JP2004066327A - レーザ加工装置、加工方法、および当該加工方法を用いた回路基板の製造方法 - Google Patents

レーザ加工装置、加工方法、および当該加工方法を用いた回路基板の製造方法 Download PDFInfo

- Publication number

- JP2004066327A JP2004066327A JP2002232609A JP2002232609A JP2004066327A JP 2004066327 A JP2004066327 A JP 2004066327A JP 2002232609 A JP2002232609 A JP 2002232609A JP 2002232609 A JP2002232609 A JP 2002232609A JP 2004066327 A JP2004066327 A JP 2004066327A

- Authority

- JP

- Japan

- Prior art keywords

- laser

- laser beam

- optical path

- laser light

- energy distribution

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000003754 machining Methods 0.000 title claims abstract description 12

- 238000000034 method Methods 0.000 title claims description 26

- 238000004519 manufacturing process Methods 0.000 title claims description 7

- 230000003287 optical effect Effects 0.000 claims abstract description 148

- 238000005553 drilling Methods 0.000 claims abstract description 23

- 239000000919 ceramic Substances 0.000 claims abstract description 16

- 230000001678 irradiating effect Effects 0.000 claims abstract description 16

- 238000009826 distribution Methods 0.000 claims description 41

- 238000003672 processing method Methods 0.000 claims description 7

- 239000007772 electrode material Substances 0.000 claims description 4

- 239000010410 layer Substances 0.000 description 17

- 239000000463 material Substances 0.000 description 7

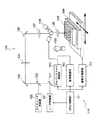

- 238000010586 diagram Methods 0.000 description 6

- 238000004080 punching Methods 0.000 description 5

- 239000000758 substrate Substances 0.000 description 5

- 238000007493 shaping process Methods 0.000 description 4

- 238000010521 absorption reaction Methods 0.000 description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 229910000859 α-Fe Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/0604—Shaping the laser beam, e.g. by masks or multi-focusing by a combination of beams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/03—Observing, e.g. monitoring, the workpiece

- B23K26/032—Observing, e.g. monitoring, the workpiece using optical means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/0604—Shaping the laser beam, e.g. by masks or multi-focusing by a combination of beams

- B23K26/0613—Shaping the laser beam, e.g. by masks or multi-focusing by a combination of beams having a common axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/064—Shaping the laser beam, e.g. by masks or multi-focusing by means of optical elements, e.g. lenses, mirrors or prisms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/064—Shaping the laser beam, e.g. by masks or multi-focusing by means of optical elements, e.g. lenses, mirrors or prisms

- B23K26/0643—Shaping the laser beam, e.g. by masks or multi-focusing by means of optical elements, e.g. lenses, mirrors or prisms comprising mirrors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/064—Shaping the laser beam, e.g. by masks or multi-focusing by means of optical elements, e.g. lenses, mirrors or prisms

- B23K26/0648—Shaping the laser beam, e.g. by masks or multi-focusing by means of optical elements, e.g. lenses, mirrors or prisms comprising lenses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/0665—Shaping the laser beam, e.g. by masks or multi-focusing by beam condensation on the workpiece, e.g. for focusing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/067—Dividing the beam into multiple beams, e.g. multifocusing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/073—Shaping the laser spot

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/0011—Working of insulating substrates or insulating layers

- H05K3/0017—Etching of the substrate by chemical or physical means

- H05K3/0026—Etching of the substrate by chemical or physical means by laser ablation

- H05K3/0029—Etching of the substrate by chemical or physical means by laser ablation of inorganic insulating material

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Laser Beam Processing (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002232609A JP2004066327A (ja) | 2002-08-09 | 2002-08-09 | レーザ加工装置、加工方法、および当該加工方法を用いた回路基板の製造方法 |

| CNB038188279A CN100396424C (zh) | 2002-08-09 | 2003-08-07 | 激光加工设备、加工方法及利用其制造电路板的方法 |

| US10/523,392 US7807944B2 (en) | 2002-08-09 | 2003-08-07 | Laser processing device, processing method, and method of producing circuit substrate using the method |

| PCT/JP2003/010052 WO2004014595A1 (ja) | 2002-08-09 | 2003-08-07 | レーザ加工装置、加工方法、および当該加工方法を用いた回路基板の製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002232609A JP2004066327A (ja) | 2002-08-09 | 2002-08-09 | レーザ加工装置、加工方法、および当該加工方法を用いた回路基板の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004066327A true JP2004066327A (ja) | 2004-03-04 |

| JP2004066327A5 JP2004066327A5 (enExample) | 2005-08-25 |

Family

ID=31711839

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002232609A Pending JP2004066327A (ja) | 2002-08-09 | 2002-08-09 | レーザ加工装置、加工方法、および当該加工方法を用いた回路基板の製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7807944B2 (enExample) |

| JP (1) | JP2004066327A (enExample) |

| CN (1) | CN100396424C (enExample) |

| WO (1) | WO2004014595A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006114445A1 (de) * | 2005-04-28 | 2006-11-02 | Sms Elotherm Gmbh | Vorrichtung und verfahren zum behandeln von zylindrisch geformten flächen mittels eines im wesentlichen kreisrunden querschnitt aufweisenden laserstrahls |

| KR20180114918A (ko) * | 2016-02-18 | 2018-10-19 | 상하이 마이크로 일렉트로닉스 이큅먼트(그룹) 컴퍼니 리미티드 | 노광 시스템, 노광 장치 및 노광 방법 |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4579575B2 (ja) * | 2004-05-14 | 2010-11-10 | 株式会社半導体エネルギー研究所 | レーザ照射方法及びレーザ照射装置 |

| WO2007049525A1 (en) | 2005-10-26 | 2007-05-03 | Semiconductor Energy Laboratory Co., Ltd. | Laser irradiation apparatus and manufacturing method of semiconductor device |

| KR101414867B1 (ko) * | 2006-06-26 | 2014-07-03 | 오르보테크 엘티디. | 인쇄 회로 기판 타깃의 정렬 |

| US7945087B2 (en) | 2006-06-26 | 2011-05-17 | Orbotech Ltd. | Alignment of printed circuit board targets |

| US8173931B2 (en) * | 2008-06-13 | 2012-05-08 | Electro Scientific Industries, Inc. | Automatic recipe management for laser processing a work piece |

| TWI469842B (zh) * | 2010-09-30 | 2015-01-21 | Mitsuboshi Diamond Ind Co Ltd | 雷射加工裝置、被加工物之加工方法及被加工物之分割方法 |

| CN102350591B (zh) * | 2011-07-08 | 2015-01-28 | 厦门大学 | 矩形水波导激光加工装置 |

| US9931712B2 (en) * | 2012-01-11 | 2018-04-03 | Pim Snow Leopard Inc. | Laser drilling and trepanning device |

| JP6388823B2 (ja) * | 2014-12-01 | 2018-09-12 | 株式会社ディスコ | レーザー加工装置 |

| JP6599098B2 (ja) * | 2014-12-12 | 2019-10-30 | 株式会社ディスコ | レーザー加工装置 |

| WO2017109928A1 (ja) * | 2015-12-25 | 2017-06-29 | ギガフォトン株式会社 | レーザ照射装置 |

| JP6306659B1 (ja) * | 2016-10-19 | 2018-04-04 | ファナック株式会社 | ビーム分配器 |

| CN107234345B (zh) * | 2017-07-14 | 2019-06-14 | 大族激光科技产业集团股份有限公司 | 一种激光切割系统及其切割方法 |

| CN107702797B (zh) * | 2017-08-31 | 2023-06-23 | 中国工程物理研究院激光聚变研究中心 | 可调谐脉冲序列发生装置 |

| TWI686256B (zh) * | 2018-04-13 | 2020-03-01 | 財團法人工業技術研究院 | 雷射清潔裝置及方法 |

| CN111438447A (zh) * | 2018-12-29 | 2020-07-24 | 东泰高科装备科技有限公司 | 一种薄膜开孔方法、太阳能电池封装膜及开孔方法 |

| CN110587123A (zh) * | 2019-09-17 | 2019-12-20 | 深圳市牧激科技有限公司 | 激光加工装置及其加工方法 |

| CN110893519A (zh) * | 2019-12-26 | 2020-03-20 | 深圳中科光子科技有限公司 | 一种双光源四工位的激光加工设备及加工方法 |

| CN111922511A (zh) * | 2020-06-12 | 2020-11-13 | 大族激光科技产业集团股份有限公司 | 一种激光加工装置、加工设备、加工系统及加工方法 |

| CN111922521B (zh) * | 2020-07-10 | 2021-09-03 | 清华大学 | 一种实现聚酰亚胺烧蚀或碳化的飞秒激光加工系统和方法 |

| CN112589813B (zh) * | 2020-12-15 | 2025-10-28 | 青岛丰光精密机械股份有限公司 | 工业机器人手臂关节切割系统 |

| JP2022105463A (ja) * | 2021-01-02 | 2022-07-14 | 大船企業日本株式会社 | プリント基板のレーザ加工方法およびプリント基板のレーザ加工機 |

| CN114465080A (zh) * | 2022-02-09 | 2022-05-10 | 江苏亮点光电科技有限公司 | 一种扇角可切换的一字线激光器 |

| CN114951975A (zh) * | 2022-05-31 | 2022-08-30 | 苏州科韵激光科技有限公司 | 激光加工设备和方法 |

| CN119794622B (zh) * | 2024-12-18 | 2025-11-28 | 北京理工大学 | 一种时/频整形激光在厚电极上构建超低损耗通孔的方法 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0199793A (ja) | 1987-10-09 | 1989-04-18 | Mitsubishi Electric Corp | レーザー分光装置 |

| JP2683926B2 (ja) * | 1988-01-25 | 1997-12-03 | 三菱電機株式会社 | 絶縁被覆電線の被覆剥離方法及びその装置 |

| JPH058072A (ja) | 1991-07-04 | 1993-01-19 | Nec Corp | レーザ加工方法 |

| JPH0724587A (ja) * | 1993-07-13 | 1995-01-27 | Matsushita Electric Ind Co Ltd | レーザ照射装置 |

| JPH07331422A (ja) | 1994-06-09 | 1995-12-19 | Toshiba Corp | レーザ・アブレーション装置 |

| US5523543A (en) * | 1994-09-09 | 1996-06-04 | Litel Instruments | Laser ablation control system and method |

| US6373026B1 (en) * | 1996-07-31 | 2002-04-16 | Mitsubishi Denki Kabushiki Kaisha | Laser beam machining method for wiring board, laser beam machining apparatus for wiring board, and carbonic acid gas laser oscillator for machining wiring board |

| JP3159906B2 (ja) * | 1995-10-23 | 2001-04-23 | アルプス電気株式会社 | 液晶表示素子の製造方法 |

| US5837961A (en) * | 1995-11-24 | 1998-11-17 | Miller; Richard T. | Laser wire stripping apparatus having multiple synchronous mirrors and a method therefor |

| JPH09164493A (ja) | 1995-12-18 | 1997-06-24 | Mitsubishi Electric Corp | レーザ加工装置 |

| JPH10137959A (ja) | 1996-11-07 | 1998-05-26 | Sanei Kikai:Kk | レーザ加工装置 |

| US5948219A (en) * | 1997-05-07 | 1999-09-07 | Advanced Micro Devices, Inc. | Apparatus for selectively exposing a semiconductor topography to an electric field |

| JP3175006B2 (ja) | 1997-05-28 | 2001-06-11 | 住友重機械工業株式会社 | レーザ加工装置及び加工方法 |

| JPH1147965A (ja) | 1997-05-28 | 1999-02-23 | Komatsu Ltd | レーザ加工装置 |

| US6156030A (en) * | 1997-06-04 | 2000-12-05 | Y-Beam Technologies, Inc. | Method and apparatus for high precision variable rate material removal and modification |

| JPH11147188A (ja) | 1997-11-13 | 1999-06-02 | Toshiba Corp | レ−ザ加工装置 |

| US6313435B1 (en) * | 1998-11-20 | 2001-11-06 | 3M Innovative Properties Company | Mask orbiting for laser ablated feature formation |

| KR100469023B1 (ko) * | 1999-03-05 | 2005-01-29 | 미쓰비시덴키 가부시키가이샤 | 레이저가공장치 |

| JP2000280085A (ja) | 1999-03-30 | 2000-10-10 | Seiko Epson Corp | レーザ加工装置及びその加工方法 |

| TWI223581B (en) * | 1999-04-02 | 2004-11-01 | Murata Manufacturing Co | Method for machining ceramic green sheet and apparatus for machining the same |

| EP1072350A1 (de) | 1999-07-12 | 2001-01-31 | MDC Max Dätwyler AG Bleienbach | Verfahren zur Erzeugung einer Intensitätsverteilung über einen Arbeitslaserstrahl sowie Vorrichtung hierzu |

| JP2002096187A (ja) * | 2000-09-18 | 2002-04-02 | Sumitomo Heavy Ind Ltd | レーザ加工装置及び加工方法 |

| TW503143B (en) * | 2000-10-06 | 2002-09-21 | Hitachi Via Mechanics Ltd | Method and apparatus for drilling printed wiring boards |

| JP2002217550A (ja) | 2001-01-16 | 2002-08-02 | Toshiba Corp | レーザ加工方法、レーザ加工装置および多層配線基板の製造方法 |

| US6621044B2 (en) * | 2001-01-18 | 2003-09-16 | Anvik Corporation | Dual-beam materials-processing system |

| DE10145184B4 (de) * | 2001-09-13 | 2005-03-10 | Siemens Ag | Verfahren zum Laserbohren, insbesondere unter Verwendung einer Lochmaske |

| JP3687607B2 (ja) * | 2001-12-25 | 2005-08-24 | 松下電工株式会社 | プリプレグの切断方法 |

-

2002

- 2002-08-09 JP JP2002232609A patent/JP2004066327A/ja active Pending

-

2003

- 2003-08-07 WO PCT/JP2003/010052 patent/WO2004014595A1/ja not_active Ceased

- 2003-08-07 US US10/523,392 patent/US7807944B2/en not_active Expired - Fee Related

- 2003-08-07 CN CNB038188279A patent/CN100396424C/zh not_active Expired - Fee Related

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006114445A1 (de) * | 2005-04-28 | 2006-11-02 | Sms Elotherm Gmbh | Vorrichtung und verfahren zum behandeln von zylindrisch geformten flächen mittels eines im wesentlichen kreisrunden querschnitt aufweisenden laserstrahls |

| KR20180114918A (ko) * | 2016-02-18 | 2018-10-19 | 상하이 마이크로 일렉트로닉스 이큅먼트(그룹) 컴퍼니 리미티드 | 노광 시스템, 노광 장치 및 노광 방법 |

| JP2019505850A (ja) * | 2016-02-18 | 2019-02-28 | シャンハイ マイクロ エレクトロニクス イクイプメント(グループ)カンパニー リミティド | 露光システム、露光装置及び露光方法 |

| KR102143085B1 (ko) * | 2016-02-18 | 2020-08-10 | 상하이 마이크로 일렉트로닉스 이큅먼트(그룹) 컴퍼니 리미티드 | 노광 시스템, 노광 장치 및 노광 방법 |

| US10942458B2 (en) | 2016-02-18 | 2021-03-09 | Shanghai Micro Electronics Equipment (Group) Co., Ltd. | Exposure system, exposure device and exposure method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1675020A (zh) | 2005-09-28 |

| CN100396424C (zh) | 2008-06-25 |

| US7807944B2 (en) | 2010-10-05 |

| US20050232316A1 (en) | 2005-10-20 |

| WO2004014595A1 (ja) | 2004-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2004066327A (ja) | レーザ加工装置、加工方法、および当該加工方法を用いた回路基板の製造方法 | |

| EP3511106B1 (en) | Laser based machining of glass material | |

| JP2018518601A (ja) | 複数ビーム付加的製造 | |

| TWI378839B (en) | Laser machining method and laser machining apparatus | |

| US20040112881A1 (en) | Circle laser trepanning | |

| KR102627353B1 (ko) | 하이브리드 펄스 스캐너가 구비된 레이저 조사장치및 이를 이용한 버큠플레이트의 마이크로홀 가공방법 | |

| TW202027578A (zh) | 印刷電路板的雷射加工方法及其雷射加工機 | |

| JP2020108904A5 (enExample) | ||

| JP2017080796A (ja) | 加工樹脂基板の製造方法およびレーザー加工装置 | |

| JP5183826B2 (ja) | レーザ加工方法およびレーザ加工機 | |

| JP4006247B2 (ja) | レーザ加工方法及びレーザ加工装置 | |

| JP4489782B2 (ja) | レーザ加工方法 | |

| JP3720034B2 (ja) | 穴あけ加工方法 | |

| KR100594528B1 (ko) | 레이저 가공 장치, 가공 방법 및 상기 가공 방법을 이용한회로 기판의 제조 방법 | |

| CN111629857A (zh) | 激光加工方法 | |

| JP2007029952A (ja) | レーザ加工装置及びレーザ加工方法 | |

| WO2002083355A1 (en) | Circle laser trepanning | |

| JP2008137058A (ja) | レーザ加工装置及びレーザ加工方法 | |

| JP3605722B2 (ja) | レーザ穴あけ加工方法及び加工装置 | |

| CN107662055B (zh) | 脆性材料基板的激光加工方法及激光加工装置 | |

| TW201803678A (zh) | 脆性材料基板之雷射加工方法及雷射加工裝置 | |

| JPH10323788A (ja) | レーザ加工装置 | |

| JP2008284577A (ja) | レーザ加工方法、フレキシブルプリント基板 | |

| TWI836806B (zh) | 基於多層雷射照射之遮罩製造方法 | |

| JP3978152B2 (ja) | レーザ加工方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050208 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050208 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20061204 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20070423 |