JP5796013B2 - カーボンナノチューブカラムと、カーボンナノチューブカラムをプローブとして作成及び使用する方法 - Google Patents

カーボンナノチューブカラムと、カーボンナノチューブカラムをプローブとして作成及び使用する方法 Download PDFInfo

- Publication number

- JP5796013B2 JP5796013B2 JP2012528877A JP2012528877A JP5796013B2 JP 5796013 B2 JP5796013 B2 JP 5796013B2 JP 2012528877 A JP2012528877 A JP 2012528877A JP 2012528877 A JP2012528877 A JP 2012528877A JP 5796013 B2 JP5796013 B2 JP 5796013B2

- Authority

- JP

- Japan

- Prior art keywords

- column

- carbon nanotube

- probe

- growth

- metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 title claims description 190

- 239000002041 carbon nanotube Substances 0.000 title claims description 173

- 229910021393 carbon nanotube Inorganic materials 0.000 title claims description 173

- 239000000523 sample Substances 0.000 title claims description 96

- 238000004519 manufacturing process Methods 0.000 title 1

- 239000000463 material Substances 0.000 claims description 105

- 239000000758 substrate Substances 0.000 claims description 101

- 229910052751 metal Inorganic materials 0.000 claims description 99

- 239000002184 metal Substances 0.000 claims description 99

- 238000012360 testing method Methods 0.000 claims description 61

- 239000002105 nanoparticle Substances 0.000 claims description 6

- 239000000853 adhesive Substances 0.000 claims 4

- 230000001070 adhesive effect Effects 0.000 claims 4

- 241000255925 Diptera Species 0.000 claims 1

- 239000007789 gas Substances 0.000 description 58

- 238000000034 method Methods 0.000 description 51

- 239000000243 solution Substances 0.000 description 42

- 230000008569 process Effects 0.000 description 38

- 230000000873 masking effect Effects 0.000 description 37

- 239000002243 precursor Substances 0.000 description 35

- 239000012159 carrier gas Substances 0.000 description 33

- 238000000151 deposition Methods 0.000 description 24

- 229910000679 solder Inorganic materials 0.000 description 24

- 239000003054 catalyst Substances 0.000 description 20

- 238000010168 coupling process Methods 0.000 description 19

- 238000001465 metallisation Methods 0.000 description 19

- 230000008878 coupling Effects 0.000 description 18

- 238000005859 coupling reaction Methods 0.000 description 18

- 238000002347 injection Methods 0.000 description 18

- 239000007924 injection Substances 0.000 description 18

- 229910052799 carbon Inorganic materials 0.000 description 17

- 230000008859 change Effects 0.000 description 14

- 239000002245 particle Substances 0.000 description 14

- 230000004044 response Effects 0.000 description 14

- 230000008021 deposition Effects 0.000 description 12

- 230000007246 mechanism Effects 0.000 description 12

- 239000011248 coating agent Substances 0.000 description 11

- 238000000576 coating method Methods 0.000 description 11

- KTWOOEGAPBSYNW-UHFFFAOYSA-N ferrocene Chemical compound [Fe+2].C=1C=C[CH-]C=1.C=1C=C[CH-]C=1 KTWOOEGAPBSYNW-UHFFFAOYSA-N 0.000 description 11

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 10

- 229910052737 gold Inorganic materials 0.000 description 10

- 239000010931 gold Substances 0.000 description 10

- 229910052709 silver Inorganic materials 0.000 description 10

- 239000004332 silver Substances 0.000 description 10

- 238000004544 sputter deposition Methods 0.000 description 10

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 9

- 229910052802 copper Inorganic materials 0.000 description 9

- 239000010949 copper Substances 0.000 description 9

- 239000004065 semiconductor Substances 0.000 description 9

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 8

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 8

- 238000005245 sintering Methods 0.000 description 8

- 230000007423 decrease Effects 0.000 description 7

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 6

- 239000004020 conductor Substances 0.000 description 6

- 238000011010 flushing procedure Methods 0.000 description 6

- 230000001965 increasing effect Effects 0.000 description 6

- 239000007769 metal material Substances 0.000 description 6

- 238000005086 pumping Methods 0.000 description 6

- 239000002904 solvent Substances 0.000 description 5

- 239000003351 stiffener Substances 0.000 description 5

- 229910052786 argon Inorganic materials 0.000 description 4

- 238000005229 chemical vapour deposition Methods 0.000 description 4

- 238000009713 electroplating Methods 0.000 description 4

- 238000002844 melting Methods 0.000 description 4

- 230000008018 melting Effects 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 3

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 238000000231 atomic layer deposition Methods 0.000 description 3

- 239000000919 ceramic Substances 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 229910052759 nickel Inorganic materials 0.000 description 3

- 235000012431 wafers Nutrition 0.000 description 3

- 239000008096 xylene Substances 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- YNQLUTRBYVCPMQ-UHFFFAOYSA-N Ethylbenzene Chemical compound CCC1=CC=CC=C1 YNQLUTRBYVCPMQ-UHFFFAOYSA-N 0.000 description 2

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- ZSWFCLXCOIISFI-UHFFFAOYSA-N cyclopentadiene Chemical class C1C=CC=C1 ZSWFCLXCOIISFI-UHFFFAOYSA-N 0.000 description 2

- 125000000118 dimethyl group Chemical group [H]C([H])([H])* 0.000 description 2

- 238000007772 electroless plating Methods 0.000 description 2

- CBMIPXHVOVTTTL-UHFFFAOYSA-N gold(3+) Chemical compound [Au+3] CBMIPXHVOVTTTL-UHFFFAOYSA-N 0.000 description 2

- 230000006698 induction Effects 0.000 description 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- 229920002120 photoresistant polymer Polymers 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 238000007650 screen-printing Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 description 1

- IMQPRQCPYLSVDB-UHFFFAOYSA-N [Au].C(C)P(C)C Chemical compound [Au].C(C)P(C)C IMQPRQCPYLSVDB-UHFFFAOYSA-N 0.000 description 1

- YPAHSIQRPDEZJI-UHFFFAOYSA-N [Au].CC(P(C)C)(C)C Chemical compound [Au].CC(P(C)C)(C)C YPAHSIQRPDEZJI-UHFFFAOYSA-N 0.000 description 1

- KTWQIPKJTRJCTR-UHFFFAOYSA-N [Au].ClCP(C)C Chemical compound [Au].ClCP(C)C KTWQIPKJTRJCTR-UHFFFAOYSA-N 0.000 description 1

- 125000005595 acetylacetonate group Chemical group 0.000 description 1

- 150000004945 aromatic hydrocarbons Chemical class 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 150000001555 benzenes Chemical class 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- SYBBXLKWGHAVHP-UHFFFAOYSA-M chlorogold;triethylphosphane Chemical compound [Cl-].[Au+].CCP(CC)CC SYBBXLKWGHAVHP-UHFFFAOYSA-M 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- 239000011370 conductive nanoparticle Substances 0.000 description 1

- GPRSOIDYHMXAGW-UHFFFAOYSA-N cyclopenta-1,3-diene cyclopentanecarboxylic acid iron Chemical compound [CH-]1[CH-][CH-][C-]([CH-]1)C(=O)O.[CH-]1C=CC=C1.[Fe] GPRSOIDYHMXAGW-UHFFFAOYSA-N 0.000 description 1

- UBCZLWARZCERJD-UHFFFAOYSA-N cyclopentane;2-cyclopentylacetonitrile;iron Chemical compound [Fe].[CH]1[CH][CH][CH][CH]1.N#CC[C]1[CH][CH][CH][CH]1 UBCZLWARZCERJD-UHFFFAOYSA-N 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 235000012489 doughnuts Nutrition 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000010410 layer Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000002071 nanotube Substances 0.000 description 1

- 239000011368 organic material Substances 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 238000009832 plasma treatment Methods 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 229910052703 rhodium Inorganic materials 0.000 description 1

- 239000010948 rhodium Substances 0.000 description 1

- MHOVAHRLVXNVSD-UHFFFAOYSA-N rhodium atom Chemical compound [Rh] MHOVAHRLVXNVSD-UHFFFAOYSA-N 0.000 description 1

- 229910052707 ruthenium Inorganic materials 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R3/00—Apparatus or processes specially adapted for the manufacture or maintenance of measuring instruments, e.g. of probe tips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82B—NANOSTRUCTURES FORMED BY MANIPULATION OF INDIVIDUAL ATOMS, MOLECULES, OR LIMITED COLLECTIONS OF ATOMS OR MOLECULES AS DISCRETE UNITS; MANUFACTURE OR TREATMENT THEREOF

- B82B3/00—Manufacture or treatment of nanostructures by manipulation of individual atoms or molecules, or limited collections of atoms or molecules as discrete units

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y30/00—Nanotechnology for materials or surface science, e.g. nanocomposites

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/15—Nano-sized carbon materials

- C01B32/158—Carbon nanotubes

- C01B32/16—Preparation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y10/00—Nanotechnology for information processing, storage or transmission, e.g. quantum computing or single electron logic

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B2202/00—Structure or properties of carbon nanotubes

- C01B2202/08—Aligned nanotubes

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R1/00—Details of instruments or arrangements of the types included in groups G01R5/00 - G01R13/00 and G01R31/00

- G01R1/02—General constructional details

- G01R1/06—Measuring leads; Measuring probes

- G01R1/067—Measuring probes

- G01R1/06711—Probe needles; Cantilever beams; "Bump" contacts; Replaceable probe pins

- G01R1/06755—Material aspects

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Nanotechnology (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Chemistry (AREA)

- Composite Materials (AREA)

- Theoretical Computer Science (AREA)

- Mathematical Physics (AREA)

- Carbon And Carbon Compounds (AREA)

- Measuring Leads Or Probes (AREA)

- Testing Or Measuring Of Semiconductors Or The Like (AREA)

Description

H2/アルゴン比:0対0.5

キャリアガス324の組成:

H2/アルゴン比:0対0.5

空気:0〜20標準立方センチメートル/分(sccm)

成長溶液326の濃度:

キシレン中のフェロセンの濃度:0.0004〜0.05グラム/ミリリットル

チャンバ302の温度Tf:700〜850℃

蒸発器318の温度Te:105〜250℃

成長溶液326のポンプ量ζ:2〜18ミリリットル/時(ml/h)

キャリアガス324の流量Q1:50〜500sccm

キャリアガス310の流量Q2:0〜200sccm

カーボンナノチューブの成長時間「t」:1〜180分

温度制御デバイス306の端部304から注入管316の端部314までの長さ「L」:8〜26センチメートル

[0064] 上記パラメータ及び他のパラメータはすべて、成長材料226の表面222から成長するカーボンナノチューブカラム214の機械的特徴に影響を与えることができる。このような機械的特徴の例は、一般に繰り返し可能な弾性範囲(以下「弾性範囲」と呼ぶ)、及びカラム214の剛性(例えば、フックの法則に従った、F*dであり、dは力Fに応答して移動する距離であり、*は乗算である、バネ定数「k」)を含むことができる。上記パラメータは、カラム214の端部220から端部218までの長さに沿って実質的に均一の機械的特徴を有するカラム214を得るために、カーボンナノチューブカラム214が成長する間、実質的に一定に維持することができる。あるいは、これらのパラメータのうちの1つ又は複数は、カラム214が成長する間、カラム214の端部220から端部218までの長さに沿ってカラムの上記機械的特徴(及び/又は他の機械的特徴)のうちの1つ又は複数を変更するために変更することができる。

「直接」とは、パラメータの値の増加が機械的特徴の値の増加を引き起こし、パラメータの値の減少が機械的特徴の値の減少を引き起こす一方で、他のすべてのパラメータは変化しないことを意味し、

「間接的」とは、パラメータの値の増加が機械的特徴の値の減少を引き起こし、パラメータの値の減少が機械的特徴の値の増加を引き起こす一方で、他のすべてのパラメータは変化しないことを意味する。

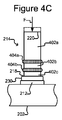

[0066] 図4Aは、カラム214の剛性に影響を与える上記で識別されたパラメータのうちの1つ又は複数が変化する間に、図3のシステム300で成長するカーボンナノチューブカラム214の例を示す。図4Aに示すように、カラム214は剛性領域402a、402b、及び402cと、軟質領域404a及び404bとを含む。3つの剛性領域402a、402b、及び402cと、2つの軟質領域404a及び404bとが示されているが、代替的に、カラム214の長さに沿って、より多くの又はより少ない剛性領域及び/又はより多くの又はより少ない軟質領域も形成できる。本明細書で使用する場合、軟質領域404a及び404bは、剛性領域402a、402b、及び402cの剛性よりも低い剛性を有する領域である。同様に、剛性領域402a、402b、及び402cは、軟質領域404a及び404bよりも高い剛性を有する領域である。

Claims (7)

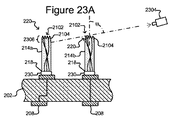

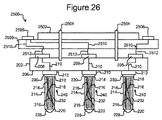

- プローブカードアセンブリであって、

テストされる電子デバイスのテストを制御するためのテスターへの電気インターフェイスを備える配線基板と、

テストされる前記電子デバイスの端子に対応するパターンで配置された複数のプローブを備えるプローブ基板であって、それぞれの前記プローブが、カーボンナノチューブのバンドルを含むカーボンナノチューブカラムを備えるプローブ基板と、

前記カーボンナノチューブカラムのうちの1つを前記プローブ基板の複数の端子のうちの1つに接合する接着材料接合部であって、それぞれの前記接着材料接合部が、前記カーボンナノチューブカラムのうちの前記1つのカーボンナノチューブカラムと、前記複数の端子のうちの前記1つの端子とに溶着された焼結ナノ粒子の塊を含む、接着材料接合部と、

を備え、

前記プローブ基板が前記配線基板に機械的に結合され、前記プローブが、前記プローブ基板及び前記配線基板を通して前記電気インターフェイスに電気的に接続されるプローブカードアセンブリ。 - それぞれの前記カーボンナノチューブカラムが、前記カーボンナノチューブの長さに沿った複数の交互の剛性領域及び軟質領域を有し、各軟質領域が、前記剛性領域のそれぞれの剛性値よりも低い剛性値を有する、請求項1に記載のプローブカードアセンブリ。

- 前記カーボンナノチューブカラムのそれぞれの外側に配置された前記カーボンナノチューブの少なくとも一部上に堆積された導電性金属をさらに含み、前記金属が前記カーボンナノチューブカラムの導電性を高くする、請求項1に記載のプローブカードアセンブリ。

- 前記カーボンナノチューブカラムのそれぞれの内側に配置された前記カーボンナノチューブの少なくとも一部上に堆積された導電性金属をさらに含み、前記金属が前記カーボンナノチューブカラムの導電性を高くする、請求項1に記載のプローブカードアセンブリ。

- 前記接着材料接合部によって、前記カーボンナノチューブカラムの第1の端部が、前記プローブ基板の前記端子に接合され、

前記第1の端部と反対の前記カーボンナノチューブカラムの第2の端部が、コンタクトチップを備える、請求項1に記載のプローブカードアセンブリ。 - 各コンタクトチップが、

前記カーボンナノチューブカラムの前記第2の端部の鋭利な構造と、

前記カーボンナノチューブカラムの前記第2の端部上に堆積された導電性金属と、

を有する、請求項5に記載のプローブカードアセンブリ。 - 各コンタクトチップが、前記カーボンナノチューブカラムの前記第2の端部に接合材料によって結合されたコンタクトチップ構造を有する、請求項5に記載のプローブカードアセンブリ。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US24220609P | 2009-09-14 | 2009-09-14 | |

| US61/242,206 | 2009-09-14 | ||

| US12/632,428 US8354855B2 (en) | 2006-10-16 | 2009-12-07 | Carbon nanotube columns and methods of making and using carbon nanotube columns as probes |

| US12/632,428 | 2009-12-07 | ||

| PCT/US2010/048129 WO2011031759A2 (en) | 2009-09-14 | 2010-09-08 | Carbon nanotube columns and methods of making and using carbon nanotube columns as probes |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013504509A JP2013504509A (ja) | 2013-02-07 |

| JP2013504509A5 JP2013504509A5 (ja) | 2013-09-26 |

| JP5796013B2 true JP5796013B2 (ja) | 2015-10-21 |

Family

ID=43733080

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012528877A Expired - Fee Related JP5796013B2 (ja) | 2009-09-14 | 2010-09-08 | カーボンナノチューブカラムと、カーボンナノチューブカラムをプローブとして作成及び使用する方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8354855B2 (ja) |

| JP (1) | JP5796013B2 (ja) |

| KR (2) | KR101889366B1 (ja) |

| TW (1) | TWI526689B (ja) |

| WO (1) | WO2011031759A2 (ja) |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7439731B2 (en) | 2005-06-24 | 2008-10-21 | Crafts Douglas E | Temporary planar electrical contact device and method using vertically-compressible nanotube contact structures |

| US8045859B2 (en) * | 2008-05-02 | 2011-10-25 | The United States Of America As Represented By The Secretary Of The Navy | High-speed underwater data transmission system and method |

| EP2329502B1 (en) | 2008-09-29 | 2014-09-17 | Wentworth Laboratories, Inc. | Methods of fabricating nanotube probes |

| US8272124B2 (en) * | 2009-04-03 | 2012-09-25 | Formfactor, Inc. | Anchoring carbon nanotube columns |

| US20100252317A1 (en) * | 2009-04-03 | 2010-10-07 | Formfactor, Inc. | Carbon nanotube contact structures for use with semiconductor dies and other electronic devices |

| US8872176B2 (en) | 2010-10-06 | 2014-10-28 | Formfactor, Inc. | Elastic encapsulated carbon nanotube based electrical contacts |

| US9267968B2 (en) | 2010-12-09 | 2016-02-23 | Wentworth Laboratories, Inc. | Probe card assemblies and probe pins including carbon nanotubes |

| US9505615B2 (en) | 2011-07-27 | 2016-11-29 | California Institute Of Technology | Method for controlling microstructural arrangement of nominally-aligned arrays of carbon nanotubes |

| WO2013052176A2 (en) * | 2011-07-27 | 2013-04-11 | California Institute Of Technology | Carbon nanotube foams with controllable mechanical properties |

| EP2763167B1 (en) | 2011-09-26 | 2016-06-29 | Fujitsu Limited | Heat-dissipating material and method for producing same, and electronic device and method for producing same |

| JP5863168B2 (ja) * | 2011-11-10 | 2016-02-16 | 株式会社日本マイクロニクス | プローブカード及びその製造方法 |

| US9616635B2 (en) | 2012-04-20 | 2017-04-11 | California Institute Of Technology | Multilayer foam structures of nominally-aligned carbon nanotubes (CNTS) |

| US10266402B2 (en) * | 2012-11-20 | 2019-04-23 | Formfactor, Inc. | Contactor devices with carbon nanotube probes embedded in a flexible film and processes of making such |

| US9523713B2 (en) * | 2013-05-28 | 2016-12-20 | Intel Corporation | Interconnects including liquid metal |

| TWI539164B (zh) | 2013-11-22 | 2016-06-21 | 財團法人工業技術研究院 | 塗佈探針及其製作方法 |

| US10732201B2 (en) | 2014-04-13 | 2020-08-04 | Infineon Technologies Ag | Test probe and method of manufacturing a test probe |

| WO2017156502A1 (en) | 2016-03-10 | 2017-09-14 | Carnegie Mellon University | Integrated electronic device with flexible and stretchable substrate |

| US20200041543A1 (en) * | 2017-03-21 | 2020-02-06 | Nidec-Read Corporation | Probe structure and method for producing probe structure |

| US20190011497A1 (en) * | 2017-07-09 | 2019-01-10 | Texas Instruments Incorporated | Test Fixture with Sintered Connections Between Mother Board and Daughter Board |

| JP2019035698A (ja) * | 2017-08-18 | 2019-03-07 | 日本電産リード株式会社 | プローブ構造体、及びプローブ構造体の製造方法 |

| KR102221162B1 (ko) * | 2019-04-04 | 2021-02-26 | 연세대학교 산학협력단 | 금속 나노입자가 코팅된 탄소나노튜브 네트워크를 포함하는 접촉식 마이크로 소자 및 이의 제조 방법 |

| US11774467B1 (en) | 2020-09-01 | 2023-10-03 | Microfabrica Inc. | Method of in situ modulation of structural material properties and/or template shape |

Family Cites Families (75)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE69728410T2 (de) | 1996-08-08 | 2005-05-04 | William Marsh Rice University, Houston | Makroskopisch manipulierbare, aus nanoröhrenanordnungen hergestellte vorrichtungen |

| JP3740295B2 (ja) | 1997-10-30 | 2006-02-01 | キヤノン株式会社 | カーボンナノチューブデバイス、その製造方法及び電子放出素子 |

| US6020747A (en) | 1998-01-26 | 2000-02-01 | Bahns; John T. | Electrical contact probe |

| JP2002518280A (ja) | 1998-06-19 | 2002-06-25 | ザ・リサーチ・ファウンデーション・オブ・ステイト・ユニバーシティ・オブ・ニューヨーク | 整列した自立炭素ナノチューブおよびその合成 |

| US6346189B1 (en) | 1998-08-14 | 2002-02-12 | The Board Of Trustees Of The Leland Stanford Junior University | Carbon nanotube structures made using catalyst islands |

| US6597090B1 (en) | 1998-09-28 | 2003-07-22 | Xidex Corporation | Method for manufacturing carbon nanotubes as functional elements of MEMS devices |

| US6232706B1 (en) | 1998-11-12 | 2001-05-15 | The Board Of Trustees Of The Leland Stanford Junior University | Self-oriented bundles of carbon nanotubes and method of making same |

| KR100398276B1 (ko) | 1998-12-03 | 2003-09-19 | 다이켄카가쿠 코교 가부시키가이샤 | 전자장치의 표면신호조작용 프로우브 및 그 제조방법 |

| AUPQ065099A0 (en) | 1999-05-28 | 1999-06-24 | Commonwealth Scientific And Industrial Research Organisation | Substrate-supported aligned carbon nanotube films |

| US6401526B1 (en) | 1999-12-10 | 2002-06-11 | The Board Of Trustees Of The Leland Stanford Junior University | Carbon nanotubes and methods of fabrication thereof using a liquid phase catalyst precursor |

| DE10006964C2 (de) | 2000-02-16 | 2002-01-31 | Infineon Technologies Ag | Elektronisches Bauelement mit einer leitenden Verbindung zwischen zwei leitenden Schichten und Verfahren zum Herstellen eines elektronischen Bauelements |

| AU2001261689A1 (en) | 2000-05-16 | 2001-11-26 | Rensselaer Polytechnic Institute | Electrically conducting nanocomposite materials for biomedical applications |

| US6709566B2 (en) | 2000-07-25 | 2004-03-23 | The Regents Of The University Of California | Method for shaping a nanotube and a nanotube shaped thereby |

| US6457350B1 (en) | 2000-09-08 | 2002-10-01 | Fei Company | Carbon nanotube probe tip grown on a small probe |

| US7258901B1 (en) | 2000-09-08 | 2007-08-21 | Fei Company | Directed growth of nanotubes on a catalyst |

| JP2002141633A (ja) * | 2000-10-25 | 2002-05-17 | Lucent Technol Inc | 垂直にナノ相互接続された回路デバイスからなる製品及びその製造方法 |

| JP2002179418A (ja) | 2000-12-13 | 2002-06-26 | Tohoku Techno Arch Co Ltd | カーボン・ナノチューブ作成方法 |

| JP3912583B2 (ja) | 2001-03-14 | 2007-05-09 | 三菱瓦斯化学株式会社 | 配向性カーボンナノチューブ膜の製造方法 |

| US6890506B1 (en) | 2001-04-12 | 2005-05-10 | Penn State Research Foundation | Method of forming carbon fibers |

| US7160531B1 (en) | 2001-05-08 | 2007-01-09 | University Of Kentucky Research Foundation | Process for the continuous production of aligned carbon nanotubes |

| DE10132787A1 (de) | 2001-07-06 | 2003-01-30 | Infineon Technologies Ag | Katalysatormaterial, Kohlenstoffnanoröhren-Anordnung und Verfahren zum Herstellen einer Kohlenstoffnanoröhren-Anordnung |

| JP3768937B2 (ja) | 2001-09-10 | 2006-04-19 | キヤノン株式会社 | 電子放出素子、電子源及び画像表示装置の製造方法 |

| AU2002357037A1 (en) | 2001-11-30 | 2003-06-17 | The Trustees Of Boston College | Coated carbon nanotube array electrodes |

| EP1341184B1 (en) | 2002-02-09 | 2005-09-14 | Samsung Electronics Co., Ltd. | Memory device utilizing carbon nanotubes and method of fabricating the memory device |

| AU2003210961A1 (en) | 2002-02-11 | 2003-09-04 | Rensselaer Polytechnic Institute | Directed assembly of highly-organized carbon nanotube architectures |

| JP3860057B2 (ja) * | 2002-03-20 | 2006-12-20 | アンリツ株式会社 | 電気接点装置及び接触子 |

| US20040208788A1 (en) | 2003-04-15 | 2004-10-21 | Colton Jonathan S. | Polymer micro-cantilevers and their methods of manufacture |

| US6626684B1 (en) | 2002-06-24 | 2003-09-30 | Hewlett-Packard Development Company, L.P. | Nanotube socket system and method |

| EP1578599A4 (en) | 2002-08-01 | 2008-07-02 | Oregon State | METHOD FOR SYNTHETIZING NANOSTRUCTURES AT FIXED PLACES |

| JP2006501484A (ja) | 2002-09-20 | 2006-01-12 | ザ トラスティーズ オブ ボストン カレッジ | ナノスケール磁気顕微鏡用のナノチューブカンチレバープローブ |

| JP3933035B2 (ja) | 2002-11-06 | 2007-06-20 | 富士ゼロックス株式会社 | カーボンナノチューブの製造装置および製造方法 |

| WO2004046031A1 (en) | 2002-11-18 | 2004-06-03 | Rensselaer Polytechnic Institute | Nanotube polymer composite and methods of making same |

| TWI220162B (en) | 2002-11-29 | 2004-08-11 | Ind Tech Res Inst | Integrated compound nano probe card and method of making same |

| US6933222B2 (en) | 2003-01-02 | 2005-08-23 | Intel Corporation | Microcircuit fabrication and interconnection |

| WO2004102582A1 (en) | 2003-03-05 | 2004-11-25 | University Of Florida | Carbon nanotube-based probes, related devices and methods of forming the same |

| US7082683B2 (en) | 2003-04-24 | 2006-08-01 | Korea Institute Of Machinery & Materials | Method for attaching rod-shaped nano structure to probe holder |

| TWI220163B (en) | 2003-04-24 | 2004-08-11 | Ind Tech Res Inst | Manufacturing method of high-conductivity nanometer thin-film probe card |

| US7531267B2 (en) | 2003-06-02 | 2009-05-12 | Kh Chemicals Co., Ltd. | Process for preparing carbon nanotube electrode comprising sulfur or metal nanoparticles as a binder |

| US20050019245A1 (en) | 2003-07-21 | 2005-01-27 | Dmitri Koulikov | Continuous production of carbon nanotubes and fullerenes |

| GB0318987D0 (en) | 2003-08-13 | 2003-09-17 | Univ Warwick | Probe |

| JP2005083857A (ja) | 2003-09-08 | 2005-03-31 | Yoshikazu Nakayama | ナノチューブプローブ及び製造方法 |

| US7473411B2 (en) | 2003-12-12 | 2009-01-06 | Rensselaer Polytechnic Institute | Carbon nanotube foam and method of making and using thereof |

| DE602004013641D1 (de) | 2004-03-02 | 2008-06-19 | Eth Zuerich | Kraftsensor |

| US7250188B2 (en) | 2004-03-31 | 2007-07-31 | Her Majesty The Queen In Right Of Canada, As Represented By The Minister Of National Defense Of Her Majesty's Canadian Government | Depositing metal particles on carbon nanotubes |

| US20050233263A1 (en) | 2004-04-20 | 2005-10-20 | Applied Materials, Inc. | Growth of carbon nanotubes at low temperature |

| US7251884B2 (en) | 2004-04-26 | 2007-08-07 | Formfactor, Inc. | Method to build robust mechanical structures on substrate surfaces |

| US20050285116A1 (en) | 2004-06-29 | 2005-12-29 | Yongqian Wang | Electronic assembly with carbon nanotube contact formations or interconnections |

| US20060028220A1 (en) | 2004-07-21 | 2006-02-09 | K&S Interconnect, Inc. | Reinforced probes for testing semiconductor devices |

| JP4167212B2 (ja) | 2004-10-05 | 2008-10-15 | 富士通株式会社 | カーボンナノチューブ構造体、半導体装置、および半導体パッケージ |

| US7621044B2 (en) * | 2004-10-22 | 2009-11-24 | Formfactor, Inc. | Method of manufacturing a resilient contact |

| JP2006125846A (ja) | 2004-10-26 | 2006-05-18 | Olympus Corp | カンチレバー |

| CN100501413C (zh) | 2005-01-22 | 2009-06-17 | 鸿富锦精密工业(深圳)有限公司 | 集成电路检测装置及其制备方法 |

| US20060188721A1 (en) | 2005-02-22 | 2006-08-24 | Eastman Kodak Company | Adhesive transfer method of carbon nanotube layer |

| US20060198956A1 (en) | 2005-03-04 | 2006-09-07 | Gyula Eres | Chemical vapor deposition of long vertically aligned dense carbon nanotube arrays by external control of catalyst composition |

| US7439731B2 (en) | 2005-06-24 | 2008-10-21 | Crafts Douglas E | Temporary planar electrical contact device and method using vertically-compressible nanotube contact structures |

| US7538040B2 (en) | 2005-06-30 | 2009-05-26 | Nantero, Inc. | Techniques for precision pattern transfer of carbon nanotubes from photo mask to wafers |

| DE102006039651A1 (de) | 2005-08-31 | 2007-03-22 | Hitachi Kenki Finetech Co., Ltd. | Cantilever und Prüfvorrichtung |

| WO2007033188A2 (en) | 2005-09-12 | 2007-03-22 | University Of Dayton | Substrate-enhanced electroless deposition (seed) of metal nanoparticles on carbon nanotubes |

| CN1964028B (zh) | 2005-11-11 | 2010-08-18 | 鸿富锦精密工业(深圳)有限公司 | 散热器 |

| US7727624B2 (en) | 2005-11-22 | 2010-06-01 | Rensselaer Polytechnic Institute | Super-compressible carbon nanotube films and micro-bundles |

| US7625817B2 (en) | 2005-12-30 | 2009-12-01 | Intel Corporation | Method of fabricating a carbon nanotube interconnect structures |

| US20070158768A1 (en) | 2006-01-06 | 2007-07-12 | Honeywell International, Inc. | Electrical contacts formed of carbon nanotubes |

| KR101159074B1 (ko) | 2006-01-14 | 2012-06-25 | 삼성전자주식회사 | 도전성 탄소나노튜브 팁, 이를 구비한 스캐닝 프로브마이크로스코프의 탐침 및 상기 도전성 탄소나노튜브 팁의제조 방법 |

| JP4806762B2 (ja) | 2006-03-03 | 2011-11-02 | 国立大学法人 名古屋工業大学 | Spmカンチレバー |

| US20070235713A1 (en) | 2006-04-03 | 2007-10-11 | Motorola, Inc. | Semiconductor device having carbon nanotube interconnects and method of fabrication |

| EP1845124A1 (en) | 2006-04-14 | 2007-10-17 | Arkema France | Conductive carbon nanotube-polymer composite |

| WO2007139244A1 (en) | 2006-05-30 | 2007-12-06 | Korea Basic Science Institute | A carbon nanotube of which surface is modified by transition metal coordination, and a method for modifying the same |

| US7731503B2 (en) | 2006-08-21 | 2010-06-08 | Formfactor, Inc. | Carbon nanotube contact structures |

| US8130007B2 (en) | 2006-10-16 | 2012-03-06 | Formfactor, Inc. | Probe card assembly with carbon nanotube probes having a spring mechanism therein |

| TWI360182B (en) | 2007-10-05 | 2012-03-11 | Ind Tech Res Inst | Method for making a conductive film |

| US8149007B2 (en) | 2007-10-13 | 2012-04-03 | Formfactor, Inc. | Carbon nanotube spring contact structures with mechanical and electrical components |

| JP5266491B2 (ja) * | 2007-12-25 | 2013-08-21 | ニッタ株式会社 | カーボンナノチューブの製造方法 |

| US20100252317A1 (en) | 2009-04-03 | 2010-10-07 | Formfactor, Inc. | Carbon nanotube contact structures for use with semiconductor dies and other electronic devices |

| US8272124B2 (en) | 2009-04-03 | 2012-09-25 | Formfactor, Inc. | Anchoring carbon nanotube columns |

| US8872176B2 (en) | 2010-10-06 | 2014-10-28 | Formfactor, Inc. | Elastic encapsulated carbon nanotube based electrical contacts |

-

2009

- 2009-12-07 US US12/632,428 patent/US8354855B2/en not_active Expired - Fee Related

-

2010

- 2010-09-08 KR KR1020127009762A patent/KR101889366B1/ko active IP Right Grant

- 2010-09-08 KR KR1020187022982A patent/KR20180095099A/ko not_active Application Discontinuation

- 2010-09-08 WO PCT/US2010/048129 patent/WO2011031759A2/en active Application Filing

- 2010-09-08 JP JP2012528877A patent/JP5796013B2/ja not_active Expired - Fee Related

- 2010-09-13 TW TW099130847A patent/TWI526689B/zh not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| TW201113529A (en) | 2011-04-16 |

| TWI526689B (zh) | 2016-03-21 |

| KR20120082427A (ko) | 2012-07-23 |

| JP2013504509A (ja) | 2013-02-07 |

| WO2011031759A3 (en) | 2011-08-25 |

| US8354855B2 (en) | 2013-01-15 |

| US20100083489A1 (en) | 2010-04-08 |

| WO2011031759A2 (en) | 2011-03-17 |

| KR20180095099A (ko) | 2018-08-24 |

| KR101889366B1 (ko) | 2018-08-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5796013B2 (ja) | カーボンナノチューブカラムと、カーボンナノチューブカラムをプローブとして作成及び使用する方法 | |

| US7736615B2 (en) | Device structure of carbon fibers and manufacturing method thereof | |

| US6322713B1 (en) | Nanoscale conductive connectors and method for making same | |

| US8756802B2 (en) | Carbon nanotube contact structures for use with semiconductor dies and other electronic devices | |

| US8149007B2 (en) | Carbon nanotube spring contact structures with mechanical and electrical components | |

| US7727814B2 (en) | Microelectronic package interconnect and method of fabrication thereof | |

| KR100813243B1 (ko) | 탄소나노튜브를 이용한 반도체 소자의 층간 배선 및 그제조 방법 | |

| EP1719168B1 (en) | Methods of fabricating interconnects for semiconductor components | |

| US9837746B2 (en) | Method for forming an electrical connection to a sample support in an electron microscope holder | |

| US20050167816A1 (en) | Method for making a socket to perform testing on integrated circuits | |

| US6835613B2 (en) | Method of producing an integrated circuit with a carbon nanotube | |

| JP5220417B2 (ja) | メタライズ・エラストマ・プローブ構造体 | |

| US20090246507A1 (en) | Systems and methods for fabrication and transfer of carbon nanotubes | |

| JP2008297197A (ja) | 分岐型カーボンナノチューブの成長方法 | |

| US8350160B2 (en) | Structure, electronic device, and method for fabricating a structure | |

| US20130181352A1 (en) | Method of Growing Carbon Nanotubes Laterally, and Lateral Interconnections and Effect Transistor Using the Same | |

| KR101825095B1 (ko) | 탄소막이 코팅된 반도체 검사 장치용 프로브 핀 및 그 제조방법 | |

| JP5444912B2 (ja) | 電子機器及びその製造方法 | |

| RU2573474C2 (ru) | Наноструктурное устройство и способ изготовления наноструктур | |

| Siah et al. | Development of a CMOS-Compatible Carbon Nanotube Array Transfer Method. Micromachines 2021, 12, 95 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130807 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130807 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20141027 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20141106 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20150205 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20150305 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20150403 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150507 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150717 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150817 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5796013 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |