JP5814218B2 - 内接歯車式ポンプ - Google Patents

内接歯車式ポンプ Download PDFInfo

- Publication number

- JP5814218B2 JP5814218B2 JP2012263018A JP2012263018A JP5814218B2 JP 5814218 B2 JP5814218 B2 JP 5814218B2 JP 2012263018 A JP2012263018 A JP 2012263018A JP 2012263018 A JP2012263018 A JP 2012263018A JP 5814218 B2 JP5814218 B2 JP 5814218B2

- Authority

- JP

- Japan

- Prior art keywords

- rotor

- outer ring

- cam

- wall surface

- reference line

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000002093 peripheral effect Effects 0.000 claims description 41

- 238000005192 partition Methods 0.000 description 15

- 238000005520 cutting process Methods 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 238000003825 pressing Methods 0.000 description 4

- 229910000838 Al alloy Inorganic materials 0.000 description 3

- 238000005266 casting Methods 0.000 description 3

- 238000011109 contamination Methods 0.000 description 3

- 238000004904 shortening Methods 0.000 description 3

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 238000013459 approach Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000010363 phase shift Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C28/00—Control of, monitoring of, or safety arrangements for, pumps or pumping installations specially adapted for elastic fluids

- F04C28/18—Control of, monitoring of, or safety arrangements for, pumps or pumping installations specially adapted for elastic fluids characterised by varying the volume of the working chamber

- F04C28/22—Control of, monitoring of, or safety arrangements for, pumps or pumping installations specially adapted for elastic fluids characterised by varying the volume of the working chamber by changing the eccentricity between cooperating members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C14/00—Control of, monitoring of, or safety arrangements for, machines, pumps or pumping installations

- F04C14/10—Control of, monitoring of, or safety arrangements for, machines, pumps or pumping installations characterised by changing the positions of the inlet or outlet openings with respect to the working chamber

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C14/00—Control of, monitoring of, or safety arrangements for, machines, pumps or pumping installations

- F04C14/18—Control of, monitoring of, or safety arrangements for, machines, pumps or pumping installations characterised by varying the volume of the working chamber

- F04C14/22—Control of, monitoring of, or safety arrangements for, machines, pumps or pumping installations characterised by varying the volume of the working chamber by changing the eccentricity between cooperating members

- F04C14/223—Control of, monitoring of, or safety arrangements for, machines, pumps or pumping installations characterised by varying the volume of the working chamber by changing the eccentricity between cooperating members using a movable cam

- F04C14/226—Control of, monitoring of, or safety arrangements for, machines, pumps or pumping installations characterised by varying the volume of the working chamber by changing the eccentricity between cooperating members using a movable cam by pivoting the cam around an eccentric axis

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C18/00—Rotary-piston pumps specially adapted for elastic fluids

- F04C18/08—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing

- F04C18/10—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of internal-axis type with the outer member having more teeth or tooth equivalents, e.g. rollers, than the inner member

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C2/00—Rotary-piston machines or pumps

- F04C2/08—Rotary-piston machines or pumps of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing

- F04C2/10—Rotary-piston machines or pumps of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of internal-axis type with the outer member having more teeth or tooth-equivalents, e.g. rollers, than the inner member

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Rotary Pumps (AREA)

- Details And Applications Of Rotary Liquid Pumps (AREA)

Description

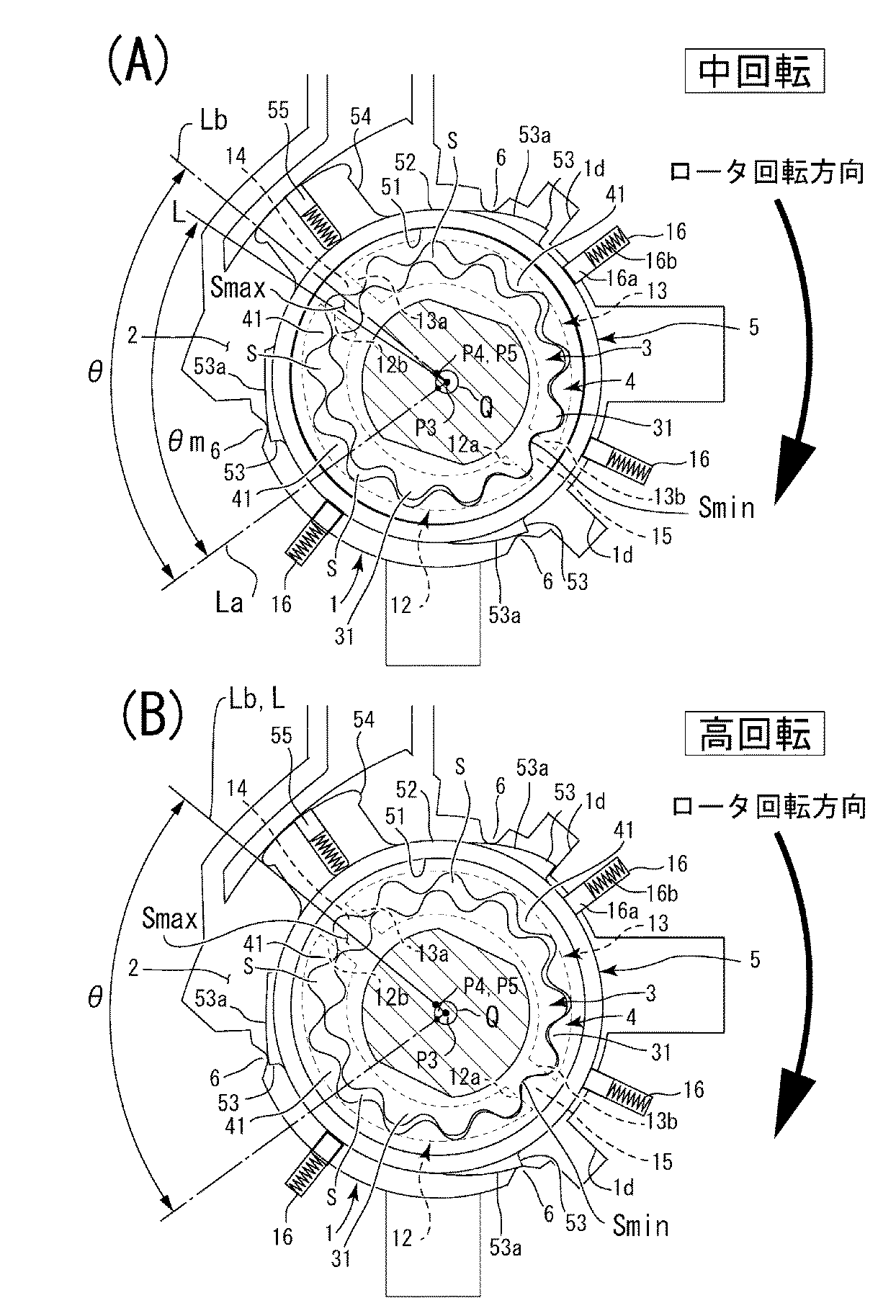

るためにカム突起部が当接するストッパ壁面部が形成されることにより、アウターリング

は、所定の揺動範囲内で確実に作動させることができる。

4…アウターロータ、5…アウターリング、51…包持内周部、52…外周面、

53…カム突起部、6…突出壁面部、7…操作手段、

P3…(インナーロータの)回転中心、P4…(アウターロータの)回転中心、

P5…(アウターリングの)直径中心、Q…軌跡円、e…偏心量。

Claims (3)

- インナーロータと、該インナーロータの回転中心に対して所定の偏心量を有して回転するアウターロータと、該アウターロータを回転自在に包持する包持内周部と外周面の周方向に沿って少なくとも3個のカム突起部が形成されてなるアウターリングと、該アウターリングが揺動自在に配置されるロータ室を有するポンプハウジングと、前記ロータ室の内周側面に形成され且つ前記カム突起部と同数で且つ該カム突起部と常時当接する突出壁面部と、前記アウターリングを揺動させる操作手段とからなり、該操作手段により前記アウターリングの包持内周部の直径中心が前記インナーロータの回転中心に対して前記偏心量を半径とする軌跡円上に沿う移動が行われるように前記突出壁面部の位置が設定される構成とし、前記突出壁面部と前記カム突起部との当接及び摺動では、前記突出壁面部は、前記カム突起部に対して同一部分の点接触としてなることを特徴とする内接歯車式ポンプ。

- 請求項1において、前記突出壁面部は、前記カム突起部と当接する部分を円弧形状としてなることを特徴とする内接歯車式ポンプ。

- 請求項1又は2において、前記ロータ室内には前記アウターリングの揺動角度を所定範囲内に規制するために前記カム突起部が当接するストッパ壁面部が形成されてなることを特徴とする内接歯車式ポンプ。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012263018A JP5814218B2 (ja) | 2012-11-30 | 2012-11-30 | 内接歯車式ポンプ |

| US14/088,220 US9399994B2 (en) | 2012-11-30 | 2013-11-22 | Internal gear pump |

| EP13194348.2A EP2738388B1 (en) | 2012-11-30 | 2013-11-26 | Internal gear pump |

| CN201310614670.8A CN103850929A (zh) | 2012-11-30 | 2013-11-28 | 内接齿轮式泵 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012263018A JP5814218B2 (ja) | 2012-11-30 | 2012-11-30 | 内接歯車式ポンプ |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015183801A Division JP2015227665A (ja) | 2015-09-17 | 2015-09-17 | 内接歯車式ポンプ |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2014109210A JP2014109210A (ja) | 2014-06-12 |

| JP5814218B2 true JP5814218B2 (ja) | 2015-11-17 |

Family

ID=49724459

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012263018A Expired - Fee Related JP5814218B2 (ja) | 2012-11-30 | 2012-11-30 | 内接歯車式ポンプ |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9399994B2 (ja) |

| EP (1) | EP2738388B1 (ja) |

| JP (1) | JP5814218B2 (ja) |

| CN (1) | CN103850929A (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5814280B2 (ja) * | 2012-11-30 | 2015-11-17 | 株式会社山田製作所 | 内接歯車式ポンプ |

| JP2016070219A (ja) * | 2014-09-30 | 2016-05-09 | 株式会社山田製作所 | オイルポンプ構造 |

| CN108119662B (zh) * | 2016-11-28 | 2020-12-25 | 株式会社山田制作所 | 热敏阀和油泵 |

| CN107605720B (zh) * | 2017-10-27 | 2019-06-28 | 湖南机油泵股份有限公司 | 一种基于双开关电磁阀的三级或四级可变排量机油泵 |

| US12168980B2 (en) * | 2023-04-20 | 2024-12-17 | Genesis Advanced Technology Inc. | Hypotrochoid positive-displacement machine |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2192242T3 (es) | 1996-12-04 | 2003-10-01 | Siegfried A Dipl-Ing Eisenmann | Bomba anular de engranajes continuamente variable. |

| DE10338212A1 (de) * | 2003-08-20 | 2005-03-10 | Zahnradfabrik Friedrichshafen | Volumenstromvariable Rotorpumpe |

| JP5014841B2 (ja) * | 2007-03-08 | 2012-08-29 | 日立オートモティブシステムズ株式会社 | 可変容量ポンプ |

| SE533387C2 (sv) | 2008-09-22 | 2010-09-14 | Ji Ee Industry Co Ltd | Variabel deplacementpump |

| JP5879683B2 (ja) | 2010-12-21 | 2016-03-08 | アイシン精機株式会社 | オイルポンプ |

-

2012

- 2012-11-30 JP JP2012263018A patent/JP5814218B2/ja not_active Expired - Fee Related

-

2013

- 2013-11-22 US US14/088,220 patent/US9399994B2/en not_active Expired - Fee Related

- 2013-11-26 EP EP13194348.2A patent/EP2738388B1/en not_active Not-in-force

- 2013-11-28 CN CN201310614670.8A patent/CN103850929A/zh active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| EP2738388B1 (en) | 2017-12-27 |

| EP2738388A1 (en) | 2014-06-04 |

| US9399994B2 (en) | 2016-07-26 |

| US20140154119A1 (en) | 2014-06-05 |

| JP2014109210A (ja) | 2014-06-12 |

| CN103850929A (zh) | 2014-06-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5814218B2 (ja) | 内接歯車式ポンプ | |

| JP5814280B2 (ja) | 内接歯車式ポンプ | |

| JP6200164B2 (ja) | 可変容量型ベーンポンプ | |

| JP6165019B2 (ja) | ベーンポンプ | |

| JP2009144689A (ja) | 内接ギヤ形ポンプ | |

| JP6130887B2 (ja) | 内接歯車式ポンプ | |

| JP6616129B2 (ja) | 可変容量ポンプ | |

| US20160265527A1 (en) | Oil pump | |

| JP2015227665A (ja) | 内接歯車式ポンプ | |

| JP6948195B2 (ja) | ポンプ装置 | |

| CN110325740B (zh) | 汽车液体摆式叶片泵 | |

| JP4215160B2 (ja) | 内接歯車ポンプおよびその製造方法 | |

| JP2013221464A (ja) | 可変容量オイルポンプ | |

| JPH10205461A (ja) | 可変吐出量ベーンポンプ | |

| JP5973719B2 (ja) | 内接歯車式ポンプ | |

| JP2010265852A (ja) | ベーンポンプ | |

| JP7037458B2 (ja) | ポンプ装置 | |

| JPH0430387Y2 (ja) | ||

| JP5106000B2 (ja) | 可変容量型ベーンポンプ | |

| JP2004257357A (ja) | ベーン式バキュームポンプ | |

| US20210164471A1 (en) | Compressor | |

| WO2023042530A1 (ja) | オイルポンプ | |

| WO2003016678A1 (en) | Wankel rotary machine | |

| JP2016176391A (ja) | 可変容量オイルポンプ | |

| WO2016103663A1 (ja) | 燃料ポンプ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20141218 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20141218 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20150224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150317 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150518 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150818 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150917 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5814218 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |