EP3216979B1 - Systeme de coffrage - Google Patents

Systeme de coffrage Download PDFInfo

- Publication number

- EP3216979B1 EP3216979B1 EP16158965.0A EP16158965A EP3216979B1 EP 3216979 B1 EP3216979 B1 EP 3216979B1 EP 16158965 A EP16158965 A EP 16158965A EP 3216979 B1 EP3216979 B1 EP 3216979B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- formwork

- concrete

- pressure sensors

- pressure

- accordance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000009416 shuttering Methods 0.000 title description 7

- 238000009415 formwork Methods 0.000 claims description 141

- 238000000034 method Methods 0.000 claims description 6

- 230000000712 assembly Effects 0.000 claims description 3

- 238000000429 assembly Methods 0.000 claims description 3

- 238000010276 construction Methods 0.000 claims description 2

- 230000005641 tunneling Effects 0.000 description 4

- 238000007906 compression Methods 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 230000018109 developmental process Effects 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000004458 analytical method Methods 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 230000001276 controlling effect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000014509 gene expression Effects 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 238000000275 quality assurance Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21D—SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND CHAMBERS

- E21D11/00—Lining tunnels, galleries or other underground cavities, e.g. large underground chambers; Linings therefor; Making such linings in situ, e.g. by assembling

- E21D11/04—Lining with building materials

- E21D11/10—Lining with building materials with concrete cast in situ; Shuttering also lost shutterings, e.g. made of blocks, of metal plates or other equipment adapted therefor

- E21D11/105—Transport or application of concrete specially adapted for the lining of tunnels or galleries ; Backfilling the space between main building element and the surrounding rock, e.g. with concrete

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21D—SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND CHAMBERS

- E21D11/00—Lining tunnels, galleries or other underground cavities, e.g. large underground chambers; Linings therefor; Making such linings in situ, e.g. by assembling

- E21D11/04—Lining with building materials

- E21D11/10—Lining with building materials with concrete cast in situ; Shuttering also lost shutterings, e.g. made of blocks, of metal plates or other equipment adapted therefor

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21D—SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND CHAMBERS

- E21D11/00—Lining tunnels, galleries or other underground cavities, e.g. large underground chambers; Linings therefor; Making such linings in situ, e.g. by assembling

- E21D11/04—Lining with building materials

- E21D11/10—Lining with building materials with concrete cast in situ; Shuttering also lost shutterings, e.g. made of blocks, of metal plates or other equipment adapted therefor

- E21D11/102—Removable shuttering; Bearing or supporting devices therefor

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21D—SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND CHAMBERS

- E21D5/00—Lining shafts; Linings therefor

- E21D5/04—Lining shafts; Linings therefor with brick, concrete, stone, or similar building materials

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G21/00—Preparing, conveying, or working-up building materials or building elements in situ; Other devices or measures for constructional work

- E04G21/02—Conveying or working-up concrete or similar masses able to be heaped or cast

Definitions

- the present invention relates to a formwork system, in particular for tunneling, comprising at least one support arrangement for supporting a formwork comprising a plurality of formwork elements, which formwork system has at least one control for the support of the formwork elements and the concrete supply for the space to be concreted.

- Such a formwork system is for example from the European patent 2 626 509 , the DE 28 26 623 A1 , the JP 2008 088696 A , the DE 100 40 777 A1 or the JP 2 932323 B2 known.

- a formwork system in particular for tunneling, known, which comprises at least one support assembly for supporting at least one formwork element, which formwork system further comprises at least one concrete pump, a plurality of concrete feeds to the shuttering element and at least one controller, wherein on the formwork element at least two pressure sensors vertically arranged at different positions and are connected to the control of the formwork system, which pressure sensors are designed to measure the pressure acting on the formwork elements pressure at at least two different heights of the formwork element, and that the control is designed, the pump operation in response to the signal of the pressure sensors to control.

- a formwork system with the features of the preamble of claim 1 is from the post-published EP 3,168,413 A1 known.

- At least two pressure sensors are arranged vertically in different positions on the shuttering element and / or on the support arrangement and connected to the control of the shuttering system.

- the pressure sensors are designed to measure the pressure acting on the formwork elements due to the concrete loaded in the formwork at at least two different heights of the formwork element.

- the control system is designed to control the concrete infeeds individually depending on the signal from the pressure sensors. In this way it is possible to detect the concrete pressure acting at different points on the formwork element or preferably a plurality of formwork elements and the control can compare pressure values measured with nominal values by the pressure sensors and individually control the concrete feed so that the concrete pressure at the different points of the concrete Shuttering elements set specifications. In this way, a concrete wall, in particular a concrete vault with predetermined homogeneous material properties in the entire wall or vault area can be produced.

- the support assembly has at least one hydraulic support beam for supporting the formwork element and the controller is designed to control the force of the support beam in dependence on the pressure measured in the pressure sensors.

- the pressure can thus be regulated not only on the individual concrete supply, but also on the Abstütztik means of the support beams.

- the pressure sensors need not be provided in the formwork itself, but may be disposed on the force receiving elements of the formwork elements, e.g. at the points where the support structure statically supports the formwork element.

- the entire formwork consists of several formwork elements, as is customary in tunneling, one is able to accurately detect the pressure acting on the individual formwork elements pressure on the support points of the formwork elements and the concrete feeders and / or the supporting force of the hydraulic support beams to control or regulate accordingly.

- the pressure sensor is arranged at the connection point between the support beams and the formwork element and / or the support arrangement.

- Such an arrangement is easy to implement, e.g. by per se known force transducer.

- the pressure sensors are distributed uniformly over the entire surface of the wall and thus over the surface of the formwork elements, if several are used. On In this way, a very good pressure distribution of the concrete can be detected on the formwork and possibly readjusted.

- the formwork system includes at least one vibrator, and the controller is designed to control the vibrator as a function of the pressure measured in the pressure sensors.

- the vibrating device can be arranged, for example, in connection with the formwork elements.

- external vibrators can also be provided in connection with the concrete feeders, which influence the viscosity of the supplied concrete.

- a plurality of vibrators are arranged at different locations of the formwork element and the controller is designed to control the vibrator individually as a function of the signals of the pressure sensors.

- the vibrators are arranged evenly distributed over the formwork elements. In this way, a uniform compression can be achieved over the surface of the formwork.

- the controller is designed to control the concrete pump in response to the signals of the pressure sensors.

- Different concrete pumps can be provided for different concrete feeds and the delivery pressure of the concrete pump can be influenced by the pressure exerted by the concrete on the formwork element.

- the at least one concrete pump is connected via at least one distributor device with a plurality of concrete feeders.

- the controller is designed to control the distributor device as a function of the signals from the pressure sensors in order to achieve a homogeneous, predetermined pressure profile and thus desired material properties of the concrete wall created.

- the controller has a screen for displaying the formwork elements and the pressure values measured there.

- a screen for displaying the formwork elements and the pressure values measured there.

- an operator can see which pressure values have been recorded on different parts of the formwork elements and can immediately detect whether the concrete has been supplied in a predetermined manner to the space behind the formwork elements. This is e.g. In the construction of a tunnel vault is extremely important because it must be ensured that the concrete at all points beyond the formwork elements consistently fills the gap between a tunnel wall and the formwork elements and thus is able to meet the required strength properties of the tunnel arch.

- this has at least four formwork elements, which are supported by at least four support beams against the support assembly.

- the four formwork elements are more or less the form the upper semicircle of the tunnel arch.

- the four formwork elements are curved for this purpose and form a vaulted area for a tunnel arch.

- the formwork system preferably has a plurality of horizontally arranged one behind the other support arrangements with their own formwork elements.

- the controller is then designed to control the pressurization of the formwork elements of the individual support arrangements individually as a function of the pressure values of the pressure sensors. In this way, a homogeneous tunnel formwork over a greater length can be produced in one operation, over the area a very good homogeneity of the concrete wall is achieved.

- a concrete wall is constructed in which the pressure acting on the formwork element pressure is determined at different locations by means of pressure sensors and the at least one concrete pump and / or the concrete feed is controlled in response to the signals of the pressure sensors or be.

- care can be taken by the individual control of the concrete feed or the concrete pump (s) that a uniform pressure profile or a predetermined pressure profile over the surface of the formwork elements is achieved, which brings tunnel vault with required strength properties with it.

- the signals of the pressure sensors and vibrators or distribution devices can be controlled between the concrete feeders so as to fill the concrete supply to the individual points between a tunnel wall and the formwork elements as evenly and homogeneously.

- the signals of the pressure sensors are used.

- the signals of other sensors such as e.g. Temperature sensors, optical sensors or chemical sensors for the control of the support assembly, the individual concrete feeders and the vibrators are used.

- the properties of the concrete filled into the formwork can thus be ascertained, evaluated and utilized for the control of the concrete feeders, support arrangement and vibrating devices.

- the controller preferably has a screen, which represents the formwork system area, as well as a Beton Valllan Attache for the different areas of the formwork elements.

- the measured forces are preferably via software evaluated and displayed digitally and visually.

- the controller has an interface for controlling other components, such as a vibrator, as well as for loading the data on external media or on an additional PC. Due to the detected signals of the pressure sensors, the compression control can take place automatically beyond the formwork elements.

- a counter-check is made to the static calculation of the shuttering process.

- the safety for the formwork system as well as for the persons who operate the formwork system is considerably increased. Homogeneous and better tunnel walls are achieved, which optimizes concreting processes.

- the invention achieves the creation of standards compliant concrete walls and vaults.

- the outputs of the controller can also be used for safety systems, if voltage overshoots or pressure peaks at individual points of the formwork elements should be detected.

- the invention contributes to the quality assurance of the building.

- An essential aspect of the invention is that on the targeted control of the concrete pump and / or the concrete supply and / or the at least one vibrating the compression processes of the concrete beyond the formwork elements can be controlled specifically and individually, thus desired material properties of the finished concrete wall or achieve the finished concrete vault.

- a tunnel formwork system usually has a plurality of formwork elements, e.g. four formwork elements distributed over the vault sector and three to six support assemblies in a row, each with four formwork elements, so that in total the system preferably has between ten and fifty formwork elements.

- Fig. 1 shows a tunnel formwork system 10 according to the invention, which is located in a broken tunnel vault 12.

- the tunnel formwork system 10 comprises a support arrangement 14 for supporting a formwork 15, which consists of articulated interconnected formwork elements 16-26 whose outer side is slightly curved and the tunnel vault 12 assigns. Between the outside of the formwork elements 16-26 and the tunnel vault or the Tunneln 12 a void 28 is formed, which is filled with concrete 13.

- the support assembly 14 includes hydraulic support beams 30 to support the formwork members 16-26 with a predetermined pressure against the filled concrete 13.

- the formwork system 10 according to the invention is controlled by a central controller 32, which preferably has a screen 34 for displaying the formwork system of the associated measured values.

- the formwork system 10 further comprises a concrete feed pump 36 with a manifold 38 and concrete pipes 40, which run to individual concrete feeders 42, which in the Fig. 2 and 5 are shown in more detail.

- the central controller 32 is connected to pressure sensors 44, as well as with temperature sensors or Ultrasonic transducer 46, which detect both the pressure acting on the formwork elements 16-26 pressure due to the filled concrete and the temperature of the concrete, so as to give the central control 32 feedback, on the one hand on the density and the degree of filling of the concrete in the space between the Outside of the formwork elements 16-26 and the tunnel wall 12 as well as the chemical reaction in the setting of the concrete, which is associated with a heat generation or a change in density.

- the controller is also connected to a concrete analysis device 48, which evaluates, for example, the setting behavior of a concrete sample and possibly its strength in order to conclude conclusions about the strength and the concrete between the formwork elements 16-26 and the tunnel wall can.

- the controller 32 is of course connected to the concrete pump 36, as well as to the distribution device 38. Furthermore, the controller preferably has a USB port 50, as well as a wireless port 52, such as Wi-Fi® or Bluetooth®.

- a USB port 50 as well as a wireless port 52, such as Wi-Fi® or Bluetooth®.

- Fig. 3 also shows the formwork system 10 Fig. 1 , here the connection of the central controller 32 with vibrators 54 is shown.

- the central controller 32 can individually control the individual vibrators 54 as a function of the sensor values in order to effect a targeted compaction of the concrete in the different regions of the tunnel wall 12, in order to ensure as homogeneous a concrete quality as possible over the entire tunnel wall 12.

- Fig. 4 shows the connection of the central controller 32 with mirror difference sensors 56, which may be, for example, pressure sensors, optical sensors, thermal sensors, ultrasonic sensors or chemical sensors. These mirror-difference sensors 56 are uniformly distributed over the outside of the formwork elements 16-26. In this way, it is easily possible, a different level h1, h2 of the concrete 13 on the two sides of the To detect the tunnel wall and to ensure by individual control of the concrete feeders 42 and vibrator 54 that the filling level is even on both sides or is compensated.

- mirror difference sensors 56 may be, for example, pressure sensors, optical sensors, thermal sensors, ultrasonic sensors or chemical sensors.

- Fig. 5 shows the connection of the central controller 32 with the individual concrete feeders 42.

- the concrete pump 36 and the manifold 38 and other unillustrated distribution elements, such as shut-off valves it is possible to supply the concrete specifically to the individual concrete feeders 42 so as to be homogeneous To reach concrete feed.

- Fig. 6 shows the connection of the central controller 32 with pressure transducers 58, which extend evenly over the upper portion of the tunnel formwork, ie on the upper formwork elements 20-24, so that it can be verified by this arrangement of pressure sensors 58, whether the concrete 13 between the tunnel wall 12 and the outside of the formwork elements 16-26 is actually completely filled, which is reflected in corresponding pressure values.

- These pressure sensors can also be designed as hydraulic cylinders that deliver a controllable support pressure for the formwork elements.

- These pressure sensors 58 can therefore also be used for pressure control of the support pressure of the formwork elements 20 to 24.

- FIG. 7 a plan view of the formwork system according to the invention according to the Fig. 1-6 , but in isolation, ie not in operating position in a tunnel vault 12.

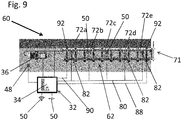

- Fig. 8 shows a formwork system 60 for the production of straight walls.

- the formwork system 60 includes a support assembly 62, a central controller 32 with a display 34, a concrete pump 36, possibly a manifold, not shown, optionally a concrete analyzer 48 and a number of planar formwork members 72-78 arranged one above the other and side by side are so as to form a wall of desired size.

- the controller is connected via a first control line 80 with concrete feeders 82. Via a second control line 84, the controller 32 is connected to a temperature sensor or ultrasonic sensor 86. Via a third control line 88 and a fourth control line 90, the controller 32 is connected to pressure transducers 92. To this The central controller 32 detects the pressure conditions as well as the temperature conditions on the concrete 13 side facing the formwork 71, which is formed from the individual shuttering elements 72-78.

- Fig. 9 shows the formwork system 60 Fig. 8 in supervision. It should be noted here that in the figures identical or functionally identical parts are provided with identical reference numerals.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Geology (AREA)

- Mechanical Engineering (AREA)

- Lining And Supports For Tunnels (AREA)

- On-Site Construction Work That Accompanies The Preparation And Application Of Concrete (AREA)

Claims (14)

- Système de coffrage (10 ; 60), en particulier pour la construction de tunnels, comprenant au moins un ensemble d'appui (14) destiné au support d'au moins un élément de coffrage (16-26 ; 72-78), lequel système de coffrage comprend également au moins une pompe à béton (36), plusieurs alimentations en béton (42) conduisant à l'élément de coffrage et au moins une commande (32), au moins deux capteurs de pression (44 ; 92) étant, sur l'élément de coffrage (16-26 ; 72-78) et/ou sur l'ensemble d'appui (14), disposés au niveau de positions différentes verticales et raccordés à la commande (32) du système de coffrage, lesquels capteurs de pression (44 ; 92) sont conçus pour mesurer la pression agissant sur les éléments de coffrage (16-26 ; 72-78) au niveau d'au moins deux hauteurs différentes de l'élément de coffrage, la commande (32) étant conçue pour commander les alimentations en béton (42) individuellement en fonction du signal des capteurs de pression (44 ; 92), et l'ensemble d'appui (14) comportant au moins un support d'appui (30) hydraulique destiné au support de l'élément de coffrage (16-26 ; 72-78), la commande (32) étant conçue pour commander la force du support d'appui (30) en fonction des valeurs de pression mesurées avec les capteurs de pression (44 ; 92), caractérisé en ce que le système de coffrage comprend au moins un dispositif vibreur (54), et en ce que la commande (32) est conçue pour commander le dispositif vibreur (54) en fonction des valeurs de pression mesurées avec les capteurs de pression (44 ; 92).

- Système de coffrage (10 ; 60) selon la revendication 1, caractérisé en ce qu'au moins un des capteurs de pression (44 ; 92) est disposé sur le point de raccordement entre le support d'appui (30) et l'élément de coffrage (16-26 ; 72-78) et/ou l'ensemble d'appui (14).

- Système de coffrage (10 ; 60) selon la revendication 1 ou 2, caractérisé en ce que plusieurs capteurs de pression (44 ; 92) sont disposés de façon répartie à plat sur l'élément de coffrage (16-26 ; 72-78).

- Système de coffrage (10 ; 60) selon l'une des revendications précédentes, caractérisé en ce que plusieurs capteurs de pression (44 ; 92) sont disposés entre l'élément de coffrage (16-26 ; 72-78) et l'ensemble d'appui (14).

- Système de coffrage (10 ; 60) selon l'une des revendications précédentes, caractérisé en ce que plusieurs dispositifs vibreurs (54) sont disposés à différents endroits de l'élément de coffrage (16-26 ; 72-78), et en ce que la commande (32) est conçue pour commander les dispositifs vibreurs individuellement en fonction des signaux des capteurs de pression (44 ; 92).

- Système de coffrage (10 ; 60) selon l'une des revendications précédentes, caractérisé en ce que le dispositif vibreur (54) est disposé dans une alimentation en béton.

- Système de coffrage (10 ; 60) selon l'une des revendications précédentes, caractérisé en ce que la commande (32) est conçue pour commander la pompe à béton (36) en fonction des signaux des capteurs de pression (44 ; 92).

- Système de coffrage (10 ; 60) selon la revendication 7, caractérisé en ce que la pompe à béton (36) au moins au nombre de un est raccordée aux alimentations en béton (42) par le biais d'au moins un dispositif de distribution (38), et en ce que la commande (32) est conçue pour commander le dispositif de distribution (38) en fonction des signaux des capteurs de pression (44 ; 92).

- Système de coffrage (10 ; 60) selon l'une des revendications précédentes, caractérisé en ce que la commande (32) comporte un écran (34) destiné à la représentation des éléments de coffrage (16-26 ; 72-78) et des valeurs de pression qui y sont mesurées.

- Système de coffrage (10 ; 60) selon l'une des revendications précédentes, caractérisé en ce qu'il comprend au moins quatre éléments de coffrage (16-26 ; 72-78) qui sont supportés par au moins quatre cylindres d'appui (30) contre l'ensemble d'appui (14).

- Système de coffrage (10 ; 60) selon la revendication 10, caractérisé en ce que les éléments de coffrage (16-26) sont bombés et forment un coffrage (15) pour une voûte de tunnel.

- Système de coffrage (10 ; 60) selon l'une des revendications précédentes, caractérisé en ce qu'il contient plusieurs ensembles d'appui (14) disposés les uns derrière les autres horizontalement avec des éléments de coffrage (16-26 ; 72-78) propres, et en ce que la commande (32) est conçue pour commander l'application de la pression sur les éléments de coffrage des ensembles d'appui (14) individuels en fonction des valeurs de pression des capteurs de pression (44 ; 92).

- Procédé de construction d'une paroi en béton avec un système de coffrage (10 ; 60) selon l'une des revendications précédentes, la pression de béton qui agit sur l'élément de coffrage (16-26 ; 72-78) étant déterminée en différents endroits au moyen des capteurs de pression (44 ; 92), et la pompe à béton (36) au moins au nombre de un et/ou les alimentations en béton (42) étant commandée(s) en fonction des signaux des capteurs de pression (44 ; 92), caractérisé en ce qu'au moins un dispositif vibreur (54) est commandé en fonction des signaux des capteurs de pression (44 ; 92).

- Procédé selon la revendication 13, caractérisé en ce qu'au moins un dispositif de distribution entre les alimentations en béton (42) est commandé en fonction des signaux des capteurs de pression (44 ; 92).

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP16158965.0A EP3216979B1 (fr) | 2016-03-07 | 2016-03-07 | Systeme de coffrage |

| US15/450,799 US9945229B2 (en) | 2016-03-07 | 2017-03-06 | Formwork system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP16158965.0A EP3216979B1 (fr) | 2016-03-07 | 2016-03-07 | Systeme de coffrage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3216979A1 EP3216979A1 (fr) | 2017-09-13 |

| EP3216979B1 true EP3216979B1 (fr) | 2019-05-08 |

Family

ID=55484918

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16158965.0A Active EP3216979B1 (fr) | 2016-03-07 | 2016-03-07 | Systeme de coffrage |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US9945229B2 (fr) |

| EP (1) | EP3216979B1 (fr) |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6737462B2 (ja) * | 2016-05-31 | 2020-08-12 | 戸田建設株式会社 | 覆工コンクリート類の充填検知方法及びコンクリート類の充填検知センサ |

| CN107448217A (zh) * | 2017-09-25 | 2017-12-08 | 中铁十七局集团第工程有限公司 | 一种实用隧道衬砌台车振捣系统 |

| JP7179436B2 (ja) * | 2017-10-24 | 2022-11-29 | 株式会社フジタ | 防水シート |

| JP6975611B2 (ja) * | 2017-10-24 | 2021-12-01 | 株式会社フジタ | 防水シート |

| JP6969999B2 (ja) * | 2017-12-14 | 2021-11-24 | 株式会社フジタ | コンクリート打設型枠 |

| JP6983055B2 (ja) * | 2017-12-21 | 2021-12-17 | 株式会社フジタ | 覆工コンクリート打設装置 |

| JP6970004B2 (ja) * | 2017-12-21 | 2021-11-24 | 株式会社フジタ | 覆工コンクリート打設装置 |

| JP7182899B2 (ja) * | 2018-04-25 | 2022-12-05 | 清水建設株式会社 | トンネル覆工施工管理システム、トンネル覆工施工管理方法 |

| DE102018111120A1 (de) * | 2018-05-09 | 2019-11-14 | J. Wagner Gmbh | Verfahren zum Betrieb einer Fördervorrichtung und Fördervorrichtung |

| JP7018614B2 (ja) * | 2018-08-03 | 2022-02-14 | 株式会社奥村組 | コンクリート構造物における誘発目地の形成方法 |

| JP7018615B2 (ja) * | 2018-08-06 | 2022-02-14 | 株式会社奥村組 | トンネル覆工コンクリートの天端部打設方法 |

| JP7153266B2 (ja) * | 2018-10-01 | 2022-10-14 | 清水建設株式会社 | トンネル覆工施工システム、トンネル覆工施工方法 |

| PL3663484T3 (pl) * | 2018-12-04 | 2022-11-07 | Peri Se | Układ i sposób do przesyłania danych do przeprowadzania analizy nacisku na element szalunkowy |

| JP7100896B2 (ja) * | 2019-02-28 | 2022-07-14 | 有限会社 伊藤 | セントルにおける車輪ユニットの取り付け方法及びセントルの車輪ユニット案内装置 |

| DE102019108781A1 (de) | 2019-04-03 | 2020-10-08 | Peri Gmbh | Computergestütztes Verfahren und Einrichtung zur optimierten Steuerung der Förderleistung einer Betonpumpe oder dergleichen |

| US11402287B2 (en) | 2019-09-10 | 2022-08-02 | Structural Group, Inc. | Mechanical formwork pressure sensor for in-situ measurement of fluid pressure during concrete matertal placement and method of using the same |

| CN110486055A (zh) * | 2019-09-11 | 2019-11-22 | 刘怀福 | 一种隧道二衬混凝土浇筑防脱空振捣控制装置及方法 |

| CN110656958B (zh) * | 2019-10-15 | 2021-02-26 | 中铁五局集团第一工程有限责任公司 | 一种平稳式施工装置 |

| CN110645019B (zh) * | 2019-10-15 | 2021-02-26 | 中铁五局集团第一工程有限责任公司 | 一种集成式隧道施工设备 |

| CN110645020B (zh) * | 2019-10-15 | 2021-02-26 | 中铁五局集团第一工程有限责任公司 | 一种施工设备行走方法 |

| DE102019127693A1 (de) | 2019-10-15 | 2021-04-15 | Putzmeister Engineering Gmbh | Steuerarmatur, Anordnung und Verfahren zur Herstellung von Betonbauteilen |

| CN110617070B (zh) * | 2019-10-15 | 2020-12-11 | 中铁五局集团第一工程有限责任公司 | 一种隧道施工方法 |

| CN111022074B (zh) * | 2019-10-28 | 2021-08-03 | 中国人民解放军96782部队 | 一种全液压控制泵控分离的钢模台车 |

| CN110987161A (zh) * | 2019-12-16 | 2020-04-10 | 辽宁工程技术大学 | 一种矿用吸能防冲巷道支架频率检测装置 |

| DE102019219918A1 (de) * | 2019-12-17 | 2021-06-17 | Peri Gmbh | Schalungsplatte für eine Schalungsvorrichtung |

| CN110924988B (zh) * | 2019-12-20 | 2021-03-23 | 浙江正方交通建设有限公司 | 隧道二衬混凝土溜槽浇筑体系及施工方法 |

| CN112392508B (zh) * | 2020-11-06 | 2023-06-23 | 湖南五新模板有限公司 | 一种防上浮仰拱模板装置 |

| CN112502745A (zh) * | 2020-12-15 | 2021-03-16 | 中国铁建重工集团股份有限公司 | 一种浇筑系统及衬砌台车 |

| CN114704086B (zh) * | 2022-04-06 | 2024-02-20 | 河南省中创建筑工程有限公司 | 一种模板装置 |

| CN115354849B (zh) * | 2022-08-30 | 2023-06-23 | 河南省水利第一工程局 | 滑动模板智能控制系统及方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3168413A1 (fr) * | 2015-11-16 | 2017-05-17 | ÖSTU-STETTIN Hoch- und Tiefbau GmbH | Dispositif et procédé de soutènement d'un tunnel |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1591907A (en) * | 1925-08-01 | 1926-07-06 | Harvey J Yager | Collapsible and portable core form |

| US2213159A (en) * | 1937-07-23 | 1940-08-27 | Trussed Concrete Steel Co | Concrete form |

| US2705359A (en) * | 1953-05-28 | 1955-04-05 | Strandberg Arthur Beck | Monolithic building construction |

| DE1434325A1 (de) * | 1961-05-17 | 1968-10-24 | Josef Boessner | Schalungshaut fuer eine Kletterschaltung und Verfahren zur Herstellung turmartiger Bauwerke aus Beton |

| GB1142313A (en) * | 1965-02-19 | 1969-02-05 | Byggforbattring Ab | A method of sliding-mould concrete casting, and a sliding mould for use in such casting |

| US3775929A (en) * | 1971-06-11 | 1973-12-04 | Laser Alignment | Method for installing ceilings |

| US3973885A (en) * | 1973-03-07 | 1976-08-10 | Enor Nominees Pty. Limited | Apparatus for progressively constructing a wall of cementitious material |

| US4126407A (en) * | 1975-07-09 | 1978-11-21 | Ahlgren Nils H | Methods of shifting heavy and/or loaded structures |

| US4040774A (en) * | 1976-04-29 | 1977-08-09 | Research-Cottrel, Inc. | Apparatus for constructing concrete walls |

| US4505622A (en) * | 1977-05-17 | 1985-03-19 | Magyar Szenbanyaszati Troszt | Process and arrangement for the support of underground cavity systems by an efficient safety casing wall |

| SE432792B (sv) * | 1982-04-01 | 1984-04-16 | Dynapac Maskin Ab | Forfarande och anordning for att astadkomma optimal packningsgrad vid packning av olika material sasom asfalt, jord etc medelst en vibrerande velt |

| DE3406980C1 (de) * | 1984-02-25 | 1985-04-04 | Hochtief Ag Vorm. Gebr. Helfmann, 4300 Essen | Verfahren und Vorrichtung zum fortlaufenden Auskleiden eines Tunnels mit Ortbeton |

| DE3826623A1 (de) * | 1988-08-05 | 1990-02-08 | Schlecht Karl | Verfahren und vorrichtung zur ueberwachung, steuerung und/oder regelung des fuelldrucks bei der tunnelbetonierung |

| US4930935A (en) * | 1988-12-29 | 1990-06-05 | David W. Somero | Screeding apparatus and method |

| US4974700A (en) * | 1989-06-12 | 1990-12-04 | Gates & Sons, Inc. | Movable support mechanism for construction of elevator shafts and the like |

| JP2932323B2 (ja) * | 1991-08-06 | 1999-08-09 | 清水建設株式会社 | シールド掘進機 |

| SE501234C2 (sv) * | 1993-04-29 | 1994-12-12 | Thurner Geodynamik Ab | Förfarande och anordning för mätning och dokumentation av packningsresultat och styrning av en vält vid packning av ett utlagt underlag |

| US5471391A (en) * | 1993-12-08 | 1995-11-28 | Caterpillar Inc. | Method and apparatus for operating compacting machinery relative to a work site |

| JP2842855B2 (ja) * | 1996-02-22 | 1999-01-06 | 株式会社東洋テクノス | セミシールド工法における長距離推進工法及び装置 |

| US5991687A (en) * | 1997-07-02 | 1999-11-23 | Case Corporation | System and method for communicating information related to a geographical area |

| US6188942B1 (en) * | 1999-06-04 | 2001-02-13 | Caterpillar Inc. | Method and apparatus for determining the performance of a compaction machine based on energy transfer |

| DE10040777A1 (de) * | 2000-08-21 | 2002-03-07 | Tachus Gmbh | Verfahren und Maschine für den Tunnelbau, Schalelement und Schalsystem |

| CA2354226A1 (fr) * | 2001-01-31 | 2002-07-31 | Cal Holland | Appareil robotique et methode d'entretien non destructif de canalisations croisees |

| JP4669173B2 (ja) * | 2001-09-05 | 2011-04-13 | 酒井重工業株式会社 | 振動型締固め車両における締固め度管理装置 |

| US6880643B1 (en) * | 2002-02-07 | 2005-04-19 | Novariant, Inc. | System and method for land-leveling |

| JP2003270080A (ja) * | 2002-03-15 | 2003-09-25 | Hitachi Industries Co Ltd | 振動試験装置および振動試験方法 |

| US7731450B2 (en) * | 2006-09-07 | 2010-06-08 | Caterpillar Inc. | Method of operating a compactor machine via path planning based on compaction state data and mapping information |

| JP2008088696A (ja) * | 2006-10-02 | 2008-04-17 | Maeda Corp | トンネル覆工の施工方法 |

| DE102007018743A1 (de) * | 2007-04-22 | 2008-10-23 | Bomag Gmbh | Verfahren und System zur Steuerung von Verdichtungsmaschinen |

| JP2009155819A (ja) * | 2007-12-25 | 2009-07-16 | Kajima Corp | トンネル内の覆工コンクリート打設装置 |

| US8142103B2 (en) * | 2009-02-20 | 2012-03-27 | Caterpillar Trimble Control Technologies Llc | Wireless sensor with kinetic energy power arrangement |

| DE102011076131A1 (de) * | 2011-05-19 | 2012-11-22 | Hamm Ag | System zur Bereitstellung von einen Vibrationszustand repräsentierenden Informationen für den Betrieb vibrationsemittierender Maschinen, insbesondere Baumaschinen |

| GB2498524B (en) * | 2012-01-17 | 2016-07-27 | M3 Group Ltd | Tunnel Lining |

| EP2626509B1 (fr) | 2012-02-08 | 2015-04-08 | Kern Tunneltechnik SA | Appareillage de coffrage |

| EP2981649B1 (fr) * | 2013-04-02 | 2019-04-24 | Roger Arnold Stromsoe | Dispositif et procédé de compactage de sol |

-

2016

- 2016-03-07 EP EP16158965.0A patent/EP3216979B1/fr active Active

-

2017

- 2017-03-06 US US15/450,799 patent/US9945229B2/en active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3168413A1 (fr) * | 2015-11-16 | 2017-05-17 | ÖSTU-STETTIN Hoch- und Tiefbau GmbH | Dispositif et procédé de soutènement d'un tunnel |

Also Published As

| Publication number | Publication date |

|---|---|

| US9945229B2 (en) | 2018-04-17 |

| US20170254202A1 (en) | 2017-09-07 |

| EP3216979A1 (fr) | 2017-09-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3216979B1 (fr) | Systeme de coffrage | |

| DE19652811B4 (de) | Verfahren und Einrichtung zum Beschichten von Tunnelinnenwänden mit Spritzbeton | |

| EP2927372B1 (fr) | Engin automobile et procédé de commande d'un engin automobile | |

| EP1727964B1 (fr) | Avancement d'elements tubulaires dans un terrain | |

| EP3168413B1 (fr) | Dispositif et procédé de soutènement d'un tunnel | |

| EP3112542A1 (fr) | Dispositif et procede de couplage thermique de parties betonnees de batiment | |

| DE102015106296A1 (de) | Wärmedämmelement | |

| EP4118023A1 (fr) | Procédé de formation d'une structure de guidage pour guider une cabine d'ascenseur dans une gaine d'ascenseur | |

| EP3513039B1 (fr) | Procédé d'évaluation de signaux de mesure | |

| DE102016124106A1 (de) | Einstellung des verdichtungsaufwands unter verwendung von vibrationssensoren | |

| EP2354344B1 (fr) | Dispositif de montage d'une poutre porteuse en porte-à-faux sur un bâtiment | |

| DE202009010486U1 (de) | Schalldämmwand aus Gabionen mit Kern aus Holzspannbeton | |

| EP3296476A1 (fr) | Dispositif de liaison d'un mur de bâtiment à une dalle de sol ou de plafond et élément de moulage d'un tel système | |

| DE2700594A1 (de) | Verbau fuer eine baugrubenwand und verfahren zur herstellung | |

| DE3407938A1 (de) | Verfahren und vorrichtung zum pruefen bzw. verfestigen des baugrundes bei bohrpfaehlen | |

| CH715137A2 (de) | Verfahren und Vorrichtung zum Ausbau von Hohlräumen unter Tage. | |

| EP3460134B1 (fr) | Dispositif de raccordement par transmission de force entre deux éléments constructifs | |

| WO2010075855A1 (fr) | Système de goujon pour construction en béton | |

| AT16064U1 (de) | Wandkonstruktion | |

| DE19504235A1 (de) | Verfahren zur Herstellung von wärmeisolierten Tafeln für die Großtafelbauweise | |

| AT513020B1 (de) | Halbfertig-Bauteil zum Erstellen von Bauwerken | |

| EP2591353B1 (fr) | Dispositif et procédé de caractérisation in situ des paramètres de qualité et/ou des propriétés de systèmes de liants inorganiques | |

| AT523597A2 (de) | Schalungssystem, Ankervorrichtung, Ankerstab, Verwendung eines Ankerstabs und Verfahren | |

| DE102020132151A1 (de) | Verfahren und Vorrichtung zur additiven Fertigung von Bauwerken oder Bauteilen von Bauwerken | |

| EP3123867B1 (fr) | Procede et dispositif d'orientation simplifiee d'une machine de remplissage pour la fabrication de saucisses |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20170925 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20180711 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20181219 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 1130404 Country of ref document: AT Kind code of ref document: T Effective date: 20190515 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502016004507 Country of ref document: DE |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: KERN TUNNELTECHNIK SA |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20190508 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190908 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190808 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190808 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190809 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502016004507 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| 26N | No opposition filed |

Effective date: 20200211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200307 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200307 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190508 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190908 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20240321 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240326 Year of fee payment: 9 Ref country code: GB Payment date: 20240320 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240328 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20240401 Year of fee payment: 9 |