JP6825317B2 - 円すいころ軸受及び動力伝達装置 - Google Patents

円すいころ軸受及び動力伝達装置 Download PDFInfo

- Publication number

- JP6825317B2 JP6825317B2 JP2016219768A JP2016219768A JP6825317B2 JP 6825317 B2 JP6825317 B2 JP 6825317B2 JP 2016219768 A JP2016219768 A JP 2016219768A JP 2016219768 A JP2016219768 A JP 2016219768A JP 6825317 B2 JP6825317 B2 JP 6825317B2

- Authority

- JP

- Japan

- Prior art keywords

- tapered roller

- contact

- large end

- end surface

- power transmission

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/583—Details of specific parts of races

- F16C33/585—Details of specific parts of races of raceways, e.g. ribs to guide the rollers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/22—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings

- F16C19/225—Details of the ribs supporting the end of the rollers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/22—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings

- F16C19/34—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load

- F16C19/36—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with a single row of rollers

- F16C19/364—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with a single row of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/34—Rollers; Needles

- F16C33/36—Rollers; Needles with bearing-surfaces other than cylindrical, e.g. tapered; with grooves in the bearing surfaces

- F16C33/366—Tapered rollers, i.e. rollers generally shaped as truncated cones

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H57/00—General details of gearing

- F16H57/04—Features relating to lubrication or cooling or heating

- F16H57/042—Guidance of lubricant

- F16H57/0421—Guidance of lubricant on or within the casing, e.g. shields or baffles for collecting lubricant, tubes, pipes, grooves, channels or the like

- F16H57/0424—Lubricant guiding means in the wall of or integrated with the casing, e.g. grooves, channels, holes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H57/00—General details of gearing

- F16H57/04—Features relating to lubrication or cooling or heating

- F16H57/0467—Elements of gearings to be lubricated, cooled or heated

- F16H57/0469—Bearings or seals

- F16H57/0471—Bearing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H57/00—General details of gearing

- F16H57/04—Features relating to lubrication or cooling or heating

- F16H57/048—Type of gearings to be lubricated, cooled or heated

- F16H57/0493—Gearings with spur or bevel gears

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/54—Systems consisting of a plurality of bearings with rolling friction

- F16C19/546—Systems with spaced apart rolling bearings including at least one angular contact bearing

- F16C19/547—Systems with spaced apart rolling bearings including at least one angular contact bearing with two angular contact rolling bearings

- F16C19/548—Systems with spaced apart rolling bearings including at least one angular contact bearing with two angular contact rolling bearings in O-arrangement

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/40—Linear dimensions, e.g. length, radius, thickness, gap

- F16C2240/70—Diameters; Radii

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2326/00—Articles relating to transporting

- F16C2326/01—Parts of vehicles in general

- F16C2326/06—Drive shafts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2361/00—Apparatus or articles in engineering in general

- F16C2361/61—Toothed gear systems, e.g. support of pinion shafts

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rolling Contact Bearings (AREA)

- General Details Of Gearings (AREA)

Description

そこで、本発明は、円すいころ軸受において、内輪の大鍔部と円すいころとの間に生じる接触面圧の低下と、これらの間に形成される油膜厚さの増大とを両立させることを目的とする。

この場合、円すいころの大端面において、エッジロードにより接触面圧が局所的に大きくなるのを防ぐことができる。

この動力伝達装置によれば、動力伝達軸を支持する軸受は前記円すいころ軸受と同じ作用効果を奏することから、動力伝達軸の回転性能を高めることが可能となる。

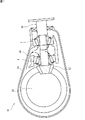

図1は、本発明の円すいころを備えているデファレンシャル装置の断面図である。このデファレンシャル装置51は、自動車のエンジンの出力を伝達する動力伝達経路に配置されており、エンジンの出力をデファレンシャル装置51の両側(図1の紙面貫通方向の両側)それぞれ配置された駆動軸(図示せず)に伝達する。

ここで、鍔面7bと大端面4bとの接触位置から円すいころ4のコーンセンタC0までの距離を「R」とする。なお、コーンセンタC0は、円すいころ4の円すい形状(外周面形状)の頂点を意味する。また、鍔面7bと大端面4bとの接触位置は、接触楕円Sの中心C1を意味する。そして、大端面4bの曲率半径Rrは前記距離Rよりも小さく(Rr<R)、鍔面7bの曲率半径Riは前記距離Rよりも大きい(Ri>R)。

2≦(Ri−R)/(R−Rr)≦10 ・・・ (1)

接触面圧及び楕円率を算出するための接触楕円Sの寸法a,bは、ヘルツの式を用いた接触理論により求められる。なお、この際に用いられる変数として、円すいころ4と内輪2の縦弾性係数を207.9GPa、ポアソン比を0.3、荷重を基本動定格荷重の40%になるアキシャル荷重としている。また、図4では、接触楕円Sの寸法bを一定とし、寸法aを変数とした場合のグラフである。

内輪2の大鍔部7と円すいころ4との間における接触形態を良好にするためには、これらの間に形成される油膜厚さがより重要であり、この点に着目すると、前記寸法比「(Ri−R)/(R−Rr)」の上限値を「6」又は「5」とするのが好ましく、この場合、寸法比(Ri−R)/(R−Rr)は、2以上であり、6(又は5)以下となる。この場合、油膜厚さを大きくすることができるため、面圧が多少大きくなっても軸受の昇温を抑えることができる。

なお、鍔面7bにおける接触楕円Sの位置(中心C1の位置)を設定する手段としては、点P、点Q、コーンセンタC0の位置を調整すればよい。本実施形態では、図3に示すように円すいころ軸受1の中心線L0を含む断面において、点P、点Q及びコーンセンタC0は、共通する直線L1上に位置しているが、これら点P、点Q、コーンセンタC0は、共通する直線L1上に位置していなくてもよい。

3:外輪 3a:外軌道面 4:円すいころ

4b:大端面 7:大鍔部 7b:鍔面

10:保持器 31:径方向外側端縁 32:径方向内側端縁

51:デファレンシャル装置(動力伝達装置) 52:ピニオン軸(動力伝達軸)

55:ハウジング C0:コーンセンタ

C1:中心(接触位置) R:距離

Rr:大端面の曲率半径 Ri:鍔面の曲率半径

S:接触楕円

Claims (3)

- 外周側に内軌道面を有していると共に当該内軌道面の軸方向一方側に径方向外側へ突出している大鍔部を有する内輪と、内周側に外軌道面を有している外輪と、前記内軌道面及び前記外軌道面に転がり接触する複数の円すいころと、を備え、

前記円すいころは、軸方向一方側に凸曲面状の大端面を有し、

前記大鍔部は、前記大端面と接触する凹曲面状の鍔面を有し、

前記大端面と前記鍔面との接触位置から前記円すいころのコーンセンタまでの距離をR、前記大端面の曲率半径をRr(ただし、Rr<R)、前記鍔面の曲率半径をRi(ただし、Ri>R)とすると、

2≦(Ri−R)/(R−Rr)≦10

の関係を満たしている、円すいころ軸受。 - 前記大端面と前記鍔面とが接触することで生じる接触楕円は、当該鍔面の径方向外側端縁よりも径方向内側に位置している、請求項1に記載の円すいころ軸受。

- ハウジングと、当該ハウジング内に設けられている動力伝達軸と、当該動力伝達軸を回転自在に支持する軸受とを備え、前記軸受が請求項1又は2に記載の円すいころ軸受である、動力伝達装置。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016219768A JP6825317B2 (ja) | 2016-11-10 | 2016-11-10 | 円すいころ軸受及び動力伝達装置 |

| US15/803,095 US10060477B2 (en) | 2016-11-10 | 2017-11-03 | Tapered roller bearing and power transmission device |

| DE102017126097.8A DE102017126097A1 (de) | 2016-11-10 | 2017-11-08 | Kegelrollenlager und kraftübertragungsvorrichtung |

| CN201711108431.XA CN108071683B (zh) | 2016-11-10 | 2017-11-09 | 圆锥滚子轴承及动力传递装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016219768A JP6825317B2 (ja) | 2016-11-10 | 2016-11-10 | 円すいころ軸受及び動力伝達装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2018076927A JP2018076927A (ja) | 2018-05-17 |

| JP6825317B2 true JP6825317B2 (ja) | 2021-02-03 |

Family

ID=62026236

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016219768A Expired - Fee Related JP6825317B2 (ja) | 2016-11-10 | 2016-11-10 | 円すいころ軸受及び動力伝達装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US10060477B2 (ja) |

| JP (1) | JP6825317B2 (ja) |

| CN (1) | CN108071683B (ja) |

| DE (1) | DE102017126097A1 (ja) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6825317B2 (ja) * | 2016-11-10 | 2021-02-03 | 株式会社ジェイテクト | 円すいころ軸受及び動力伝達装置 |

| DE102019007309A1 (de) | 2018-11-23 | 2020-05-28 | Sew-Eurodrive Gmbh & Co Kg | Lagersystem mit einem Lager und Getriebe mit einem Lagersystem |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2951036B2 (ja) * | 1991-04-30 | 1999-09-20 | エヌティエヌ株式会社 | 円すいころ軸受 |

| JPH0575520U (ja) | 1992-03-19 | 1993-10-15 | 光洋精工株式会社 | 円錐ころ軸受 |

| JP2000065066A (ja) * | 1998-08-19 | 2000-03-03 | Nippon Seiko Kk | 円筒ころ軸受 |

| JP3637866B2 (ja) * | 2000-11-14 | 2005-04-13 | 日産自動車株式会社 | トロイダル型無段変速機 |

| US6502996B2 (en) * | 2001-05-11 | 2003-01-07 | The Timken Company | Bearing with low wear and low power loss characteristics |

| JP2005076675A (ja) * | 2003-08-28 | 2005-03-24 | Ntn Corp | 自動車トランスミッション用円錐ころ軸受 |

| JP2007051703A (ja) * | 2005-08-18 | 2007-03-01 | Jtekt Corp | 円錐ころ軸受、及びこれを用いたトランスミッション用軸受装置 |

| JP2007051702A (ja) * | 2005-08-18 | 2007-03-01 | Jtekt Corp | 円錐ころ軸受、及びこれを用いた車両用ピニオン軸支持装置 |

| DE102010034618A1 (de) * | 2010-08-18 | 2012-02-23 | Schaeffler Technologies Gmbh & Co. Kg | Wälzlager, Wälzkörper und Herstellungsverfahren für die Wälzkörper |

| JP2015113972A (ja) * | 2013-12-16 | 2015-06-22 | 株式会社ジェイテクト | 円すいころ軸受及び動力伝達装置 |

| JP6256023B2 (ja) * | 2014-01-16 | 2018-01-10 | 株式会社ジェイテクト | 円すいころ軸受及び動力伝達装置 |

| JP6350099B2 (ja) * | 2014-08-11 | 2018-07-04 | 株式会社ジェイテクト | 円すいころ軸受 |

| JP6492646B2 (ja) * | 2014-12-26 | 2019-04-03 | 株式会社ジェイテクト | 円すいころ軸受 |

| JP6825317B2 (ja) * | 2016-11-10 | 2021-02-03 | 株式会社ジェイテクト | 円すいころ軸受及び動力伝達装置 |

-

2016

- 2016-11-10 JP JP2016219768A patent/JP6825317B2/ja not_active Expired - Fee Related

-

2017

- 2017-11-03 US US15/803,095 patent/US10060477B2/en active Active

- 2017-11-08 DE DE102017126097.8A patent/DE102017126097A1/de not_active Withdrawn

- 2017-11-09 CN CN201711108431.XA patent/CN108071683B/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US20180128316A1 (en) | 2018-05-10 |

| CN108071683A (zh) | 2018-05-25 |

| DE102017126097A1 (de) | 2018-05-17 |

| US10060477B2 (en) | 2018-08-28 |

| JP2018076927A (ja) | 2018-05-17 |

| CN108071683B (zh) | 2020-12-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6492646B2 (ja) | 円すいころ軸受 | |

| JPWO2009020087A1 (ja) | 複列ローラ軸受 | |

| JP6256023B2 (ja) | 円すいころ軸受及び動力伝達装置 | |

| WO2012099120A1 (ja) | 転がり軸受 | |

| JPWO2015076271A1 (ja) | 円筒ころ軸受及びトランスミッション用軸受装置 | |

| JP6874455B2 (ja) | 転がり軸受 | |

| JP6825317B2 (ja) | 円すいころ軸受及び動力伝達装置 | |

| JP6028377B2 (ja) | 円すいころ軸受 | |

| JPH0712135A (ja) | 転がり軸受 | |

| JP6991823B2 (ja) | スラストころ軸受及びスラストころ軸受用軌道輪 | |

| JP2012202453A (ja) | 自動調心ころ軸受 | |

| JP2017053420A (ja) | 転がり軸受 | |

| CN106050904A (zh) | 球形滚子轴承装置 | |

| JP2014105809A (ja) | 転がり軸受用保持器 | |

| US20170122368A1 (en) | Tapered Roller Bearing | |

| JP5668877B2 (ja) | 二つ割り転がり軸受及びこれを備えた軸受装置 | |

| CN107588094B (zh) | 圆锥滚子轴承 | |

| JP2016102525A (ja) | 自動調心ころ軸受 | |

| JP4453804B2 (ja) | 転がり軸受 | |

| JP6350099B2 (ja) | 円すいころ軸受 | |

| JP5625474B2 (ja) | 二つ割り転がり軸受及びこれを備えた軸受装置 | |

| KR101885140B1 (ko) | 저 토크 테이퍼 롤러 베어링 | |

| JP2015222089A (ja) | ニードル軸受 | |

| JP2015132320A (ja) | 自動調心ころ軸受 | |

| CN206072111U (zh) | 滚动轴承 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20191014 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20200813 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200901 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20201215 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20201228 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6825317 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |