JP2009141106A - プリント配線基板、空気調和機、プリント配線基板の半田付け方法 - Google Patents

プリント配線基板、空気調和機、プリント配線基板の半田付け方法 Download PDFInfo

- Publication number

- JP2009141106A JP2009141106A JP2007315713A JP2007315713A JP2009141106A JP 2009141106 A JP2009141106 A JP 2009141106A JP 2007315713 A JP2007315713 A JP 2007315713A JP 2007315713 A JP2007315713 A JP 2007315713A JP 2009141106 A JP2009141106 A JP 2009141106A

- Authority

- JP

- Japan

- Prior art keywords

- soldering

- printed wiring

- wiring board

- solder

- land

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/11—Printed elements for providing electric connections to or between printed circuits

- H05K1/111—Pads for surface mounting, e.g. lay-out

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/30—Assembling printed circuits with electric components, e.g. with resistor

- H05K3/32—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits

- H05K3/34—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by soldering

- H05K3/341—Surface mounted components

- H05K3/3421—Leaded components

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/30—Assembling printed circuits with electric components, e.g. with resistor

- H05K3/32—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits

- H05K3/34—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by soldering

- H05K3/3457—Solder materials or compositions; Methods of application thereof

- H05K3/3468—Applying molten solder

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09209—Shape and layout details of conductors

- H05K2201/09372—Pads and lands

- H05K2201/09381—Shape of non-curved single flat metallic pad, land or exposed part thereof; Shape of electrode of leadless component

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09209—Shape and layout details of conductors

- H05K2201/09654—Shape and layout details of conductors covering at least two types of conductors provided for in H05K2201/09218 - H05K2201/095

- H05K2201/09681—Mesh conductors, e.g. as a ground plane

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09209—Shape and layout details of conductors

- H05K2201/09654—Shape and layout details of conductors covering at least two types of conductors provided for in H05K2201/09218 - H05K2201/095

- H05K2201/09781—Dummy conductors, i.e. not used for normal transport of current; Dummy electrodes of components

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09818—Shape or layout details not covered by a single group of H05K2201/09009 - H05K2201/09809

- H05K2201/099—Coating over pads, e.g. solder resist partly over pads

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/10—Details of components or other objects attached to or integrated in a printed circuit board

- H05K2201/10007—Types of components

- H05K2201/10166—Transistor

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/10—Details of components or other objects attached to or integrated in a printed circuit board

- H05K2201/10613—Details of electrical connections of non-printed components, e.g. special leads

- H05K2201/10621—Components characterised by their electrical contacts

- H05K2201/10689—Leaded Integrated Circuit [IC] package, e.g. dual-in-line [DIL]

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/04—Soldering or other types of metallurgic bonding

- H05K2203/046—Means for drawing solder, e.g. for removing excess solder from pads

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Manufacturing & Machinery (AREA)

- Electric Connection Of Electric Components To Printed Circuits (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007315713A JP2009141106A (ja) | 2007-12-06 | 2007-12-06 | プリント配線基板、空気調和機、プリント配線基板の半田付け方法 |

| US12/219,530 US20090145644A1 (en) | 2007-12-06 | 2008-07-23 | Printed wiring board, air conditioner, and method of soldering printed wiring board |

| CN2010105207306A CN101969742A (zh) | 2007-12-06 | 2008-07-25 | 印刷线路板、空调机、印刷线路板的钎焊方法 |

| CN2008101334790A CN101453836B (zh) | 2007-12-06 | 2008-07-25 | 印刷线路板、空调机、印刷线路板的钎焊方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007315713A JP2009141106A (ja) | 2007-12-06 | 2007-12-06 | プリント配線基板、空気調和機、プリント配線基板の半田付け方法 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009199661A Division JP2009283983A (ja) | 2009-08-31 | 2009-08-31 | プリント配線基板、空気調和機、プリント配線基板の半田付け方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009141106A true JP2009141106A (ja) | 2009-06-25 |

| JP2009141106A5 JP2009141106A5 (enExample) | 2009-08-06 |

Family

ID=40720450

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007315713A Pending JP2009141106A (ja) | 2007-12-06 | 2007-12-06 | プリント配線基板、空気調和機、プリント配線基板の半田付け方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20090145644A1 (enExample) |

| JP (1) | JP2009141106A (enExample) |

| CN (2) | CN101453836B (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6921244B2 (ja) * | 2018-01-15 | 2021-08-18 | 本田技研工業株式会社 | ブレーズ装置及び方法 |

| WO2019211998A1 (ja) * | 2018-05-01 | 2019-11-07 | 三菱電機株式会社 | はんだ付けノズル、はんだ付け装置、はんだ付け方法およびプリント配線板の製造方法 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5666272A (en) * | 1994-11-29 | 1997-09-09 | Sgs-Thomson Microelectronics, Inc. | Detachable module/ball grid array package |

| US5679929A (en) * | 1995-07-28 | 1997-10-21 | Solectron Corporqtion | Anti-bridging pads for printed circuit boards and interconnecting substrates |

| JPH10173329A (ja) | 1996-12-10 | 1998-06-26 | Matsushita Electric Works Ltd | 噴流式半田付け装置 |

| US5877033A (en) * | 1997-03-10 | 1999-03-02 | The Foxboro Company | System for detection of unsoldered components |

| JP3633505B2 (ja) * | 2001-04-27 | 2005-03-30 | 松下電器産業株式会社 | プリント配線基板およびプリント配線基板の半田付け方法 |

| CN100446650C (zh) * | 2001-12-18 | 2008-12-24 | 爱立信股份有限公司 | 装配电子电路的设备和方法 |

| JP2006313792A (ja) * | 2005-05-06 | 2006-11-16 | Sony Corp | プリント配線基板 |

| JP4207934B2 (ja) * | 2005-08-09 | 2009-01-14 | 三菱電機株式会社 | 4方向リードフラットパッケージic実装プリント配線基板、4方向リードフラットパッケージicの半田付方法、空気調和機。 |

| CN1852638B (zh) * | 2006-01-24 | 2010-05-12 | 华为技术有限公司 | 一种印刷焊膏的方法及印锡钢网 |

-

2007

- 2007-12-06 JP JP2007315713A patent/JP2009141106A/ja active Pending

-

2008

- 2008-07-23 US US12/219,530 patent/US20090145644A1/en not_active Abandoned

- 2008-07-25 CN CN2008101334790A patent/CN101453836B/zh not_active Expired - Fee Related

- 2008-07-25 CN CN2010105207306A patent/CN101969742A/zh active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| CN101453836B (zh) | 2011-03-30 |

| CN101453836A (zh) | 2009-06-10 |

| US20090145644A1 (en) | 2009-06-11 |

| CN101969742A (zh) | 2011-02-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10843284B2 (en) | Method for void reduction in solder joints | |

| JP4207934B2 (ja) | 4方向リードフラットパッケージic実装プリント配線基板、4方向リードフラットパッケージicの半田付方法、空気調和機。 | |

| JP5496118B2 (ja) | プリント配線基板、4方向リードフラットパッケージicの半田付方法および空気調和機 | |

| JP3988720B2 (ja) | 4方向リードフラットパッケージic実装プリント配線基板及び4方向リードフラットパッケージicの半田付け方法、4方向リードフラットパッケージic実装プリント配線基板を備えた空気調和機。 | |

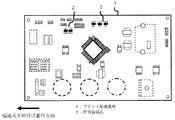

| JP2009141106A (ja) | プリント配線基板、空気調和機、プリント配線基板の半田付け方法 | |

| JP2009283983A (ja) | プリント配線基板、空気調和機、プリント配線基板の半田付け方法 | |

| JP5599151B2 (ja) | 二列リード形電子部品実装プリント配線基板、二列リード形電子部品の半田付け方法、空気調和機 | |

| CN1929717B (zh) | 导线型电子器件安装印刷电路基板、导线型电子器件的软钎焊方法、空气调节器 | |

| CN100475002C (zh) | 印刷布线基板及锡焊方法以及装配有印刷布线基板的空调器 | |

| JP2009141106A5 (enExample) | ||

| CN110958786A (zh) | 一种片上贴片的pcba侧面上锡焊接的方法 | |

| JP4952904B2 (ja) | プリント配線基板とこれを備えたモータ制御装置 | |

| JP2003331960A (ja) | 端子付き電子部品 | |

| JP4041991B2 (ja) | プリント配線基板 | |

| JP5885162B2 (ja) | プリント配線基板 | |

| JPH09181424A (ja) | 電子部品、プリント配線板及びプリント配線板の製造方法 | |

| JP2006286899A (ja) | プリント配線板の製造方法 | |

| JP4543205B2 (ja) | プリント基板の部分はんだ付け方法 | |

| JP2008091557A (ja) | 電子部品の実装方法および実装装置 | |

| JP2018107381A (ja) | プリント回路アセンブリ及びその製造方法 | |

| JP2013110333A (ja) | 基板及びリード付き部品の半田付け方法 | |

| JP2007250732A (ja) | 電子部品およびその製造方法 | |

| JPH05267833A (ja) | 表面実装用プリント配線板 | |

| JP2006114720A (ja) | 実装基板及びその製造方法 | |

| KR20060014117A (ko) | 인쇄회로기판 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090610 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090610 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090721 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20091124 |