JP6426737B2 - 電子的構成要素とパターン化ナノワイヤ透明伝導体との接合 - Google Patents

電子的構成要素とパターン化ナノワイヤ透明伝導体との接合 Download PDFInfo

- Publication number

- JP6426737B2 JP6426737B2 JP2016531742A JP2016531742A JP6426737B2 JP 6426737 B2 JP6426737 B2 JP 6426737B2 JP 2016531742 A JP2016531742 A JP 2016531742A JP 2016531742 A JP2016531742 A JP 2016531742A JP 6426737 B2 JP6426737 B2 JP 6426737B2

- Authority

- JP

- Japan

- Prior art keywords

- layer

- conductive

- substrate

- adhesive

- matrix material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002070 nanowire Substances 0.000 title claims description 202

- 239000004020 conductor Substances 0.000 title description 24

- 239000010410 layer Substances 0.000 claims description 260

- 239000000758 substrate Substances 0.000 claims description 128

- 239000011159 matrix material Substances 0.000 claims description 101

- 229920000642 polymer Polymers 0.000 claims description 77

- 239000000853 adhesive Substances 0.000 claims description 61

- 230000001070 adhesive effect Effects 0.000 claims description 61

- 238000000034 method Methods 0.000 claims description 54

- 238000000576 coating method Methods 0.000 claims description 31

- 239000011248 coating agent Substances 0.000 claims description 30

- 239000012790 adhesive layer Substances 0.000 claims description 28

- 239000007788 liquid Substances 0.000 claims description 21

- 238000012546 transfer Methods 0.000 claims description 18

- 229910052751 metal Inorganic materials 0.000 claims description 16

- 239000002184 metal Substances 0.000 claims description 16

- 239000002923 metal particle Substances 0.000 claims description 15

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims description 12

- 229910052709 silver Inorganic materials 0.000 claims description 10

- 229910052802 copper Inorganic materials 0.000 claims description 9

- 239000010949 copper Substances 0.000 claims description 9

- 229910052737 gold Inorganic materials 0.000 claims description 9

- 239000010931 gold Substances 0.000 claims description 9

- 239000004332 silver Substances 0.000 claims description 9

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 8

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 claims description 8

- 239000004820 Pressure-sensitive adhesive Substances 0.000 claims description 7

- 238000004519 manufacturing process Methods 0.000 claims description 7

- 229910052782 aluminium Inorganic materials 0.000 claims description 6

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 6

- 239000000463 material Substances 0.000 description 24

- 230000008569 process Effects 0.000 description 22

- 239000000203 mixture Substances 0.000 description 21

- 239000006185 dispersion Substances 0.000 description 17

- -1 disulfonates Chemical class 0.000 description 15

- 238000007639 printing Methods 0.000 description 15

- 239000004372 Polyvinyl alcohol Substances 0.000 description 11

- 239000000178 monomer Substances 0.000 description 11

- 238000000059 patterning Methods 0.000 description 11

- 229920002451 polyvinyl alcohol Polymers 0.000 description 11

- 239000002904 solvent Substances 0.000 description 11

- 239000004094 surface-active agent Substances 0.000 description 11

- 230000005540 biological transmission Effects 0.000 description 10

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 9

- 229920000139 polyethylene terephthalate Polymers 0.000 description 7

- 239000005020 polyethylene terephthalate Substances 0.000 description 7

- 239000002861 polymer material Substances 0.000 description 7

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 6

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 6

- 230000008021 deposition Effects 0.000 description 6

- 238000000151 deposition Methods 0.000 description 6

- 239000011521 glass Substances 0.000 description 6

- 230000003287 optical effect Effects 0.000 description 6

- 239000002245 particle Substances 0.000 description 6

- 238000002834 transmittance Methods 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 5

- 239000011230 binding agent Substances 0.000 description 5

- 239000001866 hydroxypropyl methyl cellulose Substances 0.000 description 5

- 229920003088 hydroxypropyl methyl cellulose Polymers 0.000 description 5

- UFVKGYZPFZQRLF-UHFFFAOYSA-N hydroxypropyl methyl cellulose Chemical compound OC1C(O)C(OC)OC(CO)C1OC1C(O)C(O)C(OC2C(C(O)C(OC3C(C(O)C(O)C(CO)O3)O)C(CO)O2)O)C(CO)O1 UFVKGYZPFZQRLF-UHFFFAOYSA-N 0.000 description 5

- 235000010979 hydroxypropyl methyl cellulose Nutrition 0.000 description 5

- 239000007787 solid Substances 0.000 description 5

- 238000005507 spraying Methods 0.000 description 5

- 239000004034 viscosity adjusting agent Substances 0.000 description 5

- 206010073306 Exposure to radiation Diseases 0.000 description 4

- 239000000654 additive Substances 0.000 description 4

- 230000008859 change Effects 0.000 description 4

- 229920001940 conductive polymer Polymers 0.000 description 4

- 238000001035 drying Methods 0.000 description 4

- 238000009472 formulation Methods 0.000 description 4

- 239000004973 liquid crystal related substance Substances 0.000 description 4

- 239000004417 polycarbonate Substances 0.000 description 4

- 229920000515 polycarbonate Polymers 0.000 description 4

- 229920000728 polyester Polymers 0.000 description 4

- 238000006116 polymerization reaction Methods 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- IDOQDZANRZQBTP-UHFFFAOYSA-N 2-[2-(2,4,4-trimethylpentan-2-yl)phenoxy]ethanol Chemical compound CC(C)(C)CC(C)(C)C1=CC=CC=C1OCCO IDOQDZANRZQBTP-UHFFFAOYSA-N 0.000 description 3

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 3

- 239000002042 Silver nanowire Substances 0.000 description 3

- 229920004929 Triton X-114 Polymers 0.000 description 3

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 3

- 229920002678 cellulose Polymers 0.000 description 3

- 238000006243 chemical reaction Methods 0.000 description 3

- 239000008199 coating composition Substances 0.000 description 3

- 239000000470 constituent Substances 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 238000004132 cross linking Methods 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 238000007756 gravure coating Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 229930195733 hydrocarbon Natural products 0.000 description 3

- 235000019447 hydroxyethyl cellulose Nutrition 0.000 description 3

- 238000007641 inkjet printing Methods 0.000 description 3

- 238000003475 lamination Methods 0.000 description 3

- 229920000609 methyl cellulose Polymers 0.000 description 3

- 239000001923 methylcellulose Substances 0.000 description 3

- 235000010981 methylcellulose Nutrition 0.000 description 3

- 229920000098 polyolefin Polymers 0.000 description 3

- 238000007650 screen-printing Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 238000011282 treatment Methods 0.000 description 3

- 239000000230 xanthan gum Substances 0.000 description 3

- 229920001285 xanthan gum Polymers 0.000 description 3

- 235000010493 xanthan gum Nutrition 0.000 description 3

- 229940082509 xanthan gum Drugs 0.000 description 3

- LCZVSXRMYJUNFX-UHFFFAOYSA-N 2-[2-(2-hydroxypropoxy)propoxy]propan-1-ol Chemical compound CC(O)COC(C)COC(C)CO LCZVSXRMYJUNFX-UHFFFAOYSA-N 0.000 description 2

- CWSZBVAUYPTXTG-UHFFFAOYSA-N 5-[6-[[3,4-dihydroxy-6-(hydroxymethyl)-5-methoxyoxan-2-yl]oxymethyl]-3,4-dihydroxy-5-[4-hydroxy-3-(2-hydroxyethoxy)-6-(hydroxymethyl)-5-methoxyoxan-2-yl]oxyoxan-2-yl]oxy-6-(hydroxymethyl)-2-methyloxane-3,4-diol Chemical compound O1C(CO)C(OC)C(O)C(O)C1OCC1C(OC2C(C(O)C(OC)C(CO)O2)OCCO)C(O)C(O)C(OC2C(OC(C)C(O)C2O)CO)O1 CWSZBVAUYPTXTG-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 2

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 2

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 2

- 229920000663 Hydroxyethyl cellulose Polymers 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 2

- 239000002033 PVDF binder Substances 0.000 description 2

- 239000004642 Polyimide Substances 0.000 description 2

- 239000004793 Polystyrene Substances 0.000 description 2

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 2

- XECAHXYUAAWDEL-UHFFFAOYSA-N acrylonitrile butadiene styrene Chemical compound C=CC=C.C=CC#N.C=CC1=CC=CC=C1 XECAHXYUAAWDEL-UHFFFAOYSA-N 0.000 description 2

- 239000004676 acrylonitrile butadiene styrene Substances 0.000 description 2

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 2

- 230000003667 anti-reflective effect Effects 0.000 description 2

- 239000003849 aromatic solvent Substances 0.000 description 2

- 238000009835 boiling Methods 0.000 description 2

- 239000001913 cellulose Substances 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 239000008367 deionised water Substances 0.000 description 2

- 229910021641 deionized water Inorganic materials 0.000 description 2

- 238000010017 direct printing Methods 0.000 description 2

- GNTDGMZSJNCJKK-UHFFFAOYSA-N divanadium pentaoxide Chemical compound O=[V](=O)O[V](=O)=O GNTDGMZSJNCJKK-UHFFFAOYSA-N 0.000 description 2

- 230000008020 evaporation Effects 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 229920002313 fluoropolymer Polymers 0.000 description 2

- 230000004927 fusion Effects 0.000 description 2

- 238000007646 gravure printing Methods 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 239000003112 inhibitor Substances 0.000 description 2

- 150000002576 ketones Chemical class 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- 125000005487 naphthalate group Chemical group 0.000 description 2

- 230000009972 noncorrosive effect Effects 0.000 description 2

- 238000007645 offset printing Methods 0.000 description 2

- 238000000206 photolithography Methods 0.000 description 2

- 229920002120 photoresistant polymer Polymers 0.000 description 2

- 229920002492 poly(sulfone) Polymers 0.000 description 2

- 229920000058 polyacrylate Polymers 0.000 description 2

- 229920001721 polyimide Polymers 0.000 description 2

- 229920000193 polymethacrylate Polymers 0.000 description 2

- 229920001296 polysiloxane Polymers 0.000 description 2

- 229920002223 polystyrene Polymers 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- SQGYOTSLMSWVJD-UHFFFAOYSA-N silver(1+) nitrate Chemical compound [Ag+].[O-]N(=O)=O SQGYOTSLMSWVJD-UHFFFAOYSA-N 0.000 description 2

- 238000011410 subtraction method Methods 0.000 description 2

- 230000003746 surface roughness Effects 0.000 description 2

- 229920002554 vinyl polymer Polymers 0.000 description 2

- 239000008096 xylene Substances 0.000 description 2

- ZRYCRPNCXLQHPN-UHFFFAOYSA-N 3-hydroxy-2-methylbenzaldehyde Chemical compound CC1=C(O)C=CC=C1C=O ZRYCRPNCXLQHPN-UHFFFAOYSA-N 0.000 description 1

- 229920002284 Cellulose triacetate Polymers 0.000 description 1

- 229910002482 Cu–Ni Inorganic materials 0.000 description 1

- XDTMQSROBMDMFD-UHFFFAOYSA-N Cyclohexane Chemical compound C1CCCCC1 XDTMQSROBMDMFD-UHFFFAOYSA-N 0.000 description 1

- 229920002943 EPDM rubber Polymers 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 1

- 239000004354 Hydroxyethyl cellulose Substances 0.000 description 1

- 229910019142 PO4 Inorganic materials 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004697 Polyetherimide Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 229920001328 Polyvinylidene chloride Polymers 0.000 description 1

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical compound CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- ULUAUXLGCMPNKK-UHFFFAOYSA-N Sulfobutanedioic acid Chemical class OC(=O)CC(C(O)=O)S(O)(=O)=O ULUAUXLGCMPNKK-UHFFFAOYSA-N 0.000 description 1

- 239000004809 Teflon Substances 0.000 description 1

- 229920006362 Teflon® Polymers 0.000 description 1

- 239000012963 UV stabilizer Substances 0.000 description 1

- NNLVGZFZQQXQNW-ADJNRHBOSA-N [(2r,3r,4s,5r,6s)-4,5-diacetyloxy-3-[(2s,3r,4s,5r,6r)-3,4,5-triacetyloxy-6-(acetyloxymethyl)oxan-2-yl]oxy-6-[(2r,3r,4s,5r,6s)-4,5,6-triacetyloxy-2-(acetyloxymethyl)oxan-3-yl]oxyoxan-2-yl]methyl acetate Chemical compound O([C@@H]1O[C@@H]([C@H]([C@H](OC(C)=O)[C@H]1OC(C)=O)O[C@H]1[C@@H]([C@@H](OC(C)=O)[C@H](OC(C)=O)[C@@H](COC(C)=O)O1)OC(C)=O)COC(=O)C)[C@@H]1[C@@H](COC(C)=O)O[C@@H](OC(C)=O)[C@H](OC(C)=O)[C@H]1OC(C)=O NNLVGZFZQQXQNW-ADJNRHBOSA-N 0.000 description 1

- DHKHKXVYLBGOIT-UHFFFAOYSA-N acetaldehyde Diethyl Acetal Natural products CCOC(C)OCC DHKHKXVYLBGOIT-UHFFFAOYSA-N 0.000 description 1

- 150000001241 acetals Chemical class 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-M acrylate group Chemical group C(C=C)(=O)[O-] NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000007774 anilox coating Methods 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 125000003118 aryl group Chemical group 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- 239000002041 carbon nanotube Substances 0.000 description 1

- 239000001768 carboxy methyl cellulose Substances 0.000 description 1

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 1

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 229920002301 cellulose acetate Polymers 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 239000003431 cross linking reagent Substances 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000003618 dip coating Methods 0.000 description 1

- 239000004815 dispersion polymer Substances 0.000 description 1

- NLEBIOOXCVAHBD-QKMCSOCLSA-N dodecyl beta-D-maltoside Chemical compound O[C@@H]1[C@@H](O)[C@H](OCCCCCCCCCCCC)O[C@H](CO)[C@H]1O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1 NLEBIOOXCVAHBD-QKMCSOCLSA-N 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 239000003623 enhancer Substances 0.000 description 1

- 229920006332 epoxy adhesive Polymers 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- 238000004299 exfoliation Methods 0.000 description 1

- 239000004811 fluoropolymer Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000007731 hot pressing Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 238000011031 large-scale manufacturing process Methods 0.000 description 1

- 238000000608 laser ablation Methods 0.000 description 1

- 238000007644 letterpress printing Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 150000002736 metal compounds Chemical class 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 229910052752 metalloid Inorganic materials 0.000 description 1

- 150000002738 metalloids Chemical class 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 229920003986 novolac Polymers 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- KDLHZDBZIXYQEI-UHFFFAOYSA-N palladium Substances [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 235000021317 phosphate Nutrition 0.000 description 1

- 150000003013 phosphoric acid derivatives Chemical class 0.000 description 1

- 238000009832 plasma treatment Methods 0.000 description 1

- 229920000636 poly(norbornene) polymer Polymers 0.000 description 1

- 229920000548 poly(silane) polymer Polymers 0.000 description 1

- 229920002239 polyacrylonitrile Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1

- 229920000767 polyaniline Polymers 0.000 description 1

- 229920000015 polydiacetylene Polymers 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 229920001601 polyetherimide Polymers 0.000 description 1

- 229920006254 polymer film Polymers 0.000 description 1

- 239000003505 polymerization initiator Substances 0.000 description 1

- 229920000306 polymethylpentene Polymers 0.000 description 1

- 229920005862 polyol Polymers 0.000 description 1

- 150000003077 polyols Chemical class 0.000 description 1

- 229920013636 polyphenyl ether polymer Polymers 0.000 description 1

- 229920001955 polyphenylene ether Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920000734 polysilsesquioxane polymer Polymers 0.000 description 1

- 239000005077 polysulfide Substances 0.000 description 1

- 229920001021 polysulfide Polymers 0.000 description 1

- 150000008117 polysulfides Polymers 0.000 description 1

- 229920000123 polythiophene Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 235000019422 polyvinyl alcohol Nutrition 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 229920002102 polyvinyl toluene Polymers 0.000 description 1

- 239000005033 polyvinylidene chloride Substances 0.000 description 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000000523 sample Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229920005573 silicon-containing polymer Polymers 0.000 description 1

- 239000013464 silicone adhesive Substances 0.000 description 1

- 150000003378 silver Chemical class 0.000 description 1

- 229910001961 silver nitrate Inorganic materials 0.000 description 1

- 238000007767 slide coating Methods 0.000 description 1

- 238000007764 slot die coating Methods 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 239000012453 solvate Substances 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 150000003871 sulfonates Chemical class 0.000 description 1

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 239000005061 synthetic rubber Substances 0.000 description 1

- 238000010345 tape casting Methods 0.000 description 1

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- 238000012876 topography Methods 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

- GPRLSGONYQIRFK-MNYXATJNSA-N triton Chemical compound [3H+] GPRLSGONYQIRFK-MNYXATJNSA-N 0.000 description 1

- 239000002966 varnish Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/22—Secondary treatment of printed circuits

- H05K3/28—Applying non-metallic protective coatings

- H05K3/284—Applying non-metallic protective coatings for encapsulating mounted components

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/03—Arrangements for converting the position or the displacement of a member into a coded form

- G06F3/041—Digitisers, e.g. for touch screens or touch pads, characterised by the transducing means

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/03—Arrangements for converting the position or the displacement of a member into a coded form

- G06F3/041—Digitisers, e.g. for touch screens or touch pads, characterised by the transducing means

- G06F3/0412—Digitisers structurally integrated in a display

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/03—Arrangements for converting the position or the displacement of a member into a coded form

- G06F3/041—Digitisers, e.g. for touch screens or touch pads, characterised by the transducing means

- G06F3/047—Digitisers, e.g. for touch screens or touch pads, characterised by the transducing means using sets of wires, e.g. crossed wires

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/0277—Bendability or stretchability details

- H05K1/028—Bending or folding regions of flexible printed circuits

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/0296—Conductive pattern lay-out details not covered by sub groups H05K1/02 - H05K1/0295

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/09—Use of materials for the conductive, e.g. metallic pattern

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/09—Use of materials for the conductive, e.g. metallic pattern

- H05K1/092—Dispersed materials, e.g. conductive pastes or inks

- H05K1/097—Inks comprising nanoparticles and specially adapted for being sintered at low temperature

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/02—Apparatus or processes for manufacturing printed circuits in which the conductive material is applied to the surface of the insulating support and is thereafter removed from such areas of the surface which are not intended for current conducting or shielding

- H05K3/04—Apparatus or processes for manufacturing printed circuits in which the conductive material is applied to the surface of the insulating support and is thereafter removed from such areas of the surface which are not intended for current conducting or shielding the conductive material being removed mechanically, e.g. by punching

- H05K3/046—Apparatus or processes for manufacturing printed circuits in which the conductive material is applied to the surface of the insulating support and is thereafter removed from such areas of the surface which are not intended for current conducting or shielding the conductive material being removed mechanically, e.g. by punching by selective transfer or selective detachment of a conductive layer

- H05K3/048—Apparatus or processes for manufacturing printed circuits in which the conductive material is applied to the surface of the insulating support and is thereafter removed from such areas of the surface which are not intended for current conducting or shielding the conductive material being removed mechanically, e.g. by punching by selective transfer or selective detachment of a conductive layer using a lift-off resist pattern or a release layer pattern

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/10—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern

- H05K3/103—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern by bonding or embedding conductive wires or strips

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/30—Assembling printed circuits with electric components, e.g. with resistor

- H05K3/32—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits

- H05K3/321—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by conductive adhesives

- H05K3/323—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by conductive adhesives by applying an anisotropic conductive adhesive layer over an array of pads

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2203/00—Indexing scheme relating to G06F3/00 - G06F3/048

- G06F2203/041—Indexing scheme relating to G06F3/041 - G06F3/045

- G06F2203/04103—Manufacturing, i.e. details related to manufacturing processes specially suited for touch sensitive devices

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2203/00—Indexing scheme relating to G06F3/00 - G06F3/048

- G06F2203/041—Indexing scheme relating to G06F3/041 - G06F3/045

- G06F2203/04112—Electrode mesh in capacitive digitiser: electrode for touch sensing is formed of a mesh of very fine, normally metallic, interconnected lines that are almost invisible to see. This provides a quite large but transparent electrode surface, without need for ITO or similar transparent conductive material

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/03—Use of materials for the substrate

- H05K1/0393—Flexible materials

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/02—Fillers; Particles; Fibers; Reinforcement materials

- H05K2201/0203—Fillers and particles

- H05K2201/0242—Shape of an individual particle

- H05K2201/026—Nanotubes or nanowires

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/10—Details of components or other objects attached to or integrated in a printed circuit board

- H05K2201/10007—Types of components

- H05K2201/10128—Display

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/01—Tools for processing; Objects used during processing

- H05K2203/0104—Tools for processing; Objects used during processing for patterning or coating

- H05K2203/0143—Using a roller; Specific shape thereof; Providing locally adhesive portions thereon

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/14—Related to the order of processing steps

- H05K2203/1461—Applying or finishing the circuit pattern after another process, e.g. after filling of vias with conductive paste, after making printed resistors

- H05K2203/1469—Circuit made after mounting or encapsulation of the components

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/15—Position of the PCB during processing

- H05K2203/1545—Continuous processing, i.e. involving rolls moving a band-like or solid carrier along a continuous production path

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Theoretical Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Human Computer Interaction (AREA)

- Chemical & Material Sciences (AREA)

- Nanotechnology (AREA)

- Dispersion Chemistry (AREA)

- Laminated Bodies (AREA)

- Non-Insulated Conductors (AREA)

- Manufacturing Of Electric Cables (AREA)

- Parts Printed On Printed Circuit Boards (AREA)

Description

[1]

電子アセンブリを製造するための方法であって、

基材上のパターン化導電性ナノワイヤ層を覆うレジスト層に導電性接着剤を適用することと、

電子的構成要素の電気接点を前記導電性接着剤と係合させて、前記電子的構成要素と前記導電性ナノワイヤ層との間に電気的接続を提供することと、

を含む、方法。

[2]

前記導電性接着剤が、中に金属粒子を有する接着剤の層を備える、項目1に記載の方法。

[3]

前記金属粒子が、銀、金、銅、アルミニウム、及びこれらの組み合わせから選択される、項目2に記載の方法。

[4]

前記導電性接着剤が、アクリル系感圧性接着剤、熱接合接着剤、又はこれらの組み合わせを含む、項目2又は3に記載の方法。

[5]

前記レジスト層が、約10ナノメートル〜約300ナノメートルの厚さを有する、項目1〜4のいずれか一項に記載の方法。

[6]

前記レジスト層が、約40ナノメートル〜約200ナノメートルの厚さを有する、項目1〜4のいずれか一項に記載の方法。

[7]

前記レジスト層が、約1.30〜約2.50の屈折率を有する、項目1〜6のいずれか一項に記載の方法。

[8]

前記導電性接着剤が、テープを含む、項目1〜7のいずれか一項に記載の方法。

[9]

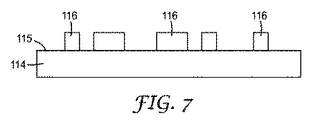

前記基材上の前記パターン化導電性ナノワイヤ層が、

ナノワイヤを含む導電性層で基材をコーティングすることと、

前記導電性層上にレジストマトリクス材料でパターンを適用して、露出した導電性層の1つ又は2つ以上の第1の領域と、レジストマトリクス材料の1つ又は2つ以上の第2の領域と、を前記基材上に生成することと、

前記レジストマトリクス材料を固化又は硬化させることと、

前記パターンにストリッピング可能なポリマー層を上塗りすることと、

前記ストリッピング可能なポリマー層を固化又は硬化させることと、

前記ストリッピング可能なポリマー層を前記基材から剥離することと、

前記露出した導電性層を前記基材の前記1つ又は2つ以上の第1の領域において前記基材から除去して、前記基材上にパターン化導電性層を形成することと、によって生成され、前記パターン化導電性層が、前記レジストマトリクス材料によって覆われるナノワイヤを含む、項目1〜8のいずれか一項に記載の方法。

[10]

前記基材上の前記パターン化導電性ナノワイヤ層が、

ナノワイヤを含む導電性層で基材をコーティングすることと、

前記導電性層上にストリッピング可能なポリマー液形成層でパターンを適用して、露出した導電性層の1つ又は2つ以上の第1の領域と、前記ストリッピング可能なポリマー液形成層で被覆された1つ又は2つ以上の第2の領域と、を前記基材上に生成することと、

前記ストリッピング可能なポリマー液形成層を固化又は硬化させてストリッピング可能なポリマー層にすることと、

前記ストリッピング可能なポリマー層を前記基材から剥離することと、前記基材の前記1つ又は2つ以上の第2の領域において前記導電性層の部分を除去して、前記基材上にパターン化導電性層を形成することと、によって生成される、項目1〜8のいずれか一項に記載の方法。

[11]

前記導電性接着剤が、

基材上の前記パターン化導電性ナノワイヤ層を覆う前記レジスト層に転写テープの第1の側面を適用することであって、前記転写テープの前記第1の側面が、金属粒子を含む接着性マトリクスを含む第1の導電性接着剤層を備え、前記接着性マトリクスが、感圧性接着剤、熱接合接着剤、又はこれらの組み合わせを含み、前記金属粒子が、前記レジスト層から突出するナノワイヤと接触する、適用することと、

前記第1の側面の反対側の前記転写テープの第2の側面上で、電子的構成要素の金属接点を導電性接着剤層と係合させて、前記電子的構成要素と前記導電性ナノワイヤ層との間に電気的接続を提供することと、によって適用される、項目1に記載の方法。

[12]

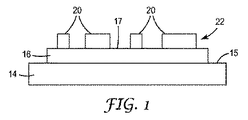

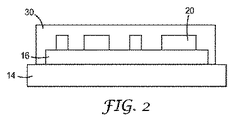

電子アセンブリであって、

導電性ナノワイヤのパターンを上に備える基材であって、前記導電性ナノワイヤが、レジストマトリクス材料の層によって覆われる、基材と、

前記レジストマトリクス材料の層上の導電性接着剤と、

前記導電性接着剤と接触している電子的構成要素の電気接点と、

を備える、電子アセンブリ。

[13]

前記レジストマトリクス材料が、約10ナノメートル〜約300ナノメートルの厚さを有する、項目12に記載の電子アセンブリ。

[14]

前記レジストマトリクス材料が、約40ナノメートル〜約200ナノメートルの厚さを有する、項目12に記載の電子アセンブリ。

[15]

前記導電性接着剤が転写テープを備え、前記転写テープが、前記レジストマトリクス材料の層と接触する第1の導電性接着剤層を上に有する第1の側面と、前記第1の側面の反対側の第2の側面と、を備え、前記第2の側面が、前記電子的構成要素の前記電気接点と接触する第2の導電性接着剤層を備える、項目12〜14のいずれか一項に記載の電子アセンブリ。

[16]

前記第1の導電性接着剤層が、金属粒子を含む接着剤のマトリクスを含み、前記接着剤が、感圧性接着剤、熱接合接着剤、及びこれらの組み合わせを含み、前記第1の導電性接着剤層内の前記金属粒子が、前記導電性パターン及び前記レジストマトリクス材料から突出するナノワイヤと接触する、項目15に記載の電子アセンブリ。

[17]

前記金属粒子が、銀、金、銅、アルミニウム、又はこれらの組み合わせを含む、項目16に記載の電子アセンブリ。

[18]

前記電子的構成要素が、フレキシブル回路を含む、項目12〜17のいずれか一項に記載の電子アセンブリ。

[19]

項目1〜11のいずれか一項に記載の方法に従って製造される、電子アセンブリ。

[20]

タッチスクリーンディスプレイであって、

液晶ディスプレイと、

電子アセンブリであって、

前記液晶ディスプレイ上のガラス基材であって、導電性ナノワイヤのパターンをその上に備え、前記導電性ナノワイヤが、レジストマトリクス材料の層によって覆われる、ガラス基材と、

前記レジストマトリクス材料の層上の導電性接着剤と、

前記導電性接着剤と接触しているフレキシブル回路の電気接点と、を備える、電子アセンブリと、

前記電子アセンブリを覆う可撓性透明面と、を備える、タッチスクリーンディスプレイ。

[21]

前記第1の導電性接着剤層が、金属粒子が充填された接着剤のマトリクスを含み、前記接着剤が、感圧性接着剤、熱接合接着剤、及びこれらの組み合わせを含み、前記第1の導電性接着剤層内の前記金属粒子が、前記導電性パターンから突出して前記レジストマトリクス材料へと至るナノワイヤと接触する、項目20に記載のディスプレイ。

[22]

前記レジストマトリクス材料が、約10ナノメートル〜約300ナノメートルの厚さを有する、項目20又は21に記載のディスプレイ。

Claims (9)

- 電子アセンブリを製造するための方法であって、

基材上のパターン化導電性ナノワイヤ層を覆うレジスト層に導電性接着剤を適用することと、

電子部品の電気接点を前記導電性接着剤と係合させて、前記電子部品と前記導電性ナノワイヤ層との間に電気的接続を提供することと、

を含む、方法。 - 前記導電性接着剤が、中に金属粒子を有する接着剤の層を備える、請求項1に記載の方法。

- 前記基材上の前記パターン化導電性ナノワイヤ層が、

ナノワイヤを含む導電性層で基材をコーティングすることと、

前記導電性層上にレジストマトリクス材料でパターンを適用して、露出した導電性層の1つ又は2つ以上の第1の領域と、レジストマトリクス材料の1つ又は2つ以上の第2の領域と、を前記基材上に生成することと、

前記レジストマトリクス材料を固化又は硬化させることと、

前記パターンにストリッピング可能なポリマー層を上塗りすることと、

前記ストリッピング可能なポリマー層を固化又は硬化させることと、

前記ストリッピング可能なポリマー層を前記基材から剥離することと、

前記露出した導電性層を前記基材の前記1つ又は2つ以上の第1の領域において前記基材から除去して、前記基材上に前記パターン化導電性ナノワイヤ層を形成することと、によって生成され、前記パターン化導電性ナノワイヤ層が、前記レジストマトリクス材料によって覆われるナノワイヤを含む、請求項1又は2のいずれかに記載の方法。 - 前記基材上の前記パターン化導電性ナノワイヤ層が、

ナノワイヤを含む導電性層で基材をコーティングすることと、

前記導電性層上にストリッピング可能なポリマー液形成層でパターンを適用して、露出した導電性層の1つ又は2つ以上の第1の領域と、前記ストリッピング可能なポリマー液形成層で被覆された1つ又は2つ以上の第2の領域と、を前記基材上に生成することと、

前記ストリッピング可能なポリマー液形成層を固化又は硬化させてストリッピング可能なポリマー層にすることと、

前記ストリッピング可能なポリマー層を前記基材から剥離することと、前記基材の前記1つ又は2つ以上の第2の領域において前記導電性層の部分を除去して、前記基材上に前記パターン化導電性ナノワイヤ層を形成することと、によって生成される、請求項1又は2のいずれかに記載の方法。 - 前記導電性接着剤が、

基材上の前記パターン化導電性ナノワイヤ層を覆う前記レジスト層に転写テープの第1面を適用すること、

前記第1面の反対側の前記転写テープの第2面上で、電子部品の金属接点を導電性接着剤層と係合させて、前記電子部品と前記導電性ナノワイヤ層との間に電気的接続を提供することと、によって適用され、

前記転写テープの前記第1面が、金属粒子を含む接着性マトリクスを含む第1の導電性接着剤層を備え、前記接着性マトリクスが、感圧性接着剤、熱接合接着剤、又はこれらの組み合わせを含み、前記金属粒子が、前記レジスト層から突出するナノワイヤと接触する、請求項1に記載の方法。 - 電子アセンブリであって、

導電性ナノワイヤのパターンを上に備える基材であって、前記導電性ナノワイヤが、レジストマトリクス材料の層によって覆われる、基材と、

前記レジストマトリクス材料の層上の導電性接着剤と、

前記導電性接着剤と接触している電子部品の電気接点と、

を備える、電子アセンブリ。 - 前記レジストマトリクス材料が、約10ナノメートル〜約300ナノメートルの厚さを有する、請求項6に記載の電子アセンブリ。

- 前記導電性接着剤が転写テープを備え、前記転写テープが、前記レジストマトリクス材料の層と接触する第1の導電性接着剤層を上に有する第1面と、前記第1面の反対側の第2面と、を備え、前記第2面が、前記電子部品の前記電気接点と接触する第2の導電性接着剤層を備える、請求項6又は7のいずれかに記載の電子アセンブリ。

- 前記第1の導電性接着剤層が金属粒子を含む接着性マトリクスを含み、前記金属粒子が、銀、金、銅、アルミニウム、又はこれらの組み合わせを含む、請求項8に記載の電子アセンブリ。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201361860841P | 2013-07-31 | 2013-07-31 | |

| US61/860,841 | 2013-07-31 | ||

| PCT/US2014/047212 WO2015017143A1 (en) | 2013-07-31 | 2014-07-18 | Bonding electronic components to patterned nanowire transparent conductors |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016530622A JP2016530622A (ja) | 2016-09-29 |

| JP2016530622A5 JP2016530622A5 (ja) | 2017-08-17 |

| JP6426737B2 true JP6426737B2 (ja) | 2018-11-21 |

Family

ID=52432333

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016531742A Expired - Fee Related JP6426737B2 (ja) | 2013-07-31 | 2014-07-18 | 電子的構成要素とパターン化ナノワイヤ透明伝導体との接合 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US9980394B2 (ja) |

| EP (1) | EP3028126B1 (ja) |

| JP (1) | JP6426737B2 (ja) |

| KR (1) | KR102254683B1 (ja) |

| CN (1) | CN105453001B (ja) |

| BR (1) | BR112016002093A2 (ja) |

| SG (2) | SG10201808518RA (ja) |

| WO (1) | WO2015017143A1 (ja) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SG11201602419WA (en) | 2013-09-30 | 2016-04-28 | 3M Innovative Properties Co | Protective coating for printed conductive pattern on patterned nanowire transparent conductors |

| US20150108632A1 (en) * | 2013-10-23 | 2015-04-23 | Nano And Advanced Materials Institute Limited | Thin film with negative temperature coefficient behavior and method of making thereof |

| JP6592246B2 (ja) * | 2015-01-27 | 2019-10-16 | 株式会社コムラテック | 電子回路基板およびその製造方法 |

| US10298152B2 (en) * | 2015-04-20 | 2019-05-21 | Lawrence Livermore National Security, Llc | Harvesting mechanical and thermal energy by combining nanowires and phase change materials |

| CN107735755B (zh) * | 2015-07-08 | 2020-08-25 | 夏普株式会社 | 触摸面板装置 |

| JP6654954B2 (ja) * | 2016-03-31 | 2020-02-26 | デクセリアルズ株式会社 | 異方性導電接続構造体 |

| CN108885515A (zh) * | 2016-04-05 | 2018-11-23 | 3M创新有限公司 | 对金属互连结构具有增强粘附性的纳米线接触垫 |

| TWI732892B (zh) * | 2016-07-26 | 2021-07-11 | 日商松下知識產權經營股份有限公司 | 透視型電極用積層板、透視型電極素材、組件及透視型電極用積層板之製造方法 |

| WO2019032846A1 (en) * | 2017-08-10 | 2019-02-14 | Molex, Llc | METHOD AND APPARATUS FOR FORMING AN ELECTRICAL CIRCUIT COMPRISING ALUMINUM AND ONE OR MORE DISSOLVABLE METALS |

| CA2985254A1 (en) | 2017-11-14 | 2019-05-14 | Vuereal Inc | Integration and bonding of micro-devices into system substrate |

| DE102018106959A1 (de) | 2018-03-23 | 2019-09-26 | Osram Opto Semiconductors Gmbh | Optoelektronisches bauelement und verfahren zur herstellung eines optoelektronischen bauelements |

| WO2020150902A1 (zh) * | 2019-01-22 | 2020-07-30 | 深圳市柔宇科技有限公司 | 柔性显示面板及其制作方法 |

| US11387202B2 (en) | 2019-03-01 | 2022-07-12 | Invensas Llc | Nanowire bonding interconnect for fine-pitch microelectronics |

| WO2020212336A1 (de) | 2019-04-15 | 2020-10-22 | Wika Alexander Wiegand Se & Co. Kg | Sensor zur erfassung von druck, füllstand, dichte, temperatur, masse und/oder durchfluss |

| DE112020001959A5 (de) | 2019-04-17 | 2021-12-30 | Wika Alexander Wiegand Se & Co. Kg | Sensor zur Erfassung von Druck und/oder Füllstand und/oder Durchfluss und/oder Dichte und/oder Masse und/oder Temperatur |

| CN112860130A (zh) * | 2019-11-26 | 2021-05-28 | 英属维尔京群岛商天材创新材料科技股份有限公司 | 触控面板及其制作方法 |

| US11261529B2 (en) * | 2020-03-31 | 2022-03-01 | Futuretech Capital, Inc. | Reduced visibility conductive micro mesh touch sensor |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6037005A (en) * | 1998-05-12 | 2000-03-14 | 3M Innovative Properties Company | Display substrate electrodes with auxiliary metal layers for enhanced conductivity |

| US6975067B2 (en) | 2002-12-19 | 2005-12-13 | 3M Innovative Properties Company | Organic electroluminescent device and encapsulation method |

| JP2008537338A (ja) | 2005-04-11 | 2008-09-11 | スリーエム イノベイティブ プロパティズ カンパニー | 導電性物品の接続方法、及び当該接続方法により接続された部品を備えた電気又は電子構成要素 |

| SG183720A1 (en) | 2005-08-12 | 2012-09-27 | Cambrios Technologies Corp | Nanowires-based transparent conductors |

| JP5409369B2 (ja) | 2006-10-12 | 2014-02-05 | カンブリオス テクノロジーズ コーポレイション | ナノワイヤベースの透明導電体およびその適用 |

| TWI500719B (zh) * | 2008-02-26 | 2015-09-21 | Cambrios Technologies Corp | 用於導電部件之網印的方法及組合物 |

| WO2010018733A1 (ja) * | 2008-08-11 | 2010-02-18 | コニカミノルタホールディングス株式会社 | 透明電極、有機エレクトロルミネッセンス素子及び透明電極の製造方法 |

| KR101938011B1 (ko) * | 2009-11-20 | 2019-01-11 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 표면-개질된 접착제 |

| KR101219139B1 (ko) * | 2009-12-24 | 2013-01-07 | 제일모직주식회사 | 이방 도전성 페이스트, 필름 및 이를 포함하는 회로접속구조체 |

| JP5718449B2 (ja) * | 2010-03-23 | 2015-05-13 | カンブリオス テクノロジーズ コーポレイション | 金属ナノワイヤを有する透明導体のエッチングパターン形成 |

| JP4870836B1 (ja) * | 2010-11-19 | 2012-02-08 | 日本写真印刷株式会社 | 狭額縁タッチ入力シートの製造方法 |

| CN103080876A (zh) | 2010-07-05 | 2013-05-01 | Dic株式会社 | 带透明导电层的基体及其制造方法、以及触控面板用透明导电膜层叠体、触控面板 |

| US20120247527A1 (en) | 2010-12-21 | 2012-10-04 | Alphabet Energy, Inc. | Electrode structures for arrays of nanostructures and methods thereof |

| EP2672369A4 (en) * | 2011-02-04 | 2014-11-12 | Shinetsu Polymer Co | CAPACITIVE SENSING SHEET AND METHOD FOR MANUFACTURING THE SAME |

| US9835913B2 (en) * | 2011-04-15 | 2017-12-05 | 3M Innovative Properties Company | Transparent electrode for electronic displays |

| JP2013077435A (ja) * | 2011-09-30 | 2013-04-25 | Oji Holdings Corp | 導電性転写シートおよび導電性積層体 |

| KR20130071863A (ko) | 2011-12-21 | 2013-07-01 | 삼성전기주식회사 | 터치패널 |

| JP5993028B2 (ja) * | 2012-11-08 | 2016-09-14 | アルプス電気株式会社 | 導電体及びその製造方法 |

| EP2929417A4 (en) | 2012-12-07 | 2016-07-20 | 3M Innovative Properties Co | METHOD FOR PRODUCING TRANSPARENT CONDUCTORS ON A SUBSTRATE |

| JP6322188B2 (ja) * | 2013-03-26 | 2018-05-09 | 株式会社カネカ | 導電性フィルム基板、透明導電性フィルムおよびその製造方法、ならびにタッチパネル |

-

2014

- 2014-07-18 CN CN201480042647.9A patent/CN105453001B/zh not_active Expired - Fee Related

- 2014-07-18 WO PCT/US2014/047212 patent/WO2015017143A1/en active Application Filing

- 2014-07-18 BR BR112016002093A patent/BR112016002093A2/pt not_active IP Right Cessation

- 2014-07-18 SG SG10201808518RA patent/SG10201808518RA/en unknown

- 2014-07-18 SG SG11201600591VA patent/SG11201600591VA/en unknown

- 2014-07-18 KR KR1020167003895A patent/KR102254683B1/ko active IP Right Grant

- 2014-07-18 US US14/897,521 patent/US9980394B2/en active Active

- 2014-07-18 JP JP2016531742A patent/JP6426737B2/ja not_active Expired - Fee Related

- 2014-07-18 EP EP14832317.3A patent/EP3028126B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US9980394B2 (en) | 2018-05-22 |

| SG10201808518RA (en) | 2018-10-30 |

| EP3028126A1 (en) | 2016-06-08 |

| KR102254683B1 (ko) | 2021-05-21 |

| BR112016002093A2 (pt) | 2017-08-01 |

| WO2015017143A1 (en) | 2015-02-05 |

| SG11201600591VA (en) | 2016-02-26 |

| US20160143153A1 (en) | 2016-05-19 |

| CN105453001A (zh) | 2016-03-30 |

| JP2016530622A (ja) | 2016-09-29 |

| EP3028126B1 (en) | 2020-10-07 |

| KR20160036571A (ko) | 2016-04-04 |

| EP3028126A4 (en) | 2017-01-25 |

| CN105453001B (zh) | 2018-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6426737B2 (ja) | 電子的構成要素とパターン化ナノワイヤ透明伝導体との接合 | |

| US10831233B2 (en) | Method of making transparent conductors on a substrate | |

| KR102264357B1 (ko) | 패턴화된 나노와이어 투명 전도체 상의 인쇄된 전도성 패턴을 위한 보호 코팅 | |

| US20190114003A1 (en) | Nanowire contact pads with enhanced adhesion to metal interconnects | |

| US10492305B2 (en) | Patterned overcoat layer | |

| US11284521B2 (en) | Electronic devices comprising a via and methods of forming such electronic devices | |

| US20190357360A1 (en) | Methods for Preparing Electrically Conductive Patterns and Articles Containing Electrically Conductive Patterns |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170705 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170705 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180731 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180807 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180910 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20180925 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20181025 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6426737 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |