WO2011001482A1 - 蒸し機能付き製パン機 - Google Patents

蒸し機能付き製パン機 Download PDFInfo

- Publication number

- WO2011001482A1 WO2011001482A1 PCT/JP2009/006379 JP2009006379W WO2011001482A1 WO 2011001482 A1 WO2011001482 A1 WO 2011001482A1 JP 2009006379 W JP2009006379 W JP 2009006379W WO 2011001482 A1 WO2011001482 A1 WO 2011001482A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- container

- steaming

- cooking

- kneading

- steam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A21—BAKING; EDIBLE DOUGHS

- A21B—BAKERS' OVENS; MACHINES OR EQUIPMENT FOR BAKING

- A21B7/00—Baking plants

- A21B7/005—Baking plants in combination with mixing or kneading devices

Definitions

- the present invention relates to a baking machine with a steaming function generally used for home use.

- Patent Document 1 Japanese Patent Laid-Open No. 2007-275504 discloses a bread maker that generates steam (heated steam) in a cooking chamber when baking dough for the purpose of giving gloss to the outer skin of bread. Are listed.

- the bread maker of Patent Document 2 includes two cooking containers: a steaming cooking container having a steam introduction hole in the bottom wall and a bread cooking container having no steam introduction hole in the bottom wall. These cooking containers can be used properly according to the cooking purpose. Thereby, various steaming cooking is enabled besides the manufacture of bread.

- JP 2007-275504 A Japanese Patent No. 3342420

- bread that has a soft texture not only inside but also inside has become popular.

- Generally well-known bread is generally baked by applying heat from the outside and transferring the heat to the center. That is, bread is baked by applying high-temperature heat (190 ° C. to 220 ° C.) from the outside in order to transfer heat to the center. For this reason, the bread has a feature that the outer skin is baked and the outer skin is harder than the inside.

- the bread generally has an L value of 32 to 60 (color difference meter CR-300 manufactured by Konica Minolta, measured in Lab mode), and a crust thickness (hard portion of the outer skin) of 1.5 mm to 3 0 mm.

- white bread is almost white bread baked so that the outer skin is not baked or slightly attached.

- white bread generally has an L value of 60 or more (Konica Minolta color difference meter CR-300, measured in Lab mode), and crust thickness (hard portion of outer skin) of 0.2 mm to 1.5 mm.

- L value 60 or more (Konica Minolta color difference meter CR-300, measured in Lab mode)

- crust thickness hard portion of outer skin

- the first method is a method of baking at a slightly low temperature of about 170 ° C. in a short time.

- the second method is a method of baking at a low temperature of 145 ° C. to 150 ° C. until heat is transmitted to the center of the bread. In this case, however, a long firing time is required.

- Steamed bread is bread in which the dough is heated with steam and swelled to gelatinize starch.

- a bread making machine having a steaming function such as the bread making machines of Patent Documents 1 and 2 is already known.

- steamed bread cannot be manufactured. That is, the bread maker of Patent Document 1 uses steam supplementarily to give gloss or the like to the outer skin of the bread, and does not use steam for the purpose of steaming cooking.

- the bread maker of Patent Document 2 is capable of steaming cooking when a steaming cooking container having a steam introduction hole is provided on the bottom wall.

- bread dough usually has low viscosity, the dough will come out of the container through the steam introduction hole. Therefore, in the bread maker of patent document 2, bread dough cannot be steamed and cooked.

- an object of the present invention is to solve the above-mentioned problem, and to provide a bread maker with a steaming function that can produce soft bread not only in the inside but also in the outer skin such as white bread or steamed bread. is there.

- the inventors of the present invention have found the following as a result of intensive studies in order to solve the problems of the prior art. That is, the inventors of the present invention use steam as a main heating source, and the steam enters into the dough, and heat is efficiently transferred into the dough as compared with the case where the container is directly heated using a heater. I found out. That is, by efficiently transferring heat into the dough, the temperature of the steam can be set to a low temperature so that the outer skin of the bread is not baked, so that the outer skin such as white bread or steamed bread can be It has been found that soft bread can be produced. Based on this finding, the present invention has been conceived.

- a bottomed cylindrical device main body provided with a heating chamber inside, An outer lid capable of opening and closing the upper opening of the device body;

- a kneading container for storing cooking ingredients and storing steaming cooking water stored in the heating chamber;

- a kneading blade arranged in the kneading container, for kneading the cooking material in the kneading container;

- a drive unit for rotationally driving the kneading blade;

- a steam cooking container that is smaller in size than the kneading container and can contain cooking materials kneaded in the kneading container,

- a heating unit for heating the kneading container;

- a temperature detector for detecting the temperature in the heating chamber;

- a selection unit capable of selecting a specific cooking course from a plurality of cooking courses;

- a control unit for controlling the heating unit and the driving unit based on the cooking course selected by

- the bread maker with a steaming function according to the first aspect, wherein a steam introduction through hole is not provided in a bottom wall of the steam cooking container.

- the steam cooking container is formed such that the steam passage gap has a substantially uniform width in the supported state.

- a bread maker with the described steaming function is provided.

- the steam cooking container is formed so that a bottom wall thereof does not contact the kneading blade in the supported state.

- a bread maker with a steaming function described in 1. is provided.

- the supported member that is in contact with the upper end of the kneading container when supported is a heat insulating member.

- the supported member has a steaming function according to the fifth aspect, wherein a tapered portion is formed so that the steaming cooking container is positioned without backlash. Provide bread making machine.

- the steaming cooking container has a flange portion around the upper end portion, and the supported member is provided in at least two places on the lower surface of the flange portion.

- a bread maker with a steaming function according to the sixth aspect is provided.

- the bread maker with a steaming function according to the seventh aspect, wherein a steam introduction through hole is provided in a side wall of the steam cooking container.

- the steam introduction through hole is provided above a predetermined upper end position of the cooked food steamed in the steaming cooking container.

- the bread maker with a steaming function according to the eighth or ninth aspect, wherein the steam introducing through hole is provided in the vicinity of the flange portion.

- the bread maker with a steaming function according to any one of the seventh to tenth aspects, wherein an outer diameter of the flange portion is larger than a diameter of an upper opening of the kneading container.

- the steam-functionalized product according to any one of the first to eleventh aspects, wherein the kneading container cannot be removed unless the steaming container is removed.

- the steam-functionalized product according to any one of the first to eleventh aspects, wherein the kneading container cannot be removed unless the steaming container is removed.

- the kneading container comprises: A handle mounting portion that protrudes above the upper opening of the kneading container and supports the supported member; A handle rotatably attached to the handle attachment portion, When the said steaming container is supported, the said handle is located between the said flange part and the upper end part of the said kneading container,

- the bread maker with a steaming function as described in a 12th aspect is provided.

- the steaming cooking container when the steaming cooking container is supported above the bottom surface of the kneading container, between the side wall of the steaming cooking container and the side wall of the kneading container. A gap for passing steam is formed over the entire circumference. Accordingly, when the kneading container containing water is heated in the state where the steaming cooking container is supported, the steam generated in the kneading container is discharged into the heating chamber through the gap for passing the steam. It will be. That is, when the steam generated in the kneading container passes through the gap for passing steam, the steam cooking container can be uniformly heated by the steam.

- the heat of the steam can be efficiently transmitted to the steaming container, so that the temperature of the steam can be lowered to a temperature at which the outer skin is not colored.

- the bread dough in the said steaming cooking container can be heated from the upper surface side with the vapor

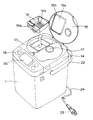

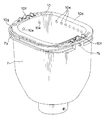

- FIG. 1 is a longitudinal sectional view of a bread maker with a steaming function according to an embodiment of the present invention

- FIG. 2 is a perspective view of a bread maker with a steaming function according to an embodiment of the present invention

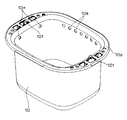

- FIG. 3 is a perspective view of a steam cooking container provided in the bread maker with the steaming function of

- FIG. 4 is a partially enlarged view of the steaming cooking container of FIG.

- FIG. 5 is a partially enlarged view of the steaming cooking container of FIG.

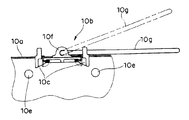

- FIG. 6 is a perspective view showing a state where the steaming cooking container of FIG.

- FIG. 3 is set in a kneading container

- FIG. 7 is a longitudinal sectional view showing a state where the steaming cooking container is removed from the bread maker with the steaming function of FIG.

- FIG. 8 is a graph showing the temperature change of the steam cooking container after the shaping fermentation process.

- FIG. 1 is a longitudinal sectional view of a bread maker with a steaming function according to an embodiment of the present invention

- FIG. 2 is a perspective view thereof

- FIG. 3 is a perspective view of a steaming container provided in the bread maker with the steaming function of FIG. 1, and FIGS. 4 and 5 are partially enlarged views thereof.

- FIG. 6 is a perspective view showing a state where the steaming cooking container of FIG. 3 is set in a kneading container.

- the bread maker according to the present embodiment includes a bottomed cylindrical resin main body 1 having a heating chamber 1a therein.

- a chassis 2 is attached to the lower part of the device main body 1.

- a motor 3, which is an example of a drive unit, and a container support 4 are attached to the chassis 2.

- the motor 3 applies a rotational force to the lower connector 6 supported rotatably on the container support 4 via a transmission mechanism 5 including a pulley and a belt.

- the lower connector 6 is configured to be able to engage with an upper connector 8 rotatably supported at the lower portion of the kneading container 7.

- the kneading container 7 is a detachable container that is accommodated in the heating chamber 1a and accommodates cooking materials such as bread, cakes, and rice cakes.

- the kneading container 7 is also a container in which water for steaming cooked food such as bread dough is placed.

- the kneading container 7 also functions as a steam generating section that generates steam by being heated by a heater 11 described later in a state where water is added.

- the kneading container 7 is configured so that water does not leak.

- the kneading container 7 is attached on the container support 4 by engaging the lower connector 6 and the upper connector 8, while the heating chamber is removed by disengaging the lower connector 6 and the upper connector 8. It is removable from 1a.

- the top 8 of the connector is attached so as to protrude upward from the bottom wall of the kneading container 7.

- a kneading blade 9 for kneading the cooking material accommodated in the kneading container 7 is detachably attached to the tip of the connector upper 8. The kneading blade 9 is driven to rotate when the rotational force of the motor 3 is transmitted to the transmission mechanism 5 and the lower connector 6 and the upper connector 8 rotate.

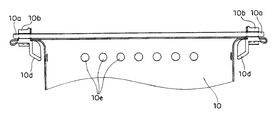

- These handle attachment portions 7a are provided with through holes, and a substantially semicircular handle 7b is rotatably attached to the through holes. Thereby, attachment / detachment and carrying of the kneading container 7 are facilitated.

- the handle attaching portion 7a also has a function of detachably supporting the steam cooking container 10.

- the steaming cooking container 10 is a container for storing steamed food, and is a container for producing a soft bread not only in the interior of white bread or steamed bread but also in the outer skin. As shown in FIG. 1, the steam cooking container 10 is formed to be smaller in size than the kneading container 7. For example, when the kneading container 7 has a size capable of producing 1 ⁇ size bread, the steaming container 10 is formed to a size capable of producing 0.5 ⁇ size bread.

- the container 10 for steam cooking is comprised so that a bottom wall may not touch the kneading blade 9. FIG. Thereby, the trouble of removing the kneading blade 9 can be eliminated when the steam cooking container 10 is attached.

- the bottom wall of the steam cooking container 10 is not provided with a through-hole so that dough does not fall out and steam cooking water does not leak.

- a flange portion 10a Around the upper end portion of the steaming cooking container 10 is provided a flange portion 10a that projects radially outward.

- a supported member 10b is attached to the flange portion 10a at a position corresponding to the handle attachment portion 7a.

- the supported member 10b is composed of a heat insulating member such as a resin. Accordingly, as shown in FIGS. 1 and 6, when the steaming container 10 is set above the kneading container 7, the heat of the kneading container 7 is not transmitted to the steaming container 10. That is, the steam cooking container 10 is heated mainly by steam (heated steam) generated in the kneading container 7.

- the tapered member 10b is provided with a tapered portion.

- the tapered portion is composed of a first tapered portion 10c shown in FIG. 4 and a second tapered portion 10d shown in FIG.

- the 1st taper-shaped part 10c is provided with two inclined surfaces which incline so that it may mutually approach as it approaches the flange part 10a.

- the second tapered portion 10d includes two inclined surfaces that are orthogonal to the two inclined surfaces of the first tapered portion 10c and are inclined so as to approach the side wall of the steaming vessel 10 as the distance from the flange portion 10a increases. As shown in FIG.

- the handle attachment portion 7a slides on the first and second tapered portions 10c, 10d. .

- the steam cooking container 10 is positioned in a state in which a steam passage gap 30 is left between the steam cooking container 10 and the kneading container 7. Vapor generated by boiling water in the kneading vessel 7 is released from the kneading vessel 7 into the heating chamber 1 a through the gap 30.

- the clearance gap 30 is formed in the uniform width

- One or more steam introduction through-holes 10e are provided on the side wall of the steam cooking container 10.

- the steam generated in the kneading container 7 is introduced into the steaming cooking container 10 through the steam introducing through hole 10e.

- the diameter of the outer periphery of the flange portion 10 a is designed to be larger than the diameter of the upper opening of the kneading container 7. Accordingly, the steam generated in the kneading container 7 is prevented from linearly moving from the gap 30 into the heating chamber 1a, and the steam is easily introduced into the steaming and cooking container 10 through the steam introducing through hole 10d.

- the steam introducing through hole 10d is preferably disposed in the vicinity of the flange portion 10a.

- the through-hole 10e for steam introduction is provided in a position higher than the upper-end planned position of the cooked food after cooking cooked in the steaming cooking container 10. Thereby, steam can be efficiently supplied to the upper surface of the food.

- the through-hole 10e for steam introduction is provided at a position lower than the upper end of the cooked product, the through-hole 10e for steam introduction is blocked by the cooked product during cooking.

- Two handle attachment portions 10f are provided on the upper portion of the steaming cooking container 10.

- a handle 10g having a substantially semicircular arc shape is rotatably attached to these handle attachment portions 10f. Thereby, attachment / detachment and carrying of the steaming container 10 are facilitated.

- the kneading container 7 is not removable from the container support 4 unless the steam cooking container 10 is removed.

- the handle 7b of the kneading container 7 is positioned below the flange portion 10a in a state where the steam cooking container 10 is supported by the handle attachment portion 7a as shown in FIG. ing. Thereby, the danger of a burn can be suppressed.

- the heating chamber 1a is provided with a heater 11 that is an example of a heating unit that heats the kneading container 7, and a temperature sensor 12 that is an example of a temperature detection unit that detects the temperature in the heating chamber 1a.

- the heater 11 is arrange

- a sheathed heater can be used.

- the temperature sensor 12 is arranged at a position slightly away from the heater 11 so that the average temperature in the heating chamber 1a can be detected.

- a lid 13 that can open and close the upper opening of the device main body 1 is rotatably attached to the upper portion of the device main body 1.

- the lid 13 includes a lid body 14 and an outer lid 15.

- the lid body 14 is provided with a secondary material container 16 for storing secondary materials such as raisins and nuts, and a yeast container 17 for storing yeast.

- the auxiliary material container 16 and the yeast container 17 are disposed above the kneading container 7.

- the secondary material container 16 is configured to be detachable and includes a concave knob portion 16a for easy attachment / detachment.

- the bottom wall of the secondary material container 16 is rotatably attached to the bottom wall 14a of the lid body 14 so that the secondary material stored in the secondary material container 16 can be put into the kneading container 7. It is composed of an opening / closing plate 16b.

- the opening / closing plate 16b is connected to the solenoid 18 and is opened when the solenoid 18 is driven.

- the bottom wall of the yeast container 17 is open / close attached to the bottom wall 14a of the lid body 14 so that the yeast contained in the yeast container 17 can be put into the kneading container 7.

- the on-off valve 17a is connected to a solenoid (not shown) and is opened when the solenoid is driven.

- the outer lid 15 is attached so that the upper openings of the auxiliary material container 16 and the yeast container 17 can be opened and closed.

- a secondary material container lid 15 a made of a heat insulating member such as resin is attached at a position corresponding to the secondary material container 16 of the outer lid 15.

- a packing 15b is attached to the outer peripheral portion of the auxiliary material container lid 15a.

- a selection unit 19 that can select a specific cooking course from a plurality of cooking courses, a display unit 20 that displays various information such as information selected by the selection unit 19, and a room temperature are detected.

- a room temperature sensor 21 is provided.

- the selection unit 19 is configured to be able to start or stop various operations, set a timer, and the like.

- the cooking course includes, for example, steamed cooking courses such as a white bread course and a steamed bread course, a bread course, a pizza dough course, a udon course, a pasta course, and the like.

- the device main body 1 controls a handle 22 for facilitating carrying of the bread maker, a power cord 24 having a plug 23 at the tip, and driving of each part.

- a control unit 25 is provided.

- the control unit 25 stores cooking sequences corresponding to a plurality of cooking courses.

- the cooking sequence refers to the heating time of the heater 11, the temperature control temperature, the rotation speed of the kneading blade 9, the drive timing of the solenoid, etc. in each cooking process in order for each cooking process such as kneading, kneading, fermentation, and baking. This is a predetermined cooking procedure program.

- control unit 25 Based on the cooking sequence corresponding to the specific cooking course selected by the selection unit 19 and the temperature detected by the temperature sensor 8, the control unit 25 opens the motor 3, the heater 7, the solenoid 18 that opens the opening / closing plate 18, and Controls driving of a solenoid (not shown) that opens the on-off valve.

- the user attaches the kneading blade 9 to the connector 8 and puts all bread ingredients except yeast, such as flour, sugar, salt, skim milk, and water, into the kneading container 7. Thereafter, the kneading container 7 is set on the container support 4 and the lid 13 is closed. At this time, as shown in FIG. 7, the steam cooking container 10 is not set above the kneading container 7.

- yeast such as flour, sugar, salt, skim milk, and water

- the user opens the outer lid 15, puts the yeast in the yeast container 17, and attaches the auxiliary material container 16 containing auxiliary materials such as raisins and nuts to the lid body 14 according to the user's preference. Thereafter, the outer lid 15 is closed.

- the user instructs the start of cooking by pressing a start button provided on the selection unit 19. From this, the pre-kneading process which kneads the bread material in the kneading container 7 by rotation of the kneading blade 9 starts.

- the kneading blade 9 is rotated again to start the post-kneading process in which the bread dough in the kneading container 7 is kneaded.

- the yeast is uniformly kneaded into the bread dough.

- the solenoid (not shown) which opens the opening-and-closing plate 16b several minutes before completion

- the process proceeds to the first fermentation process.

- the dough is fermented by this first fermentation step.

- the fact that the first fermentation process is completed is displayed on the display unit or the user is notified by sounding a notification sound or the like.

- the user opens the lid 13 and removes the kneading container 7 from the container support 4.

- the user takes out the bread dough that has undergone the first fermentation step from the kneading container 7 and performs degassing, and then shapes the bread dough as appropriate and transfers it to the steaming cooking container 10.

- the user attaches the kneading container 7 again to the container support 4 and puts a predetermined amount (for example, 60 ml) of water into the kneading container 7.

- the user suspends the steaming cooking container 10 containing the bread dough on the handle attaching portion 7 a of the kneading container 7.

- the steam cooking container 10 is provided with the first and second tapered portions 10c and 10d in the held portion 10b, the steam cooking container 10 is positioned without rattling at an appropriate position. The Thereby, a gap 30 for passing steam is formed between the kneading container 7 and the steaming cooking container 10.

- FIG. 8 is a graph showing the temperature change of the steam cooking container 10 after the shaping fermentation process.

- the user instructs the start of the shaping fermentation process, but there may be a case where the user is not aware of a display or notification sound informing that the first fermentation process has been completed. If the bread dough which passed through the 1st fermentation process is left for a long time, it will have a bad influence on taste and how to swell. For this reason, you may make it start a shaping

- the forming fermentation process is a process in which bread dough degassed by forming is expanded again into a sponge shape.

- the shaping fermentation process is also a process for increasing the temperature of the bread dough, increasing the activity of yeast, and allowing the baking process to be started in a state with the highest activity.

- This shaping fermentation process the extensibility of bread dough by fermentation action is increased, and aroma is generated.

- This shaped fermentation process is preferably performed for 30 to 60 minutes, and more preferably for 40 to 50 minutes.

- the process proceeds to the firing process.

- the steam cooking container 10 is heated to a temperature T (120 ° C. to 125 ° C.) determined in advance corresponding to the white bread course by the steam generated in the kneading container 7 by heating by the heater 11.

- T a temperature maintaining process

- the time for this temperature maintaining step varies depending on the amount of cooked food and the like, but is, for example, 5 to 55 minutes, preferably 15 to 30 minutes.

- the process proceeds to a drying process in which the temperature of the steaming cooking container 10 is higher than the predetermined temperature T.

- the predetermined temperature T is set to 120 ° C.

- the temperature of the steaming container 10 is set to 130 ° C.

- the time for this drying step varies depending on the amount of cooked food, etc., but is, for example, 1 to 10 minutes, preferably 5 minutes.

- the temperature of the steaming cooking container 10 can be made higher than the predetermined temperature T by, for example, completely evaporating the water in the kneading container 7. That is, what is necessary is just to adjust the quantity of the water put in the kneading container 7 so that the water in the kneading container 7 may evaporate completely after predetermined time progress.

- the user kneads all steamed bread ingredients and puts them in the steaming container 10.

- the user attaches the kneading container 7 onto the container support 4 and puts a predetermined amount (for example, 100 ml) of water into the kneading container 7.

- the user suspends the steaming cooking container 10 on the handle attaching portion 7 a of the kneading container 7.

- the steam cooking container 10 is provided with the first and second tapered portions 10c and 10d in the held portion 10b, the steam cooking container 10 is positioned without rattling.

- a gap 30 for passing steam is formed between the kneading container 7 and the steaming cooking container 10.

- the user instructs the start of cooking by selecting a steamed bread course from a plurality of cooking courses at the selection unit 19 and then pressing a start button provided on the selection unit 19. Thereby, the baking process of steamed bread is started.

- the steam cooking container 10 is heated to the temperature T1 (120 ° C. to 125 ° C.) determined in advance corresponding to the steamed bread course by the steam generated in the kneading container 7 by heating by the heater 11.

- T1 the temperature of the steaming container 10

- a temperature maintaining step is performed in which the temperature T1 is maintained for a predetermined time (for example, 23 to 25 minutes) corresponding to the steamed bread course.

- the time for this temperature maintaining step varies depending on the amount of cooked food and the like, but is, for example, 5 to 60 minutes, preferably 15 to 35 minutes. Thereby, steamed bread can be manufactured.

- steamed bread unlike white bread, does not need to be dried. For this reason, the drying process which makes the temperature of the container 10 for steam cooking higher than the predetermined temperature T is not performed.

- the amount of water is higher than that in the case of manufacturing the white bread so that the water put into the kneading container 7 does not completely evaporate. Should be increased (for example, 100 ml). Further, the heating temperature of the kneading container 7 by the heater 11 may be adjusted.

- the time for the baking process should be set according to the desired degree of steaming. Can do. For example, for white bread, the total time required for the baking process is 20 to 55 minutes (preferably 30 to 40 minutes), whereas for steamed bread, the total time required for the baking process is 20 to 80 minutes (preferably 30 to 60 minutes).

- the bread maker with the steaming function when the white bread course and the steamed bread course are selected by the selection unit 19, the cooked food is heated by the steam generated from the kneading vessel 7

- the temperature maintaining step is performed after the temperature of the steam cooking container 10 containing the temperature rises to 120 ° C. to 125 ° C. That is, the bread maker with the steaming function according to the first embodiment is configured to steam (cook) the steamed food at a low temperature so that the outer skin is not baked with steam as a main heating source. Has been. As a result, a bread having a soft outer skin such as white bread or steamed bread can be produced.

- the steaming cooking container 10 when the steaming cooking container 10 is suspended from the kneading container 7, the steaming cooking container 10 is placed between the side wall of the steaming cooking container 10 and the side wall of the kneading container 7. Since the steam passage gap 30 is formed over the entire circumference, the steam generated in the kneading vessel 7 is released into the heating chamber 1 a through the gap 30. That is, the steam generated in the kneading container 7 passes through the gap 30, whereby the entire steaming cooking container 10 can be heated without unevenness.

- the heat of steam can be efficiently transmitted to the steaming container 10, so that the temperature of the steam can be lowered to a temperature that does not cause the outer skin to be colored (140 ° C. or lower). become.

- the upper surface of the bread dough in the steaming cooking container 10 can be heated by the steam released into the heating chamber 1a. Since this steam can penetrate into the dough and can be heated efficiently, white bread or steamed bread can be produced at a low temperature (140 ° C. or less) that does not cause the outer skin to be colored. it can.

- 0.5 ⁇ size white bread can be produced in a baking time of about 30 minutes to 40 minutes, and baking is performed for about 30 minutes to 60 minutes. It is possible to produce steamed bread with a size of 0.5 kg per hour.

- the container containing the dough is directly heated by the heater 11 set at 120 ° C. to 125 ° C., even if the dough is baked for 70 minutes or more, the heat can be sufficiently transferred into the dough. could not.

- the temperatures T and T1 of the steaming container 10 are set to 120 ° C. to 125 ° C. in the baking step, but the present invention is not limited to this.

- the temperatures T and T1 may be in the range of 105 ° C to 140 ° C. When the temperatures T and T1 are higher than 140 ° C., it is difficult to prevent the bread hull from becoming baked. More preferably, the temperatures T and T1 are set to 135 ° C. or less. Thereby, it is possible to further suppress the possibility that the outer skin of the bread will be baked.

- the baking temperature When white bread is produced by a conventional baking method in which heat is applied from the outside, it is practically impossible to set the baking temperature to 135 ° C. or lower. Even if heat can be transferred into the dough by making the baking time very long, in this case, the outer skin is excessively dried, and the taste is significantly deteriorated.

- the temperatures T and T1 are lower than 105 ° C., there is a risk that sufficient heat will not be transmitted to the dough, resulting in raw burning, and a long baking time is required. More preferably, the temperatures T and T1 are 115 ° C. to 125 ° C. This can more reliably suppress the possibility that the outer skin of the bread will be baked, and the baking time can also be shortened.

- the steam cooking container 10 is configured to be suspended on the two handle attachment portions 7a and 7a of the kneading container 7, but the present invention is not limited to this.

- a support portion that protrudes toward the center of the heating chamber 1 a may be provided in the main body 1, and the steaming container 10 may be supported by the support portion.

- the gap 30 may be formed. That is, it is sufficient that the gap 30 is formed when the steaming cooking container 10 is supported above the bottom surface (inner bottom surface) of the kneading container 7.

- the bread maker with a steaming function according to the present invention can produce soft bread not only in the inside but also in the outer skin, such as white bread or steamed bread, especially as a bread maker generally used for home use. Useful.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Baking, Grill, Roasting (AREA)

- Manufacturing And Processing Devices For Dough (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200980160233.5A CN102469892B (zh) | 2009-07-03 | 2009-11-26 | 带蒸制功能的制面包机 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009158475A JP5260421B2 (ja) | 2009-07-03 | 2009-07-03 | 蒸し機能付き製パン機 |

| JP2009-158475 | 2009-07-03 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011001482A1 true WO2011001482A1 (ja) | 2011-01-06 |

Family

ID=43410583

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2009/006379 Ceased WO2011001482A1 (ja) | 2009-07-03 | 2009-11-26 | 蒸し機能付き製パン機 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP5260421B2 (enExample) |

| CN (1) | CN102469892B (enExample) |

| WO (1) | WO2011001482A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103784031A (zh) * | 2014-01-14 | 2014-05-14 | 周武轩 | 一种面食加工机 |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5810325B2 (ja) * | 2011-02-17 | 2015-11-11 | パナソニックIpマネジメント株式会社 | 自動製パン機 |

| JP5909642B2 (ja) * | 2011-10-21 | 2016-04-27 | パナソニックIpマネジメント株式会社 | 自動製パン機 |

| CN203074360U (zh) * | 2012-08-10 | 2013-07-24 | 浙江绍兴苏泊尔生活电器有限公司 | 一种面包机 |

| CN103040379B (zh) * | 2012-11-02 | 2015-09-16 | 九阳股份有限公司 | 一种馒头机 |

| CN103169370B (zh) * | 2013-02-20 | 2015-05-13 | 青岛澳柯玛生活电器有限公司 | 面包馒头一体机 |

| CN103300743B (zh) * | 2013-05-10 | 2016-12-28 | 浙江绍兴苏泊尔生活电器有限公司 | 一种多功能面包机及应用多功能面包机制作蒸制品的方法 |

| CN103462524B (zh) * | 2013-07-09 | 2016-03-09 | 深圳市润唐智能生活电器有限公司 | 面包机和做面包的设备 |

| CN103330510B (zh) * | 2013-07-11 | 2015-08-19 | 中山市美斯特实业有限公司 | 一种面包馒头加工机 |

| CN103330499B (zh) * | 2013-07-11 | 2016-01-13 | 中山市美斯特实业有限公司 | 一种面包馒头多功能加工机 |

| CN103330498B (zh) * | 2013-07-11 | 2015-08-19 | 中山市美斯特实业有限公司 | 一种面包馒头两用机 |

| CN103637704B (zh) * | 2013-12-06 | 2015-11-25 | 朱幕松 | 密封式全自动面包馒头机 |

| CN103720376B (zh) * | 2014-01-20 | 2016-05-04 | 广东伊莱特电器有限公司 | 一种面包机 |

| CN104106606B (zh) * | 2014-05-30 | 2016-05-18 | 李怀宗 | 面团排气搓实机 |

| CN104146618B (zh) * | 2014-08-12 | 2016-06-01 | 青岛澳柯玛生活电器有限公司 | 一种馒头桶 |

| CN104171883A (zh) * | 2014-09-09 | 2014-12-03 | 青岛澳柯玛生活电器有限公司 | 馒头制作方法和馒头机 |

| JP2022127005A (ja) * | 2021-02-19 | 2022-08-31 | パナソニックIpマネジメント株式会社 | 製パン機 |

| CN114451776B (zh) * | 2022-02-28 | 2023-03-21 | 广东美的厨房电器制造有限公司 | 面食的制作方法、装置、可读存储介质和烹饪设备 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59181069U (ja) * | 1983-05-20 | 1984-12-03 | 株式会社 フレツク | 蒸し器兼用容器 |

| JPH03133339A (ja) * | 1989-10-17 | 1991-06-06 | Samsung Electron Co Ltd | 全自動蒸しパン器 |

| JPH059432U (ja) * | 1991-07-19 | 1993-02-09 | 株式会社日立ホームテツク | 自動製パン機 |

| JPH0518422U (ja) * | 1991-07-15 | 1993-03-09 | 株式会社アイク | 電磁調理テーブル用調理容器 |

| JP3342420B2 (ja) * | 1998-09-18 | 2002-11-11 | 三洋電機株式会社 | 調理器 |

| JP2003319876A (ja) * | 2002-05-07 | 2003-11-11 | Minami Sangyo Kk | 卓上万能調理容器 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2036385U (zh) * | 1988-06-24 | 1989-04-26 | 白祺荪 | 多用蒸煮锅 |

| US6029563A (en) * | 1998-09-18 | 2000-02-29 | Sanyo Electric Co., Ltd. | Cooking machine |

| CA2341866A1 (en) * | 1999-06-29 | 2001-01-04 | Toshikatsu Maeda | Automatic bread maker |

| CN2509962Y (zh) * | 2001-12-04 | 2002-09-11 | 傅荣顺 | 蒸汽炊饭锅 |

-

2009

- 2009-07-03 JP JP2009158475A patent/JP5260421B2/ja active Active

- 2009-11-26 CN CN200980160233.5A patent/CN102469892B/zh not_active Expired - Fee Related

- 2009-11-26 WO PCT/JP2009/006379 patent/WO2011001482A1/ja not_active Ceased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59181069U (ja) * | 1983-05-20 | 1984-12-03 | 株式会社 フレツク | 蒸し器兼用容器 |

| JPH03133339A (ja) * | 1989-10-17 | 1991-06-06 | Samsung Electron Co Ltd | 全自動蒸しパン器 |

| JPH0518422U (ja) * | 1991-07-15 | 1993-03-09 | 株式会社アイク | 電磁調理テーブル用調理容器 |

| JPH059432U (ja) * | 1991-07-19 | 1993-02-09 | 株式会社日立ホームテツク | 自動製パン機 |

| JP3342420B2 (ja) * | 1998-09-18 | 2002-11-11 | 三洋電機株式会社 | 調理器 |

| JP2003319876A (ja) * | 2002-05-07 | 2003-11-11 | Minami Sangyo Kk | 卓上万能調理容器 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103784031A (zh) * | 2014-01-14 | 2014-05-14 | 周武轩 | 一种面食加工机 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102469892B (zh) | 2015-09-02 |

| JP5260421B2 (ja) | 2013-08-14 |

| JP2011010910A (ja) | 2011-01-20 |

| CN102469892A (zh) | 2012-05-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5260421B2 (ja) | 蒸し機能付き製パン機 | |

| JP3851623B2 (ja) | 自動製パン器 | |

| US5967020A (en) | Automatic bread maker | |

| JP3998062B2 (ja) | 自動製パン器およびそれを利用したパンの製造方法 | |

| WO2014162743A1 (ja) | 加熱調理器 | |

| JP5909677B2 (ja) | 自動製パン機 | |

| JP6128446B2 (ja) | 自動製パン機 | |

| CN202801319U (zh) | 自动制面包机 | |

| JP2012024323A (ja) | 蒸し機能付き製パン機 | |

| JP2019092995A (ja) | 加熱調理器 | |

| JP5409146B2 (ja) | 蒸し機能付き製パン機 | |

| JP6436334B2 (ja) | 自動製パン器 | |

| JP5316323B2 (ja) | 蒸し機能付き製パン機 | |

| JP2011050563A (ja) | 蒸し機能付き製パン機 | |

| JP2002051920A (ja) | 卓上型調理器 | |

| JP6091384B2 (ja) | 調理器 | |

| JP2014087388A (ja) | 自動製パン機 | |

| JP6136056B2 (ja) | 自動製パン機 | |

| JP2012016424A (ja) | 自動製パン機 | |

| JP4383233B2 (ja) | 自動製パン器 | |

| JP2014184093A (ja) | 製パン機 | |

| US20240315260A1 (en) | Locking mechanism for bread machine | |

| JP4222959B2 (ja) | 自動製パン器 | |

| JP2022155166A (ja) | 家庭用製パン器 | |

| JP6478944B2 (ja) | 自動製パン機 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 200980160233.5 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 09846776 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE1 | Request for preliminary examination filed after expiration of 19th month from priority date (pct application filed from 20040101) | ||

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 09846776 Country of ref document: EP Kind code of ref document: A1 |