JP5052084B2 - インホイール型モータ内蔵センサ付きアクスルユニット - Google Patents

インホイール型モータ内蔵センサ付きアクスルユニット Download PDFInfo

- Publication number

- JP5052084B2 JP5052084B2 JP2006252531A JP2006252531A JP5052084B2 JP 5052084 B2 JP5052084 B2 JP 5052084B2 JP 2006252531 A JP2006252531 A JP 2006252531A JP 2006252531 A JP2006252531 A JP 2006252531A JP 5052084 B2 JP5052084 B2 JP 5052084B2

- Authority

- JP

- Japan

- Prior art keywords

- sensor

- force

- axial

- wheel

- brake

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000005096 rolling process Methods 0.000 claims description 23

- 239000000725 suspension Substances 0.000 claims description 19

- 239000003638 chemical reducing agent Substances 0.000 claims description 15

- 230000033001 locomotion Effects 0.000 claims description 12

- 238000013016 damping Methods 0.000 claims description 9

- 238000002474 experimental method Methods 0.000 description 15

- 238000004088 simulation Methods 0.000 description 15

- 238000000034 method Methods 0.000 description 10

- 239000002184 metal Substances 0.000 description 9

- 229910052751 metal Inorganic materials 0.000 description 9

- 230000002093 peripheral effect Effects 0.000 description 9

- 238000005259 measurement Methods 0.000 description 8

- 238000006073 displacement reaction Methods 0.000 description 7

- 230000005856 abnormality Effects 0.000 description 6

- 230000005540 biological transmission Effects 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 230000007246 mechanism Effects 0.000 description 6

- 230000009467 reduction Effects 0.000 description 6

- 230000008859 change Effects 0.000 description 5

- 238000001514 detection method Methods 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 238000001746 injection moulding Methods 0.000 description 4

- 239000000843 powder Substances 0.000 description 4

- 230000035945 sensitivity Effects 0.000 description 4

- 230000004044 response Effects 0.000 description 3

- 230000004043 responsiveness Effects 0.000 description 3

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 238000005245 sintering Methods 0.000 description 2

- 230000002159 abnormal effect Effects 0.000 description 1

- 239000006096 absorbing agent Substances 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- POIUWJQBRNEFGX-XAMSXPGMSA-N cathelicidin Chemical compound C([C@@H](C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CCCCN)C(=O)N[C@@H](CO)C(=O)N[C@@H](CCCCN)C(=O)N[C@@H](CCC(O)=O)C(=O)N[C@@H](CCCCN)C(=O)N[C@@H]([C@@H](C)CC)C(=O)NCC(=O)N[C@@H](CCCCN)C(=O)N[C@@H](CCC(O)=O)C(=O)N[C@@H](CC=1C=CC=CC=1)C(=O)N[C@@H](CCCCN)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H]([C@@H](C)CC)C(=O)N[C@@H](C(C)C)C(=O)N[C@@H](CCC(N)=O)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H]([C@@H](C)CC)C(=O)N[C@@H](CCCCN)C(=O)N[C@@H](CC(O)=O)C(=O)N[C@@H](CC=1C=CC=CC=1)C(=O)N[C@@H](CC(C)C)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H](CC(N)=O)C(=O)N[C@@H](CC(C)C)C(=O)N[C@@H](C(C)C)C(=O)N1[C@@H](CCC1)C(=O)N[C@@H](CCCNC(N)=N)C(=O)N[C@@H]([C@@H](C)O)C(=O)N[C@@H](CCC(O)=O)C(=O)N[C@@H](CO)C(O)=O)NC(=O)[C@H](CC=1C=CC=CC=1)NC(=O)[C@H](CC(O)=O)NC(=O)CNC(=O)[C@H](CC(C)C)NC(=O)[C@@H](N)CC(C)C)C1=CC=CC=C1 POIUWJQBRNEFGX-XAMSXPGMSA-N 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 238000005238 degreasing Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000003912 environmental pollution Methods 0.000 description 1

- 229910000765 intermetallic Inorganic materials 0.000 description 1

- 238000004898 kneading Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 239000013307 optical fiber Substances 0.000 description 1

- 238000004663 powder metallurgy Methods 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60T—VEHICLE BRAKE CONTROL SYSTEMS OR PARTS THEREOF; BRAKE CONTROL SYSTEMS OR PARTS THEREOF, IN GENERAL; ARRANGEMENT OF BRAKING ELEMENTS ON VEHICLES IN GENERAL; PORTABLE DEVICES FOR PREVENTING UNWANTED MOVEMENT OF VEHICLES; VEHICLE MODIFICATIONS TO FACILITATE COOLING OF BRAKES

- B60T8/00—Arrangements for adjusting wheel-braking force to meet varying vehicular or ground-surface conditions, e.g. limiting or varying distribution of braking force

- B60T8/32—Arrangements for adjusting wheel-braking force to meet varying vehicular or ground-surface conditions, e.g. limiting or varying distribution of braking force responsive to a speed condition, e.g. acceleration or deceleration

- B60T8/321—Arrangements for adjusting wheel-braking force to meet varying vehicular or ground-surface conditions, e.g. limiting or varying distribution of braking force responsive to a speed condition, e.g. acceleration or deceleration deceleration

- B60T8/329—Systems characterised by their speed sensor arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K17/00—Arrangement or mounting of transmissions in vehicles

- B60K17/04—Arrangement or mounting of transmissions in vehicles characterised by arrangement, location or kind of gearing

- B60K17/043—Transmission unit disposed in on near the vehicle wheel, or between the differential gear unit and the wheel

- B60K17/046—Transmission unit disposed in on near the vehicle wheel, or between the differential gear unit and the wheel with planetary gearing having orbital motion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K7/0007—Disposition of motor in, or adjacent to, traction wheel the motor being electric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L15/00—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles

- B60L15/20—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles for control of the vehicle or its driving motor to achieve a desired performance, e.g. speed, torque, programmed variation of speed

- B60L15/2009—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles for control of the vehicle or its driving motor to achieve a desired performance, e.g. speed, torque, programmed variation of speed for braking

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L3/00—Electric devices on electrically-propelled vehicles for safety purposes; Monitoring operating variables, e.g. speed, deceleration or energy consumption

- B60L3/0023—Detecting, eliminating, remedying or compensating for drive train abnormalities, e.g. failures within the drive train

- B60L3/0061—Detecting, eliminating, remedying or compensating for drive train abnormalities, e.g. failures within the drive train relating to electrical machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L3/00—Electric devices on electrically-propelled vehicles for safety purposes; Monitoring operating variables, e.g. speed, deceleration or energy consumption

- B60L3/0023—Detecting, eliminating, remedying or compensating for drive train abnormalities, e.g. failures within the drive train

- B60L3/0076—Detecting, eliminating, remedying or compensating for drive train abnormalities, e.g. failures within the drive train relating to braking

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L7/00—Electrodynamic brake systems for vehicles in general

- B60L7/24—Electrodynamic brake systems for vehicles in general with additional mechanical or electromagnetic braking

- B60L7/26—Controlling the braking effect

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60T—VEHICLE BRAKE CONTROL SYSTEMS OR PARTS THEREOF; BRAKE CONTROL SYSTEMS OR PARTS THEREOF, IN GENERAL; ARRANGEMENT OF BRAKING ELEMENTS ON VEHICLES IN GENERAL; PORTABLE DEVICES FOR PREVENTING UNWANTED MOVEMENT OF VEHICLES; VEHICLE MODIFICATIONS TO FACILITATE COOLING OF BRAKES

- B60T13/00—Transmitting braking action from initiating means to ultimate brake actuator with power assistance or drive; Brake systems incorporating such transmitting means, e.g. air-pressure brake systems

- B60T13/74—Transmitting braking action from initiating means to ultimate brake actuator with power assistance or drive; Brake systems incorporating such transmitting means, e.g. air-pressure brake systems with electrical assistance or drive

- B60T13/741—Transmitting braking action from initiating means to ultimate brake actuator with power assistance or drive; Brake systems incorporating such transmitting means, e.g. air-pressure brake systems with electrical assistance or drive acting on an ultimate actuator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D65/00—Parts or details

- F16D65/14—Actuating mechanisms for brakes; Means for initiating operation at a predetermined position

- F16D65/16—Actuating mechanisms for brakes; Means for initiating operation at a predetermined position arranged in or on the brake

- F16D65/18—Actuating mechanisms for brakes; Means for initiating operation at a predetermined position arranged in or on the brake adapted for drawing members together, e.g. for disc brakes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2204/00—Indexing codes related to suspensions per se or to auxiliary parts

- B60G2204/10—Mounting of suspension elements

- B60G2204/30—In-wheel mountings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2300/00—Indexing codes relating to the type of vehicle

- B60G2300/50—Electric vehicles; Hybrid vehicles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K17/00—Arrangement or mounting of transmissions in vehicles

- B60K17/04—Arrangement or mounting of transmissions in vehicles characterised by arrangement, location or kind of gearing

- B60K17/043—Transmission unit disposed in on near the vehicle wheel, or between the differential gear unit and the wheel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K2007/0038—Disposition of motor in, or adjacent to, traction wheel the motor moving together with the wheel axle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K2007/0092—Disposition of motor in, or adjacent to, traction wheel the motor axle being coaxial to the wheel axle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2220/00—Electrical machine types; Structures or applications thereof

- B60L2220/40—Electrical machine applications

- B60L2220/44—Wheel Hub motors, i.e. integrated in the wheel hub

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2220/00—Electrical machine types; Structures or applications thereof

- B60L2220/50—Structural details of electrical machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/42—Drive Train control parameters related to electric machines

- B60L2240/421—Speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/42—Drive Train control parameters related to electric machines

- B60L2240/429—Current

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/46—Drive Train control parameters related to wheels

- B60L2240/461—Speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2270/00—Problem solutions or means not otherwise provided for

- B60L2270/10—Emission reduction

- B60L2270/14—Emission reduction of noise

- B60L2270/145—Structure borne vibrations

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2121/00—Type of actuator operation force

- F16D2121/18—Electric or magnetic

- F16D2121/24—Electric or magnetic using motors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2125/00—Components of actuators

- F16D2125/18—Mechanical mechanisms

- F16D2125/20—Mechanical mechanisms converting rotation to linear movement or vice versa

- F16D2125/34—Mechanical mechanisms converting rotation to linear movement or vice versa acting in the direction of the axis of rotation

- F16D2125/40—Screw-and-nut

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/64—Electric machine technologies in electromobility

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/72—Electric energy management in electromobility

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Transportation (AREA)

- Power Engineering (AREA)

- Combustion & Propulsion (AREA)

- General Engineering & Computer Science (AREA)

- Sustainable Development (AREA)

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Energy (AREA)

- Electromagnetism (AREA)

- Physics & Mathematics (AREA)

- Arrangement Or Mounting Of Propulsion Units For Vehicles (AREA)

- Force Measurement Appropriate To Specific Purposes (AREA)

- Vehicle Body Suspensions (AREA)

- Braking Arrangements (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

- Rolling Contact Bearings (AREA)

- Regulating Braking Force (AREA)

Description

ブレーキが電動ブレーキであると、ブレーキ制御が容易である。

サスペンションの減衰手段が電動で作動して減衰の程度を変化させるものであると、サスペンションの制御が容易である。このサスペンションの制御が、前記センサの出力により適切に行われる。

駆動輪と路面の接地点に作用する進行方向の力の大きさによって電気モータに流れる電流量が異なるため、予め上記作用力と電流量の関係を実験やシミュレーションにて求めておくことにより、上記作用力の大きさを算出することができる。推定手段は、このように実験やシミュレーションにより予め求めて設定しておいた作用力と電流量の関係から、電流センサの出力により、駆動輪と路面の接地点に作用する進行方向の力を算出する。この方法で進行方向の作用力を求めることにより、同作用力を精度良く検出することができる。

駆動輪と路面の接地点に作用する駆動輪の軸方向の力の大きさによって静止側軌道輪の軸方向歪みの変化が異なるため、予め上記作用力と軸方向歪みの関係を実験やシミュレーションにて求めておくことにより、上記作用力の大きさを算出することができる。推定手段は、このように実験やシミュレーションにより予め求めて設定しておいた作用力と軸方向歪みの関係から、軸方向歪みセンサの出力により、駆動輪と路面の接地点に作用する駆動輪の軸方向の力を算出する。この方法で軸方向の作用力を求めることにより、同作用力を精度良く検出することができる。

駆動輪と路面の接地点に作用する駆動輪の鉛直方向の力の大きさによって静止側軌道輪の径方向歪みの変化が異なるため、予め上記作用力と径方向歪みの関係を実験やシミュレーションにて求めておくことにより、上記作用力の大きさを算出することができる。推定手段は、このように実験やシミュレーションにより予め求めて設定しておいた作用力と径方向歪みの関係から、径方向歪みセンサの出力により、駆動輪と路面の接地点に作用する鉛直方向の力を算出する。この方法で鉛直方向の作用力を求めることにより、同作用力を精度良く検出することができる。

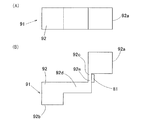

また、センサ取付部材92は、金属粉末射出成形による焼結金属品としてもよい。金属粉末射出成形は、金属、金属間化合物等の成形技術の一つであり、金属粉末をバインダーと混練する工程、この混練物を用いて射出成型する工程、成形体の脱脂処理を行なう工程、成形体の焼結を行なう工程を含む。この金属粉末射出成形によれば、一般の粉末冶金に比べて焼結密度の高い焼結体が得られ、焼結金属品を高い寸法精度で製作することができ、また機械的強度も高いという利点がある。

また、この実施形態では、内方部材がハブの一部を構成する第3世代型のハブベアリングとしたが、内方部材と車輪のハブとが互いに独立した第1または第2世代型のハブベアリングとしても良い。さらに、各世代形式のテーパころタイプであるハブベアリングAとしても良い。

また、この発明のアクスルユニットは、自動車の車輪の全てに設けても良く、あるいは一部の車輪だけに設けても良い。

2…内方部材(ハブ)

3,4…転走面

5…転動体

50…電気モータ

70…駆動輪

73…サスペンション

74…減衰手段

80…電流センサ

81…軸方向歪みセンサ

82…径方向歪みセンサ

83…推定手段

84…異常判定手段

85…電気制御ユニット

87…回転数センサ

A…ハブベアリング

B…電気モータ

C…減速機

D…ブレーキ

O…中心軸

Claims (4)

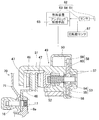

- 駆動輪の中心軸に対して、同軸上にハブベアリング、電気モータ、減速機、ブレーキを配置し、これらハブベアリング、電気モータ、減速機、ブレーキのうちの少なくとも一つの構成要素の状態から、駆動輪と路面の接地点から直交する3軸方向の力を測定するセンサを設け、前記ブレーキが、ブレーキ用電気モータの回転出力を往復直線運動に変換してブレーキパッドに制動力として伝える電動ブレーキであり、前記3軸方向の力を測定するセンサとして、前記電気モータの電流値を測定する電流センサ、および前記ブレーキに作用するブレーキ力を測定するブレーキ力センサをそれぞれ設け、前記電流センサの出力、および前記ブレーキ力センサの出力を両方を比較対照して、駆動輪と路面の接地点に作用する進行方向の力を推定する推定手段を設け、

前記ハブベアリングの状態から駆動輪と路面の接地点に作用する駆動輪の軸方向の力を推定する推定手段を設け、

前記ハブベアリングの状態から駆動輪と路面の接地点に作用する鉛直方向の力を推定する推定手段を設けたことを特徴とするインホイール型モータ内蔵センサ付きアクスルユニット。 - 請求項1において、前記インホイール型モータ内蔵センサ付きアクスルユニットは、駆動輪と路面の接地点に作用する力を減衰して車体に伝える減衰手段を有するサスペンションを介して車体に取付けられ、前記減衰手段は、電動で作動して減衰の程度を変化させるものであり、この減衰手段の減衰の程度を制御する手段に、前記センサの出力が入力されるインホイール型モータ内蔵センサ付きアクスルユニット。

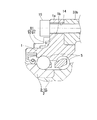

- 請求項1または請求項2において、前記3軸方向の力を測定するセンサの一つとして、前記ハブベアリングの静止側軌道輪に取付けられて、この静止側軌道輪の軸方向歪みを測定する軸方向歪みセンサを設け、この軸方向歪みセンサは、軸方向に沿った軸方向部位と、この軸方向部位に比べ剛性が低くなるように肉厚を薄くしてある径方向部位とでL字形状に構成されるセンサ取付部材を介して、前記静止側軌道輪に取付けられ、前記駆動輪の軸方向の力を推定する推定手段は、前記軸方向歪みセンサの出力から駆動輪と路面の接地点に作用する駆動輪の軸方向の力を推定するものとしたインホイール型モータ内蔵センサ付きアクスルユニット。

- 請求項1ないし請求項3のいずれか1項において、前記3軸方向の力を測定するセンサの一つとして、前記ハブベアリングの静止側軌道輪に対向して取付けられて、この静止側軌道輪の径方向歪みを測定する径方向歪みセンサを設け、前記ハブベアリングは複列の転がり軸受であり、前記径方向歪みセンサを対向させる前記複列の転がり軸受の軸方向位置は、アウトボード側列の転走面よりもアウトボード側の位置とされ、前記鉛直方向の力を推定する推定手段は、径方向歪みセンサの出力から駆動輪と路面の接地点に作用する鉛直方向の力を推定するものとしたインホイール型モータ内蔵センサ付きアクスルユニット。

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006252531A JP5052084B2 (ja) | 2006-09-19 | 2006-09-19 | インホイール型モータ内蔵センサ付きアクスルユニット |

| US12/311,109 US8307931B2 (en) | 2006-09-19 | 2007-08-29 | Sensor-equipped axle unit having a built-in motor of in-wheel type |

| DE112007002204T DE112007002204T5 (de) | 2006-09-19 | 2007-08-29 | Mit einem Sensor ausgestattete und einen eingebauten radintegrierten Motor aufweisende Achseinheit |

| CN2007800344214A CN101516663B (zh) | 2006-09-19 | 2007-08-29 | 内置内轮型电动机的带有传感器的车轴组件 |

| PCT/JP2007/000930 WO2008035455A1 (en) | 2006-09-19 | 2007-08-29 | Sensor-equipped axle unit integral with in-wheel motor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006252531A JP5052084B2 (ja) | 2006-09-19 | 2006-09-19 | インホイール型モータ内蔵センサ付きアクスルユニット |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008074135A JP2008074135A (ja) | 2008-04-03 |

| JP5052084B2 true JP5052084B2 (ja) | 2012-10-17 |

Family

ID=39200286

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006252531A Expired - Fee Related JP5052084B2 (ja) | 2006-09-19 | 2006-09-19 | インホイール型モータ内蔵センサ付きアクスルユニット |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8307931B2 (ja) |

| JP (1) | JP5052084B2 (ja) |

| CN (1) | CN101516663B (ja) |

| DE (1) | DE112007002204T5 (ja) |

| WO (1) | WO2008035455A1 (ja) |

Families Citing this family (55)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101285518B1 (ko) * | 2009-07-15 | 2013-07-17 | 주식회사 만도 | 토크 앵글 센서 및 이를 구비한 전동식 조향장치 |

| WO2011058844A1 (ja) | 2009-11-13 | 2011-05-19 | Ntn株式会社 | インホイールモータ駆動装置 |

| JP5517869B2 (ja) | 2009-11-27 | 2014-06-11 | Ntn株式会社 | インホイール型モータ内蔵センサ付き車輪用軸受装置 |

| US8323143B2 (en) * | 2009-12-02 | 2012-12-04 | Fairfield Manufacturing Company, Inc. | Integrated spindle-carrier electric wheel drive |

| KR101104006B1 (ko) | 2009-12-03 | 2012-01-06 | 현대자동차주식회사 | 차량의 리어 서스펜션 |

| JP5436191B2 (ja) | 2009-12-21 | 2014-03-05 | Ntn株式会社 | インホイール型モータ内蔵センサ付き車輪用軸受装置 |

| US8753009B2 (en) * | 2010-03-12 | 2014-06-17 | Mobius Imaging, Llc | Drive system for imaging device |

| US11944469B2 (en) | 2010-03-12 | 2024-04-02 | Mobius Imaging Llc | Caster system for mobile apparatus |

| DE102010012115A1 (de) * | 2010-03-19 | 2011-09-22 | Daimler Ag | Kraftwagen |

| JP5528168B2 (ja) * | 2010-03-26 | 2014-06-25 | Ntn株式会社 | 電気自動車用コントローラ装置 |

| GB2478800B (en) * | 2010-05-07 | 2012-02-22 | Protean Electric Ltd | An electric motor |

| JP5512385B2 (ja) * | 2010-05-17 | 2014-06-04 | Ntn株式会社 | インホイールモータ駆動装置 |

| JP5564352B2 (ja) * | 2010-07-23 | 2014-07-30 | Ntn株式会社 | インホイールモータ駆動装置 |

| DE102010042995A1 (de) * | 2010-10-27 | 2012-05-03 | Robert Bosch Gmbh | Steuervorrichtung und Verfahren zum Betreiben eines mit einer elektrischen Antriebs- und/oder Generatorvorrichtung ausgestatteten Bremssystems |

| JP2012171428A (ja) * | 2011-02-18 | 2012-09-10 | Ntn Corp | インホイールモータ駆動装置 |

| CN102092256B (zh) * | 2011-03-07 | 2012-09-19 | 同济大学 | 减小单纵臂悬架轮边电驱动系统等效簧下质量结构及方法 |

| JP5784930B2 (ja) * | 2011-03-07 | 2015-09-24 | Ntn株式会社 | 電気自動車 |

| CN102092255B (zh) * | 2011-03-07 | 2012-08-22 | 同济大学 | 减小单斜臂悬架轮边电驱动系统等效簧下质量结构及方法 |

| US8449424B2 (en) * | 2011-03-17 | 2013-05-28 | Fairfield Manufacturing Company Inc. | Integral electric motor with speed sensor, planetary gearbox and steering means |

| CN102211614B (zh) * | 2011-05-09 | 2012-09-26 | 北京科技大学 | 一种交流电传动铰接式自卸车 |

| DE102011078807B4 (de) * | 2011-07-07 | 2014-05-28 | Schaeffler Technologies Gmbh & Co. Kg | Lagerverkippungsdetektierungssystem |

| DE102011078809A1 (de) | 2011-07-07 | 2013-01-10 | Schaeffler Technologies AG & Co. KG | Erkennung einer Überbeanspruchung eines Radnabenantriebs |

| EP2740625B1 (en) * | 2011-08-02 | 2018-04-04 | NSK Ltd. | Hub bearing, speed reduction mechanism, and in-wheel motor |

| EP2758259A1 (de) * | 2011-09-22 | 2014-07-30 | Schaeffler Technologies GmbH & Co. KG | Radaufhängungseinrichtung mit darin lenkbar angebundenem radlagerträger und integriertem radantriebsmotor |

| KR101294124B1 (ko) * | 2011-10-21 | 2013-08-08 | 주식회사 만도 | 인휠 모터 시스템 |

| JP5809927B2 (ja) * | 2011-10-28 | 2015-11-11 | Ntn株式会社 | インホイールモータ駆動装置 |

| WO2013077409A1 (ja) | 2011-11-24 | 2013-05-30 | Ntn株式会社 | 電動車両制御装置 |

| KR101332349B1 (ko) | 2011-12-07 | 2013-11-22 | 주식회사 센트랄 | 차량용 인휠구동 시스템 |

| DE102012204795A1 (de) * | 2012-03-26 | 2013-09-26 | Schaeffler Technologies AG & Co. KG | Radnabenmotor mit Potenzialausgleich |

| CN104470746B (zh) * | 2012-05-10 | 2017-04-19 | 戈尔德霍弗股份公司 | 用于机动车的驱动装置 |

| CN102774269B (zh) * | 2012-07-14 | 2015-09-30 | 盐城工学院 | 一种可实现大角度转向的不等长双横臂悬架轮边驱动装置 |

| WO2014143890A1 (en) | 2013-03-15 | 2014-09-18 | Mobius Imaging, Llc | Caster system for mobile apparatus |

| EP3711671B1 (en) | 2013-03-15 | 2025-04-23 | Mobius Imaging, Llc | Imaging system |

| JP5975051B2 (ja) * | 2014-02-26 | 2016-08-23 | トヨタ自動車株式会社 | 車両制御装置及び車両制御方法 |

| JP2014159275A (ja) * | 2014-03-26 | 2014-09-04 | Ntn Corp | インホイールモータ駆動装置 |

| JP6300635B2 (ja) * | 2014-05-21 | 2018-03-28 | Ntn株式会社 | 電動ブレーキ装置 |

| EP3196085B1 (en) * | 2015-11-13 | 2018-12-12 | Igarashi Electric Works Ltd. | Electric parking brake device |

| EP3246185B1 (en) * | 2016-05-19 | 2020-09-16 | Chang Hui Lin | Direct drive system for electric car |

| JP6799946B2 (ja) * | 2016-05-26 | 2020-12-16 | Ntn株式会社 | 電動式直動アクチュエータ |

| DE102016006536B4 (de) * | 2016-05-27 | 2018-03-15 | Audi Ag | Elektrische Antriebseinheit für ein Rad eines Kraftfahrzeugs sowie Radaufhängung für die Räder einer Achse eines Kraftfahrzeugs |

| RU2633129C1 (ru) * | 2016-08-24 | 2017-10-11 | Общество с ограниченной ответственностью "Полимагнит Санкт-Петербург" | Мотор-колесо транспортного средства и транспортное средство с таким мотор-колесом |

| DE102017207074A1 (de) * | 2017-04-27 | 2018-10-31 | Robert Bosch Gmbh | Elektromotorisch angetriebene Radvorrichtung |

| JP7140608B2 (ja) * | 2017-10-17 | 2022-09-21 | Ntn株式会社 | 車両用動力装置および発電機付き車輪用軸受装置 |

| NO20171853A1 (en) * | 2017-11-21 | 2019-05-22 | Fm Equipment As | Assembly and method for a vehicle |

| DE102018202659B4 (de) * | 2018-02-22 | 2025-02-13 | Zf Friedrichshafen Ag | Dämpfungsanordnung für Leistungselektronikanwendungen |

| JP6907993B2 (ja) * | 2018-04-19 | 2021-07-21 | トヨタ自動車株式会社 | 回転体の作用力検出装置 |

| WO2019241765A1 (en) | 2018-06-15 | 2019-12-19 | Indigo Technologies, Inc. | A sealed axial flux motor with integrated cooling |

| EP3587202B1 (en) * | 2018-06-29 | 2023-04-05 | Volvo Car Corporation | System and method for determinig water content in brake fluid |

| DE102018218925B4 (de) * | 2018-11-06 | 2024-10-02 | Audi Ag | Anordnung einer Radnabe an einem Radträger für ein Fahrzeug, Radnabenantrieb für ein Fahrzeug sowie Fahrzeug |

| CN109552058B (zh) * | 2018-12-21 | 2021-04-16 | 北京工业大学 | 一种电动汽车用集成缓速制热的一体式电机系统 |

| DE102019116603A1 (de) * | 2019-02-26 | 2020-08-27 | Paxos Consulting & Engineering GmbH & Co. KG | Elektrischer Radnabenmotor |

| IT201900017300A1 (it) * | 2019-09-26 | 2021-03-26 | Amer Spa | Struttura di motoruota perfezionata |

| DE102020109606A1 (de) | 2020-04-07 | 2021-10-07 | Schaeffler Technologies AG & Co. KG | Sensoranordnung zur Erfassung von Drehmoment und Drehzahl/Drehwinkel |

| CN111638070B (zh) * | 2020-05-11 | 2022-04-15 | 天津职业技术师范大学(中国职业培训指导教师进修中心) | 一种轮毂电机减振性能测试系统及其测试方法 |

| JP2023137919A (ja) * | 2022-03-18 | 2023-09-29 | ロベルト・ボッシュ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツング | 液圧制御ユニット |

Family Cites Families (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5127485A (en) * | 1988-06-29 | 1992-07-07 | Aisin Aw Co., Ltd. | Electric motorized wheel with integral motorized cooling oil pump |

| JP2769323B2 (ja) * | 1988-06-29 | 1998-06-25 | アイシン・エィ・ダブリュ株式会社 | 減速機付モータ駆動装置及び電動車両 |

| JPH0395261A (ja) * | 1989-09-07 | 1991-04-19 | Toray Ind Inc | 樹脂組成物 |

| US5087229A (en) * | 1991-05-06 | 1992-02-11 | General Motors Corporation | Independently suspended steerable motor wheel apparatus |

| JPH05332401A (ja) * | 1992-05-27 | 1993-12-14 | Toyota Motor Corp | 電気自動車用減速装置 |

| US5691584A (en) * | 1993-09-09 | 1997-11-25 | Honda Giken Kogyo Kabushiki Kaisha | Wheel motor for vehicles |

| JP3369673B2 (ja) * | 1993-09-28 | 2003-01-20 | 本田技研工業株式会社 | ホイールモータ |

| SE516990C2 (sv) * | 1998-12-29 | 2002-04-02 | Volvo Car Corp | Arrangemang för hjulupphängning i fordon |

| NL1014182C2 (nl) * | 2000-01-26 | 2001-07-27 | Special Products For Industry | Wiel voorzien van aandrijfmiddelen. |

| US7530415B2 (en) * | 2000-01-26 | 2009-05-12 | E-Traction Europe B.V. | Wheel provided with driving means |

| US7014000B2 (en) * | 2000-05-11 | 2006-03-21 | Hill-Rom Services, Inc. | Braking apparatus for a patient support |

| US6494278B1 (en) * | 2000-10-02 | 2002-12-17 | Ervin Weisz | Electric wheelchair drive system |

| JP3699371B2 (ja) | 2001-07-17 | 2005-09-28 | Ntn株式会社 | インホイールモータ型駆動ユニットおよびハイブリッドシステム |

| US6768932B2 (en) * | 2001-12-07 | 2004-07-27 | General Motors Corporation | Wheel motor system |

| US7597169B2 (en) * | 2001-12-07 | 2009-10-06 | Gm Global Technology Operations, Inc. | Wheel module |

| WO2003057529A2 (en) * | 2002-01-08 | 2003-07-17 | Hypercar, Inc. | Advanced composite hybrid-electric vehicle |

| US7423393B2 (en) | 2002-05-07 | 2008-09-09 | Kabushiki Kaisha Bridgestone | Car control method and car control apparatus |

| DE10304916A1 (de) * | 2003-02-07 | 2004-08-26 | O&K Orenstein & Koppel Ag | Verfahren und Vorrichtung zur Radsturzverstellung |

| JP4221580B2 (ja) * | 2003-06-16 | 2009-02-12 | 三菱自動車工業株式会社 | 車両駆動用減速機付きインホイールモータ |

| KR100552732B1 (ko) * | 2003-07-10 | 2006-02-20 | 현대자동차주식회사 | 차량의 롤오버 방지장치 |

| JP2005048823A (ja) | 2003-07-31 | 2005-02-24 | Koyo Seiko Co Ltd | センサ付きハブユニット |

| JP2005069897A (ja) * | 2003-08-25 | 2005-03-17 | Bridgestone Corp | 入力検出装置、及び、試験車両 |

| EP1666860B1 (en) | 2003-08-29 | 2011-12-28 | Jtekt Corporation | Hub unit with sensor |

| JP2005099003A (ja) * | 2003-08-29 | 2005-04-14 | Koyo Seiko Co Ltd | センサ付きハブユニット |

| CN2650092Y (zh) * | 2003-11-13 | 2004-10-20 | 东南大学 | 汽车车轮多维力测量传感器 |

| JP4478037B2 (ja) * | 2004-01-30 | 2010-06-09 | 日立オートモティブシステムズ株式会社 | 車両制御装置 |

| JP4312078B2 (ja) * | 2004-02-25 | 2009-08-12 | トヨタ自動車株式会社 | 電動輪 |

| JP4276579B2 (ja) * | 2004-05-17 | 2009-06-10 | トヨタ自動車株式会社 | インホイールモータに設けられる部品の搭載構造 |

| JP2005354844A (ja) * | 2004-06-11 | 2005-12-22 | Toyota Motor Corp | 車両制御装置 |

| US7938210B2 (en) * | 2004-06-15 | 2011-05-10 | Massachusetts Institute Of Technology | Wheel-embedded suspension |

| EP2177413B1 (en) | 2004-07-15 | 2015-02-25 | Hitachi, Ltd. | Vehicle control system |

| JP2006090958A (ja) * | 2004-09-27 | 2006-04-06 | Jtekt Corp | センサ装置およびセンサ付き転がり軸受ユニット |

| JP2006101572A (ja) * | 2004-09-28 | 2006-04-13 | Nissan Motor Co Ltd | 燃料電池システム |

| US7591335B2 (en) * | 2006-07-13 | 2009-09-22 | Mattel, Inc. | Children's ride-on vehicles having ground detection systems |

-

2006

- 2006-09-19 JP JP2006252531A patent/JP5052084B2/ja not_active Expired - Fee Related

-

2007

- 2007-08-29 DE DE112007002204T patent/DE112007002204T5/de not_active Withdrawn

- 2007-08-29 US US12/311,109 patent/US8307931B2/en not_active Expired - Fee Related

- 2007-08-29 CN CN2007800344214A patent/CN101516663B/zh not_active Expired - Fee Related

- 2007-08-29 WO PCT/JP2007/000930 patent/WO2008035455A1/ja not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008074135A (ja) | 2008-04-03 |

| WO2008035455A1 (en) | 2008-03-27 |

| CN101516663A (zh) | 2009-08-26 |

| CN101516663B (zh) | 2012-11-14 |

| US20090236157A1 (en) | 2009-09-24 |

| US8307931B2 (en) | 2012-11-13 |

| DE112007002204T5 (de) | 2009-08-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5052084B2 (ja) | インホイール型モータ内蔵センサ付きアクスルユニット | |

| JP5436191B2 (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP5517869B2 (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP5110854B2 (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP2007292158A (ja) | センサ付車輪用軸受 | |

| WO2007066482A1 (ja) | センサ付車輪用軸受 | |

| JP5615033B2 (ja) | インホイールモータ駆動装置 | |

| WO2007023785A1 (ja) | センサ付車輪用軸受 | |

| JP4925624B2 (ja) | センサ付車輪用軸受 | |

| JP2007071280A (ja) | センサ付車輪用軸受 | |

| JP2008081090A (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP4931525B2 (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP4931537B2 (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP2008074136A (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP2007057258A (ja) | センサ付車輪用軸受 | |

| JP2007057259A (ja) | センサ付車輪用軸受 | |

| JP5334370B2 (ja) | センサ付車輪用軸受 | |

| JP2008081089A (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP2007057257A (ja) | センサ付車輪用軸受 | |

| JP2010032229A (ja) | センサ付車輪用軸受 | |

| JP2008075789A (ja) | インホイール型モータ内蔵センサ付き車輪用軸受装置 | |

| JP2008249566A (ja) | センサ付車輪用軸受 | |

| JP2009024816A (ja) | センサ付車輪用軸受 | |

| JP2007292231A (ja) | センサ付車輪用軸受 | |

| JP2007292233A (ja) | センサ付車輪用軸受 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090828 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111227 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120227 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120724 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120724 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5052084 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150803 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |