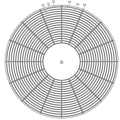

JP6993090B2 - Cmp研磨パッドのための研磨くず除去溝 - Google Patents

Cmp研磨パッドのための研磨くず除去溝 Download PDFInfo

- Publication number

- JP6993090B2 JP6993090B2 JP2017056833A JP2017056833A JP6993090B2 JP 6993090 B2 JP6993090 B2 JP 6993090B2 JP 2017056833 A JP2017056833 A JP 2017056833A JP 2017056833 A JP2017056833 A JP 2017056833A JP 6993090 B2 JP6993090 B2 JP 6993090B2

- Authority

- JP

- Japan

- Prior art keywords

- polishing

- groove

- grooves

- supply

- radial

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/26—Lapping pads for working plane surfaces characterised by the shape of the lapping pad surface, e.g. grooved

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/12—Lapping plates for working plane surfaces

- B24B37/16—Lapping plates for working plane surfaces characterised by the shape of the lapping plate surface, e.g. grooved

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B57/00—Devices for feeding, applying, grading or recovering grinding, polishing or lapping agents

- B24B57/02—Devices for feeding, applying, grading or recovering grinding, polishing or lapping agents for feeding of fluid, sprayed, pulverised, or liquefied grinding, polishing or lapping agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D11/00—Constructional features of flexible abrasive materials; Special features in the manufacture of such materials

-

- H10P52/00—

-

- H10P52/402—

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Polishing Bodies And Polishing Tools (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/079,824 | 2016-03-24 | ||

| US15/079,824 US10875146B2 (en) | 2016-03-24 | 2016-03-24 | Debris-removal groove for CMP polishing pad |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2017208530A JP2017208530A (ja) | 2017-11-24 |

| JP2017208530A5 JP2017208530A5 (enExample) | 2020-04-16 |

| JP6993090B2 true JP6993090B2 (ja) | 2022-01-13 |

Family

ID=59886174

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017056833A Active JP6993090B2 (ja) | 2016-03-24 | 2017-03-23 | Cmp研磨パッドのための研磨くず除去溝 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10875146B2 (enExample) |

| JP (1) | JP6993090B2 (enExample) |

| KR (1) | KR102363154B1 (enExample) |

| CN (1) | CN107225498A (enExample) |

| FR (1) | FR3049205B1 (enExample) |

| TW (1) | TWI773663B (enExample) |

Families Citing this family (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102017216033A1 (de) * | 2017-09-12 | 2019-03-14 | Carl Zeiss Smt Gmbh | Verfahren zum Bearbeiten eines Werkstücks bei der Herstellung eines optischen Elements |

| CN108214285A (zh) * | 2018-01-25 | 2018-06-29 | 成都时代立夫科技有限公司 | 一种化学机械抛光垫 |

| JP7026942B2 (ja) * | 2018-04-26 | 2022-03-01 | 丸石産業株式会社 | 研磨パッド用の下敷及び該下敷を使用する研磨方法 |

| KR102059647B1 (ko) * | 2018-06-21 | 2019-12-26 | 에스케이씨 주식회사 | 슬러리 유동성이 향상된 연마패드 및 이의 제조방법 |

| US20210263418A1 (en) * | 2018-07-27 | 2021-08-26 | Asml Netherlands B.V. | Tool for modifying a support surface |

| KR101952829B1 (ko) * | 2018-08-13 | 2019-02-27 | 최유섭 | 금속부품의 연마가공장치 및 이를 이용한 연마가공방법 |

| JP7178662B2 (ja) * | 2019-04-10 | 2022-11-28 | パナソニックIpマネジメント株式会社 | 研磨装置および研磨方法 |

| TWI771668B (zh) | 2019-04-18 | 2022-07-21 | 美商應用材料股份有限公司 | Cmp期間基於溫度的原位邊緣不對稱校正 |

| WO2020255744A1 (ja) * | 2019-06-19 | 2020-12-24 | 株式会社クラレ | 研磨パッド、研磨パッドの製造方法及び研磨方法 |

| CN110732983A (zh) * | 2019-10-30 | 2020-01-31 | 郑州伯利森新材料科技有限公司 | 一种硬脆材料加工用免修整超硬砂轮及其制备方法 |

| GB2590511B (en) * | 2019-11-20 | 2023-10-25 | Best Engineered Surface Tech Llc | Hybrid CMP conditioning head |

| TWI797501B (zh) * | 2019-11-22 | 2023-04-01 | 美商應用材料股份有限公司 | 在拋光墊中使用溝槽的晶圓邊緣不對稱校正 |

| KR102746090B1 (ko) | 2020-03-13 | 2024-12-26 | 삼성전자주식회사 | Cmp 패드 및 이를 구비하는 화학적 기계적 연마 장치 |

| US20210299816A1 (en) * | 2020-03-25 | 2021-09-30 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Cmp polishing pad with protruding structures having engineered open void space |

| KR102570825B1 (ko) * | 2020-07-16 | 2023-08-28 | 한국생산기술연구원 | 다공성 돌출 패턴을 포함하는 연마 패드 및 이를 포함하는 연마 장치 |

| CN114496880B (zh) * | 2020-10-26 | 2025-07-25 | 昆明物理研究所 | 一种化学抛光夹具 |

| WO2023013576A1 (ja) | 2021-08-04 | 2023-02-09 | 株式会社クラレ | 研磨パッド |

| KR102685134B1 (ko) * | 2022-06-09 | 2024-07-15 | 케이피엑스케미칼 주식회사 | 개선된 연마속도를 갖는 연마패드 및 이를 포함하는 화학적 기계적 연마장치 |

| KR102685136B1 (ko) * | 2022-06-09 | 2024-07-15 | 케이피엑스케미칼 주식회사 | 개선된 연마속도를 갖는 연마패드 및 이를 포함하는 화학적 기계적 연마장치 |

| KR20240105053A (ko) * | 2022-12-28 | 2024-07-05 | 삼성전자주식회사 | 화학 기계적 연마 장치 및 이의 제어 방법 |

| CN116276633B (zh) * | 2023-02-13 | 2025-09-16 | 上海芯谦集成电路有限公司 | 一种具有透气孔的抛光垫 |

| US20250108477A1 (en) * | 2023-09-28 | 2025-04-03 | Applied Materials, Inc. | Chemical mechanical polishing edge control with pad recesses |

| CN120651714A (zh) * | 2025-07-22 | 2025-09-16 | 四川省贝特化工科技有限公司 | 一种囊包颗粒用智能检测装置及其检测方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006156876A (ja) | 2004-12-01 | 2006-06-15 | Toyo Tire & Rubber Co Ltd | 研磨パッド、研磨方法ならびに半導体デバイスの製造方法および半導体デバイス |

| JP2007081322A (ja) | 2005-09-16 | 2007-03-29 | Jsr Corp | 化学機械研磨パッドの製造方法 |

| US20090311955A1 (en) | 2008-03-14 | 2009-12-17 | Nexplanar Corporation | Grooved CMP pad |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| MY114512A (en) | 1992-08-19 | 2002-11-30 | Rodel Inc | Polymeric substrate with polymeric microelements |

| US5645469A (en) | 1996-09-06 | 1997-07-08 | Advanced Micro Devices, Inc. | Polishing pad with radially extending tapered channels |

| JPH11156699A (ja) | 1997-11-25 | 1999-06-15 | Speedfam Co Ltd | 平面研磨用パッド |

| US6135868A (en) * | 1998-02-11 | 2000-10-24 | Applied Materials, Inc. | Groove cleaning device for chemical-mechanical polishing |

| GB2345255B (en) | 1998-12-29 | 2000-12-27 | United Microelectronics Corp | Chemical-Mechanical Polishing Pad |

| US6749714B1 (en) * | 1999-03-30 | 2004-06-15 | Nikon Corporation | Polishing body, polisher, polishing method, and method for producing semiconductor device |

| ATE293515T1 (de) * | 2000-06-19 | 2005-05-15 | Struers As | Eine schleif- und/oder polierscheibe mit mehreren zonen |

| EP1369204B1 (en) * | 2002-06-03 | 2006-10-11 | JSR Corporation | Polishing pad and process for manufacturing a polishing pad |

| US6843711B1 (en) * | 2003-12-11 | 2005-01-18 | Rohm And Haas Electronic Materials Cmp Holdings, Inc | Chemical mechanical polishing pad having a process-dependent groove configuration |

| US7329174B2 (en) | 2004-05-20 | 2008-02-12 | Jsr Corporation | Method of manufacturing chemical mechanical polishing pad |

| JP4645825B2 (ja) | 2004-05-20 | 2011-03-09 | Jsr株式会社 | 化学機械研磨パッド及び化学機械研磨方法 |

| KR101279819B1 (ko) * | 2005-04-12 | 2013-06-28 | 롬 앤드 하스 일렉트로닉 머티리얼스 씨엠피 홀딩스 인코포레이티드 | 방사-편향 연마 패드 |

| JP2009220265A (ja) * | 2008-02-18 | 2009-10-01 | Jsr Corp | 化学機械研磨パッド |

| US20120083187A1 (en) * | 2009-06-18 | 2012-04-05 | Jsr Corporation | Polyurethane, composition for formation of polishing layers that contains same, pad for chemical mechanical polishing, and chemical mechanical polishing method using same |

| SG10201404152UA (en) * | 2009-07-16 | 2014-09-26 | Cabot Microelectronics Corp | Grooved cmp polishing pad |

| KR20110100080A (ko) * | 2010-03-03 | 2011-09-09 | 삼성전자주식회사 | 화학적 기계적 연마 공정용 연마 패드 및 이를 포함하는 화학적 기계적 연마 설비 |

| JP2012106328A (ja) * | 2010-03-25 | 2012-06-07 | Toyo Tire & Rubber Co Ltd | 積層研磨パッド |

| KR101232787B1 (ko) * | 2010-08-18 | 2013-02-13 | 주식회사 엘지화학 | 연마 시스템용 연마 패드 |

| US9211628B2 (en) * | 2011-01-26 | 2015-12-15 | Nexplanar Corporation | Polishing pad with concentric or approximately concentric polygon groove pattern |

| US8968058B2 (en) * | 2011-05-05 | 2015-03-03 | Nexplanar Corporation | Polishing pad with alignment feature |

| US20140378035A1 (en) * | 2011-09-15 | 2014-12-25 | Toray Industries, Inc. | Polishing pad |

| WO2013103142A1 (ja) | 2012-01-06 | 2013-07-11 | 東レ株式会社 | 研磨パッド |

| TWI599447B (zh) * | 2013-10-18 | 2017-09-21 | 卡博特微電子公司 | 具有偏移同心溝槽圖樣之邊緣排除區的cmp拋光墊 |

| JP2016124043A (ja) | 2014-12-26 | 2016-07-11 | 東洋ゴム工業株式会社 | 研磨パッド |

-

2016

- 2016-03-24 US US15/079,824 patent/US10875146B2/en active Active

-

2017

- 2017-03-23 KR KR1020170036719A patent/KR102363154B1/ko active Active

- 2017-03-23 CN CN201710180712.XA patent/CN107225498A/zh active Pending

- 2017-03-23 TW TW106109816A patent/TWI773663B/zh active

- 2017-03-23 JP JP2017056833A patent/JP6993090B2/ja active Active

- 2017-03-24 FR FR1752492A patent/FR3049205B1/fr active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006156876A (ja) | 2004-12-01 | 2006-06-15 | Toyo Tire & Rubber Co Ltd | 研磨パッド、研磨方法ならびに半導体デバイスの製造方法および半導体デバイス |

| JP2007081322A (ja) | 2005-09-16 | 2007-03-29 | Jsr Corp | 化学機械研磨パッドの製造方法 |

| US20090311955A1 (en) | 2008-03-14 | 2009-12-17 | Nexplanar Corporation | Grooved CMP pad |

Also Published As

| Publication number | Publication date |

|---|---|

| US20170274496A1 (en) | 2017-09-28 |

| KR102363154B1 (ko) | 2022-02-15 |

| CN107225498A (zh) | 2017-10-03 |

| FR3049205B1 (fr) | 2021-08-06 |

| FR3049205A1 (fr) | 2017-09-29 |

| KR20170113203A (ko) | 2017-10-12 |

| TWI773663B (zh) | 2022-08-11 |

| JP2017208530A (ja) | 2017-11-24 |

| TW201800181A (zh) | 2018-01-01 |

| US10875146B2 (en) | 2020-12-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6993090B2 (ja) | Cmp研磨パッドのための研磨くず除去溝 | |

| KR100471527B1 (ko) | 연마체, 연마장치, 연마방법 및 반도체 소자의 제조방법 | |

| US6843711B1 (en) | Chemical mechanical polishing pad having a process-dependent groove configuration | |

| CN1213834C (zh) | 化学机械抛光的方法 | |

| CN100347828C (zh) | 带有用于降低浆液消耗的凹槽排列的研磨垫 | |

| US6955587B2 (en) | Grooved polishing pad and method | |

| KR101601281B1 (ko) | 고속 연마 방법 | |

| CN104476384B (zh) | 半导体晶片双面抛光的方法 | |

| JP2000511355A (ja) | Sof半導体ウェーハの化学・機械的平坦化法 | |

| KR20080071933A (ko) | 패드 텍스쳐에 슬러리를 보유하기 위한 홈을 갖는 연마패드 | |

| US7108597B2 (en) | Polishing pad having grooves configured to promote mixing wakes during polishing | |

| EP1699596B1 (en) | Chemical mechanical polishing method for reducing slurry reflux | |

| KR20050107760A (ko) | 웨이퍼 연마 및 패드 컨디셔닝 방법 | |

| CN113579991B (zh) | 一种硅片的最终抛光方法、系统以及硅片 | |

| JP4449905B2 (ja) | 研磨布及び研磨布の加工方法並びにそれを用いた基板の製造方法 | |

| ISHIZUKA et al. | PCD Dressers for Chemical Mechanical Planarization with Uniform Polishing | |

| KR101455919B1 (ko) | 웨이퍼 양면 연마 장치의 정반 구조 | |

| KR20100079398A (ko) | Cmp 패드의 그루브, 이의 제작방법 및 이를 포함한 cmp 패드 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200309 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200309 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20210415 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210608 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20210903 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20211029 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20211116 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20211209 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6993090 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R157 | Certificate of patent or utility model (correction) |

Free format text: JAPANESE INTERMEDIATE CODE: R157 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |