JP2009502571A - 多層容器および製造方法 - Google Patents

多層容器および製造方法 Download PDFInfo

- Publication number

- JP2009502571A JP2009502571A JP2008523925A JP2008523925A JP2009502571A JP 2009502571 A JP2009502571 A JP 2009502571A JP 2008523925 A JP2008523925 A JP 2008523925A JP 2008523925 A JP2008523925 A JP 2008523925A JP 2009502571 A JP2009502571 A JP 2009502571A

- Authority

- JP

- Japan

- Prior art keywords

- layers

- preform

- layer

- composition

- plastic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 7

- 239000000203 mixture Substances 0.000 claims abstract description 49

- 239000004033 plastic Substances 0.000 claims abstract description 32

- 229920003023 plastic Polymers 0.000 claims abstract description 32

- 229920000089 Cyclic olefin copolymer Polymers 0.000 claims abstract description 22

- 239000004417 polycarbonate Substances 0.000 claims abstract description 15

- 229920000515 polycarbonate Polymers 0.000 claims abstract description 15

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 claims abstract description 13

- 239000004713 Cyclic olefin copolymer Substances 0.000 claims abstract description 12

- 239000002991 molded plastic Substances 0.000 claims abstract description 9

- 239000004677 Nylon Substances 0.000 claims abstract description 6

- 229920001778 nylon Polymers 0.000 claims abstract description 6

- 239000004715 ethylene vinyl alcohol Substances 0.000 claims abstract description 4

- 229920000219 Ethylene vinyl alcohol Polymers 0.000 claims abstract description 3

- RZXDTJIXPSCHCI-UHFFFAOYSA-N hexa-1,5-diene-2,5-diol Chemical compound OC(=C)CCC(O)=C RZXDTJIXPSCHCI-UHFFFAOYSA-N 0.000 claims abstract description 3

- 239000000463 material Substances 0.000 claims description 26

- 230000004888 barrier function Effects 0.000 claims description 13

- 238000000071 blow moulding Methods 0.000 claims description 12

- 239000007789 gas Substances 0.000 claims description 11

- 239000011347 resin Substances 0.000 claims description 10

- 229920005989 resin Polymers 0.000 claims description 10

- 230000003647 oxidation Effects 0.000 claims description 7

- 238000007254 oxidation reaction Methods 0.000 claims description 7

- 239000011261 inert gas Substances 0.000 claims description 6

- 238000000034 method Methods 0.000 claims description 5

- 238000000465 moulding Methods 0.000 description 7

- 238000010102 injection blow moulding Methods 0.000 description 5

- 230000004048 modification Effects 0.000 description 4

- 238000012986 modification Methods 0.000 description 4

- 239000011521 glass Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 238000000748 compression moulding Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000001125 extrusion Methods 0.000 description 2

- 238000010101 extrusion blow moulding Methods 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 238000001746 injection moulding Methods 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- -1 polyethylene Polymers 0.000 description 2

- 230000001954 sterilising effect Effects 0.000 description 2

- 238000004659 sterilization and disinfection Methods 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 150000002632 lipids Chemical class 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000003856 thermoforming Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/09—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels

- B29C48/10—Articles with cross-sections having partially or fully enclosed cavities, e.g. pipes or channels flexible, e.g. blown foils

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/14—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the particular extruding conditions, e.g. in a modified atmosphere or by using vibration

- B29C48/141—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the particular extruding conditions, e.g. in a modified atmosphere or by using vibration extruding in a clean room

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B1/00—Layered products having a non-planar shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/306—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising vinyl acetate or vinyl alcohol (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

- B32B27/325—Layered products comprising a layer of synthetic resin comprising polyolefins comprising polycycloolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/34—Layered products comprising a layer of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/36—Layered products comprising a layer of synthetic resin comprising polyesters

- B32B27/365—Layered products comprising a layer of synthetic resin comprising polyesters comprising polycarbonates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D1/00—Containers having bodies formed in one piece, e.g. by casting metallic material, by moulding plastics, by blowing vitreous material, by throwing ceramic material, by moulding pulped fibrous material, by deep-drawing operations performed on sheet material

- B65D1/02—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents

- B65D1/0207—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents characterised by material, e.g. composition, physical features

- B65D1/0215—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents characterised by material, e.g. composition, physical features multilayered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/46—Component parts, details or accessories; Auxiliary operations characterised by using particular environment or blow fluids other than air

- B29C2049/4602—Blowing fluids

- B29C2049/4638—Blowing fluids being a hot gas, i.e. gas with a temperature higher than ambient temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3008—Preforms or parisons made of several components at neck portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3012—Preforms or parisons made of several components at flange portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3016—Preforms or parisons made of several components at body portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/302—Preforms or parisons made of several components at bottom portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3024—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique

- B29C2949/3026—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3024—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique

- B29C2949/3026—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components

- B29C2949/3028—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components having three or more components

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3024—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique

- B29C2949/3026—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components

- B29C2949/3028—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components having three or more components

- B29C2949/303—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components having three or more components having more than three components

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

- B29C2949/3034—Preforms or parisons made of several components having components being injected having two or more components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

- B29C2949/3034—Preforms or parisons made of several components having components being injected having two or more components being injected

- B29C2949/3036—Preforms or parisons made of several components having components being injected having two or more components being injected having three or more components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

- B29C2949/3034—Preforms or parisons made of several components having components being injected having two or more components being injected

- B29C2949/3036—Preforms or parisons made of several components having components being injected having two or more components being injected having three or more components being injected

- B29C2949/3038—Preforms or parisons made of several components having components being injected having two or more components being injected having three or more components being injected having more than three components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3048—Preforms or parisons made of several components having components being thermoformed

- B29C2949/3051—Preforms or parisons made of several components having components being thermoformed having two or more components being thermoformed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3048—Preforms or parisons made of several components having components being thermoformed

- B29C2949/3051—Preforms or parisons made of several components having components being thermoformed having two or more components being thermoformed

- B29C2949/3052—Preforms or parisons made of several components having components being thermoformed having two or more components being thermoformed having three or more components being thermoformed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3048—Preforms or parisons made of several components having components being thermoformed

- B29C2949/3051—Preforms or parisons made of several components having components being thermoformed having two or more components being thermoformed

- B29C2949/3052—Preforms or parisons made of several components having components being thermoformed having two or more components being thermoformed having three or more components being thermoformed

- B29C2949/3054—Preforms or parisons made of several components having components being thermoformed having two or more components being thermoformed having three or more components being thermoformed having more than three components being thermoformed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3056—Preforms or parisons made of several components having components being compression moulded

- B29C2949/3058—Preforms or parisons made of several components having components being compression moulded having two or more components being compression moulded

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3056—Preforms or parisons made of several components having components being compression moulded

- B29C2949/3058—Preforms or parisons made of several components having components being compression moulded having two or more components being compression moulded

- B29C2949/306—Preforms or parisons made of several components having components being compression moulded having two or more components being compression moulded having three or more components being compression moulded

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3056—Preforms or parisons made of several components having components being compression moulded

- B29C2949/3058—Preforms or parisons made of several components having components being compression moulded having two or more components being compression moulded

- B29C2949/306—Preforms or parisons made of several components having components being compression moulded having two or more components being compression moulded having three or more components being compression moulded

- B29C2949/3062—Preforms or parisons made of several components having components being compression moulded having two or more components being compression moulded having three or more components being compression moulded having more than three components being compression moulded

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/04—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould using liquids, gas or steam

- B29C35/041—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould using liquids, gas or steam using liquids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/08—Biaxial stretching during blow-moulding

- B29C49/10—Biaxial stretching during blow-moulding using mechanical means for prestretching

- B29C49/12—Stretching rods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/48—Moulds

- B29C49/4823—Moulds with incorporated heating or cooling means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/03—3 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/24—All layers being polymeric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2270/00—Resin or rubber layer containing a blend of at least two different polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/30—Properties of the layers or laminate having particular thermal properties

- B32B2307/306—Resistant to heat

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/54—Yield strength; Tensile strength

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/714—Inert, i.e. inert to chemical degradation, corrosion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/724—Permeability to gases, adsorption

- B32B2307/7242—Non-permeable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/726—Permeability to liquids, absorption

- B32B2307/7265—Non-permeable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/738—Thermoformability

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2439/00—Containers; Receptacles

- B32B2439/40—Closed containers

- B32B2439/60—Bottles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2439/00—Containers; Receptacles

- B32B2439/80—Medical packaging

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Ceramic Engineering (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

- Containers Having Bodies Formed In One Piece (AREA)

- Laminated Bodies (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

- Wrappers (AREA)

Abstract

【選択図】図1

Description

Claims (9)

- 少なくとも3つの連続的な層A、B、およびCを有する多層側壁(12)を含むブロー成形プラスチック容器であって、

前記層AおよびCは、同一のプラスチック組成物のものであり、且つ前記層Bと異なる組成物のものであり、

前記層AおよびCは、環状オレフィンポリマー、環状オレフィンコポリマー、アクリロニトリル、およびそれらの混合物からなる群より選択される組成物のものであり、

前記層Bは、環状オレフィンポリマー、環状オレフィンコポリマー、ポリカーボネート、およびそれらの混合物からなる群より選択される組成物のものである、

ことを特徴とするブロー成形プラスチック容器。 - 少なくとも3つの連続的な層A、B、およびCを有する多層側壁(12)を含むブロー成形プラスチック容器であって、

前記層AおよびCは、同一のプラスチック組成物のものであり、且つ前記層Bと異なる組成物のものであり、

前記層AおよびCは、ポリカーボネート、アクリロニトリル、およびそれらの混合物からなる群より選択される組成物のものであり、

前記層Bは、ナイロン、ポリカーボネート、およびそれらの混合物からなる群より選択される組成物のものである、

ことを特徴とするブロー成形プラスチック容器。 - 少なくとも3つの連続的な層A、B、およびCを有する多層側壁(12)を含むブロー成形プラスチック容器であって、

前記層AおよびCは、同一のプラスチック組成物のものであり、且つ前記層Bと異なる組成物のものであり、

前記層AおよびCは、アクリロニトリル組成物のものであり、前記層Bは、エチレンビニルアルコール組成物のものである、

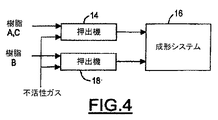

ことを特徴とするブロー成形プラスチック容器。 - (a)少なくとも2つのプラスチック材料(A、B)を関連した押出機(14、18)に送るステップと、

(b)それぞれが前記少なくとも2つのプラスチック材料からなる少なくとも2つの層を有するプレフォーム(28)を形成するステップと、

(c)前記プレフォームをブロー成形してプラスチック容器(10)にするステップと、を含む、多層プラスチック容器を製造する方法であって、

前記ステップ(a)は、前記少なくとも1つの押出機内のプラスチック材料の酸化を防ぐために、前記押出機の少なくとも1つに不活性ガスを送るステップを含む、

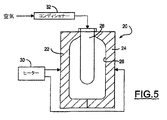

ことを特徴とする多層プラスチック容器を製造する方法。 - 前記ステップ(c)は、前記プレフォームをブロー金型(20)内でブロー成形することによって行なわれ、

前記プレフォームと無関係に、熱を前記ブロー金型に加える、

ことを特徴とする請求項4に記載の方法。 - 前記ステップ(c)は、圧力下のガスをプレフォームに加えることによって行なわれ、

ガスを、プレフォームに送る前に調節する、

ことを特徴とする請求項5に記載の方法。 - (a)少なくとも2つのプラスチック材料(A、B)を関連した押出機(14、18)に送るステップと、

(b)それぞれが前記少なくとも2つのプラスチック材料からなる少なくとも2つの層を有するプレフォーム(28)を形成するステップと、

(c)プレフォームをブロー成形してプラスチック容器(10)にするステップと、を含む、多層プラスチック容器を製造する方法であって、

前記ステップ(a)は、バリア樹脂(B)を前記押出機の1つ(18)に送るステップと、前記バリア樹脂の酸化を防ぐために、不活性ガスを前記1つの押出機に送るステップと、を含む、

ことを特徴とする多層プラスチック容器を製造する方法。 - (a)少なくとも2つのプラスチック材料(A、B)を関連した押出機(14、18)に送るステップと、

(b)プラスチック材料を金型(16)の中に射出して、少なくとも2つの層を有するプレフォーム(28)を形成するステップと、

(c)前記プレフォームをブロー成形してプラスチック容器(10)にするステップと、を含む、多層プラスチック容器を製造する方法であって、

前記ステップ(a)は、前記少なくとも1つの押出機内のプラスチック材料の酸化を防ぐために、不活性ガスを前記少なくとも1つの押出機に送るステップを含む、

ことを特徴とする多層プラスチック容器を製造する方法。 - (a)少なくとも2つのプラスチック材料(A、B)を関連した押出機(14、18)に送るステップと、

(b)それぞれが前記少なくとも2つのプラスチック材料からなる少なくとも2つの層を有するプレフォーム(28)を形成するステップと、

(c)前記プレフォームをブロー金型(20)内でブロー成形してプラスチック容器(10)にするステップと、を含む、多層プラスチック容器を製造する方法であって、

前記プレフォームと無関係に熱を前記ブロー金型に加える、

ことを特徴とする多層プラスチック容器を製造する方法。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/190,454 US20070026173A1 (en) | 2005-07-27 | 2005-07-27 | Multilayer containers and methods of manufacture |

| PCT/US2006/027358 WO2007015750A1 (en) | 2005-07-27 | 2006-07-14 | Multilayer containers and methods of manufacture |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009502571A true JP2009502571A (ja) | 2009-01-29 |

| JP2009502571A5 JP2009502571A5 (ja) | 2012-02-02 |

Family

ID=37150208

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008523925A Pending JP2009502571A (ja) | 2005-07-27 | 2006-07-14 | 多層容器および製造方法 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20070026173A1 (ja) |

| EP (1) | EP1912791A1 (ja) |

| JP (1) | JP2009502571A (ja) |

| CN (1) | CN101228029A (ja) |

| BR (1) | BRPI0614486A2 (ja) |

| CA (1) | CA2629741A1 (ja) |

| NO (1) | NO20081039L (ja) |

| WO (1) | WO2007015750A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2022507207A (ja) * | 2018-11-13 | 2022-01-18 | エスアイオーツー・メディカル・プロダクツ・インコーポレイテッド | 実質的に平坦な底部を有するポリマーバイアル、及びそのようなポリマーバイアルを製造する射出延伸ブロー成形方法 |

| JP2022163101A (ja) * | 2020-06-19 | 2022-10-25 | 大日本印刷株式会社 | プリフォーム及びボトル |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4328269B2 (ja) * | 2004-07-28 | 2009-09-09 | 株式会社日立製作所 | ガスタービン装置 |

| US20090036862A1 (en) * | 2007-08-01 | 2009-02-05 | Owens-Ilinois Healthcare Packaging Inc. | Multilayer plastic container and method of storing lyophilized products |

| JP5315074B2 (ja) * | 2009-02-04 | 2013-10-16 | 株式会社大協精工 | 衛生品用容器 |

| US20130126462A1 (en) * | 2011-11-17 | 2013-05-23 | Wisys Technology Foundation, Inc. | Ultraviolet-Blocking Recyclable Plastic Container |

| CN104661813A (zh) * | 2012-10-17 | 2015-05-27 | 东丽株式会社 | 叠层膜 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61268434A (ja) * | 1985-05-22 | 1986-11-27 | 東洋製罐株式会社 | 多層プラスチツク容器及びその製法 |

| JPS63302017A (ja) * | 1987-06-02 | 1988-12-08 | Kuraray Co Ltd | 多層容器の製造法 |

| JPH04259529A (ja) * | 1991-02-14 | 1992-09-16 | Denki Kagaku Kogyo Kk | 耐熱性飽和ポリエステル容器の製造方法 |

| JPH1180492A (ja) * | 1997-08-29 | 1999-03-26 | Kishimoto Akira | 耐熱性及び耐衝撃性の改善された透明環状オレフィン系共重合体組成物 |

| JPH11268104A (ja) * | 1998-03-24 | 1999-10-05 | Nippon Steel Chem Co Ltd | ブロー成形装置と成形方法および成形体 |

| JP2002210888A (ja) * | 2001-01-19 | 2002-07-31 | Nippon Synthetic Chem Ind Co Ltd:The | 多層容器 |

Family Cites Families (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS54142271A (en) * | 1978-04-28 | 1979-11-06 | Kureha Chem Ind Co Ltd | Multi-layer blow molded article |

| AU549286B2 (en) * | 1981-01-22 | 1986-01-23 | Toyo Boseki K.K. | Blow moulded multiply vessel |

| US4513037A (en) * | 1983-12-29 | 1985-04-23 | General Electric Company | Multilayered hollow polycarbonate containers |

| US4550043A (en) | 1984-02-17 | 1985-10-29 | Continental Plastic Containers, Inc. | Preform with internal barrier and internal layer of high thermal stability and products made from the same |

| JPS61235126A (ja) * | 1985-04-12 | 1986-10-20 | Nissei Ee S B Kikai Kk | 多層容器の製造方法 |

| US4753845A (en) * | 1986-01-30 | 1988-06-28 | Kyoraku Co., Ltd. | Multi-layer polymeric structure |

| AU610555B2 (en) * | 1987-02-06 | 1991-05-23 | Mitsubishi Gas Chemical Company, Inc. | Parison and blow-moulded containers and processes for production thereof |

| JPH0813499B2 (ja) * | 1987-03-04 | 1996-02-14 | 三菱瓦斯化学株式会社 | 多層容器及びその製造法 |

| JP2543544B2 (ja) * | 1987-11-30 | 1996-10-16 | 三菱瓦斯化学株式会社 | ガスバリヤ―性多層構造物 |

| US4847129A (en) * | 1988-09-16 | 1989-07-11 | Continental Pet Technologies, Inc. | Multilayer preform for hot fill containers |

| US4937130A (en) * | 1989-01-18 | 1990-06-26 | General Electric Company | Polycarbonate container having internal layers of amorphous polyamide |

| US6217818B1 (en) | 1995-07-07 | 2001-04-17 | Continental Pet Technologies, Inc. | Method of making preform and container with crystallized neck finish |

| US5851471A (en) | 1996-05-16 | 1998-12-22 | The Coca-Cola Company | Method for injection molding a multi-layer preform for use in blow molding a plastic bottle |

| US6123211A (en) * | 1997-10-14 | 2000-09-26 | American National Can Company | Multilayer plastic container and method of making the same |

| US6312772B1 (en) * | 1997-10-20 | 2001-11-06 | Hoechst Celanese Corporation | Multilayer laminate formed from a substantially stretched non-molten wholly aromatic liquid crystalline polymer and non-polyester thermoplastic polymer |

| US6746757B1 (en) * | 1997-12-09 | 2004-06-08 | Mitsubishi Engineering-Plastics Corporation | Multilayered molding |

| WO2000000399A1 (fr) * | 1998-06-30 | 2000-01-06 | Nippon Zeon Co., Ltd. | Recipient et produit moule par soufflage |

| DE19943545A1 (de) | 1999-04-09 | 2001-03-15 | Ticona Gmbh | Mehrschichtbehälter mit verbesserter Haftung zwischen den Polymerschichten und hervorragenden Barriereeigenschaften |

| JP4593759B2 (ja) * | 1999-11-16 | 2010-12-08 | 株式会社フジシールインターナショナル | ラベル付き容器 |

| JP3647707B2 (ja) * | 2000-02-03 | 2005-05-18 | 株式会社フジシールインターナショナル | ポリオレフィン系シュリンクラベル |

| US6423776B1 (en) * | 2000-05-02 | 2002-07-23 | Honeywell International Inc. | Oxygen scavenging high barrier polyamide compositions for packaging applications |

| JP2002103428A (ja) * | 2000-09-29 | 2002-04-09 | Toyo Seikan Kaisha Ltd | 多層プリフォームおよびこれを用いて製造した多層ボトル |

| US6878774B2 (en) * | 2000-12-08 | 2005-04-12 | Toyo Seikan Kaisha, Ltd. | Resin composition and multi-layer container using the same |

| CA2446583A1 (en) * | 2001-05-23 | 2002-11-28 | Michael R. Mitten | Multi-layer stain and heat resistant plastic container for storing and heating food; methods of making the same |

| ES2841433T3 (es) | 2001-06-18 | 2021-07-08 | Becton Dickinson Co | Tubo para recolección de sangre |

| US7291369B2 (en) * | 2001-10-03 | 2007-11-06 | 3M Innovative Properties Company | Multi-layer articles including a fluoroelastomer layer and a barrier layer and method of making the same |

| JP4334170B2 (ja) * | 2001-10-05 | 2009-09-30 | 株式会社クレハ | 多層シートおよびプレス・スルー・パック容器 |

| MY134275A (en) * | 2002-05-17 | 2007-11-30 | Otsuka Pharma Co Ltd | Multi-layer film and medicine container using the same |

| FR2839976B1 (fr) * | 2002-05-21 | 2004-07-30 | Solvay | Composition polymere comportant un copolymere olefinique cyclique |

| US20030232213A1 (en) * | 2002-05-23 | 2003-12-18 | William Shepler | Multilayer storage container |

| US20030235667A1 (en) * | 2002-06-25 | 2003-12-25 | Darr Richard C. | Multilayered plastic container |

| EP1617990A4 (en) * | 2003-05-01 | 2006-08-09 | Avery Dennison Corp | MULTILAYER FOIL |

| WO2006091694A1 (en) * | 2005-02-23 | 2006-08-31 | Topas Advanced Polymers, Inc. | Multilayer films including cycloolefin copolymer and styrene-butadiene copolymer |

| US20060198973A1 (en) * | 2005-03-03 | 2006-09-07 | Jester Randy D | Packaging with cycloolefin food/beverage contact layer |

-

2005

- 2005-07-27 US US11/190,454 patent/US20070026173A1/en not_active Abandoned

-

2006

- 2006-07-14 JP JP2008523925A patent/JP2009502571A/ja active Pending

- 2006-07-14 WO PCT/US2006/027358 patent/WO2007015750A1/en active Application Filing

- 2006-07-14 BR BRPI0614486-1A patent/BRPI0614486A2/pt not_active IP Right Cessation

- 2006-07-14 CA CA002629741A patent/CA2629741A1/en not_active Abandoned

- 2006-07-14 EP EP06787287A patent/EP1912791A1/en not_active Withdrawn

- 2006-07-14 CN CNA2006800271971A patent/CN101228029A/zh active Pending

-

2008

- 2008-02-27 NO NO20081039A patent/NO20081039L/no not_active Application Discontinuation

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61268434A (ja) * | 1985-05-22 | 1986-11-27 | 東洋製罐株式会社 | 多層プラスチツク容器及びその製法 |

| JPS63302017A (ja) * | 1987-06-02 | 1988-12-08 | Kuraray Co Ltd | 多層容器の製造法 |

| JPH04259529A (ja) * | 1991-02-14 | 1992-09-16 | Denki Kagaku Kogyo Kk | 耐熱性飽和ポリエステル容器の製造方法 |

| JPH1180492A (ja) * | 1997-08-29 | 1999-03-26 | Kishimoto Akira | 耐熱性及び耐衝撃性の改善された透明環状オレフィン系共重合体組成物 |

| JPH11268104A (ja) * | 1998-03-24 | 1999-10-05 | Nippon Steel Chem Co Ltd | ブロー成形装置と成形方法および成形体 |

| JP2002210888A (ja) * | 2001-01-19 | 2002-07-31 | Nippon Synthetic Chem Ind Co Ltd:The | 多層容器 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2022507207A (ja) * | 2018-11-13 | 2022-01-18 | エスアイオーツー・メディカル・プロダクツ・インコーポレイテッド | 実質的に平坦な底部を有するポリマーバイアル、及びそのようなポリマーバイアルを製造する射出延伸ブロー成形方法 |

| JP7455828B2 (ja) | 2018-11-13 | 2024-03-26 | エスアイオーツー・メディカル・プロダクツ・インコーポレイテッド | 実質的に平坦な底部を有するポリマーバイアル、及びそのようなポリマーバイアルを製造する射出延伸ブロー成形方法 |

| JP2022163101A (ja) * | 2020-06-19 | 2022-10-25 | 大日本印刷株式会社 | プリフォーム及びボトル |

| JP7439866B2 (ja) | 2020-06-19 | 2024-02-28 | 大日本印刷株式会社 | プリフォーム及びボトル |

Also Published As

| Publication number | Publication date |

|---|---|

| BRPI0614486A2 (pt) | 2011-03-29 |

| NO20081039L (no) | 2008-04-25 |

| US20070026173A1 (en) | 2007-02-01 |

| CN101228029A (zh) | 2008-07-23 |

| EP1912791A1 (en) | 2008-04-23 |

| WO2007015750A1 (en) | 2007-02-08 |

| CA2629741A1 (en) | 2007-02-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2009502571A (ja) | 多層容器および製造方法 | |

| JP4579569B2 (ja) | 多層二軸延伸ブローボトル及びその製造方法 | |

| CN1202944C (zh) | 聚酯树脂层压容器及其成形方法 | |

| EP2168752B1 (en) | Stretch blow molding process and container | |

| CN101663144A (zh) | 包括含能量吸收添加剂的内层和外层的一体吹塑内装袋容器、用于制造该内装袋容器的预制坯、以及用于生产出该内装袋容器的方法 | |

| US7588810B2 (en) | Container having foam layer | |

| DE69714219D1 (de) | Gegen hohe temperaturen und drücke beständiger mehrschichtiger behälter und verfahren zu seiner herstellung | |

| JP5018881B2 (ja) | 耐熱圧性ポリエステルボトル及びその製造方法 | |

| EP3452263B1 (en) | Injection stretch blow-molding (isbm) enhancement for semi-crystalline polyolefin containers utilizing alicyclic polyolefins | |

| CN100526049C (zh) | 被拉伸的容器螺纹及其制造方法 | |

| JP2007513812A5 (ja) | ||

| JP6072128B2 (ja) | ポリエチレン容器、プリフォームおよびボトルの製造のための射出延伸ブロー成形法 | |

| CN100425432C (zh) | 料坯,其生产方法,和从该料坯制造的双轴拉伸容器 | |

| JP2009502571A5 (ja) | ||

| KR101764922B1 (ko) | 변형된 고온 러너 시스템을 이용한 사출 블로우 몰딩 방법 및 상기 방법에 따른 프리폼, 컨테이너 | |

| CN1223451C (zh) | 延伸吹塑容器及其成形方法 | |

| CN1693153B (zh) | 具有纳米层织构的多层聚合物复合包装容器及其加工方法 | |

| TW587980B (en) | Processes for producing PET preforms and containers such as food bottles, containers and intermediate preforms obtained | |

| MX2008001118A (en) | Multilayer containers and methods of manufacture | |

| JP2996452B2 (ja) | 多層プラスチック製予備成形体、その製造方法、それを用いた二軸延伸ブロー成形容器及びその製造方法 | |

| JP3063988B2 (ja) | 耐熱バリヤー性多層ボトル | |

| KR102472731B1 (ko) | 음료 용기 및 그 제조 방법 | |

| JPH0324928A (ja) | 多層予備成形品の製造装置 | |

| JP2732299B2 (ja) | 耐熱性多層ボトルの製造方法及び装置 | |

| JP2005212849A (ja) | ブロー成形容器 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090609 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110831 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110912 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20111209 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120326 |