JP6152000B2 - 車両用樹脂製中空積層板 - Google Patents

車両用樹脂製中空積層板 Download PDFInfo

- Publication number

- JP6152000B2 JP6152000B2 JP2013155511A JP2013155511A JP6152000B2 JP 6152000 B2 JP6152000 B2 JP 6152000B2 JP 2013155511 A JP2013155511 A JP 2013155511A JP 2013155511 A JP2013155511 A JP 2013155511A JP 6152000 B2 JP6152000 B2 JP 6152000B2

- Authority

- JP

- Japan

- Prior art keywords

- plate

- resin

- main body

- sheet

- body member

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R13/00—Elements for body-finishing, identifying, or decorating; Arrangements or adaptations for advertising purposes

- B60R13/02—Internal Trim mouldings ; Internal Ledges; Wall liners for passenger compartments; Roof liners

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/001—Combinations of extrusion moulding with other shaping operations

- B29C48/0021—Combinations of extrusion moulding with other shaping operations combined with joining, lining or laminating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/025—General arrangement or layout of plant

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/07—Flat, e.g. panels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/09—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels

- B29C48/11—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels comprising two or more partially or fully enclosed cavities, e.g. honeycomb-shaped

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/12—Articles with an irregular circumference when viewed in cross-section, e.g. window profiles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/065—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of foam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/28—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer comprising a deformed thin sheet, i.e. the layer having its entire thickness deformed out of the plane, e.g. corrugated, crumpled

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/90—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article

- B29C48/904—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article using dry calibration, i.e. no quenching tank, e.g. with water spray for cooling or lubrication

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/88—Thermal treatment of the stream of extruded material, e.g. cooling

- B29C48/90—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article

- B29C48/906—Thermal treatment of the stream of extruded material, e.g. cooling with calibration or sizing, i.e. combined with fixing or setting of the final dimensions of the extruded article using roller calibration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2023/00—Use of polyalkenes or derivatives thereof as moulding material

- B29K2023/10—Polymers of propylene

- B29K2023/12—PP, i.e. polypropylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/04—Condition, form or state of moulded material or of the material to be shaped cellular or porous

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2509/00—Use of inorganic materials not provided for in groups B29K2503/00 - B29K2507/00, as filler

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/03—3 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/40—Symmetrical or sandwich layers, e.g. ABA, ABCBA, ABCCBA

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2266/00—Composition of foam

- B32B2266/02—Organic

- B32B2266/0214—Materials belonging to B32B27/00

- B32B2266/025—Polyolefin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/718—Weight, e.g. weight per square meter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/732—Dimensional properties

- B32B2307/734—Dimensional stability

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/003—Interior finishings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24628—Nonplanar uniform thickness material

- Y10T428/24661—Forming, or cooperating to form cells

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Vehicle Interior And Exterior Ornaments, Soundproofing, And Insulation (AREA)

- Laminated Bodies (AREA)

Description

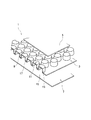

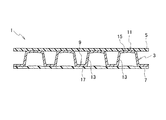

(車両用樹脂製中空積層板の構成)

まず、本発明の第1実施形態について説明する。

本体部材3、第1板状部材5および第2板状部材7を成形する合成樹脂の材料としては、例えば、低密度ポリエチレン、高密度ポリエチレン、直鎖状低密度ポリエチレン、ホモポリプロピレン、ランダムポリプロピレン、ブロック状ポリプロピレン等のポリオレフィン系樹脂およびこれらのモノマーの共重合体若しくはモノマーと他のモノマーとの共重合体、ポリ塩化ビニル、塩素化ポリ塩化ビニル、ABS、AAS、AES、ポリスチレン、ポリエチレンテレフタレート、ポリカーボネート、ポリアミド、ポリフッ化ビニリデン、ポリフェニレンサルファイド、ポリサルホン、ポリエーテルケトン及びこれらのコモノマー若しくはコモノマーと他のモノマーとの共重合体等が好ましい。これらの材料は単独で使用しても併用しても良い。以上のように各種の熱可塑性樹脂を用いることができるが、コスト面、成形性、物性、耐低温性、耐熱性等の特性とのバランスを考慮すると、ポリプロピレン系樹脂が好ましい。

第1実施形態に係る車両用樹脂製中空積層板1は、例えば、以下の方法で製造することができる。

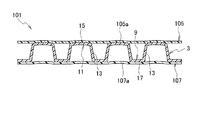

次いで、第2実施形態に係る車両用樹脂製中空積層板201について説明するが、前述した第1実施形態と同一構成の部位には、同一符号を付けて説明を省略する。

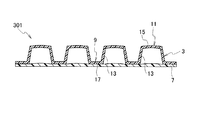

次いで、第3実施形態に係る車両用樹脂製中空積層板301について説明するが、前述した第1および第2実施形態と同一構成の部位には、同一符号を付けて説明を省略する。

3 本体部材

5 第1板状部材

7 第2板状部材

9 凹部

11 凸部

101 車両用樹脂製中空積層板

105 第1板状部材

107 第2板状部材

201 車両用樹脂製中空積層板

301 車両用樹脂製中空積層板

Claims (2)

- 複数の凹部および凸部を有すると共に合成樹脂からなる本体部材と、該本体部材の表面側に熱溶着される第1板状部材および裏面側に熱溶着される第2板状部材の少なくともいずれかと、を備えた車両用樹脂製中空積層板であって、

前記第1板状部材および第2板状部材は、合成樹脂に発泡剤を添加させて発泡させた発泡シートであり、

前記本体部材の前記複数の凸部は、等間隔に配置され、

前記本体部材、第1板状部材および第2板状部材の目付量は、850〜2000g/m 2 に設定されていることを特徴とする車両用樹脂製中空積層板。 - 前記第1板状部材および第2板状部材の発泡シートの発泡倍率は、1.2〜1.5倍に設定されたことを特徴とする請求項1に記載の車両用樹脂製中空積層板。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013155511A JP6152000B2 (ja) | 2013-07-26 | 2013-07-26 | 車両用樹脂製中空積層板 |

| US14/320,699 US20150030814A1 (en) | 2013-07-26 | 2014-07-01 | Vehicle interior member |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013155511A JP6152000B2 (ja) | 2013-07-26 | 2013-07-26 | 車両用樹脂製中空積層板 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015024572A JP2015024572A (ja) | 2015-02-05 |

| JP2015024572A5 JP2015024572A5 (ja) | 2016-08-12 |

| JP6152000B2 true JP6152000B2 (ja) | 2017-06-21 |

Family

ID=52390745

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013155511A Active JP6152000B2 (ja) | 2013-07-26 | 2013-07-26 | 車両用樹脂製中空積層板 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20150030814A1 (ja) |

| JP (1) | JP6152000B2 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6915827B2 (ja) * | 2016-07-20 | 2021-08-04 | 盟和産業株式会社 | 積層板 |

| CN110114208A (zh) * | 2016-12-27 | 2019-08-09 | 日本制铁株式会社 | 外装面板及外装面板的制造方法 |

| US11052835B2 (en) * | 2018-10-22 | 2021-07-06 | Motus Integrated Technologies | Vehicle interior component having a cover layer in contact with a foam layer |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5976334U (ja) * | 1982-11-16 | 1984-05-23 | 池田物産株式会社 | 内装材 |

| EP0943646A4 (en) * | 1996-09-30 | 2000-01-05 | Sekisui Chemical Co Ltd | EXPANDABLE SYNTHETIC RESIN COMPOSITION, SYNTHETIC RESIN FOAM, AND PROCESS FOR PRODUCING THE SAME |

| JP2003340968A (ja) * | 2002-05-30 | 2003-12-02 | Mitsubishi Chemicals Corp | 積層体 |

| JPWO2006043703A1 (ja) * | 2004-10-19 | 2008-05-22 | キョーラク株式会社 | 表皮付きブロー成形品およびその製造方法 |

| JP5603534B2 (ja) * | 2007-03-30 | 2014-10-08 | 盟和産業株式会社 | 積層板の製造方法 |

| JP6013892B2 (ja) * | 2012-11-29 | 2016-10-25 | 盟和産業株式会社 | 車両用内装部品 |

-

2013

- 2013-07-26 JP JP2013155511A patent/JP6152000B2/ja active Active

-

2014

- 2014-07-01 US US14/320,699 patent/US20150030814A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| US20150030814A1 (en) | 2015-01-29 |

| JP2015024572A (ja) | 2015-02-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2010050242A1 (ja) | サンドイッチパネルおよびサンドイッチパネル用芯材の成形方法、ならびにサンドイッチパネルの成形方法 | |

| KR20090118878A (ko) | 경량성 다층 구조물 및 제조방법 | |

| JP2011213090A (ja) | 樹脂積層板 | |

| JP2019513097A (ja) | 折り畳み式ハニカム構造物及びその製造方法 | |

| JP6986386B2 (ja) | 車両用シート部材 | |

| JP6152000B2 (ja) | 車両用樹脂製中空積層板 | |

| JP5795915B2 (ja) | ポリエチレン系樹脂発泡シート、発泡成形体、及びポリエチレン系樹脂発泡シートの製造方法 | |

| JP2017080991A (ja) | 中空構造板 | |

| US9221403B2 (en) | Interior part for vehicle and method for treating edge thereof | |

| CN203601137U (zh) | 车辆用内部部件 | |

| JP2007230130A (ja) | 発泡ハニカムコアを用いた吸音積層構造体 | |

| JP2010513053A (ja) | 発泡カバーシートを備える熱可塑性フィルム | |

| JP5932568B2 (ja) | ポリスチレン系樹脂積層発泡シート | |

| JP6650370B2 (ja) | 樹脂複合体及び樹脂複合体の製造方法 | |

| JP2005088200A (ja) | スチレン系樹脂積層発泡シートおよびその成形容器 | |

| JP2003334880A (ja) | 積層体及び成形品 | |

| JP2010280138A (ja) | ポリオレフィン系樹脂積層発泡シートの押出成形による製法 | |

| JP2007137045A (ja) | 複合発泡シート、その積層構造体及びそれらを用いたハニカム吸音構造体 | |

| JP2007069404A (ja) | 段ボール構造板 | |

| JP6468550B2 (ja) | 食品用トレイ | |

| KR20150083332A (ko) | 열팽창 마이크로캡슐을 포함하는 자동차 내장재용 경량 복합재 및 그 제조방법 | |

| JP2010269501A (ja) | ポリオレフィン系樹脂多層発泡シートの押出成形方法 | |

| JP6108440B2 (ja) | 熱可塑性樹脂中空板、及び該中空板からなる成形体 | |

| JP2009061973A (ja) | トラック貨物室用パネルの芯材 | |

| JP2012006335A (ja) | ポリスチレン系樹脂積層発泡板とその製造方法およびディスプレイパネル |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160622 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160622 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170203 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170221 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170420 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170523 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170526 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6152000 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |