WO2010055943A1 - 磁性不感高硬度恒弾性合金及びその製造法、並びにひげぜんまい、機械式駆動装置及び時計 - Google Patents

磁性不感高硬度恒弾性合金及びその製造法、並びにひげぜんまい、機械式駆動装置及び時計 Download PDFInfo

- Publication number

- WO2010055943A1 WO2010055943A1 PCT/JP2009/069458 JP2009069458W WO2010055943A1 WO 2010055943 A1 WO2010055943 A1 WO 2010055943A1 JP 2009069458 W JP2009069458 W JP 2009069458W WO 2010055943 A1 WO2010055943 A1 WO 2010055943A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- alloy

- wire

- modulus

- temperature

- young

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/52—Ferrous alloys, e.g. steel alloys containing chromium with nickel with cobalt

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/004—Heat treatment of ferrous alloys containing Cr and Ni

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/007—Heat treatment of ferrous alloys containing Co

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0236—Cold rolling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0242—Flattening; Dressing; Flexing

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

- C21D8/0273—Final recrystallisation annealing

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/06—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of rods or wires

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/12—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of articles with special electromagnetic properties

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/0075—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for rods of limited length

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/02—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for springs

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/07—Alloys based on nickel or cobalt based on cobalt

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C30/00—Alloys containing less than 50% by weight of each constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/10—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of nickel or cobalt or alloys based thereon

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B17/00—Mechanisms for stabilising frequency

- G04B17/04—Oscillators acting by spring tension

- G04B17/06—Oscillators with hairsprings, e.g. balance

- G04B17/066—Manufacture of the spiral spring

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B43/00—Protecting clockworks by shields or other means against external influences, e.g. magnetic fields

- G04B43/007—Antimagnetic alloys

Definitions

- the present invention relates to a constant elastic alloy. More specifically, the present invention relates to a Fe-Co-Ni-Cr-Mo-based constant elastic alloy, a balance spring made of the alloy, and a mechanical drive including the balance spring.

- the present invention relates to a device and a timepiece incorporating the mechanical drive device.

- the present invention relates to a Fe—Co—Ni—Cr—Mo-based constant elastic alloy having magnetic insensitivity and impact resistance.

- Patent Document 1 Japanese Patent Publication No. 31-10507 relates to a Fe—Co—Ni—Cr—Mo—W-based constant elastic alloy, whose composition is 8 to 68% Fe by weight, 1 to 75% Co. , 0.1 to 50% Ni and 0.01 to 20% Cr as main components, and further containing 2 to 20% W and 2 to 20% Mo.

- the manufacturing method involves casting a molten alloy, forging the ingot, drawing or rolling at room temperature or high temperature according to the application to obtain the required shape, annealing at 500 to 1100 ° C, and then slow cooling. It is. Alternatively, it can be processed at room temperature after annealing, then heated to 750 ° C. or lower and gradually cooled, and / or the ingot can be quenched from a high temperature. Therefore, the intermediate heat treatment after the drawing process is not described.

- Non-Patent Document 1 “Anisotropy of Elastic Modulus and Temperature Change of High Elastic Alloy“ Dia-flex ”Single Crystal”, Journal of the Japan Institute of Metals, Vol. 31, No. 3 (1967), p.263-268 Composition of 22.4% Fe, 38.0% Co, 16.5% Ni, 12.0% Cr, 4.0% Mo, 4.0% W, 1.2% Mn, 1.0% Ti and 0.8% Si included in the composition range of 1 (wt%)

- Anisotropy of Young's modulus of a single crystal having Dia-flex has a “high” elastic modulus and is used for power springs, but is not a constant elastic alloy.

- Non-Patent Document 1 describes that the orientation of a highly elastic alloy currently used as a commercially available power spring is mainly ⁇ 110 ⁇ ⁇ 112> having a small Young's modulus.

- the polycrystalline multi-element face centered cubic lattice alloy the relationship between the texture and the constant elastic properties has not been clarified.

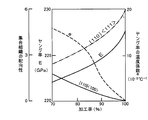

- Fig. 1 shows a thin plate obtained by rolling a wire rod processed at a drawing rate of 85.3% with a rolling rate of 50% at 650 ° C for Alloy No. I (Comparative Example), Alloy No. II (Comparative Example) and Alloy No. 12.

- Alloy number I is a commercially available constant elastic alloy (registered trademark of one applicant: Elcoloy) having a composition of Fe-27.7% Co-15.0% Ni-5.3% Cr-4.0% Mo.

- FIG. 1 shows the relationship between Young's modulus and measurement temperature for a thin plate sample of the alloy.

- the constant elastic properties are within a flat range of the Young's modulus-temperature curve near room temperature of 0 to 40 ° C. After obtaining this and making it a hairspring, it is incorporated into a mechanical drive and used in a watch.

- This alloy has a magnetic transformation point Tc of 200 ° C., near the top of the peak of the Young's modulus curve, and has a large saturation magnetic flux density of 8100 G. Therefore, as described in detail below, there is a problem that the magnetic field is easily magnetized by an external magnetic field.

- a constant elastic alloy used in a hairspring, a mechanical drive device, and a timepiece is a ferromagnetic alloy having a high saturation magnetic flux density, and thus its accuracy is significantly influenced by the magnitude of an external magnetic field.

- the structure of the timepiece becomes complicated if a magnetic-shielding structure is incorporated in the timepiece.

- the characteristics of the constant elastic alloy necessary for the accuracy of the timepiece are as follows.

- the Young's modulus is high, (c) the Young's modulus has a low temperature coefficient, and (d) has a hardness capable of exhibiting impact resistance that can sufficiently withstand external impacts.

- the present invention provides a Fe—Co—Ni—Cr—Mo-based constant elastic alloy that reduces the saturation magnetic flux density to make it weak magnetic and satisfies the above-mentioned various characteristics (a) to (d) by texture control. The purpose is to provide.

- the present inventor has intensively studied to develop a constant elastic alloy that is insensitive to an external magnetic field.

- the development of the constant elastic properties is derived from magnetism, it is extremely difficult to satisfy both physical properties of weak magnetism and constant elastic properties at the same time.

- the present inventor first made a fine blending adjustment of the ferromagnetic elements of the constant elastic alloy of Patent Document 1, that is, Fe, Co, Ni and nonmagnetic elements, such as Cr, Mo, Although research was conducted in detail, it was not possible to realize a constant elastic property at the same time as weakening by adjusting the components alone. That is, Alloy No. II and Alloy No. 12 in FIG.

- the relationship with temperature is shown in FIG. As shown in the figure, when the amount of the nonmagnetic elements Cr and Mo is increased, the peak of the Young's modulus-temperature curve moves to the low temperature side and becomes weak magnetic. That is, when the amount of the nonmagnetic element is increased, although not shown, the saturation magnetic flux density decreases and the magnetic transformation point Tc moves to the low temperature side.

- Alloy No. 12 shown in FIG. 1 is a comparative example shown in Table 1 (drawn with a reduction rate of 85.3%, heated at 650 ° C. for 2 hours after rolling with a reduction rate of 50%, but without intermediate heat treatment) 2) and belongs to the composition range of the present invention as shown in FIG. 2, but the ⁇ 110 ⁇ ⁇ 111> texture was not intentionally formed.

- the features of the present invention are as follows. (1) In the first invention, in terms of atomic weight ratio, Co20-40% and Ni7-22% total 42.0-49.5%, Cr5-13% and Mo1-6% total 13.5-16.0%, and the balance is substantially In addition, in a constant elastic alloy composed of Fe (provided that Fe 37% or more) and inevitable impurities, the texture is ⁇ 110 ⁇ ⁇ 111>, the saturation magnetic flux density is 2500-3500 G, and the Young's modulus temperature coefficient at 0-40 ° C.

- the present invention relates to a magnetic insensitive high hardness constant elastic alloy having (-5 to +5) ⁇ 10 ⁇ 5 ° C. ⁇ 1 and Vickers hardness of 350 to 550.

- W, V, Cu, Mn, Al, Si, Ti, Be, B, C are each 5% or less, Nb, Ta, Au, Ag, platinum group elements, Zr, Item (1) above, further containing 0.001 to 10% in total of 1% or more of Hf ⁇ of 3% or less, and the total of the Cr and Mo and the subcomponents being 13.5 to 16.0%

- the present invention relates to a magnetic insensitive high hardness constant elastic alloy.

- the ⁇ 110 ⁇ ⁇ 111> texture is obtained by repeatedly drawing a material having a non-oriented structure and an intermediate heat treatment at 800 to 950 ° C. After forming the formed wire, the wire is further rolled into a thin plate at a predetermined processing rate, and then the thin plate is heated at a temperature of 580 to 700 ° C.

- the present invention relates to a magnetic insensitive high hardness constant elastic alloy as described in the item (2).

- the fourth invention contains Co24.0-38.5%, Ni7.5-21.0%, Cr6.0-11.6% and Mo1.5-5.5% by atomic weight ratio as described in the above item (3)

- the present invention relates to a magnetic insensitive high hardness constant elastic alloy.

- the fifth aspect of the present invention is the above (4), which contains Co 30.0 to 35.0%, Ni 10.0 to 18.0%, Cr 8.0 to 11.0%, and Mo 2.5 to 5.5% by atomic weight ratio. It relates to the magnetically insensitive high hardness constant elastic alloy described.

- a sixth aspect of the present invention is the magnetically insensitive high hardness constant elasticity according to the above (4) or (5), wherein the drawing ratio of drawing is 92.8 to 99.9% and the rolling reduction ratio is 40 to 80%. Regarding alloys.

- the seventh invention relates to a hairspring comprising the magnetically insensitive high hardness constant elastic alloy according to any one of the above (1) to (6).

- the eighth invention relates to a mechanical drive device including the hairspring according to the above item (7).

- a ninth invention relates to a timepiece including the mechanical drive device described in the above item (8).

- an alloy having the composition described in (1) or (2) above is processed into an appropriate shape by forging and hot working, and heated at a temperature of 1100 ° C. or higher and lower than the melting point. Homogenize and cool, then repeat drawing process and intermediate heat treatment at 800-950 ° C, and after drawing into a wire with a processing rate of 90% or more, reduce the wire to a reduction rate of 20% or more

- a method for producing a magnetically insensitive high-hardness constant-elastic alloy characterized in that after rolling into a thin plate, the thin plate is heated at a temperature of 580 to 700 ° C.

- the alloy contains Co 24.0 to 38.5%, Ni 7.5 to 21.0%, Cr 6.0 to 11.6%, and Mo 1.5 to 5.5% or less in atomic weight ratio ( It is related with the manufacturing method of the magnetic insensitive high-hardness constant elastic alloy of 10 description.

- the alloy contains Co30.0 to 35.0%, Ni10.0 to 18.0%, Cr8.0 to 11.0%, and Mo2.5 to 5.5% in atomic weight ratio (10

- This relates to a method for producing a magnetically insensitive high-hardness constant elastic alloy as described in the above item.

- the present invention will be described in the order of the composition, texture, and characteristics of the constant elastic alloy, the balance spring, the mechanical drive device, the timepiece, and the manufacturing method.

- the alloy composition is a total of 42.0 to 49.5% of Co20 to 40% and Ni7 to 22%, a total of 13.5 to 16.0% of Cr5 to 13% and Mo1 to 6%, and the balance is substantially Fe (however, Fe 37% or more) and inevitable impurities were limited because of the fact that the alloy in this composition range was controlled to ⁇ 110 ⁇ ⁇ 111>, as is apparent from each example, each table and each drawing.

- the saturation magnetic flux density is 2500-3500G

- the temperature coefficient of Young's modulus at 0-40 ° C is (-5- + 5) ⁇ 10 -5 ° C -1

- the Vickers hardness is 350-550.

- the saturation magnetic flux density is less than 2500G or more than 3500G. and 0 the temperature coefficient of the Young's modulus at ⁇ 40 ° C. of greater than -5 ⁇ 10 -5 °C -1, or less than 5 ⁇ 10 -5 °C -1, Vickers - scan hard Even exceed 350 or less than 550, because magnetic insensitive high-hardness constant modulus alloy is not obtained.

- the total amount of Cr and Mo is less than 13.5% or exceeds 16.0%, desired properties cannot be obtained even if texture control is performed.

- compositions are Co24.0 to 38.5%, Ni 7.5 to 21.0%, Cr6.0 to 11.6%, Mo1.5 to 5.5%, and more particularly preferable compositions are Co30.0 to 35.0%, Ni10.0 to Contains 18.0%, Cr8.0-11.0% and Mo2.5-5.5%.

- W, V, Cu, Mn, Al, Si, Ti, Be, B, C are less than 5% each, and Nb, Ta, Au, Ag, platinum group elements, Zr, Hf are each 3% as subcomponents.

- Nb, Ta, Au, Ag, platinum group elements, Zr, Hf are each 3% as subcomponents.

- W, V, Cu, Mn, Al, Si, Ti, Be, B, C are less than 5% each

- Nb, Ta, Au, Ag, platinum group elements, Zr, Hf are each 3% as subcomponents.

- Addition of Mn, Al, Si, or Ti when deoxidation / desulfurization is required has the effect of improving forging and processing, and any of W, V, Nb, Ta, and platinum group elements can be used.

- the platinum group element is composed of Pt, Ir, Ru, Rh, Pd, and Os, but the effect is uniform and can be regarded as a component with the same effect.

- the sum of the subcomponents and Cr, Mo be in the range of 13.5 to 16.0%.

- the balance of the above composition is impurities inevitably contained due to Fe, Co, Ni, Cr, Mo and the like.

- FIG. 2 shows a saturation magnetic flux density Bs of 2500 G and 3500 G for a Fe- (Co + Ni)-(Cr + Mo + ⁇ ) pseudo ternary alloy ( ⁇ : secondary component) having a ⁇ 110 ⁇ ⁇ 111> texture. And -5 ⁇ 10 ⁇ 5 ° C ⁇ 1 and 5 ⁇ 10 ⁇ 5 ° C ⁇ 1 contours of temperature coefficient e of Young's modulus at 0 to 40 ° C (however, the unit of ° C -1 is omitted in the figure) It is shown at the same time.

- Non-patent document 1 shows the ⁇ 111 ⁇ ⁇ 111> texture in which the ⁇ 111> direction showing the maximum Young's modulus foreseen for a single crystal is the largest in the Young's modulus oriented in the rolling direction.

- the saturation magnetic flux density is remarkably lowered by increasing the content of the nonmagnetic element, and by forming a ⁇ 110 ⁇ ⁇ 111> texture with a large Young's modulus, As the Young's modulus near room temperature below 40 ° C increases, the temperature coefficient decreases, and as a result, a weakly magnetic constant elastic alloy is realized.

- D In the ⁇ 110 ⁇ ⁇ 111> texture, the crystals on the surface of the rolled sheet are preferentially oriented parallel to the ⁇ 110 ⁇ plane, and appear in the cross section of the rolled sheet obtained by cutting the rolled sheet in a direction perpendicular to the rolling direction. The crystal is preferentially oriented in the ⁇ 111> direction.

- ⁇ 110 ⁇ ⁇ 112> which is a texture of a known Fe-Co-Ni-Cr-Mo-W system face-centered cubic multielement high-elasticity alloy

- the texture of the present invention has a preferred orientation in the rolling direction. It is shifted 19.47 degrees compared with the known one.

- the ⁇ 110 ⁇ ⁇ 111> texture is a wire with a ⁇ 111> fiber structure developed by repeatedly drawing a material having an unoriented structure and an intermediate heat treatment at 800 to 950 ° C.

- the wire can be formed by rolling at a predetermined rolling reduction.

- Saturation magnetic flux density Alloy number I (comparative example) in Fig. 1 shows that the saturation magnetic flux density is 8100G, which is very high, while the alloy of the present invention has a saturation magnetic flux density of 2500-3500G. Corresponding to the low magnetic permeability. For this reason, the alloy of the present invention is insensitive to an external magnetic field, and is hardly magnetized by an external magnetic field in an environment where a device including a hairspring or the like is exposed. When the saturation magnetic flux density exceeds 3500G, weak magnetism is impaired.

- the saturation magnetic flux density is less than 2500 G

- the nonmagnetic metal content increases, so the magnetic transformation point Tc also decreases to 40 ° C or less, and the Young's modulus decreases rapidly at temperatures below Tc.

- the coefficient increases beyond 5 ⁇ 10 -5 ° C -1 . That is, when Tc is 40 ° C. or lower, the constant elastic property having a temperature coefficient of Young's modulus ( ⁇ 5 to +5) ⁇ 10 ⁇ 5 ° C. ⁇ 1 at 0 to 40 ° C. cannot be obtained.

- (B) Temperature coefficient of Young's modulus The temperature coefficient of Young's modulus of the present invention is as small as (-5 to +5) x10 -5 ° C -1 in the range of 0 to 40 ° C and has excellent constant elastic properties. Yes.

- the Young's modulus was measured by a free resonance method in the case of a wire, and by a dynamic viscoelastic method in the case of a thin plate.

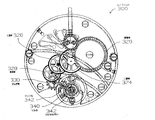

- FIG. 3 a representative known balance spring is shown, generally having a cross-sectional width of about 0.1 mm and a thickness of about 0.03 mm.

- the constant elastic alloy of the present invention can be preferably used for such a hairspring.

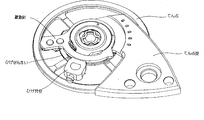

- FIG. 4 shows a known component of a mechanical watch.

- a balance 340 and a balance spring 342 are components of the mechanical drive device.

- FIG. 5 is an enlarged view of the balance with hairspring and hairspring.

- FIG. 6 shows a timepiece, and the components shown in FIG. 4 are arranged on the back side of the dial.

- Patent Document 2 Republished Patent Publication WO01 / 053896, filed by one of the present applicants, in particular, FIGS. Section (1) ending on page 13, line 2; page 4, line 9 to page 5, bottom to line 7).

- the present inventors formed a non-oriented structure in the homogenization process for the manufacturing process of the hairspring material, and increased the orientation of ⁇ 111> fiber structure in the drawing process with an intermediate heat treatment, Then, when creating a balance spring thin plate by rolling, a ⁇ 110 ⁇ ⁇ 111> texture can be formed by rolling at a specific reduction ratio and heating at a predetermined temperature after rolling. It was. Hereinafter, it demonstrates in order of the process of this invention method.

- an appropriate melting furnace such as a high-frequency melting furnace in air, preferably in a non-oxidizing atmosphere (gas such as hydrogen, argon, nitrogen) or in vacuum 5%

- (C) Homogenization treatment The mixture is heated at a temperature of 1100 ° C. or higher and lower than the melting point, preferably 1150 to 1300 ° C. for an appropriate period of time, preferably 0.5 to 5 hours, followed by homogenization and cooling. If the homogenization temperature is less than 1100 ° C, the solidified structure remains, making it difficult to obtain a highly oriented fiber structure. On the other hand, if partial melting occurs, the effect of subsequent solidification appears. .

- FIG. 7 shows the orientation of the fiber structure, saturation magnetic flux density Bs, Young's modulus E of an alloy having the same composition as Alloy No. 12 (FIG. 1) after drawing at various working rates and then heating at 650 ° C. for 2 hours. And the relationship between the Vickers hardness Hv and the drawing rate.

- the orientation of the ⁇ 100> fiber axis decreases with increasing the processing rate, but the orientation of the ⁇ 111> fiber axis increases particularly significantly at a processing rate of 90% or more, and this is accompanied by the saturation magnetic flux density.

- Bs, Young's modulus E and Vickers hardness Hv also increase.

- FIG. 8 shows the orientation of the fiber structure when a wire material subjected to wire drawing with a processing rate of 99.9% is heated at various temperatures for an alloy having the same composition as Alloy No. 12. This shows the relationship with the heating temperature.

- Even in the intermediate heat treatment at temperatures below 800 ° C high orientation of ⁇ 111> fiber axes can be obtained, but the work hardening due to the work distortion of the drawing process has not yet sufficiently softened the structure, and the drawing process to be performed is difficult.

- the ⁇ 111> fiber axis decreases rapidly.

- the structure becomes a homogeneous and disordered structure having no preferred orientation, that is, a non-oriented structure. Therefore, after heating at a temperature of 1100 ° C or higher and below the melting point, once the solidified structure is erased to form a homogeneous and non-oriented structure, drawing is performed to form a wire, and then the wire is 800 to 950 By performing an intermediate heat treatment in the temperature range of ° C., a wire having a ⁇ 111> fiber axis with higher orientation can be obtained.

- the drawing rate of the present invention corresponds to the total rate of processing obtained by adding these up.

- FIG. 1 A ⁇ 111 ⁇ pole figure of the surface is shown in FIG.

- the orientation of the reverse pole figure and pole figure is EBSP (Electron Back Scattering Pattern Analy- sis) measured by analysis method. From this figure, it is clear that a highly oriented ⁇ 110 ⁇ ⁇ 111> texture is formed.

- the highly oriented ⁇ 111> fiber structure of the wire is rolled in the direction of the wire axis, only the fiber structure having the ⁇ 111> fiber axis is still retained in the rolling process with a rolling reduction of less than 20%.

- a ⁇ 110 ⁇ ⁇ 111> texture with a large Young's modulus appears, and a thin plate having constant elastic properties can be obtained.

- the formation of a fiber structure having a highly oriented ⁇ 111> fiber axis obtained by repeatedly performing a strong wire drawing process and an intermediate heat treatment has a large Young's modulus induced by the subsequent rolling process ⁇ 110 ⁇ ⁇ 111> It is the driving force that promotes the formation of texture. Therefore, the Young's modulus of the thin plate formed by rolling to form the ⁇ 110 ⁇ ⁇ 111> texture is generally larger than the Young's modulus of the wire of the ⁇ 111> fiber shaft.

- FIG. 11 shows that alloy No. 12 was drawn at various processing rates, then subjected to 50% rolling with a constant reduction in the direction of the axis of the wire, and a constant temperature of 650 ° C. 3 shows the relationship between the Young's modulus E of the thin plate and the measurement temperature when heated for 2 hours. As the drawing rate increases, the ⁇ 110 ⁇ ⁇ 111> texture with high Young's modulus is effectively formed, and the peak of the Young's modulus-temperature curve (Tc temperature) moves to the high temperature side of 40 ° C or higher.

- the Young's modulus E of 40 ° C or less also increases, and as a result, the temperature coefficient of Young's modulus at 0 to 40 ° C decreases when the processing rate is 90% or more, and ( -5 to +5) x 10 -5 ° C A constant elastic property of -1 is obtained. That is, as seen in the same alloy number 12 in FIG. 7, it is presumed that the drawing rate increases, the saturation magnetic flux density Bs increases, and the Tc also increases. It is thought that the peak of the Young's modulus-temperature curve has moved to the high temperature side.

- FIG. 12 shows a case where the same processing as in FIG. 11 is performed.

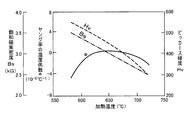

- FIG. 13 shows the saturation magnetic flux density Bs when the alloy No. 12 is drawn at a reduction rate of 99.9% and then rolled at a reduction rate of 50% in the direction of the wire axis and heated at various temperatures. This shows the relationship between the temperature coefficient e of Young's modulus and Vickers hardness Hv at 0 to 40 ° C. and the heating temperature.

- the heating temperature is preferably 580 to 700 ° C.

- the alloy of the present invention is weakly magnetized with a saturation magnetic flux density of 2500-3500G, it is insensitive to an external magnetic field and has a large Young's modulus by making it a texture of ⁇ 110 ⁇ ⁇ 111>, and its temperature coefficient Has a small (-5 to +5) ⁇ 10 -5 °C -1 , excellent constant elastic properties, large Vickers hardness of 350 to 550, and excellent impact resistance.

- a magnetic insensitive high hardness constant elastic alloy for use in mainsprings, mechanical drive devices and watches, but also as an elastic material used in general precision equipment requiring weak magnetic properties with high elasticity and constant elastic properties and strength Is also suitable.

- the round bar was heated at 1200 ° C. for 1.5 hours, homogenized, and then rapidly cooled.

- the round bar was subjected to cold drawing at room temperature to form a 10 mm wire, and then the wire was heated in vacuum at 930 ° C. for 2 hours for intermediate heat treatment.

- the wire was heated in a vacuum at 900 ° C. for 3 hours to perform an intermediate heat treatment.

- cold drawing was performed at room temperature to form a 2 mm wire, and then the wire was heated in vacuum at 880 ° C. for 3 hours to be subjected to an intermediate heat treatment.

- the wire was heated in a vacuum at 920 ° C. for 3 hours to be subjected to an intermediate heat treatment.

- the wire was subjected to cold drawing with a working rate within the range of 85.3 to 99.9% to obtain a wire with an appropriate diameter within the range of 0.5 to 0.01 mm.

- cold rolling is applied to a thin plate with an appropriate reduction rate within a range of 50 to 80%, and the thin plate is subjected to heat treatment at an appropriate temperature and time as shown in Table 1, so that various properties are obtained. Measurements were performed and the characteristic values shown in Table 1 were obtained.

- electrolytic iron, electrolytic nickel, electrolytic cobalt, electrolytic chromium, molybdenum, and 99.9% purity tungsten having the same purity as in Example 1 were used.

- 1.5 kg of the total weight of the raw material was placed in an alumina crucible, melted in a high-frequency induction electric furnace in an argon gas atmosphere with a total pressure of 10 ⁇ 1 MPa, and then stirred well to obtain a homogeneous molten alloy.

- the wire was subjected to cold drawing at room temperature to obtain a 2.0 mm wire, and then the wire was heated in a vacuum at 920 ° C. for 3 hours to be subjected to an intermediate heat treatment. Furthermore, after cold drawing at room temperature to obtain a 0.8 mm wire, the wire was heated in a vacuum at 900 ° C. for 4 hours and subjected to an intermediate heat treatment, and as shown in Table 2, 80.0-99.3% After forming a wire with an appropriate diameter at a processing rate of 40% and 70%, it is cold-rolled into a thin plate of an appropriate thickness at a rolling reduction of 40 to 70% as shown in Table 2. Heat treatment was performed over time, various characteristics were measured, and the characteristic values shown in Table 2 were obtained.

- a balance spring as shown in FIG. 3 was manufactured from a thin plate made of Example 1 (Alloy No. 12) and Example 2 (Alloy No. 24) and Alloy No. I (Comparative Example) in Table 7. After heat treatment at 2 ° C. for 2 hours, the balance spring was assembled into a mechanical drive device shown in FIGS. 4 and 5 and further incorporated into a watch as shown in FIG. Various characteristics of the watch were measured.

- a DC magnetic field of various magnitudes was applied from the outside using a device capable of applying a uniform magnetic field to the timepiece to be measured.

- the watch was placed with the dial face up in a DC magnetic field, and a DC magnetic field was applied from a direction parallel to the watch dial.

- the timepiece was rotated by 30 ° about the axis on which the hands are attached, and measurements were made in a total of 12 directions.

- Table 3 shows a summary of the incidence of stopping in 12 directions by checking the hand movement state of the timepiece in the applied magnetic field.

- Table 4 shows changes in the rate (delayed advance) of the timepiece where there is no magnetic field influence compared to before applying the magnetic field. .

- the characteristics and accuracy of the stop in the external magnetic field and the influence of the external magnetic field after removal from the magnetic field are also significantly higher than those of Alloy No. I (comparative example). Is clearly improved. Therefore, by using the hairspring of the present invention, the anti-magnetic performance of the timepiece that fully satisfies the two types of anti-magnetic timepieces specified by JIS without covering the entire movement with conventional soft magnetic iron. Can be remarkably improved.

- Comparative Examples I and II are compositions with a small total amount of Cr and Mo, which are nonmagnetic elements, have a high saturation magnetic flux density and a low Young's modulus.

- the present invention alloy is a weakly magnetic saturation flux density 2500 ⁇ 3500 G, insensitive to the external magnetic field, temperature coefficient of Young's modulus at 0 ⁇ 40 ° C. is (-5 ⁇ + 5) ⁇ 10 -5 °C - 1 small, excellent constant elastic properties, high Vickers hardness of 350 to 550, and excellent impact resistance, so constant elastic alloys for hairsprings, mechanical drives and watches As well as being suitable as a constant elastic and elastic material for general precision equipment that requires weak magnetism, high elasticity, high hardness and constant elastic properties, it makes a great contribution to the industry. It is.

- FIG. 5 is an enlarged view of FIG. 4. It is the figure which showed the timepiece.

- FIG. 6 is a characteristic diagram showing the relationship between the orientation of the fiber structure of the wire, the saturation magnetic flux density, the Young's modulus, the Vickers hardness, and the processing rate for Alloy No. 12.

- FIG. 5 is a characteristic diagram showing the relationship between the orientation of the fiber structure of the wire and the heating temperature for Alloy No. 12.

- FIG. 5 is an inverted pole figure of the fiber structure of the wire for Alloy No. 12. It is a ⁇ 111 ⁇ pole figure of a sheet rolling surface about alloy number 12.

- FIG. 5 is a characteristic diagram showing the relationship between the Young's modulus of the thin plate and the temperature for Alloy No. 12.

- FIG. 5 is a characteristic diagram showing the relationship between Young's modulus of a thin plate, its temperature coefficient, Vickers hardness, and processing rate for Alloy No. 12.

- FIG. 5 is a characteristic diagram showing the relationship between the saturation magnetic flux density of a thin plate, the temperature coefficient of Young's modulus, the Vickers hardness, and the heating temperature for Alloy No. 12.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Metallurgy (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Crystallography & Structural Chemistry (AREA)

- Thermal Sciences (AREA)

- Manufacturing & Machinery (AREA)

- General Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Heat Treatment Of Steel (AREA)

- Heat Treatment Of Sheet Steel (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/125,831 US8684594B2 (en) | 2008-11-17 | 2009-11-16 | Magnetically insensitive, highly hard and constant-modulus alloy, and its production method, as well as hair spring, mechanical driving apparatus and watch and clock |

| EP09826188.6A EP2351864B1 (en) | 2008-11-17 | 2009-11-16 | Process for producing a high-hardness constant-modulus alloy insensitive to magnetism, hair spring, mechanical driving device and watch |

| CN200980145779.3A CN102216480B (zh) | 2008-11-17 | 2009-11-16 | 磁性不灵敏高硬度恒弹性合金及其制造方法、以及游丝、机械式驱动装置及钟表 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008293713 | 2008-11-17 | ||

| JP2008-293713 | 2008-11-17 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| WO2010055943A1 true WO2010055943A1 (ja) | 2010-05-20 |

| WO2010055943A9 WO2010055943A9 (ja) | 2010-09-23 |

Family

ID=42170072

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2009/069458 Ceased WO2010055943A1 (ja) | 2008-11-17 | 2009-11-16 | 磁性不感高硬度恒弾性合金及びその製造法、並びにひげぜんまい、機械式駆動装置及び時計 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8684594B2 (enExample) |

| EP (1) | EP2351864B1 (enExample) |

| JP (1) | JP5189580B2 (enExample) |

| CN (1) | CN102216480B (enExample) |

| WO (1) | WO2010055943A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2447387A1 (fr) * | 2010-10-28 | 2012-05-02 | Générale Ressorts SA | Ressort de barillet de pièce d'horlogerie |

| DE102011001783A1 (de) * | 2011-04-04 | 2012-10-04 | Vacuumschmelze Gmbh & Co. Kg | Feder für ein mechanisches Uhrwerk, mechanisches Uhrwerk, Uhr mit einem mechanischen Uhrwerk und Verfahren zur Herstellung einer Feder |

| WO2019031577A1 (ja) * | 2017-08-09 | 2019-02-14 | 日立金属株式会社 | 合金部材、該合金部材の製造方法、および該合金部材を用いた製造物 |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2570862B1 (fr) * | 2011-09-15 | 2014-03-05 | ETA SA Manufacture Horlogère Suisse | Ensemble barillet d'horlogerie à diamètre de bonde réduit |

| EP2891724B1 (en) | 2012-08-31 | 2018-07-04 | Citizen Watch Co., Ltd. | Hair spring material for mechanical clock and hair spring using same |

| EP2757423B1 (fr) * | 2013-01-17 | 2018-07-11 | Omega SA | Pièce pour mouvement d'horlogerie |

| CN104313395A (zh) * | 2014-10-14 | 2015-01-28 | 杨雯雯 | 一种弹性合金 |

| MX389486B (es) | 2015-09-08 | 2025-03-20 | Scoperta Inc | Carburo no magnetico, que forma aleaciones para fabricar polvo |

| EP3208664B1 (de) * | 2016-02-19 | 2023-08-16 | Omega SA | Uhrwerk oder uhr ohne magnetische signatur |

| EP3301520A1 (fr) * | 2016-09-30 | 2018-04-04 | Nivarox-FAR S.A. | Composant horloger comportant un alliage haute entropie |

| JP6789140B2 (ja) * | 2017-01-31 | 2020-11-25 | セイコーインスツル株式会社 | 温度補償型てんぷ、ムーブメント及び時計 |

| EP3422116B1 (fr) * | 2017-06-26 | 2020-11-04 | Nivarox-FAR S.A. | Ressort spiral d'horlogerie |

| CN108193149B (zh) * | 2018-01-05 | 2020-11-03 | 广东电科院能源技术有限责任公司 | 一种碳纤维增强合金复合材料及其制备方法 |

| CA3095046A1 (en) | 2018-03-29 | 2019-10-03 | Oerlikon Metco (Us) Inc. | Reduced carbides ferrous alloys |

| JP7641218B2 (ja) | 2018-10-26 | 2025-03-06 | エリコン メテコ(ユーエス)インコーポレイテッド | 耐食性かつ耐摩耗性のニッケル系合金 |

| JP7523461B2 (ja) | 2019-03-28 | 2024-07-26 | エリコン メテコ(ユーエス)インコーポレイテッド | エンジンシリンダボアのコーティングのための溶射用鉄系合金 |

| AU2020269275B2 (en) | 2019-05-03 | 2025-05-22 | Oerlikon Metco (Us) Inc. | Powder feedstock for wear resistant bulk welding configured to optimize manufacturability |

| CN110923539B (zh) * | 2019-12-17 | 2021-10-08 | 南方科技大学 | 一种高熵合金及其制备方法和压缩性能测试方法 |

| CN111455199A (zh) * | 2020-04-16 | 2020-07-28 | 江苏星火特钢有限公司 | 一种高温合金真空感应炉冶炼工艺 |

| CN112301255B (zh) * | 2020-10-27 | 2021-07-30 | 上海交通大学 | 一种模具用高导热高强Co-Fe-Ni合金及其增材制造方法 |

| CN119040771B (zh) * | 2024-09-05 | 2025-06-06 | 重庆材料研究院有限公司 | 一种高机械品质因数马氏体弹性合金 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3110507B2 (ja) | 1991-09-19 | 2000-11-20 | ウエスト電気株式会社 | フィルム電動巻上げ装置 |

| WO2001053896A1 (en) | 2000-01-21 | 2001-07-26 | Seiko Instruments Inc. | Method of manufacturing mechanical timepiece |

| JP2004308827A (ja) * | 2003-04-09 | 2004-11-04 | Sii Micro Parts Ltd | ぜんまいの製造方法 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2859149A (en) * | 1952-01-14 | 1958-11-04 | Straumann Reinhard | Manufacture of watch springs utilizing wire converted into strip |

| GB918620A (en) | 1959-09-25 | 1963-02-13 | Straumann Inst Ag | Improvements in clockwork and like mechanisms |

| US3148092A (en) * | 1960-11-17 | 1964-09-08 | Westinghouse Electric Corp | Process for producing sheets of magnetic materials |

| JPS5019511B1 (enExample) | 1970-03-18 | 1975-07-08 | ||

| US3673010A (en) | 1970-05-19 | 1972-06-27 | Tohoku Special Steel Works Ltd | Cold-workable permanent magnet alloy |

| CN1006237B (zh) * | 1985-04-01 | 1989-12-27 | 首都钢铁公司特殊钢公司冶金研究所 | 高性能正频率温度系数恒弹性合金 |

| JPS63195249A (ja) | 1987-02-10 | 1988-08-12 | Res Inst Electric Magnetic Alloys | 高温恒弾性合金 |

| US6863435B2 (en) * | 1997-08-11 | 2005-03-08 | Seiko Epson Corporation | Spring, mainspring, hairspring, and driving mechanism and timepiece based thereon |

| JP3982290B2 (ja) * | 1997-08-28 | 2007-09-26 | セイコーエプソン株式会社 | バネ、ヒゲゼンマイ、および時計 |

| KR100244232B1 (en) * | 1997-12-03 | 2000-02-01 | Lg Electronics Inc | Shadow mask for cathode ray tube and method of manufacturing thereof |

| EP1327695B1 (en) * | 2000-09-21 | 2013-03-13 | Nippon Steel & Sumitomo Metal Corporation | Steel plate excellent in shape freezing property and method for production thereof |

| JP4421877B2 (ja) * | 2003-03-26 | 2010-02-24 | セイコーインスツル株式会社 | Co−Ni基高弾性合金及びCo−Ni基高弾性合金を用いた動力ぜんまいとその製造方法 |

| JP4357977B2 (ja) | 2004-02-04 | 2009-11-04 | 住友電工スチールワイヤー株式会社 | ばね用鋼線 |

| US8591669B2 (en) * | 2004-11-23 | 2013-11-26 | University Of Maryland | Method of texturing polycrystalline iron/gallium alloys and compositions thereof |

| JP2006214822A (ja) | 2005-02-02 | 2006-08-17 | Seiko Instruments Inc | 緩急可能なひげぜんまいを含む機械式時計 |

| JP2007327084A (ja) * | 2006-06-06 | 2007-12-20 | Kobe Steel Ltd | 伸線加工性に優れた線材およびその製造方法 |

-

2009

- 2009-11-16 EP EP09826188.6A patent/EP2351864B1/en active Active

- 2009-11-16 CN CN200980145779.3A patent/CN102216480B/zh active Active

- 2009-11-16 WO PCT/JP2009/069458 patent/WO2010055943A1/ja not_active Ceased

- 2009-11-16 US US13/125,831 patent/US8684594B2/en active Active

- 2009-11-16 JP JP2009261376A patent/JP5189580B2/ja active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3110507B2 (ja) | 1991-09-19 | 2000-11-20 | ウエスト電気株式会社 | フィルム電動巻上げ装置 |

| WO2001053896A1 (en) | 2000-01-21 | 2001-07-26 | Seiko Instruments Inc. | Method of manufacturing mechanical timepiece |

| JP2004308827A (ja) * | 2003-04-09 | 2004-11-04 | Sii Micro Parts Ltd | ぜんまいの製造方法 |

Non-Patent Citations (2)

| Title |

|---|

| "Anisotropy and its temperature dependence of elastic modulus for a single crystal of high elastic alloy", BULLETIN OF JAPAN INSTITUTE SOCIETY FOR MEALS., vol. 31, no. 3, 1967, pages 263 - 268 |

| BULLETIN OF JAPAN INSTITUTE OF METALS, vol. 31, no. 3, 1967, pages 263 - 268 |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2447387A1 (fr) * | 2010-10-28 | 2012-05-02 | Générale Ressorts SA | Ressort de barillet de pièce d'horlogerie |

| DE102011001783A1 (de) * | 2011-04-04 | 2012-10-04 | Vacuumschmelze Gmbh & Co. Kg | Feder für ein mechanisches Uhrwerk, mechanisches Uhrwerk, Uhr mit einem mechanischen Uhrwerk und Verfahren zur Herstellung einer Feder |

| DE102011001783B4 (de) | 2011-04-04 | 2022-11-24 | Vacuumschmelze Gmbh & Co. Kg | Feder für ein mechanisches Uhrwerk, mechanisches Uhrwerk, Uhr mit einem mechanischen Uhrwerk und Verfahren zur Herstellung einer Feder |

| WO2019031577A1 (ja) * | 2017-08-09 | 2019-02-14 | 日立金属株式会社 | 合金部材、該合金部材の製造方法、および該合金部材を用いた製造物 |

| JP2019178427A (ja) * | 2017-08-09 | 2019-10-17 | 日立金属株式会社 | 合金部材の製造方法 |

| JPWO2019031577A1 (ja) * | 2017-08-09 | 2019-11-07 | 日立金属株式会社 | 合金部材、該合金部材の製造方法、および該合金部材を用いた製造物 |

| US11492685B2 (en) | 2017-08-09 | 2022-11-08 | Hitachi Metals, Ltd. | Alloy member, process for producing said alloy member, and product including said alloy member |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010138491A (ja) | 2010-06-24 |

| CN102216480A (zh) | 2011-10-12 |

| US20110286312A1 (en) | 2011-11-24 |

| WO2010055943A9 (ja) | 2010-09-23 |

| US8684594B2 (en) | 2014-04-01 |

| CN102216480B (zh) | 2014-08-20 |

| JP5189580B2 (ja) | 2013-04-24 |

| EP2351864A4 (en) | 2013-02-27 |

| EP2351864A1 (en) | 2011-08-03 |

| EP2351864B1 (en) | 2016-08-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5189580B2 (ja) | 磁性不感高硬度恒弾性合金及びその製造法、並びにひげぜんまい、機械式駆動装置及び時計 | |

| JP2010138491A5 (enExample) | ||

| Wang et al. | Ternary Fe–P–C bulk metallic glass with good soft-magnetic and mechanical properties | |

| CN108754333B (zh) | 奥氏体系不锈钢板及使用其的高弹性极限非磁性钢材的制造方法 | |

| JP5215855B2 (ja) | Fe基合金及びその製造方法 | |

| JP5065904B2 (ja) | 形状記憶性及び超弾性を有する鉄系合金及びその製造方法 | |

| CN103052727B (zh) | 包含非晶态金属合金的制表或制钟的部件 | |

| JP2016027207A (ja) | 強靭鉄系バルク金属ガラス合金 | |

| JPH06511287A (ja) | 析出硬化型マルテンサイト系ステンレス鋼 | |

| JP5059035B2 (ja) | 高弾性・恒弾性合金及びその製造法並びに精密機器 | |

| CN109477175A (zh) | Fe基形状记忆合金材料及其制造方法 | |

| JP5486050B2 (ja) | 高弾性・恒弾性合金及びその製造法並びに精密機器 | |

| Liu et al. | Fe-based glassy alloys with high iron content and high saturation magnetization | |

| JP2021500469A (ja) | 変態誘起塑性高エントロピー合金及びその製造方法 | |

| JP2004238720A (ja) | 形状記憶合金 | |

| WO2014157146A1 (ja) | オーステナイト系ステンレス鋼板およびそれを用いた高強度鋼材の製造方法 | |

| JPWO2007066555A1 (ja) | Co基合金及びその製造方法 | |

| EP4541911A1 (en) | Fe-mn alloy, hairspring for watch, and method for producing fe-mn alloy | |

| Jilani et al. | Role of copper addition on properties of bulk metallic glass materials | |

| JP6459078B2 (ja) | Fe−Mn系恒弾性・不感磁性合金 | |

| Ikram et al. | Effect of copper and zirconium addition on properties of Fe-Co-Si-B-Nb bulk metallic glasses | |

| WO2025225580A1 (ja) | Fe―Mn合金及びFe―Mn合金からなる時計用ひげぜんまい | |

| Lesz et al. | Structure and physical properties of Fe-based metallic glasses with Ni and Co addition |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 200980145779.3 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 09826188 Country of ref document: EP Kind code of ref document: A1 |

|

| REEP | Request for entry into the european phase |

Ref document number: 2009826188 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2009826188 Country of ref document: EP |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13125831 Country of ref document: US |