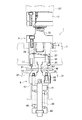

JP5869746B2 - バーリング加工方法及び金型 - Google Patents

バーリング加工方法及び金型 Download PDFInfo

- Publication number

- JP5869746B2 JP5869746B2 JP2009112702A JP2009112702A JP5869746B2 JP 5869746 B2 JP5869746 B2 JP 5869746B2 JP 2009112702 A JP2009112702 A JP 2009112702A JP 2009112702 A JP2009112702 A JP 2009112702A JP 5869746 B2 JP5869746 B2 JP 5869746B2

- Authority

- JP

- Japan

- Prior art keywords

- punch

- mold

- die

- protrusion

- burring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 23

- 239000002184 metal Substances 0.000 claims description 15

- 238000004080 punching Methods 0.000 claims description 10

- 230000003028 elevating effect Effects 0.000 description 8

- 238000000465 moulding Methods 0.000 description 5

- 230000002093 peripheral effect Effects 0.000 description 4

- 230000000149 penetrating effect Effects 0.000 description 3

- 125000006850 spacer group Chemical group 0.000 description 3

- 238000003672 processing method Methods 0.000 description 2

- 229920006311 Urethane elastomer Polymers 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000010079 rubber tapping Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

Images

Landscapes

- Punching Or Piercing (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009112702A JP5869746B2 (ja) | 2009-05-07 | 2009-05-07 | バーリング加工方法及び金型 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009112702A JP5869746B2 (ja) | 2009-05-07 | 2009-05-07 | バーリング加工方法及び金型 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010260078A JP2010260078A (ja) | 2010-11-18 |

| JP2010260078A5 JP2010260078A5 (enExample) | 2011-05-26 |

| JP5869746B2 true JP5869746B2 (ja) | 2016-02-24 |

Family

ID=43358613

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009112702A Active JP5869746B2 (ja) | 2009-05-07 | 2009-05-07 | バーリング加工方法及び金型 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5869746B2 (enExample) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013126673A (ja) * | 2011-12-19 | 2013-06-27 | Ricoh Co Ltd | 薄板バーリング加工方法及び薄板雌ねじ形成方法 |

| JP6051053B2 (ja) | 2013-01-11 | 2016-12-21 | 株式会社エフ・シー・シー | プレス部品の成形方法、プレス部品の製造方法およびプレス部品の成形用金型 |

| JP2014200876A (ja) * | 2013-04-03 | 2014-10-27 | 株式会社稲葉製作所 | 板材の雌ねじ形成方法およびねじ孔付き板材 |

| KR101510060B1 (ko) * | 2014-07-14 | 2015-04-08 | 김은태 | 안전띠 고리 금형장치 |

| JP6768437B2 (ja) * | 2016-09-30 | 2020-10-14 | 株式会社マーレ フィルターシステムズ | オイルフィルタの製造方法 |

| CN108620810A (zh) * | 2018-06-13 | 2018-10-09 | 山东吉恩纳机械工程技术有限公司 | 一种加强型调心滚子轴承保持架修整方法及工装 |

| CN113770254A (zh) * | 2021-09-28 | 2021-12-10 | 重庆平伟汽车科技股份有限公司 | 一种翻边侧整形模具及其上模和下模 |

| CN114347440B (zh) * | 2021-12-24 | 2024-04-12 | 浙江长盛滑动轴承股份有限公司 | 一种复合衬套外翻边加工设备 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2507720B2 (ja) * | 1986-12-24 | 1996-06-19 | 株式会社 アマダ | バ−リング加工方法とその加工方法に直接使用する金型 |

| JPH0433728A (ja) * | 1990-05-25 | 1992-02-05 | Toshiba Corp | バーリング加工方法 |

| JP4120119B2 (ja) * | 1999-12-15 | 2008-07-16 | 松下電器産業株式会社 | バーリングの成形方法と金型装置 |

| JP2001200813A (ja) * | 2000-01-13 | 2001-07-27 | Toyota Motor Corp | かしめ構造、かしめ方法及びかしめ装置 |

| JP2008073732A (ja) * | 2006-09-22 | 2008-04-03 | Furaito:Kk | 半抜き、バーリング加工用金型 |

-

2009

- 2009-05-07 JP JP2009112702A patent/JP5869746B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010260078A (ja) | 2010-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5869746B2 (ja) | バーリング加工方法及び金型 | |

| CN108687281B (zh) | 杯状结构体的制造方法 | |

| JP6673760B2 (ja) | 突起部成形装置、突起部成形方法 | |

| WO2017006830A1 (ja) | 突起部成形装置、突起部成形方法及び成形品 | |

| US20190232359A1 (en) | Forging apparatus and forging method | |

| WO2007032434A1 (ja) | アンダカット部を有する成形品の製造方法及びその鍛造成形装置並びに中間成形体 | |

| JP2010260078A5 (enExample) | ||

| JP4886541B2 (ja) | アンダカット部を有する成形品の鍛造成形方法及び装置 | |

| JP5234621B2 (ja) | 金属板の絞り加工方法 | |

| CN100500321C (zh) | 剪切装置 | |

| CN111872229A (zh) | 一种管件压凹点模具 | |

| JPH09141380A (ja) | 傘歯車の鍛造成形方法およびその装置 | |

| CN1281350C (zh) | 制造突缘物品的方法和装置 | |

| JP5645527B2 (ja) | パンチ金型及びそのパンチ金型を使用したねじ穴加工方法 | |

| CN212419350U (zh) | 一种管件压凹点模具 | |

| JP5632673B2 (ja) | バーリング加工方法 | |

| US8387494B2 (en) | Punching method using punch and punch for punching | |

| CN208743541U (zh) | 一种可自动退料的冲压模具 | |

| JP5240510B2 (ja) | 絞り成形装置 | |

| JP4812307B2 (ja) | バーリング金型及びバーリング加工方法 | |

| JP4804292B2 (ja) | アンダカット部を有する成形品の鍛造成形装置 | |

| JP5234622B2 (ja) | 金属板の張出し加工方法 | |

| JP4804291B2 (ja) | アンダカット部を有する成形品の製造方法 | |

| JP2007260756A (ja) | 鍛造用金型装置 | |

| JP2007118017A (ja) | ダブルアクションプレス装置とプレス方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110412 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120410 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130731 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130813 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131010 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140422 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140619 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20141104 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150120 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20150127 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20150327 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151009 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20160108 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5869746 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |