WO2012114532A1 - 溶接継手の製造方法及び溶接継手 - Google Patents

溶接継手の製造方法及び溶接継手 Download PDFInfo

- Publication number

- WO2012114532A1 WO2012114532A1 PCT/JP2011/054664 JP2011054664W WO2012114532A1 WO 2012114532 A1 WO2012114532 A1 WO 2012114532A1 JP 2011054664 W JP2011054664 W JP 2011054664W WO 2012114532 A1 WO2012114532 A1 WO 2012114532A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- welding

- joint

- welded

- weld

- weld metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K31/00—Processes relevant to this subclass, specially adapted for particular articles or purposes, but not covered by only one of the preceding main groups

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K31/00—Processes relevant to this subclass, specially adapted for particular articles or purposes, but not covered by only one of the preceding main groups

- B23K31/02—Processes relevant to this subclass, specially adapted for particular articles or purposes, but not covered by only one of the preceding main groups relating to soldering or welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K33/00—Specially-profiled edge portions of workpieces for making soldering or welding connections; Filling the seams formed thereby

- B23K33/004—Filling of continuous seams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/22—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by the composition or nature of the material

- B23K35/24—Selection of soldering or welding materials proper

- B23K35/30—Selection of soldering or welding materials proper with the principal constituent melting at less than 1550 degrees C

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/02—Seam welding; Backing means; Inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/02—Seam welding; Backing means; Inserts

- B23K9/025—Seam welding; Backing means; Inserts for rectilinear seams

- B23K9/0256—Seam welding; Backing means; Inserts for rectilinear seams for welding ribs on plates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/16—Arc welding or cutting making use of shielding gas

- B23K9/167—Arc welding or cutting making use of shielding gas and of a non-consumable electrode

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/16—Arc welding or cutting making use of shielding gas

- B23K9/173—Arc welding or cutting making use of shielding gas and of a consumable electrode

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/23—Arc welding or cutting taking account of the properties of the materials to be welded

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C1/00—Methods for use of abrasive blasting for producing particular effects; Use of auxiliary equipment in connection with such methods

- B24C1/10—Methods for use of abrasive blasting for producing particular effects; Use of auxiliary equipment in connection with such methods for compacting surfaces, e.g. shot-peening

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/34—Methods of heating

- C21D1/40—Direct resistance heating

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/34—Methods of heating

- C21D1/42—Induction heating

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D7/00—Modifying the physical properties of iron or steel by deformation

- C21D7/02—Modifying the physical properties of iron or steel by deformation by cold working

- C21D7/04—Modifying the physical properties of iron or steel by deformation by cold working of the surface

- C21D7/06—Modifying the physical properties of iron or steel by deformation by cold working of the surface by shot-peening or the like

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/50—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for welded joints

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/08—Ferrous alloys, e.g. steel alloys containing nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/20—Ferrous alloys, e.g. steel alloys containing chromium with copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/22—Ferrous alloys, e.g. steel alloys containing chromium with molybdenum or tungsten

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/24—Ferrous alloys, e.g. steel alloys containing chromium with vanadium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/26—Ferrous alloys, e.g. steel alloys containing chromium with niobium or tantalum

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/28—Ferrous alloys, e.g. steel alloys containing chromium with titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/38—Ferrous alloys, e.g. steel alloys containing chromium with more than 1.5% by weight of manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/42—Ferrous alloys, e.g. steel alloys containing chromium with nickel with copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/46—Ferrous alloys, e.g. steel alloys containing chromium with nickel with vanadium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/48—Ferrous alloys, e.g. steel alloys containing chromium with nickel with niobium or tantalum

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/50—Ferrous alloys, e.g. steel alloys containing chromium with nickel with titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/58—Ferrous alloys, e.g. steel alloys containing chromium with nickel with more than 1.5% by weight of manganese

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/04—Tubular or hollow articles

- B23K2101/045—Hollow panels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/02—Iron or ferrous alloys

- B23K2103/04—Steel or steel alloys

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/02—Iron or ferrous alloys

- B23K2103/04—Steel or steel alloys

- B23K2103/05—Stainless steel

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

Definitions

- the present invention relates to a method for manufacturing a welded joint, and more specifically, shot peening when the structure of the welded joint or the structure of the welded structure is a structure that can be welded only from one side of the steel material.

- the present invention relates to a method for manufacturing a welded joint, in which it is difficult to take measures to improve fatigue strength such as processing, and it is possible to improve the fatigue strength of the weld toe portion or root portion on the side opposite to the welded side. .

- the fatigue characteristics of welded structures are extremely important in determining the life of the structure itself.

- the weld toe portion is smoothed to reduce stress concentration as much as possible, or where peening is applied to cause fatigue.

- a method of lowering the transformation start temperature of the weld metal and improving the fatigue strength by the residual stress reduction effect utilizing transformation expansion is also disclosed.

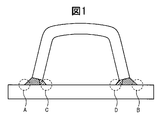

- FIG. 1 is a view showing an example of a welded joint and a welded structure.

- FIG. 1 is a schematic diagram for explaining a structure when a member having a U-shaped cross section is attached to a flat plate by welding to ensure bending rigidity.

- FIG. 1 In the case of the example shown in FIG. 1, the U-shaped member is welded to the flat plate at two locations, and the joint is a T-shaped joint. At this time, since fatigue cracks occur in the stress concentration portion, they occur in the four locations indicated by reference signs A to D in the example shown in FIG.

- the two locations indicated by reference signs A and B are located outside the welded structure, so that it is easy to carry out repairs, and the shape of the weld toe is processed smoothly in advance. It is possible to improve the fatigue strength by performing a peening process and applying compressive residual stress.

- the two weld toes indicated by reference characters C and D in FIG. 1 are structurally sealed and cannot be post-processed after the end of welding.

- This is a very simple process in which, in the case of a mechanical post-processing method such as peening, the processing must be performed while directly contacting a portion where fatigue is a problem (see reference numerals C and D in FIG. 1).

- the fatigue strength of the welded structure as shown in FIG. 1 is determined by the fatigue strength of the weld toe indicated by symbols C and D, and the fatigue strength of the weld toe indicated by symbols A and B.

- the problem remains that the fatigue strength of the entire welded structure is not improved.

- the technique disclosed in the document only discloses a technique for a joint when the weld toe is located outside.

- the welding material disclosed in Patent Document 1 is not necessarily used. Not obvious.

- the welding of the T-joint is completed by two-pass welding, but in this case, the heat generated when forming the subsequent weld bead, that is, the outer weld bead, is generated by the inner bead. Since the residual stress is broken, the original effect cannot be obtained.

- the fatigue strength of a welded structure is a factor that determines the life of the entire welded structure, and in particular, the fatigue strength of the entire welded structure is determined at a portion where the fatigue strength is lowest.

- the present invention has been made in view of the above problems, and mechanical treatment such as shot peening is applied to the weld toe portion or root portion where fatigue strength is a problem due to the existence of a sealed region in structure.

- Another object of the present invention is to provide a method for manufacturing a welded joint capable of improving fatigue strength when measures for improving fatigue strength by welding such as bead formation cannot be taken.

- the present inventors are able to achieve the improvement of the fatigue strength of the welded joint when there is a weld toe portion or root portion having a structure that cannot take measures for improving the mechanical fatigue strength.

- This invention is made

- the multi-pass welding is performed such that the transformation start temperature of the weld metal in the first pass is in the range of 175 ° C to 400 ° C.

- a first welding step in which welding is performed using a material, and then welding in which the weld metal is raised in one or more passes so that a part of the weld metal formed in the first welding step becomes an unmelted portion.

- a second welding step for retransforming all the unmelted portions into austenite by the welding heat of the final pass.

- the multi-pass welding is performed such that the transformation start temperature of the weld metal in the first pass is in the range of 175 ° C to 400 ° C.

- a first welding process in which welding is performed using a material, and then the weld metal is raised in one or more passes so that a part of the weld metal formed in the first welding process becomes an unmelted portion.

- a method for manufacturing a welded joint comprising: a second welding step for performing welding, and then a heat treatment for retransforming all the unmelted portions into austenite.

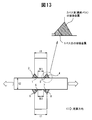

- the weld joint is a T joint, and the joint portion of the T joint is composed of an unwelded portion and welded portions on both sides sandwiching the unwelded portion, and the welded portion is subjected to multi-pass welding by partial melting welding only from one side.

- a method for manufacturing a joint is a cruciform joint, and a joint portion of the cruciform joint is composed of an unwelded portion and welded portions on both sides sandwiching the unwelded portion, and the welded portion is subjected to multi-pass welding by partial melting welding only from one side.

- the length of the unwelded portion existing between the multipass welds and the minimum thickness of the steel plate forming the T joint are the A method for manufacturing a welded joint, characterized in that it is at least three times the maximum thickness of each pass weld bead in pass welding.

- the weld joint is a T joint or a cross joint, and a joint portion of the weld joint includes an unwelded portion and welded portions on both sides sandwiching the unwelded portion, and the welded portion is subjected to partial melting welding only from one side.

- any one of (1) to (11) is characterized in that post-processing is performed by grinder processing on the toe portion of the weld bead on the welding side.

- a method for producing a welded joint according to claim 1. Any one of (1) to (11) is characterized in that after the second welding step, post-treatment by peening treatment is performed on the toe portion of the weld bead on the welding side.

- a method for producing a welded joint according to claim 1. (14) After the second welding step, the toe portion of the weld bead on the welded side is subjected to a reheating treatment with a TIG arc, (1) to (11) The manufacturing method of the welded joint in any one.

- a welded joint of the present invention there is an inner weld toe or root portion having a structure that cannot be post-processed mechanically or by welding due to the structure of the welded joint or the structure of the welded structure. Even in this case, the fatigue strength of the welded joint can be improved, the life of the entire welded structure can be improved, or the existing welded structure can be repaired to prolong the life of the welded structure.

- the industrial significance is extremely large.

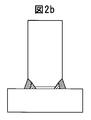

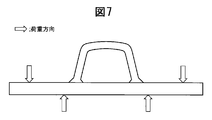

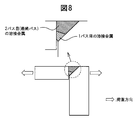

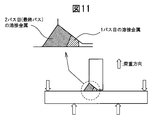

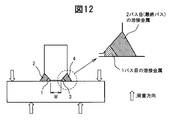

- FIG. 1 It is a schematic diagram for demonstrating an example of the manufacturing method of the welded joint of this invention, and is a partial expanded sectional view which shows the weld part of the welded joint shown in FIG.

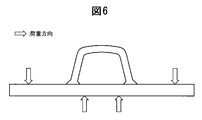

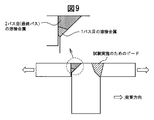

- FIG. 1 It is a schematic diagram for demonstrating the Example of the manufacturing method of the welded joint of this invention, and is sectional drawing which shows the load direction at the time of conducting the fatigue test in Example 1.

- FIG. 1 It is a schematic diagram for demonstrating the Example of the manufacturing method of the welded joint of this invention, and is sectional drawing which shows the load load direction at the time of conducting the fatigue test in Example 3.

- FIG. It is a schematic diagram for demonstrating the welded joint of this invention, and is the elements on larger scale which show the weld part of the square joint in Example 5.

- FIG. 1 It is a schematic diagram for demonstrating the Example of the manufacturing method of the welded joint of this invention, and is sectional drawing which shows the load loading direction at the time of conducting the fatigue test of the corner joint in Example 5.

- FIG. It is a schematic diagram for demonstrating the Example of the manufacturing method of the welded joint of this invention, and is sectional drawing which shows the load load direction at the time of conducting the fatigue test of the lap joint in Example 5.

- FIG. It is a schematic diagram for demonstrating the Example of the manufacturing method of the welded joint of this invention, and is sectional drawing which shows the load load direction at the time of conducting the fatigue test of the T joint in Example 5.

- FIG. 1 It is a schematic diagram for demonstrating the Example of the manufacturing method of the welded joint of this invention, and is sectional drawing which shows the load load direction at the time of conducting the fatigue test of the T joint welded from both sides in Example 6.

- FIG. It is a schematic diagram for demonstrating the Example of the manufacturing method of the welded joint of this invention, and is sectional drawing which shows the load direction at the time of conducting the fatigue test of the cross joint in Example 6.

- FIGS. 1 to 13 an embodiment of a method for manufacturing a welded joint according to the present invention will be described with reference to FIGS. 1 to 13 as appropriate.

- this embodiment is described in detail in order to make the purpose of the manufacturing method of the welded joint of the present invention better understood, the present invention is not limited unless otherwise specified.

- the fatigue strength improving methods are roughly divided into three types.

- the first is a method of applying mechanical or mechanical treatment such as impact to the surface, such as shot peening

- the second is to adjust the composition of the weld metal and use the transformation expansion of the weld metal.

