JP5291750B2 - 塗布フィルムの製造方法 - Google Patents

塗布フィルムの製造方法 Download PDFInfo

- Publication number

- JP5291750B2 JP5291750B2 JP2011081861A JP2011081861A JP5291750B2 JP 5291750 B2 JP5291750 B2 JP 5291750B2 JP 2011081861 A JP2011081861 A JP 2011081861A JP 2011081861 A JP2011081861 A JP 2011081861A JP 5291750 B2 JP5291750 B2 JP 5291750B2

- Authority

- JP

- Japan

- Prior art keywords

- film

- plastic film

- heat roller

- layer

- coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 18

- 239000002985 plastic film Substances 0.000 claims description 115

- 229920006255 plastic film Polymers 0.000 claims description 115

- 238000000576 coating method Methods 0.000 claims description 54

- 239000011248 coating agent Substances 0.000 claims description 50

- 229920002678 cellulose Polymers 0.000 claims description 7

- ODIGIKRIUKFKHP-UHFFFAOYSA-N (n-propan-2-yloxycarbonylanilino) acetate Chemical compound CC(C)OC(=O)N(OC(C)=O)C1=CC=CC=C1 ODIGIKRIUKFKHP-UHFFFAOYSA-N 0.000 claims description 6

- 239000001913 cellulose Substances 0.000 claims description 6

- 239000010408 film Substances 0.000 description 119

- 239000010410 layer Substances 0.000 description 67

- 230000037303 wrinkles Effects 0.000 description 39

- 239000002245 particle Substances 0.000 description 35

- 230000003287 optical effect Effects 0.000 description 33

- 239000010419 fine particle Substances 0.000 description 24

- 239000002346 layers by function Substances 0.000 description 21

- 239000007788 liquid Substances 0.000 description 16

- 238000010438 heat treatment Methods 0.000 description 14

- 239000011247 coating layer Substances 0.000 description 13

- 238000000034 method Methods 0.000 description 13

- 238000001035 drying Methods 0.000 description 12

- 230000005865 ionizing radiation Effects 0.000 description 8

- 230000001681 protective effect Effects 0.000 description 7

- 238000004378 air conditioning Methods 0.000 description 6

- 150000001875 compounds Chemical class 0.000 description 6

- 229920000642 polymer Polymers 0.000 description 6

- 239000011230 binding agent Substances 0.000 description 5

- 229920005989 resin Polymers 0.000 description 5

- 239000011347 resin Substances 0.000 description 5

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 4

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 4

- 230000003373 anti-fouling effect Effects 0.000 description 4

- 238000010894 electron beam technology Methods 0.000 description 4

- 229910052731 fluorine Inorganic materials 0.000 description 4

- 239000011737 fluorine Substances 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 229910010413 TiO 2 Inorganic materials 0.000 description 3

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 3

- 230000009471 action Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000007756 gravure coating Methods 0.000 description 3

- 230000001678 irradiating effect Effects 0.000 description 3

- 239000004973 liquid crystal related substance Substances 0.000 description 3

- 239000000178 monomer Substances 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 238000003825 pressing Methods 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 239000004793 Polystyrene Substances 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- -1 TiO 2 Chemical class 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 238000007611 bar coating method Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000011362 coarse particle Substances 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 239000002270 dispersing agent Substances 0.000 description 2

- 239000000428 dust Substances 0.000 description 2

- 238000007765 extrusion coating Methods 0.000 description 2

- 238000007667 floating Methods 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000012788 optical film Substances 0.000 description 2

- 239000003505 polymerization initiator Substances 0.000 description 2

- 229920000098 polyolefin Polymers 0.000 description 2

- 229920001296 polysiloxane Polymers 0.000 description 2

- 229920002223 polystyrene Polymers 0.000 description 2

- 230000001737 promoting effect Effects 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 229920002050 silicone resin Polymers 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 239000010409 thin film Substances 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

- GZVHEAJQGPRDLQ-UHFFFAOYSA-N 6-phenyl-1,3,5-triazine-2,4-diamine Chemical compound NC1=NC(N)=NC(C=2C=CC=CC=2)=N1 GZVHEAJQGPRDLQ-UHFFFAOYSA-N 0.000 description 1

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 1

- 229920000877 Melamine resin Polymers 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004721 Polyphenylene oxide Substances 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 239000006087 Silane Coupling Agent Substances 0.000 description 1

- 229910006404 SnO 2 Inorganic materials 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 238000007754 air knife coating Methods 0.000 description 1

- 125000003172 aldehyde group Chemical group 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052787 antimony Inorganic materials 0.000 description 1

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 description 1

- 238000000149 argon plasma sintering Methods 0.000 description 1

- 125000003118 aryl group Chemical group 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000007822 coupling agent Substances 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000003618 dip coating Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000005401 electroluminescence Methods 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 125000005843 halogen group Chemical group 0.000 description 1

- 150000002430 hydrocarbons Chemical group 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 1

- 150000002484 inorganic compounds Chemical class 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 229910001507 metal halide Inorganic materials 0.000 description 1

- 150000005309 metal halides Chemical class 0.000 description 1

- 239000011859 microparticle Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 125000004433 nitrogen atom Chemical group N* 0.000 description 1

- JFNLZVQOOSMTJK-KNVOCYPGSA-N norbornene Chemical compound C1[C@@H]2CC[C@H]1C=C2 JFNLZVQOOSMTJK-KNVOCYPGSA-N 0.000 description 1

- 150000002894 organic compounds Chemical class 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 125000004437 phosphorous atom Chemical group 0.000 description 1

- 229910052698 phosphorus Inorganic materials 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000570 polyether Polymers 0.000 description 1

- 229920006254 polymer film Polymers 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 239000013557 residual solvent Substances 0.000 description 1

- 239000011342 resin composition Substances 0.000 description 1

- 238000007761 roller coating Methods 0.000 description 1

- 229930195734 saturated hydrocarbon Natural products 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 125000004434 sulfur atom Chemical group 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- 229910052718 tin Inorganic materials 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

- 229910052724 xenon Inorganic materials 0.000 description 1

- FHNFHKCVQCLJFQ-UHFFFAOYSA-N xenon atom Chemical compound [Xe] FHNFHKCVQCLJFQ-UHFFFAOYSA-N 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/50—Auxiliary process performed during handling process

- B65H2301/51—Modifying a characteristic of handled material

- B65H2301/514—Modifying physical properties

- B65H2301/5143—Warming

- B65H2301/51432—Applying heat and pressure

Landscapes

- Coating Apparatus (AREA)

- Polarising Elements (AREA)

- Surface Treatment Of Optical Elements (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

Description

層112としてハードコート層としての作用を有する層を形成し、第2層113として中屈折率層を形成し、第3層114として高屈折率層を形成すると、非常に反射防止性に優れる反射防止フィルム110を得ることができる。

Claims (2)

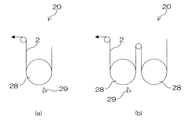

- ロール状に巻かれたプラスチックフィルムを巻き出して走行させ、前記プラスチックフィルムの変形が無くなるようヒートローラに巻き付けながら搬送し、その後、該プラスチックフィルム上に塗布液を塗布する塗布フィルムの製造方法であって、

前記ヒートローラが、クラウン形状、又は、フィルム両端部直下の表面を凹状にすることを特徴とする塗布フィルムの製造方法。 - 前記プラスチックフィルムは、厚み80μm以下のセルロースアシレートフィルムであることを特徴とする請求項1に記載の塗布フィルムの製造方法。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011081861A JP5291750B2 (ja) | 2011-04-01 | 2011-04-01 | 塗布フィルムの製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011081861A JP5291750B2 (ja) | 2011-04-01 | 2011-04-01 | 塗布フィルムの製造方法 |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009275816A Division JP4720937B2 (ja) | 2009-12-03 | 2009-12-03 | 塗布フィルムの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011136341A JP2011136341A (ja) | 2011-07-14 |

| JP2011136341A5 JP2011136341A5 (ja) | 2012-11-22 |

| JP5291750B2 true JP5291750B2 (ja) | 2013-09-18 |

Family

ID=44348291

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011081861A Active JP5291750B2 (ja) | 2011-04-01 | 2011-04-01 | 塗布フィルムの製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5291750B2 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB202105903D0 (en) * | 2021-04-26 | 2021-06-09 | British American Tobacco Investments Ltd | Apparatus for flattening sheet material |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08304956A (ja) * | 1995-04-28 | 1996-11-22 | Konica Corp | 写真用支持体 |

| JP4581307B2 (ja) * | 2001-09-06 | 2010-11-17 | Tdk株式会社 | シワ矯正方法およびシワ矯正装置並びに塗布方法 |

| JP2005007258A (ja) * | 2003-06-18 | 2005-01-13 | Fuji Photo Film Co Ltd | 塗布方法および塗布ライン |

| JP2005137983A (ja) * | 2003-11-05 | 2005-06-02 | Tdk Corp | 走行ウエブへの塗液の塗布方法、装置、幅方向膜厚プロフィールの調整方法並びにウエブのシワ矯正方法 |

| JP4297817B2 (ja) * | 2004-03-30 | 2009-07-15 | 株式会社巴川製紙所 | 塗工方法及び塗工機 |

| JP2005343597A (ja) * | 2004-06-01 | 2005-12-15 | Mitsubishi Heavy Ind Ltd | 印刷紙のしわ矯正装置及び方法 |

-

2011

- 2011-04-01 JP JP2011081861A patent/JP5291750B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2011136341A (ja) | 2011-07-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5202819B2 (ja) | 反射防止フィルムの製造方法 | |

| JP5100226B2 (ja) | 反射防止フィルムの製造方法および反射防止フィルム | |

| KR20190019069A (ko) | 반사 방지 필름 및 그 제조 방법, 그리고 반사 방지층이 부착된 편광판 | |

| JP2003045234A (ja) | 透明導電性フィルム | |

| JP6185088B2 (ja) | 積層フィルムの製造方法 | |

| JP2006126808A (ja) | 光学積層体 | |

| WO2017217526A1 (ja) | 反射防止フィルムおよびその製造方法、ならびに反射防止層付き偏光板 | |

| JP2004341070A (ja) | 防眩性フィルム及びその製造方法、反射防止フィルム、偏光板、画像表示装置 | |

| JP2014206707A (ja) | 光学用ハードコート材及び表示装置 | |

| JP4720937B2 (ja) | 塗布フィルムの製造方法 | |

| JP5291750B2 (ja) | 塗布フィルムの製造方法 | |

| JP5649843B2 (ja) | 積層フィルムのカール矯正方法及び装置、並びに積層フィルムの製造方法 | |

| JP5905035B2 (ja) | 光学フィルムの製造方法 | |

| JP6303429B2 (ja) | 機能性フィルムの製造方法及び機能性フィルム | |

| JP2008152119A (ja) | 光学フィルム | |

| JP6387604B2 (ja) | 機能性フィルムの製造方法及び機能性フィルム | |

| JPH07294708A (ja) | 防眩フィルム及びその製造方法並びに防眩フィルム適用装置 | |

| JP4977936B2 (ja) | 光学フィルムの製造方法 | |

| TWI383894B (zh) | 光學層合體 | |

| JP6070270B2 (ja) | コーティングフィルムの製造方法 | |

| JP5260578B2 (ja) | 積層フィルムの塗布方法 | |

| JP2015197467A (ja) | 偏光板保護フィルムおよびその製造方法 | |

| KR101875244B1 (ko) | 광학 필름의 제조 방법, 편광판 및 화상 표시 장치 | |

| KR101128016B1 (ko) | 대전방지 적층체 및 그를 이용한 편광판 | |

| JP2013186456A (ja) | 光学フィルムの製造方法、および光学フィルム |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121010 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20121010 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130527 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130529 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130607 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5291750 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |