cross-cut method corresponds to the above classification 0, classification 1 or classification 2. Highly maintained.

- the sealing material 1 is effective for allowing the fluid to be sealed to permeate between the metal plate 10 and the foamed rubber layer 20 even when, for example, the sealing material 1 is used at a relatively low tightening surface pressure. Therefore, it is possible to exhibit excellent sealing performance by effectively maintaining high adhesion between the metal plate 10 and the foamed rubber layer 20.

- the foamed rubber layer 20 is formed by foaming the rubber composition on the surface 11 of the metal plate 10 as described above. That is, first, a rubber composition containing a rubber polymer, a crosslinking agent and a foaming agent is prepared, and then the rubber composition is applied to the surface 11 of the metal plate 10 to form a rubber composition layer. Thereafter, the rubber composition layer is subjected to a treatment such as heating to perform crosslinking and foaming.

- the foaming agent is not particularly limited as long as it enables formation of the foamed rubber layer 20 by foaming of the rubber composition.

- a thermal decomposition type foaming agent or a microcapsule type foaming agent can be used.

- the foamed rubber layer 20 may be formed by foaming a rubber composition layer containing a pyrolytic foaming agent.

- the pyrolytic foaming agent is a foaming agent that decomposes by heating to generate gas.

- the pyrolytic foaming agent is not particularly limited, and an organic pyrolytic foaming agent and / or an inorganic pyrolytic foaming agent can be used, and an organic pyrolytic foaming that generates a relatively large amount of gas.

- An agent can be preferably used.

- examples of the organic pyrolytic foaming agent include dinitrosopentamethylenetetramine (DPT) foaming agent, azodicarbonamide (ADCA) foaming agent, p, p′-oxybisbenzenesulfonylhydrazide (OBSH). 1) or more selected from the group consisting of) series blowing agents and hydrazodicarbonamide (HDCA) type blowing agents can be used.

- DPT dinitrosopentamethylenetetramine

- ADCA azodicarbonamide

- OBSH p, p′-oxybisbenzenesulfonylhydrazide

- HDCA hydrazodicarbonamide

- the inorganic pyrolytic foaming agent for example, sodium hydrogen carbonate can be used.

- the foamed rubber layer 20 may be formed by foaming a rubber composition layer containing a microcapsule type foaming agent.

- the microcapsule-type foaming agent is a foaming agent having an expandable outer shell and a thermally expandable material (for example, hydrocarbon) enclosed in the outer shell.

- the outer shell of the microcapsule type foaming agent is made of, for example, a thermoplastic resin such as an acrylic resin.

- the foamed rubber layer 20 When the foamed rubber layer 20 is formed by foaming a rubber composition layer containing a pyrolytic foaming agent, the foamed rubber layer 20 exhibits excellent flexibility and has low stress relaxation. It has excellent adhesion to the part to be made and exhibits excellent sealing properties.

- the foamed rubber layer 20 is formed by foaming a rubber composition layer containing a microcapsule-type foaming agent

- the microcapsule-type foaming agent is made of resin outside the foamed rubber layer 20. Since the shell inevitably remains, the foamed rubber layer 20 becomes relatively hard, and when heated, causes stress relaxation (eg, sag) due to softening of the outer shell.

- the foamed rubber layer 20 formed by foaming the rubber composition layer containing the pyrolytic foaming agent there is no problem in using the microcapsule foaming agent as described above.

- the foamed rubber layer 20 is formed by foaming using a pyrolytic foaming agent. Guessed.

- the foamed rubber layer 20 heats the rubber composition layer formed on the surface 11 of the metal plate 10 at a temperature equal to or higher than the crosslinking temperature and lower than the foaming temperature (hereinafter referred to as “first heating temperature”). It is good also as what was formed by heating a rubber composition layer at the temperature more than the said foaming temperature (henceforth "the 2nd heating temperature”).

- the foamed rubber layer 20 is a first rubber which selectively proceeds with crosslinking without substantially foaming the rubber composition layer by heating the rubber composition layer at a first heating temperature. And a second step in which the rubber composition layer is heated at a second heating temperature higher than the first heating temperature, thereby generating foaming gas and further proceeding with crosslinking. .

- the rubber composition layer is formed by applying a rubber composition containing a rubber polymer, a crosslinking agent, and a foaming agent to the surface 11 of the metal plate 10 as described above.

- the crosslinking agent is not particularly limited as long as it causes crosslinking of the rubber polymer.

- the crosslinking agent is selected from the group consisting of sulfur, amine crosslinking agents, polyol crosslinking agents, quinoid crosslinking agents, and bismaleimide crosslinking agents. One or more can be used.

- a foaming agent whose foaming temperature is higher than the crosslinking temperature is used. In general, the foaming temperature of the thermally decomposable foaming agent is higher than the decomposition temperature.

- the temperature equal to or higher than the crosslinking temperature is a temperature at which crosslinking proceeds in the rubber composition layer by heating the rubber composition layer at the temperature.

- the temperature below the foaming temperature is a temperature at which the rubber composition layer does not substantially foam even when the rubber composition layer is heated at the temperature.

- the foaming ratio of the rubber composition layer is 1.5. It is a temperature that is maintained below double.

- the temperature at which the expansion ratio of the rubber composition layer is maintained at less than 1.5 times is a temperature at which the volume of the rubber composition layer is maintained at less than 1.5 times. This is a temperature at which the volume does not increase 1.5 times or more.

- the temperature equal to or higher than the foaming temperature is a temperature at which the rubber composition layer is substantially foamed by heating the rubber composition layer at the temperature.

- the foaming ratio of the rubber composition layer is 1.5. It is a temperature (temperature at which the volume of the rubber composition layer increases 1.5 times or more).

- the first heating temperature is not particularly limited as long as the temperature is not lower than the crosslinking temperature and lower than the foaming temperature, but may be a temperature within a range of 130 to 160 ° C.

- the second heating temperature is not particularly limited as long as it is equal to or higher than the foaming temperature.

- the second heating temperature may be in the range of 200 to 230 ° C. and higher than the first heating temperature.

- preliminary crosslinking eg, partial crosslinking

- first heating temperature before substantial foaming of the rubber composition layer occurs. I do.

- second heating temperature by heating the pre-crosslinked rubber composition layer at the second heating temperature, the rubber composition layer is substantially foamed and the crosslinking is further advanced. A foam rubber layer 20 is formed.

- the foamed rubber layer 20 having the foam structure with a high closed cell rate as described above and the smoothed surface 21 is provided.

- the sealing material 1 can be manufactured effectively. Further, a dense foam structure is formed in the foam rubber layer 20. Moreover, as above-mentioned, the sealing material 1 excellent in the adhesiveness of the metal plate 10 and the foamed rubber layer 20 can also be manufactured effectively.

- the foamed rubber layer 20 may be formed by foaming a rubber composition layer formed on the surface 11 of the metal plate 10 in a mold. That is, in this case, the metal plate 10 having the rubber composition layer formed on the surface 11 is placed in a mold, and the rubber composition layer is foamed in the mold. Specifically, for example, the metal plate 10 on which an unfoamed rubber composition layer is formed is placed in a mold, and then the surface of the rubber composition layer after foaming (that is, the surface 21 of the foamed rubber layer 20). The rubber composition layer is foamed such that the rubber composition layer is in contact with the inner surface of the mold. Then, the surface 21 of the foamed rubber layer 20 is peeled from the inner surface of the mold to obtain the sealing material 1 having the foamed rubber layer 20.

- the foamed rubber layer 20 may be formed by foaming a rubber composition layer having a thickness of 0.2 mm or less. That is, in this case, first, a thin rubber composition layer having a thickness of 0.2 mm or less is formed on the surface 11 of the metal plate 10, and then the rubber composition layer is foamed to form the foam rubber layer 20. .

- the thickness of the rubber composition layer before foaming is not particularly limited, but may be, for example, 0.05 mm or more.

- the amount of solvent contained in the rubber composition layer (for example, a liquid rubber composition layer containing a solvent such as toluene) inevitably increases, and as a result The time required for drying the rubber composition layer becomes longer. If the time required for drying the rubber composition layer becomes longer, the manufacturing time becomes longer and the manufacturing cost increases. That is, if the drying time of the rubber composition layer becomes long, unnecessary bubbles may be generated on the surface of the rubber composition layer during drying. In this case, the sealing property of the sealing material 1 finally formed is And undesirable effects on the appearance. Further, if the drying temperature is raised in order to shorten the drying time, unnecessary bubbles are generated on the surface of the rubber composition layer due to rapid drying, which has an undesirable effect on the sealing performance and appearance of the sealing material 1.

- the rubber composition layer for example, a liquid rubber composition layer containing a solvent such as toluene

- the rubber composition layer can be formed in a short time. Since it can dry quickly, generation

- the thickness of the rubber composition layer before foaming is, for example, the thickness of the foamed rubber layer 20 after compression when the foamed rubber layer 20 of the sealing material 1 is compressed until the thickness does not change. Can be obtained as

- a rubber composition containing a rubber polymer, a crosslinking agent and a foaming agent was prepared. That is, 100.0 parts by weight of the first NBR polymer (JSR N234L, manufactured by JSR Corporation), 12.5 parts by weight of the second NBR polymer (Nipol 1312, manufactured by Nippon Zeon Corporation), and carbon black (MT carbon) (Made by Cabot Corporation) 50.0 parts by weight, zinc white 2 types 5.0 parts by weight, stearic acid 0.5 parts by weight, anti-aging agent 11.5 parts by weight, and tackifier 2.5 parts by weight Were mixed to prepare 182.5 parts by weight of a rubber compound.

- JSR N234L manufactured by JSR Corporation

- Nipol 1312 manufactured by Nippon Zeon Corporation

- MT carbon carbon black

- both sides of the metal plate are degreased, and further, a primer (a primer solution in which a novolak phenol type phenol resin is dissolved in methyl ethyl ketone so as to have a dilution rate of 5%) is applied by a dipping method, Treated at 160 ° C. for 3 minutes.

- a primer a primer solution in which a novolak phenol type phenol resin is dissolved in methyl ethyl ketone so as to have a dilution rate of 5%

- the coating liquid containing the above-mentioned rubber composition was apply

- the thickness of the rubber composition layer formed on one side was 0.2 mm.

- a commercially available device (Dial Gauge DG-925, manufactured by Ono Sokki Co., Ltd.) was used, and a load of 10 g was applied to the surface of the rubber composition layer with a compression tool (diameter 10 mm).

- the thickness of the rubber composition layer in the finished state was measured.

- Comparative Example 1-1 A sealing material according to Comparative Example 1-1 was produced by a conventional method. That is, by placing a metal plate 10 having a rubber composition layer containing a pyrolytic foaming agent on both sides in an oven and heating at 210 ° C. for 10 minutes, the rubber composition layer is crosslinked and foamed. The sealing material according to Comparative Example 1-1 was obtained.

- Comparative Example 1-2 Similar to Comparative Example 1-1 described above, the sealing material according to Comparative Example 1-2 was heated by heating the metal plate 10 having the rubber composition layer containing the microcapsule type foaming agent formed on both sides thereof in an oven. Obtained.

- Example 1-1 The sealing material according to Example 1-1 was manufactured by foaming the rubber composition layer in the mold. That is, the metal plate 10 on which the rubber composition layer containing the pyrolytic foaming agent was formed on both sides was placed in a mold whose gap was adjusted to 1.5 mm with a spacer.

- the rubber composition layer was crosslinked and foamed by heating at 210 ° C. for 10 minutes in a state where the mold was squeezed so as to have a predetermined surface pressure by a press device, and according to Example 1-1 A sealing material was obtained.

- Example 1-2 In the same manner as in Example 1-1 described above, the metal plate 10 having the rubber composition layer containing the microcapsule-type foaming agent formed on both surfaces thereof is heated in the mold, whereby the sealing according to Example 1-2 is performed. The material was obtained.

- the thickness of the foam rubber layer on one side of the sealing material was measured in the same manner as the thickness before foaming described above.

- a measurement indenter (stylus) was lowered on the surface of the foam rubber layer. Then, the indenter was moved at a speed of 0.6 m / min within a range of 4 mm in length, and the maximum height Rz within the range was measured.

- the closed cell ratio of the foam rubber layer was measured. That is, first, a sample (30 mm ⁇ 30 mm) was cut out from the sealing material, and its weight (weight before water immersion) was measured. Subsequently, this sample was immersed in water and vacuum decompression was performed. This vacuum decompression was carried out until the weight of the sample after immersion was constant. Then, the sample was taken out from water and the weight (weight after water immersion) was measured.

- the volume of the rubber composition layer (calculated based on the thickness of the rubber composition layer before foaming).

- the volume of the foam rubber layer was calculated by multiplying the thickness of the foam rubber layer by the area (30 mm ⁇ 30 mm).

- the volume of the rubber composition layer before foaming was calculated by multiplying the thickness of the rubber composition layer before foaming by the area (30 mm ⁇ 30 mm).

- closed cell ratio (%) (volume of the total bubbles in the foamed rubber layer ⁇ volume of water permeating into the foamed rubber) ⁇ total bubbles in the foamed rubber Volume ⁇ 100.

- the minimum seal surface pressure was measured as an index indicating the sealing performance of the sealing material.

- the minimum sealing surface pressure indicates the minimum value of the clamping surface pressure that does not cause leakage of the fluid to be sealed. That is, the sealing material does not cause leakage of the fluid to be sealed with a tightening surface pressure higher than the minimum sealing surface pressure.

- Air was used as the fluid to be sealed.

- a pair of SUS flanges (diameter 60 mm, thickness 30 mm) having a cylindrical shape and a through hole for passing a bolt hole in the center was used.

- a sealing material and a spacer were arranged between a pair of flanges so that the tightening surface pressure was 0.2 MPa, and tightened.

- the internal pressure in the flange was increased to 100 kPa. Then, it was confirmed whether or not air leakage occurred when the internal pressure was maintained at 100 kPa for 1 minute. The presence or absence of leakage was confirmed by applying an aqueous solution containing a surfactant on the outer periphery of the flange and checking whether bubbles were generated on the outer periphery of the flange.

- Stress relaxation rate was measured as another index indicating the sealing property of the sealing material.

- the stress relaxation rate indicates a rate of decrease in the tightening surface pressure when a predetermined time elapses from the start of tightening when the sealing material is tightened at a predetermined tightening surface pressure.

- a sample (30 mm ⁇ 30 mm) cut out from the sealing material was set in a commercially available compression tensile tester (Autograph AG50kGN, manufactured by Shimadzu Corporation). Next, this sample was compressed at an initial surface pressure of 0.3 MPa and maintained at 25 ° C. for 1 hour. Then, the surface pressure at the time when 1 hour has elapsed from the start of compression was measured.

- [result] 2A, 2B, 2C, and 2D show optical micrographs of cross sections of the sealing materials according to Comparative Example 1-1, Example 1-1, Comparative Example 1-2, and Example 1-2, respectively. .

- a foamed rubber layer (FIGS. 2B and 2D) formed by foaming in a mold is a foamed rubber layer (FIGS. 2A and 2D) formed by normal foaming without using a mold.

- FIG. 2C it was confirmed to have a denser bubble structure and a smoother surface.

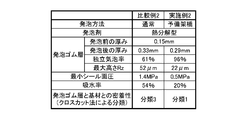

- FIG. 3 shows the thickness of the foamed rubber layer before and after foaming, the closed cell ratio and the maximum height Rz, and the minimum sealing surface pressure of the sealing material for each sealing material, together with the foaming method and the foaming agent used in the production. And the result of having evaluated stress relaxation rate is shown.

- the thicknesses of the foamed rubber layers according to Example 1-1 and Example 1-2 are controlled to a desired range by using a mold, and Comparative Example 1-1 and Comparative Example 1-2 are used. It was reduced compared with that of the foamed rubber layer.

- the closed cell ratio of the foamed rubber layer (Example 1-1) formed by foaming in the mold is the same as that formed by normal foaming (Comparative Example 1). It was remarkably increased compared with that of -1).

- a microcapsule type foaming agent was used, a high closed cell ratio was obtained regardless of the foaming method.

- the maximum height Rz of the surface of the foamed rubber layer according to Example 1-1 and Example 1-2 is significantly reduced as compared with that of the foamed rubber layer according to Comparative Example 1-1 and Comparative Example 1-2. It was done. That is, the surface of the foamed rubber layer was remarkably smoothed by foaming in the mold.

- the minimum seal surface pressure of the sealing materials according to Example 1-1 and Example 1-2 was significantly lower than that of the sealing materials according to Comparative Example 1-1 and Comparative Example 1-2. That is, the sealing performance at a low surface pressure of the sealing material was remarkably improved by foaming in the mold.

- the stress relaxation rate of the sealing materials manufactured using the pyrolytic foaming agent (Comparative Example 1-1 and Example 1-1) is the same as that of the sealing materials manufactured using the microcapsule type foaming agent (Comparison It was significantly smaller than that of Example 1-2 and Example 1-2).

- the sealing material having the foamed rubber layer formed using the pyrolytic foaming agent is compared with the sealing material having the foamed rubber layer formed using the microcapsule type foaming agent. It was confirmed that the sealing performance was excellent.

- a rubber composition containing a rubber polymer, a crosslinking agent and a foaming agent was prepared. That is, NBR polymer (Nipol DN 3335, manufactured by Nippon Zeon Co., Ltd.) 100.00 parts by weight, heavy calcium carbonate (TSS # 100, manufactured by Nitto Flour Chemical Co., Ltd.) 103.78 parts by weight, and zincated flower 2

- NBR polymer Nipol DN 3335, manufactured by Nippon Zeon Co., Ltd.

- TSS # 100 heavy calcium carbonate

- zincated flower 2 By mixing 3.19 parts by weight of seeds, 0.32 parts by weight of stearic acid, 4.15 parts by weight of anti-aging agent, 1.60 parts by weight of tackifier, and 0.64 parts by weight of wax, 213.68 parts by weight of a rubber compound was prepared.

- this rubber composition was mixed with 380.06 parts by weight of toluene as a solvent to prepare a liquid coating solution having a solid content concentration of 38% by weight.

- both sides of the metal plate are degreased, and further, a primer (a primer solution in which a novolak phenol type phenol resin is dissolved in methyl ethyl ketone so as to have a dilution rate of 5%) is applied by a dipping method, Treated at 160 ° C. for 3 minutes.

- a primer a primer solution in which a novolak phenol type phenol resin is dissolved in methyl ethyl ketone so as to have a dilution rate of 5%

- the coating liquid prepared as described above was applied to each surface of the metal plate and dried to form a rubber composition layer.

- the thickness of this rubber composition layer was 0.15 mm.

- Comparative Example 2 The sealing material which concerns on the comparative example 2 was manufactured by the normal method. That is, the rubber composition layer containing the thermally decomposable foaming agent as described above is placed in an oven and heated at 210 ° C. for 10 minutes for 10 minutes. The sealing material according to Comparative Example 2 was obtained.

- Example 2 A two-stage process involving pre-crosslinking, i.e., first heating the rubber composition layer at a first heating temperature above the crosslinking temperature and below the foaming temperature, and then subjecting the rubber composition layer to a second heating above the foaming temperature.

- the sealing material which concerns on Example 2 was manufactured by heating at temperature.

- the rubber composition layer formed on both surfaces of the metal plate was heated at 160 ° C. (first heating temperature) for 8 minutes to perform preliminary crosslinking of the rubber composition layer.

- the pre-crosslinked rubber composition layer was heated at 210 ° C. (second heating temperature) for 10 minutes, thereby foaming and further cross-linking the rubber formed layer to form a foamed rubber layer.

- a sealing material according to Example 2 was obtained by a two-stage method including a pre-crosslinking step.

- the water absorption rate of the sealing material was measured. That is, first, a sample (30 mm ⁇ 30 mm) was cut out from the sealing material, and its weight (weight before water immersion) was measured. The sample was then immersed in 90 ° C. water for 24 hours. Then, the sample was taken out from water and the weight (weight after water immersion) was measured.

- water absorption (%) (weight of foamed rubber layer after water immersion ⁇ weight of foamed rubber layer before water immersion) ⁇ (weight of foamed rubber layer before water immersion) ⁇ 100.

- a transparent pressure-sensitive adhesive tape (Cello Tape (registered trademark) CT405AP-24, manufactured by Nichiban Co., Ltd.) was affixed to the cross cut portion where the surface of the foam rubber layer was cut. Thereafter, the adhesive tape was peeled off from the surface of the foam rubber layer.

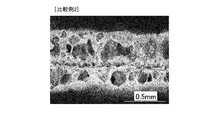

- [result] 4A and 4B show optical micrographs of cross sections of the sealing materials according to Comparative Example 2 and Example 2, respectively.

- the foamed rubber layer according to Example 2 (FIG. 4B) formed by the two-step method including pre-crosslinking is the foamed rubber layer according to Comparative Example 2 formed by the normal method (FIG. 4B).

- FIG. 4A it was confirmed that it has a more remarkably dense cell structure and a more remarkably smooth surface.

- FIG. 5 shows the thickness of the foamed rubber layer before and after foaming, the closed cell ratio and the maximum height Rz, and the minimum seal of the sealing material, together with the foaming method and the type of foaming agent used for the production of each sealing material. The result of having evaluated surface pressure and water absorption, and the adhesiveness of a foamed rubber layer and a metal plate is shown.

- the thickness of the foam rubber layer according to Example 2 was reduced as compared with that of the foam rubber layer according to Comparative Example 2.

- the closed cell ratio of the foamed rubber layer according to Example 2 significantly increased as compared with that of the foamed rubber layer according to Comparative Example 2.

- the maximum height Rz of the surface of the foam rubber layer according to Example 2 was significantly reduced as compared with that of the foam rubber layer according to Comparative Example 2. That is, the surface of the foamed rubber layer was effectively smoothed by a two-stage method including preliminary crosslinking.

- the minimum seal surface pressure of the sealing material according to Example 2 was significantly lower than that of the sealing material according to Comparative Example 2. That is, the sealing performance at a low surface pressure of the sealing material was remarkably improved by the two-stage method including preliminary crosslinking.

- the water absorption rate of the sealing material according to Example 2 was significantly lower than that of the sealing material according to Comparative Example 2. That is, in the sealing material obtained by the two-stage method including pre-crosslinking, the permeation of fluid was effectively suppressed.

- the classification according to the cross-cut method of the sealing material according to Comparative Example 2 corresponds to “Category 3”. That is, in the sealing material according to Comparative Example 2, more than 15% of the cross cut portion of the foam rubber layer was damaged.

- the classification of the sealing material according to Example 2 by the cross-cut method corresponds to “Category 1”. That is, in the sealing material according to Example 2, the damage of the cross cut portion of the foamed rubber layer was only 5% or less.

- the test result of this cross-cut method was supported by the evaluation result of the water absorption rate described above. That is, the sealing material obtained by the two-stage method including pre-crosslinking penetrates between the foamed rubber layer and the metal plate even when it is in contact with the fluid to be sealed under pressure. It has been confirmed that excellent sealing properties can be exhibited by effectively suppressing the above-described problem and effectively maintaining high adhesion between the foamed rubber layer and the metal plate.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- General Engineering & Computer Science (AREA)

- General Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Mechanical Engineering (AREA)

- Gasket Seals (AREA)

- Sealing Material Composition (AREA)

- Manufacture Of Porous Articles, And Recovery And Treatment Of Waste Products (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13755497.8A EP2821675B1 (en) | 2012-02-28 | 2013-02-28 | Sealing material and method for producing same |

| US14/381,876 US9360113B2 (en) | 2012-02-28 | 2013-02-28 | Sealing material and method for producing same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012-041271 | 2012-02-28 | ||

| JP2012041271A JP5852470B2 (ja) | 2012-02-28 | 2012-02-28 | シーリング材及びその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013129596A1 true WO2013129596A1 (ja) | 2013-09-06 |

Family

ID=49082787

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/055479 Ceased WO2013129596A1 (ja) | 2012-02-28 | 2013-02-28 | シーリング材及びその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9360113B2 (enExample) |

| EP (1) | EP2821675B1 (enExample) |

| JP (1) | JP5852470B2 (enExample) |

| WO (1) | WO2013129596A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019178210A (ja) * | 2018-03-30 | 2019-10-17 | 積水化学工業株式会社 | 樹脂発泡シート及び粘着テープ |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE537057C2 (sv) * | 2012-03-13 | 2014-12-23 | Förfarande och anordningar för att skära kompositmaterial, och tätningsanordningar tillverkade av kompositmaterial | |

| JP2015075197A (ja) * | 2013-10-10 | 2015-04-20 | Nok株式会社 | 細径ガスケットの製造方法。 |

| US9969339B2 (en) * | 2015-03-24 | 2018-05-15 | GM Global Technology Operations LLC | Device, trim element for the device, and method of forming the trim element |

| KR101883955B1 (ko) * | 2017-10-20 | 2018-07-31 | 방영혁 | 버터플라이밸브의 디스크시트 제조방법 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002161805A (ja) * | 2000-11-30 | 2002-06-07 | Nippon Gasket Co Ltd | チェーンケース付きエンジン用金属製ガスケット |

| JP2009049194A (ja) * | 2007-08-20 | 2009-03-05 | Nok Corp | ガスケット |

| JP2011074374A (ja) * | 2009-09-04 | 2011-04-14 | Sumitomo Chemical Co Ltd | 常圧架橋発泡用樹脂組成物および架橋発泡体の製造方法 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3094788B2 (ja) | 1994-04-19 | 2000-10-03 | エヌオーケー株式会社 | ガスケット材料およびその製造法 |

| JP2004035800A (ja) * | 2002-07-05 | 2004-02-05 | Nippon Leakless Corp | ガスケット素材 |

| US20060093780A1 (en) | 2002-07-05 | 2006-05-04 | Yoshiaki Hamada | Gasket material |

| US20040138321A1 (en) * | 2002-10-23 | 2004-07-15 | Nichias Corporation | Thermally expandable material, method for producing the same and soundproof sheet for automobile |

| US20050080150A1 (en) * | 2003-10-10 | 2005-04-14 | Mitsui Chemicals, Inc. | Vulcanized rubber molded product, method of producing the same, and use of the molded product |

| JP2006083236A (ja) | 2004-09-14 | 2006-03-30 | Sekisui Chem Co Ltd | シール材 |

| JP4694346B2 (ja) * | 2005-10-19 | 2011-06-08 | 西川ゴム工業株式会社 | 自動車用ウエザーストリップの製造方法 |

| JP4752674B2 (ja) * | 2006-08-21 | 2011-08-17 | 豊田合成株式会社 | ウエザストリップの製造方法 |

| JP2009242624A (ja) * | 2008-03-31 | 2009-10-22 | Sekisui Chem Co Ltd | シール材 |

| KR101622409B1 (ko) * | 2009-10-07 | 2016-05-18 | 니찌아스 카부시키카이샤 | 가스켓용 소재 |

| JP5755015B2 (ja) * | 2010-06-06 | 2015-07-29 | 日東電工株式会社 | Epdm発泡体および粘着シール材 |

-

2012

- 2012-02-28 JP JP2012041271A patent/JP5852470B2/ja active Active

-

2013

- 2013-02-28 WO PCT/JP2013/055479 patent/WO2013129596A1/ja not_active Ceased

- 2013-02-28 EP EP13755497.8A patent/EP2821675B1/en active Active

- 2013-02-28 US US14/381,876 patent/US9360113B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002161805A (ja) * | 2000-11-30 | 2002-06-07 | Nippon Gasket Co Ltd | チェーンケース付きエンジン用金属製ガスケット |

| JP2009049194A (ja) * | 2007-08-20 | 2009-03-05 | Nok Corp | ガスケット |

| JP2011074374A (ja) * | 2009-09-04 | 2011-04-14 | Sumitomo Chemical Co Ltd | 常圧架橋発泡用樹脂組成物および架橋発泡体の製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2821675A4 * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019178210A (ja) * | 2018-03-30 | 2019-10-17 | 積水化学工業株式会社 | 樹脂発泡シート及び粘着テープ |

| JP7209473B2 (ja) | 2018-03-30 | 2023-01-20 | 積水化学工業株式会社 | 樹脂発泡シート及び粘着テープ |

| JP2023033396A (ja) * | 2018-03-30 | 2023-03-10 | 積水化学工業株式会社 | 樹脂発泡シート及び粘着テープ |

Also Published As

| Publication number | Publication date |

|---|---|

| US9360113B2 (en) | 2016-06-07 |

| EP2821675B1 (en) | 2021-03-24 |

| JP2013177912A (ja) | 2013-09-09 |

| US20150014946A1 (en) | 2015-01-15 |

| EP2821675A4 (en) | 2015-12-09 |

| EP2821675A1 (en) | 2015-01-07 |

| JP5852470B2 (ja) | 2016-02-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5852470B2 (ja) | シーリング材及びその製造方法 | |

| CN101784633A (zh) | 密封材料 | |

| JP6603121B2 (ja) | 吸音材 | |

| CN103289117B (zh) | 树脂发泡体片以及树脂发泡复合体 | |

| JPWO2007072885A1 (ja) | 独立気泡発泡ゴムシート、積層体及びそれらを用いた止水・水密シール材 | |

| CN114641521B (zh) | 树脂发泡体 | |

| CN110744904A (zh) | 一种锂电池软包装用弹性铝塑膜及制备方法 | |

| WO2013042650A1 (ja) | エチレン・プロピレン・ジエンゴム発泡体、その製造方法およびシール材 | |

| EP2781542A2 (en) | Ethylene-propylene-diene buffer material and sealing material | |

| CN102029744B (zh) | 衬垫材料 | |

| WO2014148297A1 (ja) | 発泡積層体 | |

| WO2014148299A1 (ja) | 発泡積層体 | |

| JP5308854B2 (ja) | ガスケット構造体 | |

| JPH07286165A (ja) | ガスケット材料およびその製造法 | |

| JP6076162B2 (ja) | エチレン・プロピレン・ジエンゴム発泡体およびシール材 | |

| JP5702602B2 (ja) | ゴム系樹脂独立気泡発泡シート及びその製造方法 | |

| WO2005073299A1 (ja) | 熱可塑性樹脂発泡体シート及び熱可塑性樹脂発泡体シートの製造方法 | |

| JP2010031137A (ja) | 独立気泡発泡シート | |

| KR20170011569A (ko) | 충격 흡수용 금속 테이프 | |

| JP4630588B2 (ja) | ポリウレタン発泡体シート材 | |

| KR101281859B1 (ko) | 개스킷용 소재 | |

| JP5022838B2 (ja) | 制振補強シートおよび薄板の制振補強方法 | |

| JP2011189674A (ja) | 積層シート | |

| JP5231845B2 (ja) | ゴム系樹脂独立気泡発泡シート及びその製造方法 | |

| TW201538316A (zh) | 一種多孔隔離膜及其製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13755497 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2013755497 Country of ref document: EP |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14381876 Country of ref document: US |