- a method of adding ingenuity to material characteristics such as components of steel or welding material

- the third is a method of applying heat after welding.

- these methods will be called a mechanical method, a material method, and a heat treatment method, respectively.

- the present invention can be said to be a method using both a materialistic method and a heat treatment method.

- the present invention aims to improve the fatigue strength of a welded joint having a structure in which a fatigue strength improving method such as mechanical treatment cannot be performed.

- a structure has a partially sealed structure as a welded structure, or as a welded joint, there is an unwelded part such as a partial penetration, so that direct peening treatment or Indicates a case where grinder processing cannot be performed.

- a low-temperature transformation melt such a component-based welding material

- the weld metal formed at that time is called a low-temperature transformation weld metal.

- the low-temperature transformation melt contains a large amount of Ni, Cr, etc., and is also a component system that easily generates hot cracks. In such a case, depending on the shape of the joint, if one-pass welding is performed, butt solidification is likely to occur in the weld metal, and the risk of causing hot cracking is extremely high.

- Such joints that cannot take measures to improve fatigue strength by mechanical treatment, etc., include a case where a sealed space exists as shown in FIG. 1 as well as a partial penetration as shown in FIG. 2a.

- a sealed space exists as shown in FIG. 1 as well as a partial penetration as shown in FIG. 2a.

- a welded joint by welding since there is an unwelded portion even if there is no sealed space, it is directly mechanically applied to a stress concentration portion (see the portion indicated by symbol F in FIG. 2a) where fatigue becomes a problem.

- processing cannot be performed As shown in FIG. 1, when a mechanical treatment cannot be performed due to the presence of a sealed space, the locations indicated by reference characters C and D in FIG. 1 are called inner weld toes and are shown in FIG. 2a.

- a case where an unwelded portion exists is referred to as a root portion.

- the above-described fatigue strength problem of the inner weld toe portion 21 and the root portion 41 on the sealed space side is solved as follows.

- two methods are disclosed: a case where heat treatment is not performed after welding (see claim 1) and a case where heat treatment is performed (see claim 2).

- the former is referred to as a non-heat treatment type, and the latter is referred to as a heat treatment type.

- the method for manufacturing a non-heat treatment type welded joint includes a steel material 11 (of the welded joint 10 (30) in terms of the structure of the welded joint or the welded structure. 31) is a structure that can be welded only from one side, and the inner weld toe portion 21 covered with the welded structure 1 or the route portion 41, which is formed by partial penetration welding and cannot be accessed from the outside, is mechanical. Or it is a method of manufacturing a welded joint 10 (30) having a structure that cannot be post-processed by welding.

- the insoluble Second which introduces compressive residual stress to the inner weld toe portion 21 or the root portion 41 by performing welding that heats up the weld metal in one pass with welding heat input that is heated until the melted portion is retransformed into austenite. And a welding process.

- a weld bead inner weld toe, Root part

- This weld metal is a low-temperature transformation weld metal.

- a second weld bead (outer weld toe) is formed as a subsequent bead. This corresponds to the second welding process.

- a melt suitable for the strength of the steel plate forming the welded structure that is, a normal welding material, or a low-temperature transformation melt.

- a normal welding material for forming the second bead from the viewpoint of selecting a material having low hot cracking sensitivity.

- the weld joint is formed by two-pass welding, but simply by performing two-pass welding, the compressive residual stress formed by the first weld bead due to the low-temperature transformation melt disappears by the second bead. There is a danger that the fatigue strength will not improve. Therefore, when the second welding process is performed, it is necessary to generate the compressive residual stress again after the initially formed compressive residual stress disappears.

- the technical idea that forms the basis of the present invention is that the compressive residual stress is again generated by the second weld bead. That is, the compressive residual stress that improves the fatigue strength is not a residual stress that occurs when welding using a low-temperature transformation melt, but a residual stress that occurs when the second welding is performed.

- a low temperature transformation material in the prior art is a technology that introduces compressive residual stress by utilizing transformation expansion, and this compressive residual stress is generated in the cooling process during welding using the low temperature transformation material.

- this compressive residual stress corresponds to the compressive residual stress generated in the first-pass welding, but in the present invention, this compressive residual stress disappears in the second welding.

- the technical idea forming the basis of the present invention is to generate compressive residual stress again at the second welding, and further, the welding material used for the second welding is not necessarily limited to the low-temperature transformation melt.

- the untransformed part is only thermally contracted during the subsequent cooling and does not undergo transformation expansion. Sufficient compressive residual stress cannot be generated again. Further, even if welding is performed so as to simply cover the surface of the low temperature transformation weld metal formed by the first welding, the low temperature transformation weld metal formed by the first welding cannot be retransformed into austenite.

- part or all of the low temperature transformation weld metal formed in the first welding process needs to be unmelted. If all the low temperature transformation weld metal is melted in the second welding, the compressive residual stress is not reintroduced. On the other hand, in the final welding pass in the second welding process, all of the unmelted low temperature transformation weld metal must be heated before retransformation to austenite. It is not particularly difficult to examine such conditions in advance if it is a person concerned with welding. Prepare a specimen having the same shape as the actual weld joint in advance, and perform the first welding process and the second weld process with the same welding material as the welding material to be used when actually welding.

- the unmelted low temperature This is because whether or not all of the transformation weld metal has retransformed to austenite can be easily determined by observing the structure of the cross-sectional macro.

- the welding conditions may be determined in advance, and welding may be performed on the actual welded joints under these conditions.

- the transformation start temperature of the low temperature transformation weld metal can also be confirmed by collecting a test piece from the unmelted low temperature transformation weld metal portion of the weld joint prepared in advance and measuring the transformation start temperature.

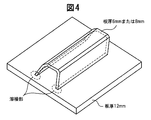

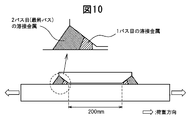

- the joint is a joint called a T joint, but the present invention aims to improve the fatigue strength by controlling the residual stress. If the effect is negligible, it is considered that there are two welds that are welded only from one side. In this case, the unwelded portion corresponds to a sealed space sandwiched between the welds on both sides. The fact that it is far enough not to affect the residual stress also depends on the welding heat input. When the heat input amount is high, the thickness of the weld metal formed in the welding pass at that time also increases. Therefore, in the present invention, the thickness of the weld metal is employed instead of the heat input amount. In the present invention, the thickness of the weld metal is defined as shown in FIG.

- one point A on the surface of the weld metal is determined.

- a tangent of the weld metal surface at A is determined, and then a straight line that intersects the tangent perpendicularly and passes through the point A is obtained.

- the intersection of this straight line and the fusion line of the weld metal is defined as B, and the distance between point A and point B is defined as the thickness at point A.

- the thickness is defined at each point of the weld metal, and the maximum value is determined as the thickness of the weld metal.

- the weld metal surface disappears. Therefore, it is necessary to determine the thickness after each welding pass and before the subsequent welding pass is performed. It is necessary to pay attention to.

- the maximum value is compared with the length of the unwelded part, and when the length of the unwelded part is more than three times the maximum value, It has been found that the existing weld metals can be regarded as independent of each other and do not affect the residual stress. When the unwelded portion is shorter than this, the welding process on one side affects the residual stress on the other side, and the fatigue strength may not always improve, so this value was set.

- the cross joint it can be considered that a T-joint welded from both sides is formed on each of the front side and the back side of one steel plate.

- the limiting conditions for forming the respective T joints must satisfy the limiting conditions set when forming the T joints.

- the cross joint in addition to this condition, it is necessary to pay attention to the welding heat transmitted through the steel plate. In this case, it is sufficient that the plate thickness is thick enough not to affect the residual stress.

- the unwelded portion and the minimum thickness of the steel plate forming the cross joint are more than three times the maximum thickness of the weld metal formed in each welding pass, the newly formed weld metal was found to be independent of each other and not to affect the residual stress.

- the unwelded portion is shorter than this, the welding process on one side affects the residual stress on the other side, and the fatigue strength may not always improve, so this value was set.

- the above is the technical idea of the present invention in the non-heat treatment type fatigue strength improving method.

- the transformation of the above-mentioned low temperature transformation weld metal is not necessarily limited to a specific transformation as long as it is a volume expansion transformation that occurs at a low temperature defined by the present invention, but is generally within the temperature range of the present invention.

- the transformation that occurs in is the martensitic transformation.

- the martensitic transformation start temperature is characterized by being determined only by the weld metal component without depending on the cooling rate during welding.

- the estimation formula using a component is also known, for example, the following estimation formula is proposed.

- Ms 719-795C-20Cr-32Ni-35.6Si-13.3Mn-23.7Mo-11.9Nb

- Ms is the martensitic transformation start temperature (° C.), and C and the like indicate weld metal component values (mass%).

- the existence of such an estimation formula is a convenient index that can be a guide for material development for welding engineers. It should be noted that the transformation that occurs in the temperature range of the present invention is mainly the martensitic transformation in the heat treatment type described below.

- the manufacturing method of the heat treatment type welded joint in the present invention is the method of manufacturing the welded joint 10 (30) having the structure of a welded joint or a welded structure as described above.

- a first welding step for performing welding in which the root portion 41 is formed using a weld metal having a transformation start temperature in the range of 175 ° C. to 400 ° C., and an inner weld toe portion formed in the first welding step A second welding process in which welding is performed to raise the weld metal in one or more passes so that at least a part of the weld metal forming 21 or the root part 41 becomes an unmelted part, and then the first welding process.

- the low temperature transformation weld metal formed in the first welding step is heated by the second welding step until all of the low temperature transformation weld metal is retransformed into austenite.

- heat treatment is performed after welding, and this heat ensures that all of the low temperature transformation weld metal parts are This is a method of retransformation to austenite. Therefore, compared with the non-heat treatment type, the first welding process is the same as the heat treatment type, and as the second welding process, a part of the low temperature transformation weld metal formed in the first welding process is unmelted.

- the welding material does not necessarily need to use a low-temperature transformation melt.

- all or part of the low temperature transformation weld metal unmelted portion formed in the first welding process is not necessarily austenite in the final welding pass of the second welding process.

- the welded joint thus prepared is then processed in a heat treatment step, and then a cross-sectional macro is taken from the welded joint to determine whether there is an unmelted portion of the low temperature transformation weld metal, Whether or not all of the unmelted low-temperature transformation weld metal has been retransformed into austenite by heat treatment may be determined from the observation of the structure of the cross-sectional macro. In this way, welding conditions and heat treatment conditions are determined in advance, and an actual welded joint may be constructed under these conditions.

- the transformation start temperature of the low temperature transformation weld metal can also be confirmed by collecting a test piece from an unmelted low temperature transformation weld metal portion of a weld joint prepared in advance and measuring the transformation start temperature.

- the second welding process has two or more passes in the non-heat treatment type

- the final pass of the second welding step is separated from the weld metal formed in the first welding step, so It is desirable to limit the welding process 2 to the case of 1-pass welding.

- transformation start temperature of weld metal used in the first welding process First, the reason for limiting the transformation start temperature of the low temperature transformation weld metal will be described.

- fatigue is a problem, and a low temperature transformation weld metal is formed at the inner weld toe or root portion where fatigue strength improvement measures cannot be implemented by mechanical or welding post-treatment, and the transformation expansion of the low temperature transformation weld metal

- compressive residual stress is introduced into the weld toe or root.

- the upper limit of the transformation start temperature 400 ° C., was set at a transformation start temperature higher than this, because the thermal shrinkage after the end of transformation increased and the compressive stress introduced during transformation expansion disappeared.

- the lower limit of 175 ° C. has almost the same effect even when the transformation start temperature is lower than this, and in order to obtain a transformation start temperature lower than 175 ° C., This value was set because an alloying element material exceeding the limited range must be added, and the cost of welding material production and the risk of hot cracking increase.

- Heat treatment method in heat treatment process Next, a heat treatment method in the heat treatment mold will be described.

- a method for heat-treating the welded joint a method such as heating with a gas burner, energization heating with an electric heater, or putting the entire structure into a heat treatment path can be considered.

- a heat treatment method by electric heating or induction heating is preferred. Electric heating or induction heating and heating by a gas burner or an electric heater are greatly different in the following points.

- Electric heating is a method in which an electric current is passed through a welded joint and heated using Joule heat generated at that time.

- Induction heating is a method in which an eddy current is generated and heated using that. appear.

- heat is transferred from the joint surface to the inside of the joint by heat conduction.

- the subject of the present invention is the fatigue of the inner weld toe or root that cannot be post-processed mechanically or welded due to the structure, and therefore cannot be directly exposed with a gas burner or the like even when heat treatment is performed. . Therefore, in order to retransform low temperature transformation weld metal into austenite by heat treatment, it is necessary to continue heating until heat is conducted to the low temperature transformation weld metal.

- Ni-based components First, the reason for limiting the component range of Ni-based materials will be described.

- C carbon 0.01 to 0.15% C serves to lower the Ms temperature by adding it to iron.

- the upper limit was made 0.15%.

- C when C is not added, martensite is difficult to obtain, and the residual stress must be reduced only with other expensive elements, which is not economical.

- the reason for limiting the addition to 0.01% or more of C was to use C, which is an inexpensive element, and set it as the minimum value that would bring about its economic merit.

- the upper limit of C is more preferably set to 0.10% from the viewpoint of weld metal cracking.

- Si silicon 0.2-0.8% Si is known as a deoxidizing element. Si has the effect of lowering the oxygen level of the weld metal. Especially during welding, there is a risk of air being mixed during welding, so it is extremely important to control the amount of Si to an appropriate value.

- the lower limit of Si when the Si content is less than 0.2%, the Si content of the low-temperature transformation welding material is also low. In this case, there is a risk that the deoxidizing effect is weakened, the oxygen level in the weld metal becomes too high, and mechanical properties, particularly toughness, are deteriorated. Therefore, in the present invention, the lower limit is set to 0.2%. On the other hand, excessive addition of Si also causes toughness deterioration, so the upper limit was made 0.8%.

- Mn Manganese

- Ni is austenite by itself, that is, a metal having a face-centered structure, and is an element that makes the austenite state more stable when added to the weld metal.

- Iron itself has an austenite structure at high temperatures and a ferrite or body core structure at low temperatures.

- Ni is added, the face-centered structure in the high-temperature region of iron becomes a more stable structure, so that it becomes a face-centered structure even in a lower temperature region than in the case where Ni is not added. This means that the temperature at which it transforms into a body-centered structure is lowered.

- the lower limit of Ni of 7.0% was determined in the sense of the minimum addition amount at which the residual stress reduction effect appears.

- the upper limit of 11.5% of Ni does not change much in effect from the viewpoint of reducing residual stress, and in addition to adding more than this, there is an economic disadvantage that Ni is expensive. This is because there is a risk of hot cracking.

- the lower limit of Ni is more preferably set to 8.0% in order to surely improve the fatigue strength. The above is the reason for limitation to the Ni-based essential components in the present invention.

- group other than the said essential component the following components can be selectively added as needed.

- Cu Copper

- Cu Copper

- 0.05-0.4% Cu is an effective element for improving welding workability because, when the welding material is a wire, it has the effect of improving the electrical conductivity by plating on the wire.

- excessive addition is not preferable in the industry because the effect of improving workability is saturated, and further, the wire manufacturing cost is increased.

- the upper limit of Cu of 0.4% is set for this reason.

- the lower limit of 0.05% of Cu was set as a minimum value at which the effect of improving the electrical conductivity was obtained.

- Nb niobium

- Nb carbide works to increase the strength of the base metal and the weld metal in a small amount, and therefore, the economic merit of effective use is great.

- the lower limit of Nb was set to 0.005% as the lowest value at which carbides can be formed and an effect of increasing strength can be expected.

- the upper limit of Nb is set to 0.1% because the effect of increasing the strength is saturated even if the problem of weld cracking due to a significant increase in strength and the problem of weld cracking can be avoided.

- V Vanadium

- V Vanadium

- Nb vanadium

- the lower limit of 0.01% for V addition is set as the lowest value at which precipitation hardening can be expected by addition.

- the upper limit of V is added more than this, precipitation hardening becomes too remarkable, and even if excessive addition is carried out, the improvement is saturated from the viewpoint of fatigue improvement effect, and further, excessive precipitation hardening is caused. Therefore, the problem of weld cracking occurs, so 0.5% was set.

- Ti Titanium 0.005 to 0.1% Ti, like Nb and V, forms carbides and causes precipitation hardening.

- the precipitation hardening of V is different from that of Nb

- the precipitation hardening of Ti is also different from Nb and V. Therefore, the range of the addition amount of Ti is also set to a range different from Nb and V.

- the lower limit of Ti addition amount of 0.005% is the minimum amount at which the effect can be expected, and the upper limit of Ti of 0.1% is excessively added, the fatigue strength improving effect is saturated, and excessively Since the problem of cracking also occurs due to the precipitation effect, this value was set.

- Cr chrome 0.1-3.0% Cr is a precipitation hardening element like Nb, V, and Ti.

- Cr has an effect of reducing the Ms temperature, and is therefore an element that should be used effectively.

- the Cr addition amount should be less than that of Ni. Excessive Cr addition does not necessarily improve the residual stress reduction effect and is not industrially preferable because Cr is expensive.

- the lower limit of 0.1% of the Cr addition amount was set as a minimum value at which the residual stress reduction effect was obtained by adding this.

- the upper limit of the Cr addition amount is 3.0% for the Ni type because the Ms temperature has already been reduced by the addition of Ni and the strength is secured by other precipitation elements. However, the residual stress reduction effect is not changed so much.

- Mo Molybdenum 0.1-2.0%

- Mo is an element having the same effect as Cr.

- Mo is an element for which precipitation hardening can be expected more than Cr. Therefore, the addition range was set narrower than Cr.

- the lower limit of 0.1% was set as the minimum value at which the effect of Mo addition can be expected.

- 2.0% of the upper limit of Mo was set because the fatigue strength improvement allowance would be saturated even if added more than this.

- group since the transformation start temperature is mainly achieved by Ni, it is desirable to set the minimum of the transformation start temperature of Ni type

- Si silicon 0.1-0.7% Si is known as a deoxidizing element.

- Si silicon

- the lower limit of Si when the amount of Si in the low temperature transformation weld metal is less than 0.1%, it means that the amount of Si in the low temperature transformation welding material is also low, and the deoxidation effect is diminished and the low temperature transformation. There is a risk that the oxygen level in the weld metal becomes too high, leading to degradation of mechanical properties, especially toughness. Therefore, the lower limit of the Si content of the low temperature transformation weld metal is set to 0.1%.

- the lower limit of Si is more preferably 0.30%. On the other hand, even if Si addition exceeding 0.7% is performed, the workability improvement effect is saturated, so the upper limit was made 0.7%.

- Mn Manganese 0.1-2.0%

- Mn is used as an element for increasing the strength, but in the Cr—Ni system in the present invention, the effect has already been obtained by Cr or the like. Therefore, the addition of Mn is mainly aimed at the deoxidation effect as in Si.

- the lower limit of 0.1% of Mn was set as the minimum value at which a deoxidizing effect was obtained.

- the upper limit of 2.0% was set to 2.0% because the deoxidation effect allowance would be saturated even if more additions were made.

- Ni nickel 4.0-8.0%

- Ni is a single austenite, that is, a metal having a face-centered structure. Iron itself has an austenite structure at a high temperature range and ferrite, that is, a body-centered structure at a low temperature range. When Ni is added, the face-centered structure in the high-temperature region of iron becomes a more stable structure, so that it becomes a face-centered structure even in a lower temperature region than in the case where Ni is not added. This means that the temperature at which it transforms into a body-centered structure is lowered. Moreover, Ni has the effect of improving the toughness of the weld metal by adding it.

- the lower limit of 4.0% of the addition amount of Ni in the Cr-Ni low temperature transformation weld metal was determined from the viewpoint of securing the minimum addition amount and toughness in which the residual stress reduction effect appears.

- the upper limit of the Ni addition amount is 8.0% in the case of Cr-based welding wires, since the Ms temperature is reduced to some extent by the addition of Cr described below, and from the viewpoint of reducing residual stress, the upper limit of Ni addition amount is However, the effect is not changed so much, and if it is added more than this, an economic demerit that Ni is expensive is caused, so this value was set.

- Cr Chromium

- Cr Chromium

- the upper limit of 15.0% of Cr is that when the amount exceeding this is added, the transformation temperature becomes too low and the transformation expansion amount becomes small, so that the effect of improving fatigue strength tends to decrease.

- the above is the reason for limiting the Cr—Ni-based essential components in the present invention.

- the following elements can be selectively added to the Cr—Ni system in the present invention.

- the purpose of adding the following components is not necessarily intended to improve the fatigue strength, but whether or not to add can be easily determined by those involved in welding.

- Cu Copper

- 0.05-0.4% Cu is an effective element for improving welding workability because it has the effect of improving the conductivity by plating on the low-temperature transformation welding material when it is a wire.

- the lower limit of 0.05% of Cu is that the amount of Cu plated on the wire is also lower when the Cu in the low temperature transformation weld metal is lower than this.

- the limit value was set.

- excessive addition of Cu not only has an effect of improving workability but also increases the wire manufacturing cost, which is not preferable from an industrial viewpoint.

- the upper limit of Cu of 0.4% is set for this reason.

- Nb niobium

- Nb carbide works to increase the strength of the weld metal in a small amount, and therefore, the economic merit of effective use is great.

- excessive carbide formation has an excessively high strength and causes a problem of weld cracking and deterioration of toughness.

- the lower limit of Nb was set to 0.005% as the lowest value at which carbides can be formed and an effect of increasing strength can be expected.

- the upper limit of Nb is set to 0.1% as a value that prevents the problem of cracking and does not impair the reliability of the weld due to toughness deterioration.

- V Vanadium

- V Vanadium

- the lower limit of V addition of 0.01% was set as the lowest value at which precipitation hardening can be expected by addition.

- the reason for setting the upper limit of V is the same as in the case of Nb, and if added more than this, precipitation hardening becomes excessively significant, causing toughness deterioration, and from the viewpoint of causing weld cracking due to excessive hardening, the upper limit is set to 0. 0.5%.

- Ti Titanium 0.005 to 0.1% Ti, like Nb and V, forms carbides and causes precipitation hardening.

- the range of the addition amount of Ti is also set to a range different from Nb and V.

- the lower limit of 0.005% of the Ti addition amount is determined as the minimum amount at which the effect can be expected, and the upper limit of 0.1% is determined from the viewpoint of preventing toughness deterioration and excessive weld cracking due to steel.

- Mo Molybdenum 0.1-2.0% Mo is also an element that can be expected to precipitate and harden like Nb, V, and Ti. However, Mo needs to be added more than Nb, V, Ti in order to obtain the same effect as Nb, V, Ti.

- the lower limit of 0.1% of the Mo addition amount was set as the minimum value at which an increase in yield strength due to precipitation hardening can be expected. Further, 2.0% of the upper limit of Mo is set to this value because the fatigue strength improvement allowance is saturated even if it is added more than this.

- the present invention relates to a method for improving the fatigue strength of the inner weld toe portion or the root portion where measures for improving the fatigue strength by mechanical treatment or the like cannot be implemented. Therefore, the weld toe portion on the side where welding is performed is not necessarily an object of the present invention. However, when a fatigue crack can improve the fatigue strength of one part, the fatigue strength of another part will determine the fatigue strength of the whole joint. Therefore, the inventors further improve the fatigue strength of the inner weld toe portion or the root portion on the side where the fatigue strength improvement measures cannot be implemented by mechanical or welding post-processing, and then further increase the fatigue strength of the opposite side. It was considered industrially significant to provide measures to improve the fatigue strength of parts.

- Measures to improve fatigue strength can be broadly divided into methods that reduce residual stress and methods that relieve stress concentration.

- a method for reducing the residual stress there is a method in which the entire structure is uniformly heated and then gradually cooled.

- the compressive residual stress introduced by the low-temperature transformation weld metal is lost, so even if it is a measure for improving fatigue strength, it cannot be applied without limitation.

- one or both of the outer weld toe portions 22 (42) on both sides of the weld bead on the welding side formed in the second welding step reference numerals 22a and 22b in FIGS. 1 and 2). , 42a and 42b), the shape of the outer weld toe 22 (42) subjected to the post-processing is smoother than that of the as-welded state by performing post-processing by machining such as grinder processing. It can be set as the method of performing the mechanical post-processing processed into.

- the method in which the weld toe is machined more smoothly than in the as-welded state is a method that relieves stress concentration, and does not significantly affect the residual stress introduced by the low-temperature transformation weld metal. Therefore, it is a preferable method as a fatigue strength improving method applied to the joint targeted by the present invention.

- post-processing by peening such as shot peening, ultrasonic peening, air peening, or the like on one or both of the outer weld toe portions 22 (42) on both sides of the weld bead on the side where welding is performed.

- peening such as shot peening, ultrasonic peening, air peening, or the like

- the shape of the outer weld toe portion 22 (42) subjected to the post-processing is processed more smoothly than the as-welded state, and the compressive residual stress is applied to the outer weld toe portion 22 (42).

- This can be a method of performing mechanical post-processing.

- Fatigue strength improvement measures by post-processing of peening treatment such as ultrasonic peening introduces compressive residual stress to the treated part in addition to the effect of relieving stress concentration. Bigger than the case. Further, since it does not significantly affect the residual stress introduced by the low temperature transformation weld metal, it is a preferable method as a fatigue strength improving method applied to the joint targeted by the present invention.

- this TIG welding is performed by performing TIG welding (TIG tanning welding) which does not use a filler material with respect to one or both of the outer weld toe portions 22 (42) on both sides of the weld bead. It can be set as the method of performing the post-process by welding which processes the shape of the outer side weld toe part 22 (42) which gave smooth rather than the state as-welded.

- TIG welding TIG tanning welding

- TIG tanning welding is a method of relieving the stress concentration at the weld toe, etc. by remelting the joint surface with welding arc heat without using a welding material.

- the method of applying heat to a welded joint requires caution in its use because it may eliminate the compressive residual stress introduced by the low temperature transformation weld metal.

- TIG tanning welding is preferable because it can achieve sufficient stress relaxation with a small heat input even if it is a method of applying heat, so that it can be applied to the joint targeted by the present invention. Is the method.

- welding in which one or both of the outer weld toe portions 22 (42) on both sides of the weld bead have the same component and transformation start temperature as the weld metal used in the first welding step.

- a post-process for forming a weld bead (decorative bead) that is a metal a post-process by welding is performed to introduce compressive residual stress to the outer weld toe 22 (42) subjected to the post-process.

- the method can be adopted.

- the method of forming a decorative bead on the weld toe portion on the side where welding is performed using the same welding material as that used to form the low-temperature transformation weld metal in the first welding process has a small amount of welding and a welded joint.

- This is a preferable method that can be applied to the joint that is the subject of the present invention.

- this method is a method for controlling the residual stress.

- the TIG tanning welding method for applying the same heat to the joint is a method for reducing the stress concentration, and the method for improving the fatigue strength is different.

- the TIG tanning welding method can be performed either before or after the heat treatment, but the method of forming the decorative bead needs to be performed after the heat treatment. is there. This is because if the cosmetic bead is formed before the heat treatment, the compressive residual stress formed by the cosmetic bead during the heat treatment disappears. If the decorative bead is formed before the heat treatment, it is necessary to set heat treatment conditions so that both the low temperature transformation weld metal formed during the first welding process and the weld metal of the decorative bead are retransformed to austenite. However, in this case, since the heating width becomes wide, the residual stress due to heat treatment and the risk of introducing deformation increase. Therefore, in the present invention, when adopting the heat treatment type fatigue strength improving method, it is desirable that the decorative bead is carried out after the heat treatment.

- the welded joint manufacturing method of the present invention direct mechanical processing of a structure that cannot be mechanically or post-processed by welding due to structural problems of the welded joint or the structure of the welded structure. Even if there is an inner weld toe or root that cannot be performed, the fatigue strength of the welded joint can be improved, the life of the entire welded structure can be improved, or the existing welded structure Can extend the life of the welded structure by repairing it, and it has great industrial significance.

- Example 1 is an example of a non-heating type fatigue strength improvement measure.

- a structure as shown in FIG. 4 was assembled by welding. The state of the welded portion at that time was as shown in FIG.

- the upper plate thickness in FIG. 4 was set to 6 mm.

- various welding materials were made as prototypes.

- SMAW manual welding

- GMAW carbon dioxide gas welding

- the amount of heat input was changed.

- the amount of heat input is described for the second pass SMAW.

- the second-pass welding material there are a case where the same welding material as that in the first pass is used and a case where a normal welding material, that is, a welding material having a strength level in the range of 490 MPa to 780 MPa is selected. In either case, the above conditions were adopted as the welding conditions.

- the welding conditions are limited to the above welding conditions. is not.

- the normal welding material the following components (welded metal components) were used.

- FIG. 6 is a schematic diagram showing a load application direction when a fatigue test is performed, and an arrow in FIG. 6 indicates a load application direction.

- the fatigue test was performed by a four-point bending test, and the fatigue load was measured by attaching a strain gauge to the inner weld toe of the weld metal formed in the first welding process. Note that the strain gauge was able to be attached because it was a specimen, and it is considered difficult to measure stress with the strain gauge in the case of an actual welded structure.

- Table 1 below shows the measurement results of the components and transformation start temperatures of the weld metal formed in the first welding process.

- the weld metal component was measured by collecting a specimen for component analysis directly from the formed weld metal after welding.

- the transformation start temperature is the result of measuring the transformation start temperature by taking a formaster test from the weld metal formed after welding. That is, a round bar-shaped test piece was collected from the weld metal, heated and cooled, and the length of the test piece at each temperature was measured to measure the expansion and contraction of the weld metal, thereby determining the transformation start temperature.

- numbers 1 to 14 indicate that the weld metal component and the transformation start temperature are within the scope of the present invention.

- the present invention relates to a method for improving fatigue strength

- the present invention is not necessarily an example of the present invention if the weld metal component and the transformation start temperature are within the scope of the present invention.

- the components and transformation start temperatures within the scope of the present invention are described as examples of the present invention.

- the components of the weld metal shown in Table 1 below are examples of Ni-based components in the present invention.

- Table 2 the components of the weld metal formed in the first welding step when a test body as shown in FIG. 4 was produced with a welded joint as shown in FIG.

- the transformation start temperature was indicated. 4 and 5, welded joints exist on the left and right, but the joints were produced under the same welding conditions.

- numbers 101 to 116 are weld metals within the scope of the present invention.

- the weld metal component and the transformation start temperature are It is not necessarily the case of the present invention that is within the scope of the present invention.

- the components and transformation start temperatures within the scope of the present invention are also described as examples of the present invention.

- Numbers 151 to 162 are comparative examples in the present invention. Among these, numbers 152, 155, 160, 161, and 162 are examples in which cracks and defects occurred in the weld metal, and the transformation start temperature was measured by selecting a weld metal portion in which no cracks occurred. In other comparative examples, cracks and the like are not generated, but since the composition of the weld metal is outside the scope of the present invention, the transformation start temperature is outside the scope of the present invention.

- Table 3 below shows the fatigue strength when the component type weld metals shown in Tables 1 and 2 are formed in the first welding step and a fatigue load as shown in FIG. 6 is applied.

- the fatigue strength at this time was determined as a stress range that does not break even when fatigue load was applied 2 million times.

- the stress range is a value measured by attaching a strain gauge to the test body before the fatigue test is performed in the vicinity of the weld metal side formed by the first-pass welding.

- the fatigue strength of 200 MPa means that the stress range was 0 to 200 MPa, and it did not break even after repeated loading 2 million times.

- SMAW manual welding method

- GMAW gas shield welding method

- [1] means the first welding process

- [2] means the second welding process.

- the components of the weld metal formed in the first welding process are those in Tables 1 and 2, and the weld metal numbers ([1] weld metal numbers) for the respective joints are shown in Table 3 below.

- the same welding material as that in the first welding process is not necessarily used, and a normal 590 MPa class welding material may be used.

- the welding materials (welding materials [2]) used in the second welding step for each joint are also shown in Table 3 below.

- Table 3 also shows the results of whether or not the weld metal formed in the first welding process has been retransformed to austenite by macro test observation.

- J1 to J36 in Table 3 indicate that the weld metal having the components and the transformation start temperature within the scope of the present invention is formed in the first welding step. It is a joint when it retransforms to austenite in the second welding process, and as can be seen from Table 3, the fatigue strengths all exceed 250 MPa.

- J33 to J36 are cases where the strength of the welding material used in the second welding process is different from that of J1 to J32, but because retransformation of the weld metal formed in the first welding process is achieved, It can be seen that the fatigue strength is improved.

- J101 to J111 are comparative examples, and since the transformation start temperature was outside the range of the present invention, the fatigue strength did not reach 250 MPa.

- J101, J103, J105, J108, and J109 are joints in which weld metals of numbers 53 and 55 in Table 1 and numbers 151, 156, and 157 in Table 2 are formed in the first welding process, and transformation starts.

- the temperature after the heating is lower than the range of the present invention.

- These joints are considered to be examples in which the effect of improving the fatigue strength is insufficient because the transformation start temperature is too low and a sufficient transformation expansion amount cannot be obtained.

- J102, J104, J106, J107, J110, and J111 are joints in which weld metals of numbers 54 and 58 in Table 1 and numbers 153, 154, 158, and 159 in Table 2 are formed by the first welding process.

- the transformation start temperature was higher than the range of the present invention and the residual stress reduction was insufficient.

- the four joints J112 to J115 have a second pass from the macro observation even though the transformation start temperature of the low temperature transformation weld metal formed in the first welding process is within the scope of the present invention. Since the heat input was small, it was found that the low temperature transformation weld metal was retransformed to austenite only in a part of the unmelted part in the second welding process. In this case, it is considered that the compressive residual stress introduced in the first welding process disappears and the compressive residual stress is not introduced again in the second welding process, so that the fatigue strength is not improved.

- the transformation start temperature was within the range of the present invention, but the amount of heat input in the second pass was inappropriate, and there was no unmelted portion of the weld metal formed in the first pass.

- the fatigue strength was not improved.

- the fatigue strength improvement effect was confirmed altogether and it became clear that it is industrially significant.

- Example 2 is an example relating to the heat treatment type fatigue strength improving method of the present invention.

- the heat treatment type method in this example in order to make the number of welding passes in the second welding process two, the upper plate thickness in FIG. Added pass welding.

- the total welding is a total of three passes, one pass in the first welding step and two passes in the second welding step.

- two types of induction heating and current heating were selected. Induction heating was performed at 2.0 kHz of 20 kW, and energization heating was performed by supplying a current of 250 A to the weld bead.

- Table 4 below shows the results of Example 2.

- the meanings of the welding materials [1] and [2], [1] weld metal number, and [2] of the welding method are the same as in Table 3.

- the determination of retransformation is a determination of whether or not retransformation was performed by heat treatment after the heat treatment.

- the fatigue test was implemented by the same method as Example 1, and let the stress range which was not fractured by 2 million times be the fatigue strength.

- the numbers from J201 to J230 are examples of the present invention when heat treatment was performed by induction heating using a 590 MPa class welding material in the second welding step, and the fatigue strengths all exceeded 250 MPa.

- J231 and J232 are examples of the present invention when the same welding material is used in the second welding process as in the first welding process, and it can be seen that there is an effect of improving fatigue strength.

- J232 to J235 are examples of the present invention in which electric heating is used for heat treatment, and an effect of improving fatigue strength is recognized.

- the weld metal formed in the first welding process is the same as J201, but the strength of the welding material used in the second welding process is 490 MPa and 780 MPa, which is different from J201.

- the fatigue strength exceeds 250 MPa, and this is an example in which the strength improvement effect has been confirmed.

- J301 to J315 in Table 4 are comparative examples in the present invention, and the fatigue strength does not reach 250 MPa, unlike the examples of the present invention.

- J301, J303, J305, J308, and J309 have a lower residual stress reduction because the transformation start temperature of the weld metal formed in the first welding process is lower than the range of the present invention and transformation expansion is insufficient. It is thought that it was not enough.

- J302, J304, J306, J307, J310, and J311 it is considered that the transformation start temperature of the weld metal formed in the first welding process is higher than the range of the present invention, and the residual stress reduction effect itself is small. .

- J312 to J315 have the transformation start temperature of the low temperature transformation weld metal within the range of the present invention, but the heat treatment was insufficient and only a part of the unmelted portion was retransformed to austenite. That was not possible.

- the last comparative example J316 in Table 4 is an example in which the weld metal in the first pass was completely melted by the weld in the second pass, and the unmelted portion disappeared. Therefore, the fatigue strength was not improved. It is an example. As mentioned above, in the case of this invention example, the fatigue strength improvement effect was confirmed altogether and it became clear that it is industrially significant.

- Example 3 in this invention is an example at the time of post-processing as a fatigue strength improvement measure to the outer side weld toe part of the weld metal formed at the 2nd welding process.

- Example 1 and Example 2 since the fatigue strength on the weld metal side formed in the first welding process was considered as a problem, the fatigue test was performed as shown in FIG. , And the difference was made in the stress at the weld metal toe portion formed in the first welding process and the second welding process.

- Example 3 in order to apply the same level of stress as shown in FIG. 7, the position of the inner two fulcrums in the four-point bending test was positioned outside the welded joint. The stress was measured by attaching a strain gauge.

- the arrow in FIG. 7 shows a load load direction.

- Fatigue strength improvement measures applied to the outer weld toe of the weld metal formed in the second welding process are shot peening, TIG tanning welding, ultrasonic peening, low temperature transformation weld metal formation, grinder processing, local heating It is either of stress relief by.