JP5117779B2 - 複合材料 - Google Patents

複合材料 Download PDFInfo

- Publication number

- JP5117779B2 JP5117779B2 JP2007178203A JP2007178203A JP5117779B2 JP 5117779 B2 JP5117779 B2 JP 5117779B2 JP 2007178203 A JP2007178203 A JP 2007178203A JP 2007178203 A JP2007178203 A JP 2007178203A JP 5117779 B2 JP5117779 B2 JP 5117779B2

- Authority

- JP

- Japan

- Prior art keywords

- resin

- prepreg

- composite material

- cscnt

- resin sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/08—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer the fibres or filaments of a layer being of different substances, e.g. conjugate fibres, mixture of different fibres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/241—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres

- C08J5/243—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres using carbon fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/024—Woven fabric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/12—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by the relative arrangement of fibres or filaments of different layers, e.g. the fibres or filaments being parallel or perpendicular to each other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/02—Composition of the impregnated, bonded or embedded layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/04—Impregnation, embedding, or binder material

- B32B2260/046—Synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/106—Carbon fibres, e.g. graphite fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/542—Shear strength

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/558—Impact strength, toughness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/08—Cars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/18—Aircraft

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Manufacturing & Machinery (AREA)

- Health & Medical Sciences (AREA)

- Inorganic Chemistry (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Textile Engineering (AREA)

- Reinforced Plastic Materials (AREA)

- Laminated Bodies (AREA)

- Carbon And Carbon Compounds (AREA)

Description

間においてCSCNT7の端部が楔効果を発揮することで両者の結合が強固とな

り、これにより繊維体3間の層間せん断強度が向上する。

及び外周面cの間)には間隙が存在し、これにより、外部から応力が加わった場

合、応力吸収が行われるため、座屈し難い。よって、複合材料とした場合に圧縮

強度が向上すると考えられる。

差を持たせることで、プリプレグ5と樹脂シート6とを積層して硬化成形により

樹脂が溶融した際、CSCNT7が高濃度側から低濃度側へと移動する。これに

より、上記楔効果をプリプレグ5と樹脂シート6との境界部分でも効率良く発現

させることが可能となる。

樹脂の組成を同一とした場合には、複合材料中で相分離が生じ難くなり、それだ

け剥離強度を向上させることが可能となる。

A:主剤 ノボラック系エポキシ樹脂若しくはビスフェノールA型エポキシ樹脂

B:硬化剤 ジシアンジアミド(主剤を硬化させるものであれば特に制限はない。)

C:硬化促進剤 DCMU若しくはイミダゾール(主剤を硬化させるものであれば特に制

限はない。)

本実施例においては、ビスフェノールA型エポキシ樹脂とジシアンジアミドとDCMUとから成る樹脂組成物が採用されている。

に対して10wt%となるように添加して、攪拌混合する。

その後、75℃×0.5hで加熱しながら攪拌する。

inで更に加熱しながら攪拌する。

なるように成形する。

2 炭素繊維束

3 一方向繊維体

4 マトリックス樹脂

5 プリプレグ

6 樹脂シート

7 カップスタック型のCNT

Claims (4)

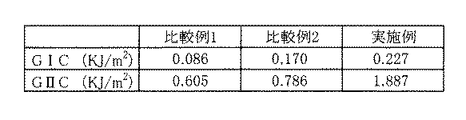

- 複数の炭素フィラメントを収束した炭素繊維束を一方向に引き揃えた一方向繊維体に、硬化性のマトリックス樹脂を含浸させて構成されるプリプレグと、硬化性樹脂で構成される樹脂シートとを交互に積層して成る複合材料であって、前記プリプレグの前記マトリックス樹脂及び前記樹脂シートの前記硬化性樹脂として同一組成で且つカップスタック型のCNTが分散状態で含有された樹脂が採用され、前記プリプレグの前記マトリックス樹脂には、このマトリックス樹脂に対して前記カップスタック型のCNTが2〜10wt%含有され、前記樹脂シートの前記硬化性樹脂には、この硬化性樹脂に対して前記カップスタック型のCNTが10〜30wt%含有されていることを特徴とする複合材料。

- 請求項1記載の複合材料において、前記カップスタック型のCNTとして、アスペクト比が2〜50に設定されているものが採用されていることを特徴とする複合材料。

- 請求項1,2いずれか1項に記載の複合材料において、前記プリプレグの前記マトリックス樹脂には、このマトリックス樹脂に対して前記カップスタック型のCNTが2〜5wt%含有されていることを特徴とする複合材料。

- 請求項1〜3いずれか1項に記載の複合材料において、前記硬化性樹脂として、ノボラック系エポキシ樹脂若しくはビスフェノールA型エポキシ樹脂を主剤とするものが採用されていることを特徴とする複合材料。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007178203A JP5117779B2 (ja) | 2007-07-06 | 2007-07-06 | 複合材料 |

| PCT/JP2008/062019 WO2009008312A1 (ja) | 2007-07-06 | 2008-07-02 | 複合材料 |

| TW097125566A TW200916513A (en) | 2007-07-06 | 2008-07-07 | Composite material |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007178203A JP5117779B2 (ja) | 2007-07-06 | 2007-07-06 | 複合材料 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009013327A JP2009013327A (ja) | 2009-01-22 |

| JP5117779B2 true JP5117779B2 (ja) | 2013-01-16 |

Family

ID=40228490

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007178203A Active JP5117779B2 (ja) | 2007-07-06 | 2007-07-06 | 複合材料 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP5117779B2 (ja) |

| TW (1) | TW200916513A (ja) |

| WO (1) | WO2009008312A1 (ja) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2513250A4 (en) * | 2009-12-14 | 2015-05-27 | Applied Nanostructured Sols | FIRE-RESISTANT COMPOSITE MATERIALS AND ARTICLES WITH CARBON NANOTUBES-INFUNDED FIBER MATERIALS |

| KR101305072B1 (ko) * | 2009-12-30 | 2013-09-11 | 제일모직주식회사 | 탄소 섬유상 금속 복합체 및 그 제조방법 |

| KR101906262B1 (ko) | 2010-02-02 | 2018-10-10 | 어플라이드 나노스트럭처드 솔루션스, 엘엘씨. | 평행하게-정렬된 카본 나노튜브를 포함하는 섬유 |

| US9017854B2 (en) | 2010-08-30 | 2015-04-28 | Applied Nanostructured Solutions, Llc | Structural energy storage assemblies and methods for production thereof |

| TWI509119B (zh) | 2012-12-03 | 2015-11-21 | Ind Tech Res Inst | 碳纖維複合材料及其製法 |

| CN107517586A (zh) * | 2015-03-31 | 2017-12-26 | 国立研究开发法人产业技术综合研究所 | 碳纤维复合材料的制造方法 |

| JP2018016030A (ja) * | 2016-07-29 | 2018-02-01 | 学校法人幾徳学園 | 炭素繊維強化プラスチックおよびその製造方法 |

| CN109676951B (zh) | 2017-10-18 | 2021-03-09 | 财团法人工业技术研究院 | 纤维复合材料及其制法 |

| US10272651B1 (en) | 2017-10-18 | 2019-04-30 | Industrial Technology Research Institute | Fiber composite and manufacturing method thereof |

| CN113242783B (zh) * | 2018-11-28 | 2023-09-12 | 三菱化学株式会社 | 布预浸料、布预浸料的制造方法、纤维增强树脂成型品、纤维增强树脂成型品的制造方法 |

| CN111805935B (zh) | 2019-04-11 | 2022-01-07 | 财团法人工业技术研究院 | 纤维复合结构 |

| CN112590252A (zh) * | 2020-11-27 | 2021-04-02 | 哈尔滨工业大学 | 一种增强热塑性自动铺放构件层间性能的方法 |

| CN114347502A (zh) * | 2022-01-05 | 2022-04-15 | 泰山玻璃纤维有限公司 | 基于膨体纱改性的碳-玻混拉板及其生产工艺 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0133280A3 (en) * | 1983-08-01 | 1986-03-19 | American Cyanamid Company | Thermoset interleafed resin matrix composites with improved compression properties |

| DE3588077T2 (de) * | 1984-03-30 | 1996-06-27 | Cytec Tech Corp | Kunststoff-Matrix-Komposite |

| JPS6265212U (ja) * | 1985-10-16 | 1987-04-23 | ||

| JPS63162733A (ja) * | 1986-12-26 | 1988-07-06 | Ube Ind Ltd | インタ−リ−フを有する繊維強化エポキシ樹脂プリプレグ |

| JPH04267139A (ja) * | 1991-02-22 | 1992-09-22 | Nec Corp | 炭素繊維強化複合材料プリプレグシート |

| JP4273092B2 (ja) * | 2005-03-30 | 2009-06-03 | 株式会社Gsiクレオス | プリプレグの製造方法およびプリプレグの製造装置 |

| JP4156620B2 (ja) * | 2005-10-07 | 2008-09-24 | 株式会社Gsiクレオス | プリプレグの製造装置及びプリプレグ |

-

2007

- 2007-07-06 JP JP2007178203A patent/JP5117779B2/ja active Active

-

2008

- 2008-07-02 WO PCT/JP2008/062019 patent/WO2009008312A1/ja not_active Ceased

- 2008-07-07 TW TW097125566A patent/TW200916513A/zh unknown

Also Published As

| Publication number | Publication date |

|---|---|

| WO2009008312A1 (ja) | 2009-01-15 |

| TW200916513A (en) | 2009-04-16 |

| JP2009013327A (ja) | 2009-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5117779B2 (ja) | 複合材料 | |

| JP3894035B2 (ja) | 炭素繊維強化基材、それからなるプリフォームおよび複合材料 | |

| US8283403B2 (en) | Carbon nanotube-reinforced nanocomposites | |

| KR102006511B1 (ko) | 개선된 충격 강도를 갖는 복합 라미네이트 및 그의 용도 | |

| US7407901B2 (en) | Impact resistant, thin ply composite structures and method of manufacturing same | |

| EP2799470B1 (en) | Carbon fiber base, prepreg, and carbon-fiber-reinforced composite material | |

| CN104736614B (zh) | 具有增强界面相的纤维增强高模量聚合物复合体 | |

| JP5228853B2 (ja) | エポキシ樹脂組成物、繊維強化複合材料およびそれらの製造方法 | |

| CN104884511B (zh) | 具有硬界面相的纤维增强聚合物复合体 | |

| KR101659591B1 (ko) | 하이브리드 세라믹 섬유강화 복합재료 제조방법 및 이에 의해 제조된 하이브리드 세라믹 섬유강화 복합재료 | |

| KR20200079313A (ko) | 층간 강인화 입자를 갖는 복합체 및 이의 제조 방법 | |

| JP4233560B2 (ja) | プリプレグの製造方法 | |

| KR102317967B1 (ko) | 아라미드 나노섬유로 강화된 탄소섬유 강화 복합소재 및 이의 제조방법 | |

| US5116668A (en) | Hybrid yarn, unidirectional hybrid prepreg and laminated material thereof | |

| JP2018118440A (ja) | 引抜成形体及びその製造方法 | |

| Ren et al. | Hybrid effect on mechanical properties of M40‐T300 carbon fiber reinforced Bisphenol A Dicyanate ester composites | |

| JP4687167B2 (ja) | エポキシ樹脂組成物、プリプレグおよび繊維強化複合材料 | |

| JPH0232843A (ja) | 成形物中間体並びに成形物 | |

| US12024606B2 (en) | Composite prepreg, preform using the same, fiber-reinforced composite material assembly, and method for producing the same | |

| JP2014162858A (ja) | プリプレグおよびその製造方法、ならびに繊維強化複合材料 | |

| JP2010059300A (ja) | 炭素繊維強化複合材料およびその製造方法 | |

| JP2006198920A (ja) | ハニカムコキュア用プリプレグ、ハニカム積層複合材およびそれらの製造方法 | |

| KR20180029805A (ko) | 스키 제조용 저온 경화형 에폭시 수지 조성물과 이에 의해 제조된 스키 제조용 프리프레그 및 이를 이용한 섬유 강화 고분자 복합재료 | |

| KR102461792B1 (ko) | 고내충격 특성을 가진 필라멘트 와인딩용 하이브리드 토우프리프레그 | |

| JP3864751B2 (ja) | 炭素繊維強化複合材料用樹脂組成物、プリプレグおよび炭素繊維強化複合材料 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101220 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110218 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111221 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20120220 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120920 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121018 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5117779 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151026 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |