JP2010514937A - プラズマ蒸着微孔性炭素材料 - Google Patents

プラズマ蒸着微孔性炭素材料 Download PDFInfo

- Publication number

- JP2010514937A JP2010514937A JP2009544163A JP2009544163A JP2010514937A JP 2010514937 A JP2010514937 A JP 2010514937A JP 2009544163 A JP2009544163 A JP 2009544163A JP 2009544163 A JP2009544163 A JP 2009544163A JP 2010514937 A JP2010514937 A JP 2010514937A

- Authority

- JP

- Japan

- Prior art keywords

- layer

- hydrocarbon

- microporous carbon

- plasma

- microporous

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000003575 carbonaceous material Substances 0.000 title claims abstract description 51

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical group [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 120

- 239000011148 porous material Substances 0.000 claims abstract description 43

- 238000004519 manufacturing process Methods 0.000 claims abstract description 6

- 229930195733 hydrocarbon Natural products 0.000 claims description 96

- 239000004215 Carbon black (E152) Substances 0.000 claims description 93

- 150000002430 hydrocarbons Chemical class 0.000 claims description 93

- 239000000758 substrate Substances 0.000 claims description 54

- 239000007789 gas Substances 0.000 claims description 44

- 229910052799 carbon Inorganic materials 0.000 claims description 43

- 239000000463 material Substances 0.000 claims description 38

- 238000000034 method Methods 0.000 claims description 30

- 238000000151 deposition Methods 0.000 claims description 29

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims description 17

- 239000001257 hydrogen Substances 0.000 claims description 17

- 229910052739 hydrogen Inorganic materials 0.000 claims description 17

- KAKZBPTYRLMSJV-UHFFFAOYSA-N vinyl-ethylene Natural products C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 claims description 13

- 238000000926 separation method Methods 0.000 claims description 12

- 239000001273 butane Substances 0.000 claims description 11

- 238000010438 heat treatment Methods 0.000 claims description 11

- IJDNQMDRQITEOD-UHFFFAOYSA-N n-butane Chemical compound CCCC IJDNQMDRQITEOD-UHFFFAOYSA-N 0.000 claims description 11

- OFBQJSOFQDEBGM-UHFFFAOYSA-N n-pentane Natural products CCCCC OFBQJSOFQDEBGM-UHFFFAOYSA-N 0.000 claims description 11

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 claims description 9

- 238000001914 filtration Methods 0.000 claims description 7

- -1 alkyne hydrocarbon Chemical class 0.000 claims description 4

- 229910021529 ammonia Inorganic materials 0.000 claims description 4

- 150000001335 aliphatic alkanes Chemical class 0.000 claims description 3

- 150000001336 alkenes Chemical class 0.000 claims description 3

- 241000700605 Viruses Species 0.000 claims description 2

- 230000008033 biological extinction Effects 0.000 claims description 2

- 239000010410 layer Substances 0.000 description 175

- 239000010408 film Substances 0.000 description 76

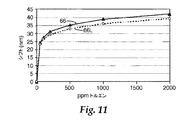

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 42

- 239000012491 analyte Substances 0.000 description 34

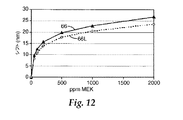

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 30

- 239000000523 sample Substances 0.000 description 29

- 238000006243 chemical reaction Methods 0.000 description 24

- 230000008021 deposition Effects 0.000 description 22

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 18

- 238000000137 annealing Methods 0.000 description 16

- 239000007788 liquid Substances 0.000 description 16

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 15

- 230000008859 change Effects 0.000 description 15

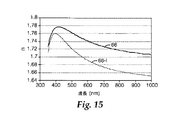

- 230000003287 optical effect Effects 0.000 description 15

- 239000000126 substance Substances 0.000 description 13

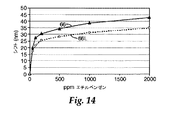

- YNQLUTRBYVCPMQ-UHFFFAOYSA-N Ethylbenzene Chemical compound CCC1=CC=CC=C1 YNQLUTRBYVCPMQ-UHFFFAOYSA-N 0.000 description 12

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 12

- 239000001301 oxygen Substances 0.000 description 12

- 229910052760 oxygen Inorganic materials 0.000 description 12

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 11

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 11

- 238000001514 detection method Methods 0.000 description 11

- 150000002500 ions Chemical class 0.000 description 11

- 229910052710 silicon Inorganic materials 0.000 description 11

- 239000010703 silicon Substances 0.000 description 11

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 10

- 229910052751 metal Inorganic materials 0.000 description 10

- 239000002184 metal Substances 0.000 description 10

- 239000002082 metal nanoparticle Substances 0.000 description 10

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 9

- 229910052786 argon Inorganic materials 0.000 description 9

- 230000005540 biological transmission Effects 0.000 description 9

- 239000002105 nanoparticle Substances 0.000 description 9

- 230000037452 priming Effects 0.000 description 9

- 229910052709 silver Inorganic materials 0.000 description 9

- 239000004332 silver Substances 0.000 description 9

- 239000012528 membrane Substances 0.000 description 8

- 150000002739 metals Chemical class 0.000 description 8

- 239000000203 mixture Substances 0.000 description 8

- 230000004044 response Effects 0.000 description 8

- 125000004429 atom Chemical group 0.000 description 7

- 238000012545 processing Methods 0.000 description 7

- 239000000243 solution Substances 0.000 description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- 238000000576 coating method Methods 0.000 description 6

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 6

- 229920000642 polymer Polymers 0.000 description 6

- 239000000725 suspension Substances 0.000 description 6

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 5

- 239000011248 coating agent Substances 0.000 description 5

- 229910003460 diamond Inorganic materials 0.000 description 5

- 239000010432 diamond Substances 0.000 description 5

- 238000009826 distribution Methods 0.000 description 5

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 5

- 229910052737 gold Inorganic materials 0.000 description 5

- 239000010931 gold Substances 0.000 description 5

- 229910052759 nickel Inorganic materials 0.000 description 5

- 229910052763 palladium Inorganic materials 0.000 description 5

- 230000035699 permeability Effects 0.000 description 5

- 239000007787 solid Substances 0.000 description 5

- 238000001179 sorption measurement Methods 0.000 description 5

- 230000003595 spectral effect Effects 0.000 description 5

- 239000010409 thin film Substances 0.000 description 5

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 239000000919 ceramic Substances 0.000 description 4

- 229910052804 chromium Inorganic materials 0.000 description 4

- 239000011651 chromium Substances 0.000 description 4

- 230000005684 electric field Effects 0.000 description 4

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 4

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 4

- 239000002243 precursor Substances 0.000 description 4

- 238000001228 spectrum Methods 0.000 description 4

- 238000007740 vapor deposition Methods 0.000 description 4

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 3

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- 238000003775 Density Functional Theory Methods 0.000 description 3

- 229910052581 Si3N4 Inorganic materials 0.000 description 3

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 3

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 3

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 description 3

- 238000002441 X-ray diffraction Methods 0.000 description 3

- 239000002253 acid Substances 0.000 description 3

- 238000004458 analytical method Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 230000001186 cumulative effect Effects 0.000 description 3

- 238000006356 dehydrogenation reaction Methods 0.000 description 3

- 229910010272 inorganic material Inorganic materials 0.000 description 3

- 239000011147 inorganic material Substances 0.000 description 3

- 238000012544 monitoring process Methods 0.000 description 3

- 229910017464 nitrogen compound Inorganic materials 0.000 description 3

- 150000002830 nitrogen compounds Chemical class 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 238000001020 plasma etching Methods 0.000 description 3

- 229910052697 platinum Inorganic materials 0.000 description 3

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- 241000894007 species Species 0.000 description 3

- 238000003786 synthesis reaction Methods 0.000 description 3

- 238000012360 testing method Methods 0.000 description 3

- 229910052719 titanium Inorganic materials 0.000 description 3

- 239000010936 titanium Substances 0.000 description 3

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 3

- 230000000007 visual effect Effects 0.000 description 3

- 235000013162 Cocos nucifera Nutrition 0.000 description 2

- 244000060011 Cocos nucifera Species 0.000 description 2

- 102100033255 Mitochondrial amidoxime-reducing component 1 Human genes 0.000 description 2

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 2

- WGLPBDUCMAPZCE-UHFFFAOYSA-N Trioxochromium Chemical compound O=[Cr](=O)=O WGLPBDUCMAPZCE-UHFFFAOYSA-N 0.000 description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 229910003481 amorphous carbon Inorganic materials 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 229910000423 chromium oxide Inorganic materials 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- PMHQVHHXPFUNSP-UHFFFAOYSA-M copper(1+);methylsulfanylmethane;bromide Chemical compound Br[Cu].CSC PMHQVHHXPFUNSP-UHFFFAOYSA-M 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000005137 deposition process Methods 0.000 description 2

- 238000010790 dilution Methods 0.000 description 2

- 239000012895 dilution Substances 0.000 description 2

- 230000002209 hydrophobic effect Effects 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 229910001092 metal group alloy Inorganic materials 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- 101150080343 mtarc1 gene Proteins 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 239000003973 paint Substances 0.000 description 2

- 229920006254 polymer film Polymers 0.000 description 2

- 150000003839 salts Chemical class 0.000 description 2

- 238000011896 sensitive detection Methods 0.000 description 2

- 230000035945 sensitivity Effects 0.000 description 2

- 238000004528 spin coating Methods 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 102000009027 Albumins Human genes 0.000 description 1

- 108010088751 Albumins Proteins 0.000 description 1

- XDTMQSROBMDMFD-UHFFFAOYSA-N Cyclohexane Chemical compound C1CCCCC1 XDTMQSROBMDMFD-UHFFFAOYSA-N 0.000 description 1

- OTMSDBZUPAUEDD-UHFFFAOYSA-N Ethane Chemical compound CC OTMSDBZUPAUEDD-UHFFFAOYSA-N 0.000 description 1

- WQZGKKKJIJFFOK-GASJEMHNSA-N Glucose Natural products OC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-GASJEMHNSA-N 0.000 description 1

- 102000057297 Pepsin A Human genes 0.000 description 1

- 108090000284 Pepsin A Proteins 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 229930003779 Vitamin B12 Natural products 0.000 description 1

- 229910021536 Zeolite Inorganic materials 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 229940050528 albumin Drugs 0.000 description 1

- 150000001345 alkine derivatives Chemical class 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000012300 argon atmosphere Substances 0.000 description 1

- SJKRCWUQJZIWQB-UHFFFAOYSA-N azane;chromium Chemical compound N.[Cr] SJKRCWUQJZIWQB-UHFFFAOYSA-N 0.000 description 1

- CXOWYMLTGOFURZ-UHFFFAOYSA-N azanylidynechromium Chemical class [Cr]#N CXOWYMLTGOFURZ-UHFFFAOYSA-N 0.000 description 1

- 239000002585 base Substances 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 125000004432 carbon atom Chemical group C* 0.000 description 1

- 238000003763 carbonization Methods 0.000 description 1

- 239000003610 charcoal Substances 0.000 description 1

- 239000002800 charge carrier Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- AGVAZMGAQJOSFJ-WZHZPDAFSA-M cobalt(2+);[(2r,3s,4r,5s)-5-(5,6-dimethylbenzimidazol-1-yl)-4-hydroxy-2-(hydroxymethyl)oxolan-3-yl] [(2r)-1-[3-[(1r,2r,3r,4z,7s,9z,12s,13s,14z,17s,18s,19r)-2,13,18-tris(2-amino-2-oxoethyl)-7,12,17-tris(3-amino-3-oxopropyl)-3,5,8,8,13,15,18,19-octamethyl-2 Chemical compound [Co+2].N#[C-].[N-]([C@@H]1[C@H](CC(N)=O)[C@@]2(C)CCC(=O)NC[C@@H](C)OP(O)(=O)O[C@H]3[C@H]([C@H](O[C@@H]3CO)N3C4=CC(C)=C(C)C=C4N=C3)O)\C2=C(C)/C([C@H](C\2(C)C)CCC(N)=O)=N/C/2=C\C([C@H]([C@@]/2(CC(N)=O)C)CCC(N)=O)=N\C\2=C(C)/C2=N[C@]1(C)[C@@](C)(CC(N)=O)[C@@H]2CCC(N)=O AGVAZMGAQJOSFJ-WZHZPDAFSA-M 0.000 description 1

- 238000009838 combustion analysis Methods 0.000 description 1

- 239000011258 core-shell material Substances 0.000 description 1

- 125000000753 cycloalkyl group Chemical group 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000007607 die coating method Methods 0.000 description 1

- 238000007865 diluting Methods 0.000 description 1

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 1

- 238000003618 dip coating Methods 0.000 description 1

- 238000002845 discoloration Methods 0.000 description 1

- 238000004980 dosimetry Methods 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 238000004070 electrodeposition Methods 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 230000005281 excited state Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000008103 glucose Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 238000007646 gravure printing Methods 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 238000005305 interferometry Methods 0.000 description 1

- 238000010849 ion bombardment Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 238000000608 laser ablation Methods 0.000 description 1

- 239000011344 liquid material Substances 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000004579 marble Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229910052752 metalloid Inorganic materials 0.000 description 1

- 150000002738 metalloids Chemical class 0.000 description 1

- 239000011859 microparticle Substances 0.000 description 1

- 239000012229 microporous material Substances 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 238000001728 nano-filtration Methods 0.000 description 1

- 239000003345 natural gas Substances 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 229920000620 organic polymer Polymers 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- 229940111202 pepsin Drugs 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920003223 poly(pyromellitimide-1,4-diphenyl ether) Polymers 0.000 description 1

- 239000013316 polymer of intrinsic microporosity Substances 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000001294 propane Substances 0.000 description 1

- 238000003908 quality control method Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000035484 reaction time Effects 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000002310 reflectometry Methods 0.000 description 1

- 238000001223 reverse osmosis Methods 0.000 description 1

- 238000010022 rotary screen printing Methods 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 238000007086 side reaction Methods 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- 238000010183 spectrum analysis Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 238000002198 surface plasmon resonance spectroscopy Methods 0.000 description 1

- 230000002459 sustained effect Effects 0.000 description 1

- 238000001308 synthesis method Methods 0.000 description 1

- 238000000427 thin-film deposition Methods 0.000 description 1

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 description 1

- 229910001887 tin oxide Inorganic materials 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- 238000000108 ultra-filtration Methods 0.000 description 1

- 238000011100 viral filtration Methods 0.000 description 1

- 239000011715 vitamin B12 Substances 0.000 description 1

- 235000019163 vitamin B12 Nutrition 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

- 238000001039 wet etching Methods 0.000 description 1

- 239000010457 zeolite Substances 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/56—After-treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D67/00—Processes specially adapted for manufacturing semi-permeable membranes for separation processes or apparatus

- B01D67/0039—Inorganic membrane manufacture

- B01D67/0053—Inorganic membrane manufacture by inducing porosity into non porous precursor membranes

- B01D67/0058—Inorganic membrane manufacture by inducing porosity into non porous precursor membranes by selective elimination of components, e.g. by leaching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D71/00—Semi-permeable membranes for separation processes or apparatus characterised by the material; Manufacturing processes specially adapted therefor

- B01D71/02—Inorganic material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D71/00—Semi-permeable membranes for separation processes or apparatus characterised by the material; Manufacturing processes specially adapted therefor

- B01D71/02—Inorganic material

- B01D71/021—Carbon

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/26—Deposition of carbon only

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/52—Controlling or regulating the coating process

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02518—Deposited layers

- H01L21/02521—Materials

- H01L21/02524—Group 14 semiconducting materials

- H01L21/02527—Carbon, e.g. diamond-like carbon

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02518—Deposited layers

- H01L21/02587—Structure

- H01L21/0259—Microstructure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02612—Formation types

- H01L21/02617—Deposition types

- H01L21/0262—Reduction or decomposition of gaseous compounds, e.g. CVD

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

- Y10T428/249953—Composite having voids in a component [e.g., porous, cellular, etc.]

- Y10T428/249978—Voids specified as micro

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/30—Self-sustaining carbon mass or layer with impregnant or other layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/60—Nonwoven fabric [i.e., nonwoven strand or fiber material]

- Y10T442/608—Including strand or fiber material which is of specific structural definition

- Y10T442/614—Strand or fiber material specified as having microdimensions [i.e., microfiber]

- Y10T442/624—Microfiber is carbon or carbonaceous

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Physics & Mathematics (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Metallurgy (AREA)

- Mechanical Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Nanotechnology (AREA)

- Carbon And Carbon Compounds (AREA)

- Chemical Vapour Deposition (AREA)

- Investigating, Analyzing Materials By Fluorescence Or Luminescence (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/618,010 US7901776B2 (en) | 2006-12-29 | 2006-12-29 | Plasma deposited microporous carbon material |

| PCT/US2007/087347 WO2008082897A1 (en) | 2006-12-29 | 2007-12-13 | Plasma deposited microporous carbon material |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010514937A true JP2010514937A (ja) | 2010-05-06 |

| JP2010514937A5 JP2010514937A5 (OSRAM) | 2011-01-20 |

Family

ID=39226855

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009544163A Ceased JP2010514937A (ja) | 2006-12-29 | 2007-12-13 | プラズマ蒸着微孔性炭素材料 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7901776B2 (OSRAM) |

| EP (1) | EP2111481A1 (OSRAM) |

| JP (1) | JP2010514937A (OSRAM) |

| KR (1) | KR20090101289A (OSRAM) |

| CN (1) | CN101573470B (OSRAM) |

| BR (1) | BRPI0720568A2 (OSRAM) |

| WO (1) | WO2008082897A1 (OSRAM) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101476487B1 (ko) | 2007-10-05 | 2014-12-24 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 플라즈마-증착된 미공성 층을 포함하는 유기 화학적 센서와, 제조 및 사용 방법 |

| US8110476B2 (en) | 2008-04-11 | 2012-02-07 | Sandisk 3D Llc | Memory cell that includes a carbon-based memory element and methods of forming the same |

| US8459200B2 (en) * | 2008-06-30 | 2013-06-11 | 3M Innovative Properties Company | Exposure indicating device |

| US8557685B2 (en) | 2008-08-07 | 2013-10-15 | Sandisk 3D Llc | Memory cell that includes a carbon-based memory element and methods of forming the same |

| CN102246278B (zh) * | 2008-12-10 | 2014-01-01 | 朗姆研究公司 | 用于促进硅电极抛光的盘和适配器组件 |

| EP2583090B1 (en) | 2010-06-15 | 2016-04-06 | 3M Innovative Properties Company | Variable capacitance sensors and methods of making the same |

| JP5810652B2 (ja) * | 2011-06-13 | 2015-11-11 | ソニー株式会社 | 液体塗布用繊維複合体 |

| GB2493698B (en) * | 2011-08-08 | 2018-02-28 | Univ Nottingham Trent | Surface plasmon resonance in thin films |

| DE102012213178A1 (de) * | 2012-04-30 | 2013-10-31 | At & S Austria Technologie & Systemtechnik Aktiengesellschaft | LED-Modul mit Leiterplatte |

| TWI565532B (zh) * | 2012-08-07 | 2017-01-11 | 國立交通大學 | 奈米球溶液塗佈方法與其應用 |

| CN102899966B (zh) * | 2012-10-22 | 2017-08-29 | 杭州春胜纸业有限公司 | 微米碳粉电磁屏蔽纸的制造方法 |

| KR101408136B1 (ko) * | 2012-10-26 | 2014-06-17 | 한국과학기술연구원 | 나노 다공성 물질의 제조방법 및 나노 다공성 물질 |

| JP5937033B2 (ja) | 2013-03-22 | 2016-06-22 | 株式会社東芝 | 半導体装置、半導体装置の製造方法、および半導体装置の製造装置 |

| EP3085434B1 (en) * | 2013-11-29 | 2019-09-18 | National Institute for Materials Science | Nanofiltration or reverse osmosis membrane made of hard carbon film, filtering filter, two-layer-bonded-type filtering filter, and methods for manufacturing same |

| US9735366B2 (en) * | 2014-09-30 | 2017-08-15 | Cnm Technologies Gmbh | Heterostructure comprising a carbon nanomembrane |

| JP6896629B2 (ja) * | 2014-12-19 | 2021-06-30 | タタ、スティール、ネダーランド、テクノロジー、ベスローテン、フェンノートシャップTata Steel Nederland Technology Bv | 蒸気流から粒子を除去するためのフィルターデバイス |

| CN106404860A (zh) * | 2016-08-30 | 2017-02-15 | 济南大学 | 一种氮化碳修饰三维石墨电极的制备方法及电致化学发光传感应用 |

| CN108344714B (zh) * | 2018-01-16 | 2020-07-31 | 东南大学 | 基于有序多孔纳米结构薄膜干涉效应的生物检测仪及其进行生物分子检测的方法 |

| CN111229164B (zh) * | 2020-02-21 | 2022-03-08 | 大连理工大学 | 一种分离烯烃烷烃的微孔炭吸附剂及其制备方法和应用 |

| US20210315293A1 (en) * | 2020-04-08 | 2021-10-14 | Luciano Castillo | Wearable face mask with anti-viral filtration media |

| CN118899205A (zh) * | 2024-07-24 | 2024-11-05 | 深圳碳闪科技有限公司 | 金规则微筛支持膜的制备方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0798278A (ja) * | 1993-08-06 | 1995-04-11 | Tdk Corp | 化学物質センサ |

| WO2006124965A1 (en) * | 2005-05-17 | 2006-11-23 | Applied Materials, Inc | A semiconductor junction formation process including low temperature plasma deposition of an optical absorption layer and high speed optical annealing |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4685940A (en) | 1984-03-12 | 1987-08-11 | Abraham Soffer | Separation device |

| IL105142A (en) | 1993-03-23 | 1997-01-10 | Aga Ab | Method of improving the selectivity of carbon membranes by chemical carbon vapor deposition |

| JP3116793B2 (ja) | 1995-11-24 | 2000-12-11 | 三菱自動車工業株式会社 | ウインドガラスの仮止め用クリップ |

| JP4128628B2 (ja) * | 1996-05-15 | 2008-07-30 | ハイピリオン カタリシス インターナショナル インコーポレイテッド | 堅い多孔質炭素構造体及びその製造方法 |

| US5972079A (en) | 1996-06-28 | 1999-10-26 | University Of Delaware | Supported carbogenic molecular sieve membrane and method of producing the same |

| RU2151737C1 (ru) | 1997-05-30 | 2000-06-27 | Акционерное общество закрытого типа "Карбид" | Способ получения пористого углеродного изделия и пористое углеродное изделие, полученное этим способом |

| US6039792A (en) | 1997-06-24 | 2000-03-21 | Regents Of The University Of California And Bp Amoco Corporation | Methods of forming and using porous structures for energy efficient separation of light gases by capillary condensation |

| CN1174916C (zh) * | 1999-04-21 | 2004-11-10 | 张震 | 碳毫微管的形成方法 |

| US6297293B1 (en) * | 1999-09-15 | 2001-10-02 | Tda Research, Inc. | Mesoporous carbons and polymers |

| DE60236642D1 (de) | 2001-04-06 | 2010-07-22 | Univ Carnegie Mellon | Verfahren zur herstellung von nanostrukturierten materialien |

| US6730364B2 (en) | 2002-03-28 | 2004-05-04 | National Science Council | Preparation of carbon molecular sieve membranes on porous substrate |

| EP1523512B1 (en) * | 2002-07-22 | 2019-12-25 | Aspen Aerogels Inc. | Polyimide aerogels, carbon aerogels, and metal carbide aerogels and methods of making same |

| US7030167B2 (en) | 2003-06-25 | 2006-04-18 | Agilent Technologies, Inc. | Nanoporous structures produced from self-assembling molecules |

| GB0317557D0 (en) | 2003-07-26 | 2003-08-27 | Univ Manchester | Microporous polymer material |

| JP2006335596A (ja) | 2005-06-01 | 2006-12-14 | Tohoku Univ | 規則性のある大表面積ミクロポーラス炭素の簡便な合成方法 |

-

2006

- 2006-12-29 US US11/618,010 patent/US7901776B2/en not_active Expired - Fee Related

-

2007

- 2007-12-13 BR BRPI0720568-6A2A patent/BRPI0720568A2/pt not_active IP Right Cessation

- 2007-12-13 JP JP2009544163A patent/JP2010514937A/ja not_active Ceased

- 2007-12-13 CN CN2007800488600A patent/CN101573470B/zh not_active Expired - Fee Related

- 2007-12-13 WO PCT/US2007/087347 patent/WO2008082897A1/en not_active Ceased

- 2007-12-13 EP EP07855117A patent/EP2111481A1/en not_active Withdrawn

- 2007-12-13 KR KR1020097015815A patent/KR20090101289A/ko not_active Ceased

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0798278A (ja) * | 1993-08-06 | 1995-04-11 | Tdk Corp | 化学物質センサ |

| WO2006124965A1 (en) * | 2005-05-17 | 2006-11-23 | Applied Materials, Inc | A semiconductor junction formation process including low temperature plasma deposition of an optical absorption layer and high speed optical annealing |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20090101289A (ko) | 2009-09-24 |

| US20080160858A1 (en) | 2008-07-03 |

| CN101573470B (zh) | 2011-08-03 |

| WO2008082897A1 (en) | 2008-07-10 |

| BRPI0720568A2 (pt) | 2014-02-04 |

| CN101573470A (zh) | 2009-11-04 |

| US7901776B2 (en) | 2011-03-08 |

| EP2111481A1 (en) | 2009-10-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010514937A (ja) | プラズマ蒸着微孔性炭素材料 | |

| KR101331710B1 (ko) | 플라즈마 증착된 미공성 분석물 검출 층 | |

| KR101372725B1 (ko) | 침투성 나노입자 반사기 | |

| Green et al. | SERS substrates fabricated by island lithography: the silver/pyridine system | |

| US6778316B2 (en) | Nanoparticle-based all-optical sensors | |

| US7450227B2 (en) | Surface enhanced Raman spectroscopy (SERS) substrates exhibiting uniform high enhancement and stability | |

| AU2008308827B2 (en) | Organic chemical sensor comprising plasma-deposited microporous layer, and method of making and using | |

| RU2360232C2 (ru) | Колориметрический датчик | |

| RU2490616C2 (ru) | Многослойные колориметрические датчики | |

| CN103492872B (zh) | 使用吸收性传感器元件的方法 | |

| EP2483669A1 (en) | Nanoplasmonic device | |

| US8647884B2 (en) | Organic chemical sensor with microporous organosilicate material | |

| JP4919228B2 (ja) | 水素ガス検知膜 | |

| WO2014098583A1 (en) | A thin-film device for detecting hydrogen | |

| McCann et al. | Novel, nanoporous silica and titania layers fabricated by magnetron sputtering | |

| CN104797416A (zh) | 亲水性构件及其制造方法 | |

| Ovchinnikov | Effect of adhesion layer on morphology and optical properties of self-organized metal nanostructures | |

| Modaresialam et al. | Sol-gel TiO 2 nanoimprinted metasurface combined to hybrid-silica sensitive layers for selective VOC detection with high refractive index sensitivity | |

| Gao | Vapor sensors using porous silicon-based optical interferometers | |

| Chan | Chemical modification of porous silicon for the detection of explosive gases | |

| Yan et al. | Iridium Metal as Potential Substrates for Experiments in Space | |

| FR3087010A1 (fr) | Sonde anisotrope et dispositif optique contenant une telle sonde pour detecter la presence d'une molecule cible. | |

| JPH06330300A (ja) | アミノ酸薄膜の形成方法及び薄膜を用いた化学センサプローブ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101129 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101129 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20121221 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130108 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130403 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130410 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130424 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20131001 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20140225 |