JP2022029308A - 配線基板及び配線基板の製造方法 - Google Patents

配線基板及び配線基板の製造方法 Download PDFInfo

- Publication number

- JP2022029308A JP2022029308A JP2020132588A JP2020132588A JP2022029308A JP 2022029308 A JP2022029308 A JP 2022029308A JP 2020132588 A JP2020132588 A JP 2020132588A JP 2020132588 A JP2020132588 A JP 2020132588A JP 2022029308 A JP2022029308 A JP 2022029308A

- Authority

- JP

- Japan

- Prior art keywords

- seed layer

- thin film

- oxide thin

- layer

- oxide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/0011—Working of insulating substrates or insulating layers

- H05K3/0017—Etching of the substrate by chemical or physical means

- H05K3/002—Etching of the substrate by chemical or physical means by liquid chemical etching

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/10—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern

- H05K3/108—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern by semi-additive methods; masks therefor

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/11—Printed elements for providing electric connections to or between printed circuits

- H05K1/115—Via connections; Lands around holes or via connections

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/02—Apparatus or processes for manufacturing printed circuits in which the conductive material is applied to the surface of the insulating support and is thereafter removed from such areas of the surface which are not intended for current conducting or shielding

- H05K3/06—Apparatus or processes for manufacturing printed circuits in which the conductive material is applied to the surface of the insulating support and is thereafter removed from such areas of the surface which are not intended for current conducting or shielding the conductive material being removed chemically or electrolytically, e.g. by photo-etch process

- H05K3/061—Etching masks

- H05K3/064—Photoresists

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/40—Forming printed elements for providing electric connections to or between printed circuits

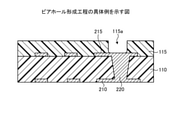

- H05K3/42—Plated through-holes or plated via connections

- H05K3/423—Plated through-holes or plated via connections characterised by electroplating method

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/46—Manufacturing multilayer circuits

- H05K3/4644—Manufacturing multilayer circuits by building the multilayer layer by layer, i.e. build-up multilayer circuits

- H05K3/4673—Application methods or materials of intermediate insulating layers not specially adapted to any one of the previous methods of adding a circuit layer

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/01—Dielectrics

- H05K2201/0137—Materials

- H05K2201/0154—Polyimide

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/01—Dielectrics

- H05K2201/0137—Materials

- H05K2201/0179—Thin film deposited insulating layer, e.g. inorganic layer for printed capacitor

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/38—Improvement of the adhesion between the insulating substrate and the metal

- H05K3/388—Improvement of the adhesion between the insulating substrate and the metal by the use of a metallic or inorganic thin film adhesion layer

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Manufacturing Of Printed Wiring (AREA)

- Production Of Multi-Layered Print Wiring Board (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020132588A JP2022029308A (ja) | 2020-08-04 | 2020-08-04 | 配線基板及び配線基板の製造方法 |

| US17/381,746 US11659667B2 (en) | 2020-08-04 | 2021-07-21 | Wiring board and method of manufacturing wiring board |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020132588A JP2022029308A (ja) | 2020-08-04 | 2020-08-04 | 配線基板及び配線基板の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2022029308A true JP2022029308A (ja) | 2022-02-17 |

| JP2022029308A5 JP2022029308A5 (enExample) | 2023-03-17 |

Family

ID=80114449

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020132588A Pending JP2022029308A (ja) | 2020-08-04 | 2020-08-04 | 配線基板及び配線基板の製造方法 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US11659667B2 (enExample) |

| JP (1) | JP2022029308A (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025164807A1 (ja) * | 2024-02-02 | 2025-08-07 | 太陽ホールディングス株式会社 | セミアディティブ工法用積層体、プリント配線板、セミアディティブ工法用積層体の製造方法およびプリント配線板を製造する方法 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5921198B2 (ja) | 1978-06-23 | 1984-05-18 | 株式会社東芝 | 導体パタ−ンの形成方法 |

| US6740221B2 (en) * | 2001-03-15 | 2004-05-25 | Applied Materials Inc. | Method of forming copper interconnects |

| JP2002373957A (ja) * | 2001-06-14 | 2002-12-26 | Shinko Electric Ind Co Ltd | 半導体装置及びその製造方法 |

| JP4494873B2 (ja) | 2004-06-02 | 2010-06-30 | 株式会社アルバック | プリント配線板、プリント配線板の製造方法およびその製造装置 |

| JP4224434B2 (ja) * | 2004-06-30 | 2009-02-12 | パナソニック株式会社 | 半導体装置及びその製造方法 |

| US7956465B2 (en) * | 2006-05-08 | 2011-06-07 | Taiwan Semiconductor Manufacturing Company, Ltd. | Reducing resistivity in interconnect structures of integrated circuits |

| US9142501B2 (en) * | 2013-03-14 | 2015-09-22 | International Business Machines Corporation | Under ball metallurgy (UBM) for improved electromigration |

| KR20200056833A (ko) * | 2018-11-15 | 2020-05-25 | 삼성전기주식회사 | 인쇄회로기판 |

-

2020

- 2020-08-04 JP JP2020132588A patent/JP2022029308A/ja active Pending

-

2021

- 2021-07-21 US US17/381,746 patent/US11659667B2/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025164807A1 (ja) * | 2024-02-02 | 2025-08-07 | 太陽ホールディングス株式会社 | セミアディティブ工法用積層体、プリント配線板、セミアディティブ工法用積層体の製造方法およびプリント配線板を製造する方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20220046800A1 (en) | 2022-02-10 |

| US11659667B2 (en) | 2023-05-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20030040083A (ko) | 박막 커패시터를 일체로 형성한 다층 배선 기판의 제조 방법 | |

| US20150083469A1 (en) | Wiring board | |

| JPWO2011010638A1 (ja) | 誘電体薄膜素子及びその製造方法 | |

| JP4713602B2 (ja) | 基板モジュールおよびその製造方法ならびに電子機器 | |

| JP2008251751A (ja) | 電子部品およびその製造方法 | |

| JP3775129B2 (ja) | 半導体チップの接続方法 | |

| JP4649198B2 (ja) | 配線基板の製造方法 | |

| CN112219458B (zh) | 布线基板 | |

| JP4584700B2 (ja) | 配線基板の製造方法 | |

| JP6309243B2 (ja) | 半導体装置およびその製造方法 | |

| US11917751B2 (en) | Multilayer wiring board and method of producing the same | |

| JP2022029308A (ja) | 配線基板及び配線基板の製造方法 | |

| JP5781877B2 (ja) | 配線基板の製造方法 | |

| TWI477217B (zh) | 具有包覆銅層之印刷電路板的製造方法 | |

| JP2019117875A (ja) | 配線基板、および配線基板を有する半導体装置 | |

| JP7367804B2 (ja) | 配線構造体 | |

| JP6676370B2 (ja) | 配線基板及び配線基板の製造方法 | |

| CN118696386A (zh) | 薄膜电容器及其制造方法、以及具备薄膜电容器的电子电路基板 | |

| WO2023162406A1 (ja) | 薄膜キャパシタ及びこれを備える電子回路基板 | |

| JP2018120932A (ja) | 貫通電極基板及び貫通電極基板を備える実装基板並びに貫通電極基板の製造方法 | |

| JP5061895B2 (ja) | キャパシタ及びそれを内蔵した配線基板 | |

| US20240276653A1 (en) | Wiring board and wiring board manufacturing method | |

| TWI849704B (zh) | 配線基板 | |

| JP7125679B2 (ja) | キャパシタ及びその製造方法 | |

| US20240421059A1 (en) | Wiring substrate and manufacturing method of wiring substrate |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20230308 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20230308 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20231227 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240123 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20240709 |