JP5138931B2 - 二重層ロールブーツ - Google Patents

二重層ロールブーツ Download PDFInfo

- Publication number

- JP5138931B2 JP5138931B2 JP2006526172A JP2006526172A JP5138931B2 JP 5138931 B2 JP5138931 B2 JP 5138931B2 JP 2006526172 A JP2006526172 A JP 2006526172A JP 2006526172 A JP2006526172 A JP 2006526172A JP 5138931 B2 JP5138931 B2 JP 5138931B2

- Authority

- JP

- Japan

- Prior art keywords

- boot seal

- layer

- inner layer

- boot

- outer layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000463 material Substances 0.000 claims description 56

- 229920001971 elastomer Polymers 0.000 claims description 15

- 239000004519 grease Substances 0.000 claims description 14

- 239000000806 elastomer Substances 0.000 claims description 12

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 claims description 10

- 238000007789 sealing Methods 0.000 claims description 8

- 229920002943 EPDM rubber Polymers 0.000 claims description 4

- 229920002725 thermoplastic elastomer Polymers 0.000 claims description 4

- 229920000459 Nitrile rubber Polymers 0.000 claims description 3

- 230000013011 mating Effects 0.000 claims description 2

- 239000010410 layer Substances 0.000 description 97

- 230000015556 catabolic process Effects 0.000 description 10

- 238000006731 degradation reaction Methods 0.000 description 10

- 239000012530 fluid Substances 0.000 description 8

- 238000001746 injection moulding Methods 0.000 description 8

- 238000000034 method Methods 0.000 description 6

- 238000002347 injection Methods 0.000 description 5

- 239000007924 injection Substances 0.000 description 5

- 238000004026 adhesive bonding Methods 0.000 description 4

- 230000036961 partial effect Effects 0.000 description 4

- 238000005452 bending Methods 0.000 description 3

- 230000009977 dual effect Effects 0.000 description 3

- 239000013536 elastomeric material Substances 0.000 description 3

- 239000004744 fabric Substances 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 125000003636 chemical group Chemical group 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 239000002355 dual-layer Substances 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- WNYHOOQHJMHHQW-UHFFFAOYSA-N 1-chloropyrene Chemical compound C1=C2C(Cl)=CC=C(C=C3)C2=C2C3=CC=CC2=C1 WNYHOOQHJMHHQW-UHFFFAOYSA-N 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000002144 chemical decomposition reaction Methods 0.000 description 1

- 238000003776 cleavage reaction Methods 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000003256 environmental substance Substances 0.000 description 1

- 229920005560 fluorosilicone rubber Polymers 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000010102 injection blow moulding Methods 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 230000002829 reductive effect Effects 0.000 description 1

- 239000012783 reinforcing fiber Substances 0.000 description 1

- 230000007017 scission Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

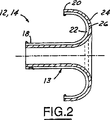

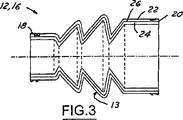

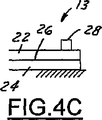

- F16J3/00—Diaphragms; Bellows; Bellows pistons

- F16J3/04—Bellows

- F16J3/041—Non-metallic bellows

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D3/00—Yielding couplings, i.e. with means permitting movement between the connected parts during the drive

- F16D3/84—Shrouds, e.g. casings, covers; Sealing means specially adapted therefor

- F16D3/843—Shrouds, e.g. casings, covers; Sealing means specially adapted therefor enclosed covers

- F16D3/845—Shrouds, e.g. casings, covers; Sealing means specially adapted therefor enclosed covers allowing relative movement of joint parts due to the flexing of the cover

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J3/00—Diaphragms; Bellows; Bellows pistons

- F16J3/04—Bellows

- F16J3/041—Non-metallic bellows

- F16J3/042—Fastening details

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J3/00—Diaphragms; Bellows; Bellows pistons

- F16J3/04—Bellows

- F16J3/041—Non-metallic bellows

- F16J3/043—Non-metallic bellows with particular means for limiting wear

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Diaphragms And Bellows (AREA)

- Sealing Devices (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/656,991 US6942223B2 (en) | 2003-09-05 | 2003-09-05 | Dual layer roll boot |

| US10/656,991 | 2003-09-05 | ||

| PCT/US2004/028514 WO2005026590A1 (en) | 2003-09-05 | 2004-09-02 | Dual layer roll boot |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007504419A JP2007504419A (ja) | 2007-03-01 |

| JP2007504419A5 JP2007504419A5 (enExample) | 2007-10-04 |

| JP5138931B2 true JP5138931B2 (ja) | 2013-02-06 |

Family

ID=34226474

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006526172A Expired - Fee Related JP5138931B2 (ja) | 2003-09-05 | 2004-09-02 | 二重層ロールブーツ |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6942223B2 (enExample) |

| JP (1) | JP5138931B2 (enExample) |

| CN (1) | CN100538098C (enExample) |

| DE (1) | DE112004001519B4 (enExample) |

| WO (1) | WO2005026590A1 (enExample) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8220127B2 (en) * | 2004-03-10 | 2012-07-17 | Ashwood River Pty Ltd | Replacement of steering rack boots |

| US20050129890A1 (en) * | 2004-08-05 | 2005-06-16 | Wang Shen-Ling A. | Automotive driveline components manufactured of hydrogenated nitrile butadiene rubber material |

| EP1970586B1 (en) * | 2005-12-22 | 2011-11-30 | NTN Corporation | Joint assembly and vehicle-use bearing unit, and axle module provided with them |

| US20100044965A1 (en) * | 2006-05-01 | 2010-02-25 | Eddie York-Shin Lou | Laminated Multiple-layered split boot |

| US8136816B1 (en) * | 2006-05-01 | 2012-03-20 | Eddie York-Shin Lou | Laminated multiple-layered split boot |

| US7395582B2 (en) | 2006-07-12 | 2008-07-08 | Honda Motor Company, Ltd. | Article retention band |

| US7913705B2 (en) * | 2007-02-07 | 2011-03-29 | Tbw Industries, Inc. | Cleaning cup system for chemical mechanical planarization apparatus |

| DE102007036981A1 (de) * | 2007-08-06 | 2009-02-12 | Zumtobel Lighting Gmbh | Feuchtraumleuchte |

| US20090058012A1 (en) * | 2007-08-31 | 2009-03-05 | Trent Edward Walters | Seal for a rotating laser transmitter |

| US8088015B2 (en) * | 2007-11-01 | 2012-01-03 | Gkn Driveline North America, Inc. | Self-repairing boot for a constant velocity joint |

| WO2009066128A1 (en) * | 2007-11-23 | 2009-05-28 | Gkn Driveline S.A. | Shaft assembly |

| US8640815B2 (en) | 2011-02-10 | 2014-02-04 | Honda Motor Company, Ltd. | Boot assembly |

| JP5313284B2 (ja) | 2011-03-28 | 2013-10-09 | 豊田合成株式会社 | 可変圧縮比エンジン用ブーツシール |

| CN103797260A (zh) * | 2011-09-21 | 2014-05-14 | Gkn动力传动系统北美有限公司 | 外滚动隔膜包覆模制高速恒速接头罩 |

| JP6121125B2 (ja) * | 2012-09-28 | 2017-04-26 | ニッタ株式会社 | ジョイント用ブーツ |

| DE102016201046A1 (de) * | 2016-01-26 | 2017-07-27 | Zf Friedrichshafen Ag | Kugelgelenk für ein Fahrzeug, insbesondere für ein Offroadfahrzeug |

| KR20190136045A (ko) * | 2017-03-31 | 2019-12-09 | 데이나 오토모티브 시스템즈 그룹 엘엘씨 | 등속 조인트 조립체 |

| DE102017217633A1 (de) * | 2017-10-04 | 2019-04-04 | Volkswagen Aktiengesellschaft | Verfahren zur Herstellung eines Dämpfungselementes, insbesondere für das Lenksystem eines Kraftfahrzeuges bzw. Dämpfungselement, insbesondere für das Lenksystem eines Kraftfahrzeuges bzw. Lenksystem eines Kraftfahrzeuges |

| CA3118431C (en) * | 2018-10-31 | 2023-10-03 | National Oilwell DHT, L.P. | Apparatus, systems, and methods for a reinforced seal element for joints on a drilling tool |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1922431A (en) * | 1929-06-29 | 1933-08-15 | Inland Mfg Co | Flexible boot for universal joints |

| US3213764A (en) * | 1963-11-27 | 1965-10-26 | Bendix Corp | Damped bellows construction |

| US3381987A (en) * | 1965-06-04 | 1968-05-07 | Ford Motor Co | Double wall seal for articulated joints |

| BR8201276A (pt) | 1981-03-20 | 1983-01-18 | Gates Rubber Co | Protetor flexivel corrugado molde conjugado para produzir pares de protetores |

| DE3506751A1 (de) * | 1984-02-29 | 1985-08-29 | John Deks Australia Pty. Ltd., Bayswater, Victoria | Vorrichtung zur abdichtung einer rohrleitungsdurchfuehrung |

| JPS60227060A (ja) * | 1984-04-26 | 1985-11-12 | Toyoda Gosei Co Ltd | 等速ジヨイントのダストブ−ツ |

| JPS61256024A (ja) | 1985-05-08 | 1986-11-13 | Toyoda Gosei Co Ltd | 機械軸継手用ブ−ツ |

| JPS61266876A (ja) * | 1985-05-20 | 1986-11-26 | Toyoda Gosei Co Ltd | 樹脂製ダストブ−ツ |

| EP0342061B1 (en) | 1988-05-13 | 1995-11-02 | Canon Kabushiki Kaisha | Projection exposure apparatus |

| EP0347061B1 (en) * | 1988-05-31 | 1992-07-15 | Keeper Co. Ltd | Flexible boot |

| JPH0650690Y2 (ja) * | 1988-05-31 | 1994-12-21 | キーパー株式会社 | フレキシブルブーツ |

| DE4037482A1 (de) * | 1990-11-24 | 1992-05-27 | Freudenberg Carl Fa | Faltenbalg aus thermoplastischem elastomer |

| US5145191A (en) * | 1991-04-10 | 1992-09-08 | International Sales & Engineering, Inc. | Heat-resistant protective cover for a drive axle joint seal |

| JPH05230314A (ja) * | 1992-02-18 | 1993-09-07 | Nippon Zeon Co Ltd | ゴム組成物 |

| CA2153009C (en) * | 1994-07-07 | 2007-05-08 | Gary D. Grabaum | Constant velocity joint boot and method of making the same |

| JPH08109966A (ja) * | 1994-10-13 | 1996-04-30 | Nok Corp | ブーツ |

| JP3725919B2 (ja) * | 1995-09-26 | 2005-12-14 | キーパー株式会社 | 樹脂製cvjブーツ |

| JPH10115326A (ja) * | 1996-10-11 | 1998-05-06 | Toyota Motor Corp | フレキシブルブーツ |

| US6386551B1 (en) * | 1997-03-05 | 2002-05-14 | Trw Inc. | Plastic sleeve and method of manufacturing the same |

| US6033608A (en) * | 1998-03-11 | 2000-03-07 | Milliken & Company | Method for making foam rubber tree bark-configured articles having manmade textiles backings |

| US6083109A (en) * | 1998-03-12 | 2000-07-04 | Federal-Mogul World Wide, Inc. | Unitized seal for telescopic shaft |

| CN1100224C (zh) * | 1998-08-04 | 2003-01-29 | 诺克株式会社 | 开裂式保护罩及用于这种保护罩的接合方法、焊接剂和加热体 |

| DE19920257A1 (de) * | 1999-05-03 | 2000-11-09 | Basf Ag | Thermoplastische Elastomerzusammensetzung |

| JP2003049944A (ja) * | 2001-08-08 | 2003-02-21 | Nitto Kogyo Co Ltd | 自在継手用ブーツ及びそのブーツを装着した自在継手 |

-

2003

- 2003-09-05 US US10/656,991 patent/US6942223B2/en not_active Expired - Fee Related

-

2004

- 2004-09-02 JP JP2006526172A patent/JP5138931B2/ja not_active Expired - Fee Related

- 2004-09-02 DE DE112004001519.7T patent/DE112004001519B4/de not_active Expired - Fee Related

- 2004-09-02 CN CNB2004800255024A patent/CN100538098C/zh not_active Expired - Fee Related

- 2004-09-02 WO PCT/US2004/028514 patent/WO2005026590A1/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| DE112004001519B4 (de) | 2017-01-26 |

| CN1846090A (zh) | 2006-10-11 |

| WO2005026590A1 (en) | 2005-03-24 |

| CN100538098C (zh) | 2009-09-09 |

| JP2007504419A (ja) | 2007-03-01 |

| US6942223B2 (en) | 2005-09-13 |

| US20050051973A1 (en) | 2005-03-10 |

| DE112004001519T5 (de) | 2006-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5138931B2 (ja) | 二重層ロールブーツ | |

| JP2003113858A (ja) | 等速ジョイント用ブーツ | |

| CN105452696B (zh) | 包覆成型的轮廓罩筒组件 | |

| CN101802428A (zh) | 等速万向接头 | |

| JP3719177B2 (ja) | 樹脂製ジョイントブーツ | |

| JP4472335B2 (ja) | 等速ジョイント用蛇腹状ブーツ | |

| US7090584B2 (en) | High temperature slip spline boot | |

| CN101523070B (zh) | 等速联轴器用防尘罩以及交叉槽式等速联轴器 | |

| JP2008309223A (ja) | トリポード型等速自在継手用ブーツ | |

| JP4657897B2 (ja) | シール構造 | |

| JP2007211927A (ja) | 等速自在継手用ブーツ | |

| US7297065B2 (en) | Automotive driveline components manufactured of silicone materials | |

| US8052536B2 (en) | Boot for universal joint | |

| JP2009228727A (ja) | 継手の防塵装置 | |

| JP2001003950A (ja) | 等速ジョイントブーツ | |

| CN101218448B (zh) | 具有整体的起伏膜区域的恒速万向节护套 | |

| RU2281423C2 (ru) | Защитный чехол из термоэластопласта для шарнира | |

| JP2009228728A (ja) | 継手の防塵装置 | |

| JP5183960B2 (ja) | 等速自在継手用ブーツ | |

| JP2014526663A (ja) | 外部転動型ダイアフラムのオーバーモールド成形された高速等速ジョイントブーツ | |

| JP2007155003A (ja) | 等速自在継手用ブーツ | |

| US20080258408A1 (en) | Boot for constant-velocity universal joint and fixing structure for the same | |

| JP2007057071A (ja) | 等速自在継手用ブーツ | |

| JPH11303885A (ja) | 自在継手用ブーツ | |

| JP2008025751A (ja) | シール構造 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070807 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070807 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100526 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100622 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100820 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110315 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110706 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20110711 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20110729 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120510 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121115 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151122 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |