JP4042095B2 - 高純度金属粉の製造方法および高純度金属粉の製造装置 - Google Patents

高純度金属粉の製造方法および高純度金属粉の製造装置 Download PDFInfo

- Publication number

- JP4042095B2 JP4042095B2 JP2002063447A JP2002063447A JP4042095B2 JP 4042095 B2 JP4042095 B2 JP 4042095B2 JP 2002063447 A JP2002063447 A JP 2002063447A JP 2002063447 A JP2002063447 A JP 2002063447A JP 4042095 B2 JP4042095 B2 JP 4042095B2

- Authority

- JP

- Japan

- Prior art keywords

- gas

- metal powder

- refining

- plasma flame

- hydrogen

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000843 powder Substances 0.000 title claims description 65

- 229910052751 metal Inorganic materials 0.000 title claims description 53

- 239000002184 metal Substances 0.000 title claims description 53

- 238000004519 manufacturing process Methods 0.000 title claims description 28

- 239000007789 gas Substances 0.000 claims description 146

- 238000007670 refining Methods 0.000 claims description 81

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims description 66

- 239000001257 hydrogen Substances 0.000 claims description 62

- 229910052739 hydrogen Inorganic materials 0.000 claims description 62

- 239000002994 raw material Substances 0.000 claims description 58

- 238000011144 upstream manufacturing Methods 0.000 claims description 11

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 10

- 239000001301 oxygen Substances 0.000 claims description 10

- 229910052760 oxygen Inorganic materials 0.000 claims description 10

- 239000003870 refractory metal Substances 0.000 claims description 5

- 238000001816 cooling Methods 0.000 claims description 3

- 238000003723 Smelting Methods 0.000 claims 1

- 230000000694 effects Effects 0.000 description 24

- 239000012535 impurity Substances 0.000 description 11

- 238000000034 method Methods 0.000 description 10

- 238000011084 recovery Methods 0.000 description 7

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 description 5

- 239000012159 carrier gas Substances 0.000 description 5

- 229910052707 ruthenium Inorganic materials 0.000 description 5

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- 238000001704 evaporation Methods 0.000 description 3

- 230000008020 evaporation Effects 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 238000000746 purification Methods 0.000 description 3

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 2

- 238000004458 analytical method Methods 0.000 description 2

- 229910052786 argon Inorganic materials 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 238000001036 glow-discharge mass spectrometry Methods 0.000 description 2

- 239000011261 inert gas Substances 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 238000005477 sputtering target Methods 0.000 description 2

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 238000000498 ball milling Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000015271 coagulation Effects 0.000 description 1

- 238000005345 coagulation Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 230000015654 memory Effects 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 238000012827 research and development Methods 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

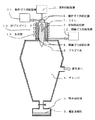

Images

Landscapes

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002063447A JP4042095B2 (ja) | 2002-03-08 | 2002-03-08 | 高純度金属粉の製造方法および高純度金属粉の製造装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002063447A JP4042095B2 (ja) | 2002-03-08 | 2002-03-08 | 高純度金属粉の製造方法および高純度金属粉の製造装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2003268422A JP2003268422A (ja) | 2003-09-25 |

| JP2003268422A5 JP2003268422A5 (enExample) | 2005-08-25 |

| JP4042095B2 true JP4042095B2 (ja) | 2008-02-06 |

Family

ID=29196709

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002063447A Expired - Fee Related JP4042095B2 (ja) | 2002-03-08 | 2002-03-08 | 高純度金属粉の製造方法および高純度金属粉の製造装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4042095B2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190067658A (ko) * | 2017-12-07 | 2019-06-17 | 한국생산기술연구원 | 고순도 구형 분말의 제조방법 |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100584570B1 (ko) | 2006-02-28 | 2006-05-30 | 한국기계연구원 | 플라즈마 반응장치 |

| EP1942202A3 (en) * | 2007-01-08 | 2010-09-29 | Heraeus, Inc. | High density, low oxygen Re and Re-based consolidated powder materials for use as deposition sources & methods of making the same |

| WO2009119196A1 (ja) * | 2008-03-28 | 2009-10-01 | 日鉱金属株式会社 | 磁性材ターゲット用白金粉末、同粉末の製造方法、白金焼結体からなる磁性材ターゲットの製造方法及び同焼結磁性材ターゲット |

| CN103736435B (zh) * | 2013-12-27 | 2015-11-18 | 中国神华能源股份有限公司 | 一种利用交流等离子体球化粉体的设备及系统 |

| KR102273282B1 (ko) * | 2020-01-30 | 2021-07-06 | 주식회사 나노코리아 | 금속 분말의 제조방법 |

| KR102467741B1 (ko) * | 2021-08-05 | 2022-11-16 | 한국핵융합에너지연구원 | 플라즈마를 이용한 아토마이징 시스템 및 아토마이징 방법 |

| KR102491080B1 (ko) * | 2021-08-05 | 2023-01-19 | 한국핵융합에너지연구원 | 플라즈마를 이용한 분말 구형화 장치 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5749937A (en) * | 1995-03-14 | 1998-05-12 | Lockheed Idaho Technologies Company | Fast quench reactor and method |

| JP2001020065A (ja) * | 1999-07-07 | 2001-01-23 | Hitachi Metals Ltd | スパッタリング用ターゲット及びその製造方法ならびに高融点金属粉末材料 |

-

2002

- 2002-03-08 JP JP2002063447A patent/JP4042095B2/ja not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190067658A (ko) * | 2017-12-07 | 2019-06-17 | 한국생산기술연구원 | 고순도 구형 분말의 제조방법 |

| KR102020314B1 (ko) * | 2017-12-07 | 2019-09-11 | 한국생산기술연구원 | 고순도 구형 분말의 제조방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003268422A (ja) | 2003-09-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5746207B2 (ja) | 熱プラズマを用いた高純度銅粉の製造方法 | |

| US7572315B2 (en) | Process for the synthesis, separation and purification of powder materials | |

| JP5427452B2 (ja) | 金属チタンの製造方法 | |

| JP2014515792A (ja) | 球状チタンおよび球状チタン合金粉末を生成する低コスト処理法 | |

| JP2001020065A (ja) | スパッタリング用ターゲット及びその製造方法ならびに高融点金属粉末材料 | |

| WO2004029332A3 (en) | Purification of electrochemically deoxidised refractory metal particles by heat processing | |

| JP2004091843A (ja) | 高純度高融点金属粉末の製造方法 | |

| JP2009287106A (ja) | チタン球状粉末の製造方法およびチタン球状粉末 | |

| JP4042095B2 (ja) | 高純度金属粉の製造方法および高純度金属粉の製造装置 | |

| JP2010100508A (ja) | 高純度シリコンの製造方法 | |

| JP2004124257A (ja) | 金属銅微粒子及びその製造方法 | |

| JP4921806B2 (ja) | タングステン超微粉及びその製造方法 | |

| JP2005336617A5 (enExample) | ||

| JP2005336617A (ja) | スパッタリング用ターゲット及びその製造方法ならびに高融点金属粉末材料 | |

| JP2006249548A (ja) | 金属粉末の製造方法およびターゲット材の製造方法 | |

| JP2002180112A (ja) | 高融点金属粉末材料の製造方法 | |

| JPH0925522A (ja) | 高純度金属材料の製造方法 | |

| JP3129709B2 (ja) | 低酸素高純度チタン材の製造方法 | |

| JP2005154834A (ja) | ルテニウム超微粉末およびその製造方法 | |

| JP5811002B2 (ja) | 中空炭素電極を用いたSiOの製造方法及び装置 | |

| JP2784324B2 (ja) | チタンの製造方法 | |

| JP3253175B2 (ja) | 球状銀微粒子の製造方法 | |

| JP2015516512A (ja) | 乾式法を利用した酸化物分散強化型白金−金合金粉末の製造方法 | |

| JP2000038622A (ja) | 遷移金属の純化精製方法 | |

| JPH0472884B2 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050221 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050221 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061026 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20061117 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20071019 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20071101 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101122 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101122 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111122 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121122 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121122 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131122 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |