WO2011033916A1 - 成膜方法および記憶媒体 - Google Patents

成膜方法および記憶媒体 Download PDFInfo

- Publication number

- WO2011033916A1 WO2011033916A1 PCT/JP2010/064572 JP2010064572W WO2011033916A1 WO 2011033916 A1 WO2011033916 A1 WO 2011033916A1 JP 2010064572 W JP2010064572 W JP 2010064572W WO 2011033916 A1 WO2011033916 A1 WO 2011033916A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- film

- substrate

- plating solution

- plating

- wafer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D7/00—Electroplating characterised by the article coated

- C25D7/12—Semiconductors

- C25D7/123—Semiconductors first coated with a seed layer or a conductive layer

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D17/00—Constructional parts, or assemblies thereof, of cells for electrolytic coating

- C25D17/001—Apparatus specially adapted for electrolytic coating of wafers, e.g. semiconductors or solar cells

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D21/00—Processes for servicing or operating cells for electrolytic coating

- C25D21/12—Process control or regulation

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D3/00—Electroplating: Baths therefor

- C25D3/02—Electroplating: Baths therefor from solutions

- C25D3/38—Electroplating: Baths therefor from solutions of copper

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/18—Electroplating using modulated, pulsed or reversing current

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/34—Pretreatment of metallic surfaces to be electroplated

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/283—Deposition of conductive or insulating materials for electrodes conducting electric current

- H01L21/285—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation

- H01L21/28506—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers

- H01L21/28512—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers on semiconductor bodies comprising elements of Group IV of the Periodic Table

- H01L21/28556—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers on semiconductor bodies comprising elements of Group IV of the Periodic Table by chemical means, e.g. CVD, LPCVD, PECVD, laser CVD

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/283—Deposition of conductive or insulating materials for electrodes conducting electric current

- H01L21/288—Deposition of conductive or insulating materials for electrodes conducting electric current from a liquid, e.g. electrolytic deposition

- H01L21/2885—Deposition of conductive or insulating materials for electrodes conducting electric current from a liquid, e.g. electrolytic deposition using an external electrical current, i.e. electro-deposition

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76841—Barrier, adhesion or liner layers

- H01L21/76871—Layers specifically deposited to enhance or enable the nucleation of further layers, i.e. seed layers

- H01L21/76873—Layers specifically deposited to enhance or enable the nucleation of further layers, i.e. seed layers for electroplating

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/04—Electroplating with moving electrodes

Definitions

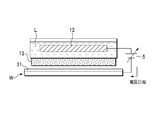

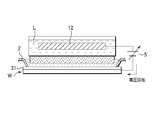

- a Co film serving as a seed layer is formed on a substrate by CVD, and the negative surface potential of the Co is lower than the oxidation potential of Co relative to the substrate. And then, with the negative voltage applied to the substrate, a plating solution mainly composed of a copper sulfate solution is immersed in the Co film, and electrolytic plating is performed on the Co film on the substrate. Forming a Cu film on the substrate.

- a DC power source 5 is connected between the wafer W serving as a cathode electrode and the anode electrode 12.

- the negative electrode of the DC power source 5 is connected to the wafer W through the electrode contact 4, and the positive electrode of the DC power source 5 is connected to the anode electrode 12.

- the DC power supply 5 has a variable output voltage.

- FIG. 2 is a flowchart for explaining a film forming method according to an embodiment of the present invention.

- the method of this embodiment is effective when the thickness of the Co film is 5 nm or less.

- the thickness of the Co film can be set in consideration of that amount. preferable. Therefore, the thickness of the Co film is preferably in the range of 1.5 to 5 nm.

- Example> A sample in which a Co film as a plating seed is formed on a substrate with a thickness of 10 nm and a sample with a thickness of 5 nm are prepared. First, without applying a voltage before immersing these samples in a plating solution A Cu film was formed by electrolytic plating. Further, for a sample on which a Co film having a thickness of 5 nm was formed, a voltage of ⁇ 20 V was applied before being immersed in the plating solution, and then a Cu film was formed by electrolytic plating.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Sustainable Development (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Chemical & Material Sciences (AREA)

- Automation & Control Theory (AREA)

- Electrodes Of Semiconductors (AREA)

- Electroplating Methods And Accessories (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/054,331 US20110174630A1 (en) | 2009-09-17 | 2010-08-27 | Film formation method and storage medium |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009-215415 | 2009-09-17 | ||

| JP2009215415A JP2011063849A (ja) | 2009-09-17 | 2009-09-17 | 成膜方法および記憶媒体 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011033916A1 true WO2011033916A1 (ja) | 2011-03-24 |

Family

ID=43758525

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2010/064572 Ceased WO2011033916A1 (ja) | 2009-09-17 | 2010-08-27 | 成膜方法および記憶媒体 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20110174630A1 (enExample) |

| JP (1) | JP2011063849A (enExample) |

| KR (1) | KR20110056455A (enExample) |

| TW (1) | TW201124564A (enExample) |

| WO (1) | WO2011033916A1 (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8858774B2 (en) | 2008-11-07 | 2014-10-14 | Novellus Systems, Inc. | Electroplating apparatus for tailored uniformity profile |

| JP5225957B2 (ja) * | 2009-09-17 | 2013-07-03 | 東京エレクトロン株式会社 | 成膜方法および記憶媒体 |

| JP5659041B2 (ja) * | 2011-02-24 | 2015-01-28 | 東京エレクトロン株式会社 | 成膜方法および記憶媒体 |

| US9909228B2 (en) | 2012-11-27 | 2018-03-06 | Lam Research Corporation | Method and apparatus for dynamic current distribution control during electroplating |

| JP6678490B2 (ja) * | 2016-03-28 | 2020-04-08 | 株式会社荏原製作所 | めっき方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000355798A (ja) * | 1999-06-15 | 2000-12-26 | Dainippon Screen Mfg Co Ltd | 基板メッキ装置 |

| JP2001123291A (ja) * | 1999-10-25 | 2001-05-08 | Hitachi Ltd | めっき方法及び装置 |

| JP2007534175A (ja) * | 2004-04-21 | 2007-11-22 | インテル・コーポレーション | 感光性誘電体層を分解することによる相互接続構造の形成 |

| JP2008007830A (ja) * | 2006-06-30 | 2008-01-17 | Fujitsu Ltd | めっき方法 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050006245A1 (en) * | 2003-07-08 | 2005-01-13 | Applied Materials, Inc. | Multiple-step electrodeposition process for direct copper plating on barrier metals |

| US20040245107A1 (en) * | 2003-06-03 | 2004-12-09 | Guangli Che | Method for improving electroplating in sub-0.1um interconnects by adjusting immersion conditions |

-

2009

- 2009-09-17 JP JP2009215415A patent/JP2011063849A/ja not_active Withdrawn

-

2010

- 2010-08-27 KR KR1020107026850A patent/KR20110056455A/ko not_active Ceased

- 2010-08-27 WO PCT/JP2010/064572 patent/WO2011033916A1/ja not_active Ceased

- 2010-08-27 US US13/054,331 patent/US20110174630A1/en not_active Abandoned

- 2010-09-16 TW TW099131353A patent/TW201124564A/zh unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000355798A (ja) * | 1999-06-15 | 2000-12-26 | Dainippon Screen Mfg Co Ltd | 基板メッキ装置 |

| JP2001123291A (ja) * | 1999-10-25 | 2001-05-08 | Hitachi Ltd | めっき方法及び装置 |

| JP2007534175A (ja) * | 2004-04-21 | 2007-11-22 | インテル・コーポレーション | 感光性誘電体層を分解することによる相互接続構造の形成 |

| JP2008007830A (ja) * | 2006-06-30 | 2008-01-17 | Fujitsu Ltd | めっき方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20110056455A (ko) | 2011-05-30 |

| US20110174630A1 (en) | 2011-07-21 |

| TW201124564A (en) | 2011-07-16 |

| JP2011063849A (ja) | 2011-03-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI404822B (zh) | Film forming method and memory media (2) | |

| EP3070191B1 (en) | Film forming apparatus for metal coating film and film forming method therefor | |

| US8377824B1 (en) | Methods and apparatus for depositing copper on tungsten | |

| TWI692552B (zh) | 電鍍設備中之電流密度的控制 | |

| US9536745B2 (en) | Tungsten film forming method | |

| JP6268008B2 (ja) | Cu配線の製造方法 | |

| TW201630036A (zh) | 用以描繪金屬氧化物還原的方法及設備 | |

| EP2200073A1 (en) | Method for forming silicide and apparatus for forming the silicide | |

| JP5208756B2 (ja) | Ti系膜の成膜方法および記憶媒体 | |

| WO2011033916A1 (ja) | 成膜方法および記憶媒体 | |

| JP2022530804A (ja) | 半導体デバイス製造における金属の電着中のシード層の保護 | |

| US20150072538A1 (en) | Method and apparatus for remote plasma treatment for reducing metal oxides on a metal seed layer | |

| JP2010065309A (ja) | Ti系膜の成膜方法および記憶媒体 | |

| US8906808B2 (en) | Etching method | |

| US20090325393A1 (en) | Heat treatment method and heat treatment apparatus | |

| JP2007043038A (ja) | 金属膜の成膜方法、成膜装置及び記憶媒体 | |

| JP7564957B2 (ja) | 基板処理方法及び基板処理装置 | |

| KR101506042B1 (ko) | 기판 무전해 도금을 위한 장치 및 방법 | |

| US20240023204A1 (en) | Coated conductor for heater embedded in ceramic | |

| JP6584326B2 (ja) | Cu配線の製造方法 | |

| US8721846B2 (en) | Method of forming film, film forming apparatus and storage medium | |

| US10508351B2 (en) | Layer-by-layer deposition using hydrogen | |

| WO2010103881A1 (ja) | Cu膜の成膜方法および記憶媒体 | |

| JP2012174845A (ja) | 成膜方法及び半導体装置の製造方法 | |

| JP2009516775A (ja) | 液晶ディスプレイ用のガラス基板上に、パターン形成された導電層を作成するための方法および装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 20107026850 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13054331 Country of ref document: US |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 10817029 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 10817029 Country of ref document: EP Kind code of ref document: A1 |