JP4783561B2 - 銅配線の形成方法 - Google Patents

銅配線の形成方法 Download PDFInfo

- Publication number

- JP4783561B2 JP4783561B2 JP2004279365A JP2004279365A JP4783561B2 JP 4783561 B2 JP4783561 B2 JP 4783561B2 JP 2004279365 A JP2004279365 A JP 2004279365A JP 2004279365 A JP2004279365 A JP 2004279365A JP 4783561 B2 JP4783561 B2 JP 4783561B2

- Authority

- JP

- Japan

- Prior art keywords

- copper

- forming

- gas

- containing film

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3205—Deposition of non-insulating-, e.g. conductive- or resistive-, layers on insulating layers; After-treatment of these layers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/283—Deposition of conductive or insulating materials for electrodes conducting electric current

- H01L21/285—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation

- H01L21/28506—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers

- H01L21/28512—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers on semiconductor bodies comprising elements of Group IV of the Periodic Table

- H01L21/28556—Deposition of conductive or insulating materials for electrodes conducting electric current from a gas or vapour, e.g. condensation of conductive layers on semiconductor bodies comprising elements of Group IV of the Periodic Table by chemical means, e.g. CVD, LPCVD, PECVD, laser CVD

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C49/00—Ketones; Ketenes; Dimeric ketenes; Ketonic chelates

- C07C49/92—Ketonic chelates

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/02—Pretreatment of the material to be coated

- C23C16/0272—Deposition of sub-layers, e.g. to promote the adhesion of the main coating

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/04—Coating on selected surface areas, e.g. using masks

- C23C16/045—Coating cavities or hollow spaces, e.g. interior of tubes; Infiltration of porous substrates

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/06—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of metallic material

- C23C16/18—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of metallic material from metallo-organic compounds

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/34—Nitrides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76841—Barrier, adhesion or liner layers

- H01L21/76843—Barrier, adhesion or liner layers formed in openings in a dielectric

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76877—Filling of holes, grooves or trenches, e.g. vias, with conductive material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/52—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames

- H01L23/522—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames including external interconnections consisting of a multilayer structure of conductive and insulating layers inseparably formed on the semiconductor body

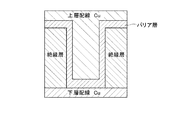

- H01L23/5226—Via connections in a multilevel interconnection structure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/52—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames

- H01L23/522—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames including external interconnections consisting of a multilayer structure of conductive and insulating layers inseparably formed on the semiconductor body

- H01L23/532—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames including external interconnections consisting of a multilayer structure of conductive and insulating layers inseparably formed on the semiconductor body characterised by the materials

- H01L23/53204—Conductive materials

- H01L23/53209—Conductive materials based on metals, e.g. alloys, metal silicides

- H01L23/53228—Conductive materials based on metals, e.g. alloys, metal silicides the principal metal being copper

- H01L23/53238—Additional layers associated with copper layers, e.g. adhesion, barrier, cladding layers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/0001—Technical content checked by a classifier

- H01L2924/0002—Not covered by any one of groups H01L24/00, H01L24/00 and H01L2224/00

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Physics & Mathematics (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Metallurgy (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Chemistry (AREA)

- Chemical Vapour Deposition (AREA)

- Electrodes Of Semiconductors (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

Priority Applications (8)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004279365A JP4783561B2 (ja) | 2004-09-27 | 2004-09-27 | 銅配線の形成方法 |

| CNB2005800325695A CN100479114C (zh) | 2004-09-27 | 2005-09-12 | 铜配线的形成方法 |

| US11/663,807 US8034403B2 (en) | 2004-09-27 | 2005-09-12 | Method for forming copper distributing wires |

| PCT/JP2005/016712 WO2006035591A1 (ja) | 2004-09-27 | 2005-09-12 | 銅配線の形成方法 |

| DE112005002353T DE112005002353B8 (de) | 2004-09-27 | 2005-09-12 | Verfahren zur Herstellung von Sammelleitungen aus Kupfer |

| KR1020077006967A KR100934887B1 (ko) | 2004-09-27 | 2005-09-12 | 구리 배선의 형성 방법 |

| KR1020087025866A KR100934888B1 (ko) | 2004-09-27 | 2005-09-12 | 구리 배선의 형성 방법 |

| TW094132164A TW200620433A (en) | 2004-09-27 | 2005-09-16 | Method of forming copper wire |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004279365A JP4783561B2 (ja) | 2004-09-27 | 2004-09-27 | 銅配線の形成方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006093552A JP2006093552A (ja) | 2006-04-06 |

| JP2006093552A5 JP2006093552A5 (enExample) | 2007-09-06 |

| JP4783561B2 true JP4783561B2 (ja) | 2011-09-28 |

Family

ID=36118743

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004279365A Expired - Fee Related JP4783561B2 (ja) | 2004-09-27 | 2004-09-27 | 銅配線の形成方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8034403B2 (enExample) |

| JP (1) | JP4783561B2 (enExample) |

| KR (2) | KR100934888B1 (enExample) |

| CN (1) | CN100479114C (enExample) |

| DE (1) | DE112005002353B8 (enExample) |

| TW (1) | TW200620433A (enExample) |

| WO (1) | WO2006035591A1 (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5323425B2 (ja) * | 2007-09-03 | 2013-10-23 | 株式会社アルバック | 半導体装置の製造方法 |

| KR100914982B1 (ko) * | 2008-01-02 | 2009-09-02 | 주식회사 하이닉스반도체 | 반도체 소자의 금속배선 및 그 형성방법 |

| KR100924557B1 (ko) * | 2008-01-04 | 2009-11-02 | 주식회사 하이닉스반도체 | 반도체 소자의 금속배선 및 그 형성방법 |

| JP5353109B2 (ja) | 2008-08-15 | 2013-11-27 | 富士通セミコンダクター株式会社 | 半導体装置の製造方法 |

| KR100973277B1 (ko) * | 2008-08-29 | 2010-07-30 | 주식회사 하이닉스반도체 | 반도체 소자의 금속배선 및 그 형성방법 |

| CN103135819A (zh) * | 2011-11-29 | 2013-06-05 | 迎辉科技股份有限公司 | 具有抗氧化金属层的导电基板 |

| JP6324800B2 (ja) * | 2014-05-07 | 2018-05-16 | 東京エレクトロン株式会社 | 成膜方法および成膜装置 |

| CN105986245A (zh) * | 2015-02-16 | 2016-10-05 | 中微半导体设备(上海)有限公司 | 改善mocvd反应工艺的部件及改善方法 |

| JP6872453B2 (ja) * | 2016-07-27 | 2021-05-19 | Dowaサーモテック株式会社 | 窒化バナジウム膜、窒化バナジウム膜の被覆部材およびその製造方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08222568A (ja) * | 1995-02-10 | 1996-08-30 | Ulvac Japan Ltd | 銅配線製造方法、半導体装置、及び銅配線製造装置 |

| JPH11217673A (ja) * | 1997-11-28 | 1999-08-10 | Japan Pionics Co Ltd | 窒化膜の製造方法 |

| JP2943805B1 (ja) * | 1998-09-17 | 1999-08-30 | 日本電気株式会社 | 半導体装置及びその製造方法 |

| WO2000029637A1 (en) * | 1998-11-12 | 2000-05-25 | President And Fellows Of Harvard College | Diffusion barrier materials with improved step coverage |

| KR100460746B1 (ko) * | 1999-04-13 | 2004-12-09 | 주식회사 하이닉스반도체 | 반도체 소자의 구리 금속 배선 형성 방법 |

| JP5031953B2 (ja) * | 2001-06-28 | 2012-09-26 | 株式会社アルバック | 銅材料充填プラグ及び銅材料充填プラグの製造方法 |

| US6916398B2 (en) * | 2001-10-26 | 2005-07-12 | Applied Materials, Inc. | Gas delivery apparatus and method for atomic layer deposition |

| JP4711624B2 (ja) * | 2001-10-26 | 2011-06-29 | アプライド マテリアルズ インコーポレイテッド | 銅電極形成アプリケーションのためのald窒化タンタル及びアルファ相タンタルの集積 |

| JP4120925B2 (ja) * | 2002-01-31 | 2008-07-16 | 宇部興産株式会社 | 銅錯体およびこれを用いた銅含有薄膜の製造方法 |

| JP2003252823A (ja) * | 2002-02-28 | 2003-09-10 | Mitsubishi Materials Corp | 有機金属化学蒸着法用有機銅化合物及びそれを用いて作製した銅薄膜 |

| US7291558B2 (en) * | 2004-11-08 | 2007-11-06 | Tel Epion Inc. | Copper interconnect wiring and method of forming thereof |

| WO2009117670A2 (en) * | 2008-03-21 | 2009-09-24 | President And Fellows Of Harvard College | Self-aligned barrier layers for interconnects |

-

2004

- 2004-09-27 JP JP2004279365A patent/JP4783561B2/ja not_active Expired - Fee Related

-

2005

- 2005-09-12 DE DE112005002353T patent/DE112005002353B8/de not_active Expired - Lifetime

- 2005-09-12 US US11/663,807 patent/US8034403B2/en active Active

- 2005-09-12 WO PCT/JP2005/016712 patent/WO2006035591A1/ja not_active Ceased

- 2005-09-12 CN CNB2005800325695A patent/CN100479114C/zh not_active Expired - Fee Related

- 2005-09-12 KR KR1020087025866A patent/KR100934888B1/ko not_active Expired - Fee Related

- 2005-09-12 KR KR1020077006967A patent/KR100934887B1/ko not_active Expired - Fee Related

- 2005-09-16 TW TW094132164A patent/TW200620433A/zh unknown

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006093552A (ja) | 2006-04-06 |

| KR20080100394A (ko) | 2008-11-17 |

| KR20070056126A (ko) | 2007-05-31 |

| CN100479114C (zh) | 2009-04-15 |

| WO2006035591A1 (ja) | 2006-04-06 |

| KR100934888B1 (ko) | 2010-01-06 |

| TW200620433A (en) | 2006-06-16 |

| CN101032007A (zh) | 2007-09-05 |

| KR100934887B1 (ko) | 2010-01-06 |

| US20100291290A1 (en) | 2010-11-18 |

| US8034403B2 (en) | 2011-10-11 |

| TWI371787B (enExample) | 2012-09-01 |

| DE112005002353B4 (de) | 2012-06-14 |

| DE112005002353B8 (de) | 2012-12-20 |

| DE112005002353T5 (de) | 2007-09-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6534133B1 (en) | Methodology for in-situ doping of aluminum coatings | |

| US6464779B1 (en) | Copper atomic layer chemical vapor desposition | |

| CN104221132B (zh) | 沉积锰和氮化锰的方法 | |

| EP1115900B1 (en) | Methods for preparing ruthenium metal films | |

| JP4674061B2 (ja) | 薄膜形成方法 | |

| US20120301706A1 (en) | METHOD OF PE-ALD OF SiNxCy AND INTEGRATION OF LINER MATERIALS ON POROUS LOW K SUBSTRATES | |

| JP2002526651A (ja) | 銅をベースとするフィルムの化学蒸着方法及びその銅源前駆体 | |

| US8283485B2 (en) | Process for selectively depositing copper thin films on substrates with copper and ruthenium areas via vapor deposition | |

| JP4783561B2 (ja) | 銅配線の形成方法 | |

| US20070264816A1 (en) | Copper alloy layer for integrated circuit interconnects | |

| KR20240141817A (ko) | 고 전도성 금속 필름을 선택적으로 침착시키는 방법 | |

| JPH10135154A (ja) | 薄膜気相成長方法 | |

| JP4959122B2 (ja) | バナジウム含有膜の形成方法 | |

| JP4654194B2 (ja) | 銅含有膜形成方法 | |

| JP2011171559A (ja) | マンガン含有低誘電率膜及びその製造方法、半導体装置の製造方法並びに成膜装置 | |

| JP2006093551A (ja) | チタン含有膜の形成方法 | |

| JP2009044056A (ja) | 銅膜作製方法 | |

| TW200818272A (en) | Film forming method and film forming apparatus | |

| WO1997047783A1 (en) | Methodology and apparatus for in-situ doping of aluminum coatings | |

| EP2014790A1 (en) | Process for forming continuous copper thin films via vapor deposition | |

| JP2013048268A (ja) | 銅膜作製方法 | |

| US20080182021A1 (en) | Continuous ultra-thin copper film formed using a low thermal budget | |

| JP3029679B2 (ja) | 金属膜形成法および気相化学反応装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070720 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070720 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110412 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110606 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110628 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110711 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140715 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4783561 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |