EP3205770B2 - Aiguillage et procédé de fabrication d'un tel aiguillage - Google Patents

Aiguillage et procédé de fabrication d'un tel aiguillage Download PDFInfo

- Publication number

- EP3205770B2 EP3205770B2 EP17000227.3A EP17000227A EP3205770B2 EP 3205770 B2 EP3205770 B2 EP 3205770B2 EP 17000227 A EP17000227 A EP 17000227A EP 3205770 B2 EP3205770 B2 EP 3205770B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rail

- support blocks

- stock rail

- stock

- tongue

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 12

- 238000010438 heat treatment Methods 0.000 claims description 83

- 238000003466 welding Methods 0.000 claims description 15

- 239000000945 filler Substances 0.000 claims description 10

- 238000003754 machining Methods 0.000 claims description 6

- 238000000034 method Methods 0.000 claims description 5

- 229910001220 stainless steel Inorganic materials 0.000 claims description 3

- 239000010935 stainless steel Substances 0.000 claims description 3

- 229910000831 Steel Inorganic materials 0.000 claims description 2

- 239000010959 steel Substances 0.000 claims description 2

- 230000001276 controlling effect Effects 0.000 claims 1

- 230000001105 regulatory effect Effects 0.000 claims 1

- 238000010276 construction Methods 0.000 description 3

- 230000000284 resting effect Effects 0.000 description 3

- 239000004020 conductor Substances 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 238000003892 spreading Methods 0.000 description 2

- FGRBYDKOBBBPOI-UHFFFAOYSA-N 10,10-dioxo-2-[4-(N-phenylanilino)phenyl]thioxanthen-9-one Chemical compound O=C1c2ccccc2S(=O)(=O)c2ccc(cc12)-c1ccc(cc1)N(c1ccccc1)c1ccccc1 FGRBYDKOBBBPOI-UHFFFAOYSA-N 0.000 description 1

- 229910000746 Structural steel Inorganic materials 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 239000004035 construction material Substances 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000013067 intermediate product Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000010327 methods by industry Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 210000005182 tip of the tongue Anatomy 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B7/00—Switches; Crossings

- E01B7/02—Tongues; Associated constructions

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B7/00—Switches; Crossings

- E01B7/24—Heating of switches

Definitions

- the invention relates to a switch device of the flat bed type for a switch system, with a base plate, a stock rail, a side rail and a sliding plate provided between the stock rail and the side rail for the switch of a switch rail, and a method for producing a switch device.

- a tongue device of the type mentioned has been known from practice for a long time.

- a special rail profile for example the special rail profile 75C1, whose old designation is BA75, is regularly used for the stock rail.

- the special rail profile is processed to create the stock rail.

- the leg of the groove is removed in the central area of the rail profile.

- the sliding plate rests on one side on a shoulder of the auxiliary rail, while on the opposite side it rests on a shoulder on the rail web of the stock rail.

- the known switch device is manufactured in such a way that first the stock rail with the sliding plate and the auxiliary rail are assembled using templates provided for this purpose. Then the welding takes place.

- the known tongue device has a number of disadvantages.

- the special rail profile required for the stock rail is comparatively expensive.

- the special rail profile is only produced in one quality. If a different quality is required for specific applications, the well-known special rail profile cannot ultimately be used. As a rule, a stock rail is then made from a solid block of appropriate quality, which is also relatively expensive.

- a switching device of the type mentioned in the opening paragraph in which a sliding plate is provided which extends at least over a substantial part of the length of the switching device, is a so-called flatbed switching device or a switching device of the flatbed type Tongue rail used, for example of the tongue profile type Fz 36.

- the continuous sliding plate is supported on a projection of the special rail profile of the stock rail on one side and on a corresponding projection of the auxiliary rail.

- the width of the switch device ie the space between the stock rail and the auxiliary rail, is comparatively small.

- the gap from the sliding plate to the top of the tongue assembly is "flat", hence the name "flat bed”.

- a switch device of the "deep bed” type differs from the flat bed type switch device.

- a machined standard rail is generally used as the stock rail.

- a larger and, in particular, higher tongue profile is used in the deep-bed switch mechanism, for example the 49E1A1 tongue profile.

- the switch does not lie on a sliding plate, but rather on individual sliding blocks or blocks spaced apart from one another. The distance from the top of the slide chairs to the top of the switch device is significantly lower than that of the flatbed switch device.

- the object of the present invention is to provide a switch device, in particular of the flat-bed type, that is to say with a sliding plate, which is simple and inexpensive to produce.

- the invention is based on a prior art flatbed switch device, which is characterized by a continuous sliding plate, in which the sliding plate rests on the side rail and on a projection of the special profile stock rail.

- the implementation of the support blocks according to the invention provides a support option for the sliding plate, so that it is no longer necessary to support the sliding plate on the stock rail.

- a support on the side rail can also be dispensed with.

- a special rail profile is not required to manufacture the stock rail. Although such a profile can be used become.

- the sliding plate is supported according to a different principle.

- a very important advantage resulting from the invention is that the stock rail can be produced from a standard rail profile by machining. If the switch device is a grooved rail switch device, a standard grooved rail profile, in particular type 60R2, can be used. Such a standard rail profile is not only significantly cheaper than a special rail profile, it can also - unlike the special rail profile - be obtained in any quality.

- the switch device In connection with the switch device according to the invention, it has been found that it makes sense to provide a plurality of support blocks distributed over the length of the switch device.

- the exact number ultimately depends on the length of the tongue device.

- the number of support blocks is between 5 and 12 per switch device.

- the support blocks are usually equally spaced. Exceptions only arise if a different arrangement is to be chosen for structural reasons. This is the case, for example, when the sliding plate has to be divided, as is the case, for example, in the area of the drive of the tongue tip of the tongue rail.

- the individual support blocks are relatively easy to assemble.

- the support blocks extend at least substantially perpendicularly away from the auxiliary rail in the direction of the stock rail. Due to the changing distance between the auxiliary rail and the stock rail, the individual support blocks can have different dimensions. For example, cube-like shapes are also provided, as well as cuboid configurations. Viewed from above, the individual support blocks usually have a square to trapezoidal shape. The trapezoidal shape is due to the curved course of the stock rail relative to the auxiliary rail.

- a through opening is provided between two adjacent support blocks.

- a corresponding passage opening should be provided between all the support blocks.

- This through-opening which preferably has a triangular or trapezoidal opening area when viewed from above, should preferably be designed in such a way that it runs at least essentially parallel to the respective component with its edge areas each facing a component. Furthermore, the majority of the area between two support blocks and the associated area between the auxiliary rail and the stock rail should be filled with the through opening. The reason for this is that the through-opening enables the areas of the aforementioned components, and in particular the stock rail, that face the through-opening to be welded very well. This is discussed in more detail below in connection with the production process.

- each of the support blocks provided is welded at the respective end faces on one side to the auxiliary rail and on the other side to the stock rail.

- the support block is attached exclusively via a welded connection.

- the support block is also screwed to the stock rail and otherwise welded. This is also discussed in more detail in connection with the manufacturing process.

- At least one screw opening which can preferably have a thread, is preferably provided on the end face of the support block facing the stock rail.

- at least one through-opening is preferably provided in the rail web of the stock rail, which enables screwing to the stock rail.

- this can also be a slot opening in order to compensate for any play that may have occurred.

- the aforementioned screw connection serves in particular to precisely maintain the expansion dimensions of the tongue device according to the invention.

- at least one filler piece is provided for arrangement between the end face on the stock rail side and the stock rail.

- the stock rail foot preferably has at least one recess in the area of one of the associated support blocks, which can extend to the rail web.

- the recess makes it possible to place the stock rail as a whole on the base plate and to push it up to the respective end faces of the support blocks. The stock rail is then screwed to the support blocks as described above.

- a heating device to be provided on the auxiliary rail.

- the heating device which is assigned a control device, if necessary with a temperature sensor, can ensure proper functioning of the tongue device according to the invention, especially in winter.

- the heating device which is preferably integrated into the auxiliary rail, can ensure that icing of the switch device, which can lead to blocking of the switch rail of the switch device, is avoided.

- the heating device assigned to the auxiliary rail can generate such thermal energy that the tongue rail is prevented from freezing to the sliding plate.

- the assignment of the heating device to the auxiliary rail makes sense here, since the auxiliary rail preferably forms the support for the sliding plate, so that thermal energy emitted by the heating device is transferred from the auxiliary rail to the sliding plate by thermal conduction.

- the heating device it is possible for the heating device to be controlled manually via appropriate switches.

- a sensor device that is assigned to the heating device in addition to or as an alternative to the manual control of the heating device.

- the sensor device preferably has at least one temperature sensor, which is used to measure the outside temperature and/or the temperature on the switch device, in particular on the sliding bed and/or the switch rail. If the temperature falls below a predetermined value, the heating device is put into operation or switched on. If, on the other hand, an upper limit temperature is reached, the heating device can be shut down or switched off, so that the energy consumption of the heating device can be kept as low as possible.

- the heating device is preferably designed as an electric heater, as a gas heater or as a geothermal heater. With a heating device designed in this way, reliable heating of the tongue device can be guaranteed as a result.

- the heating device has at least one heating pipe running along the auxiliary rail.

- the corresponding heating medium can then be guided in this heating tube.

- a corresponding resistance ladder is provided in the case of an electrical heater.

- the heating tube is preferably made of steel, in particular stainless steel.

- the heating tube preferably extends over the entire length of the auxiliary rail, but in particular at least over the length of the sliding plate. This ensures that the auxiliary rail and thus also the sliding plate is/are heated not only partially, but over their entire length.

- a recess extending along the side rail is provided in the side rail, in which the heating tube is accommodated.

- the depth of the recess is greater than or equal to the diameter of the heating tube.

- the cross section of the recess is at least partially adapted to the shape of the heating tube, so that the heating tube arranged in the recess bears flat against the auxiliary rail at least partially. It is particularly preferred in this context if the recess is U-shaped at its bottom or base, with the diameter of the bottom or base corresponding at least essentially to the diameter of the heating pipe. Ultimately, this results in a comparatively large contact surface between the heating pipe and the auxiliary rail, which promotes the transfer of heat from the heating pipe to the auxiliary rail.

- the recess in the auxiliary rail is provided on the underside and/or on the side of the auxiliary rail facing the stock rail. This configuration ensures that the heating pipe is arranged between the auxiliary rail or at least one leg of the auxiliary rail and the stock rail.

- the heating device is not accessible from the outside, so that there is no risk of the heating pipe being damaged by external influences.

- a preferred embodiment of the invention also provides for the heating tube to rest on the base plate at least in certain areas.

- the heating device can thus be used not only to deliver thermal energy to the auxiliary rail, but also to the base plate.

- the heat energy given off to the base plate can also be transferred to the slide plate by heat conduction via the stock rail.

- the heating tube is part of the assembly formed by the base plate, the support blocks of the auxiliary rail and the sliding plate. In this case, if support blocks are provided, the heating tube is arranged between the respective support blocks and the auxiliary rail.

- the heating tube bears against the support blocks at least in some areas.

- a part of the thermal energy of the heating device is then thermally conducted via the support blocks to the sliding plate, since the sliding plate ultimately rests not only on the auxiliary rail but also on the supporting blocks.

- Process engineering is in the method according to the invention for the production of the tongue device provided according to claim 1 to provide the sliding plate between the stock rail and the auxiliary rail, wherein between the stock rail and the auxiliary rail the plurality of support blocks resting on the base plate and separate from the stock rail and the auxiliary rail are provided, the sliding plate extending over the plurality of support blocks extends and rests on the plurality of support blocks, the base plate, the support blocks, the auxiliary rail and the sliding plate being first welded together to form an assembly.

- the invention also relates to an assembly of the aforementioned type for a tongue device.

- the assembly according to the invention differs from the prior art in particular in that the assembly lacks a stock rail.

- the assembly is an independent intermediate product that only becomes a point device after the stock rail is attached to the assembly.

- This way of producing an assembly differs significantly from the known production of the switch device, in which, as described above, first the stock rail with the sliding plate and the auxiliary rail are welded together after assembly using appropriate templates, which usually causes distortion. In the case of the invention, the welding also causes a delay.

- the welding group as an assembly has only one system-relevant component, namely the sliding plate. However, this can be straightened relatively easily on a press after it has cooled, so that the required evenness of the sliding plate can be restored.

- the stock rail is preferably produced from a standard rail profile by machining.

- the cost savings resulting from this and the possibility of being able to use different grades and shapes have already been described at the outset.

- the stock rail is preferably welded to the base plate of the assembly after the aforementioned assembly has been produced and the sliding plate has been adjusted if necessary.

- the welding preferably takes place in the prestressed state of the stock rail. Since in this case no templates are required for assembly, such prestressing can be carried out without further ado.

- the stock rail is screwed to the individual support blocks provided. In order to maintain the necessary spread of the switch device, one or more filler pieces are inserted between the end face of the respective support block on the stock rail side and the stock rail or the rail web of the stock rail. After the stock rail has been precisely aligned relative to the auxiliary rail, the stock rail is then welded to the base plate, as mentioned above. The welding is thus preferably carried out in the state screwed to the support blocks.

- the aforementioned through-openings between the individual support blocks play an important role.

- the interior area of the individual components in particular the interior area of the stock rail, is accessible via the passage openings. Because of this access, the stock rail can be securely welded to the base plate on its side facing the auxiliary rail.

- the switch device according to the invention results in a construction that ensures a significantly improved flatness of the sliding plate with very exact compliance with the spread dimensions between stock rail and auxiliary rail.

- a very cost-effective construction results, since expensive special profiles are not required.

- the switch device 1 is a grooved rail switch device that is provided for a switch system.

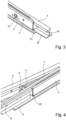

- the switch device 1 has a base plate 2 , a stock rail 3 , an auxiliary rail 4 and a slide plate 5 provided between the stock rail 3 and the auxiliary rail 4 .

- the present switch device 1 includes a switch rail 6, the switch 7 of which rests on the sliding plate 5 on the upper side.

- a plurality of support blocks 8 are arranged between the stock rail 3 and the auxiliary rail 4, on which the sliding plate 5 rests.

- the support blocks 8 are designed as separate support blocks from the stock rail 3 and the auxiliary rail 4 .

- the sliding plate 5 is only supported on the bearing blocks Bund of the side rail 4 (cf. 11 and 12 ). So there is an exclusive storage or arrangement of the sliding plate 5 on the support blocks 8 and the side rail 4 instead. There is no support on the stock rail 3

- the upper side 9 of the base plate 2 is flat and that the height of the bearing blocks 8 resting on the base plate 2 is also constant, so that the sliding plate 5 laid on the bearing blocks 8 runs parallel to the upper side 9 of the base plate 2 .

- the bearing blocks 8 and the sliding plate 5 extend in height over more than half the height of the stock rail 3 and the auxiliary rail 4, respectively, which is a characteristic of the point device of the flat bed type.

- the distance from the top of the stock rail or from the top of the stock rail to the top of the sliding plate 5 is less than half the height of the stock rail 3.

- the stock rail 3 is a standard rail profile of a standard grooved rail.

- the shape of the stock rail was produced by machining the standard rail profile. Since any standard rail profile can be used, the stock rail 3 can have any offered shape and quality. The use of a special rail profile, such as the 75C1 profile, is not necessary with switch device 1.

- the remaining components of the switch device 1 according to the invention in particular the base plate 2, the auxiliary rail 4 and also the switch rail 6 and the support blocks 8 can be made of known rail construction materials, in particular of structural steel.

- a plurality of support blocks 8 is provided.

- eight support blocks 8 are provided.

- Support blocks 8 shown in the right-hand area of the side rail 4 are at least essentially equally spaced. Only the three support blocks 8 shown on the left in the illustrated embodiment have a different spacing.

- This deviating distance results from the fact that the sliding plate 5 is divided in two in the area of an opening 10 in the side rail 4 . Due to the fact that the sliding plate 5 consists of several parts, a corresponding support via at least two support blocks 8 is required for each area of the sliding plate 5 .

- the opening 10 is used to pass through a drive element for connection to the tongue 7 of the tongue rail 6.

- the support blocks 8 each have a cuboid shape.

- the height of the individual support blocks 8 is the same in each case.

- the length of the individual support blocks 8 can be different.

- the support blocks 8 have either a rectangular or a trapezoidal shape.

- the three support blocks 8 on the left in the illustration have a comparatively small length and are approximately rectangular in shape when viewed from above. This shape results from the distance between the relevant section of the stock rail 3 and the auxiliary rail 4.

- the subsequent five additional support blocks 8 each have a trapezoidal shape, viewed from above, with the length increasing toward the right end of the auxiliary rail 4.

- the length of the support blocks 8 is determined by the distance between the stock rail 3 and the auxiliary rail 4 .

- a switch device 1 which is compared to that in 7 illustrated embodiment has a greater length, are provided correspondingly more and ends also longer support blocks 8.

- each of the support blocks 8 extends at least substantially perpendicularly away from the auxiliary rail 4 in the direction of the stock rail 3 .

- the individual support blocks 8 bear directly against the auxiliary rail 4 with their end faces facing the auxiliary rail 4 .

- a through hole 11 is provided - at least in most cases.

- Each of the through openings 11 releases a relatively large space between the associated support blocks 8 .

- the individual through-openings 11 run with their edge regions facing the respective component at least essentially parallel to the respective component.

- the individual through-openings 11 ensure access for a welding device to the interior space in order to be able to weld the stock rail 3 to the base plate 2 on the inside.

- each of the support blocks 8 has a screw opening 13 on the end face 12 facing the stock rail 3 .

- the screw opening 13 should preferably have a thread for a corresponding screw to be screwed in.

- a corresponding number of through-openings 15 are provided in the rail web 14 of the stock rail 3, through which appropriate screws can be pushed and screwed to the screw opening 13.

- filler pieces for the arrangement between the end face 12 on the stock rail side and the stock rail 3 or the rail web 14 of the stock rail 3.

- filler pieces for the arrangement between the end face 12 on the stock rail side and the stock rail 3 or the rail web 14 of the stock rail 3.

- the filler pieces should also have a through hole so that when the stock rail 3 is screwed to the support blocks 8, the filler pieces are also screwed and held securely on the screw.

- the stock rail foot 16 has a plurality of recesses for the support blocks 8 . Finally, the stock rail foot 16 is cut in the area of the support blocks 8, at most so far that the stock rail 3 can be pushed up to the end face 12 of the support blocks 8 during assembly, until the end face 12 finally comes to rest on the rail web 14.

- the base plate 2 is made from sheet metal figure 5 manufactured.

- the outer shape of the base plate 2 ultimately reflects the course of the stock rail 3 and the auxiliary rail 4 .

- the through openings 11 and various other openings 17, 18 are introduced.

- the openings 17 are used for the underside welding of the stock rail 3, the tongue rail 6 and possibly the auxiliary rail 4, while the openings 18 in the webs between the through openings 11 are used for the underside welding of the support blocks 8.

- the side rail 4 is spot-pointed on the upper side 9 of the base plate 2 .

- This state is in 6 shown.

- the support blocks 8 are then placed at the intended locations between the passage openings 11 and also scored.

- This state is in 7 shown.

- the sliding plate 5 is placed with its two sliding plate areas and also scored.

- the individual components are welded to form an assembly 19 .

- the side rail 4 is welded to the base plate 2

- the individual support blocks 8 are welded to the base plate 2 and to the end face of the side rail 4

- the sliding plate 5 is welded to the support blocks 8 and to the edge of the side rail 4.

- the assembly 19 After the assembly 19 has been created, the assembly 19 is measured. Due to the welding, there is regularly a distortion of the slide plate 5. If such a distortion is detected, the assembly 19 is straightened. In detail, after the subassembly 19 has cooled, the sliding plate 5 in particular is straightened on a press in order to restore the necessary flatness or parallelism of the sliding plate 5 to the base plate 2 .

- the stock rail 3 is produced from a standard rail profile by machining.

- the groove leg is removed, particularly in the central area of the stock rail 3 .

- the stock rail foot 16 is cut or provided with recesses for the support blocks 8, so that it is possible to place the stock rail 3 on the base plate 2 and to push it up to the support blocks 8.

- the stock rail 3 After the stock rail 3 has been appropriately aligned, it can then be screwed to the support blocks 8 .

- filler pieces are inserted at the necessary points between the end face 12 and the rail web 14 of the stock rail 3 .

- chamber plates 21, 22 are attached to the front of the stock rail 3 in order to close the assembly 20 at the front.

- the tongue rail 6 is fastened to the base plate 2.

- FIGS Figures 10 to 12 a further embodiment of the tongue device 1 is shown.

- This embodiment differs from that in FIGS Figures 1 to 9 illustrated embodiment in that a heating device 23 is provided on the auxiliary rail 4 .

- the heating device 23 which is designed as an electric heater in the present case, has a heating pipe 24 extending along the side rail 4 .

- the heating pipe 24 is made of stainless steel and extends over the entire length of the side rail 4.

- the heating device 23 is assigned a control device by means of which the operation of the heating device 23 can be controlled manually and/or automatically.

- the control device has a sensor device with at least one temperature sensor. Depending on the outside temperature and/or the temperature of the switch device, in particular the sliding plate 5, the heating device 23 is switched on and/or off.

- a recess 25 extending along the side rail 4 for receiving the heating tube 24 is provided in the side rail 4 .

- the recess 25 is located in the foot 26 of the auxiliary rail 4.

- the foot 26 is adjoined at the top by an auxiliary rail web 27 with a reduced thickness and an auxiliary rail head 28.

- the step 29 is at least substantially aligned with the upper side of the support blocks 8, so that a flat support surface for the sliding plate 5 results.

- the recess 25 has a depth which essentially corresponds to the outside diameter of the heating tube 24 .

- the cross section of the recess 25 is adapted to the shape of the heating tube 24 at least in some areas. How both out 11 as well as off 12 results, the heating pipe 24 is at least partially flat against the side rail 4 .

- the heating tube 24, in which an electrical heating conductor 30 is provided for electrical heating, is supplied at an angle ⁇ in relation to the base plate 2.

- the essential part of the length of the side rail 4, however, the heating pipe 24 runs parallel to the base plate 2 in the lower area of the side rail 4.

- the discharge of the heating pipe 24, which in 10 is not shown, can be done in the same way as in 10 shown feed, so at an angle.

- the heating pipe 24 it is also fundamentally possible for the heating pipe 24 not to be fed at an angle to the base plate 2 , i.e. for the heating pipe 24 to run parallel to the base plate 2 over the entire length of the side rail 4 .

- the recess 25 is provided on or in the side rail 4 on the side of the side rail 4 facing the stock rail 3 .

- the heating tube 24 runs at the angle ⁇ to the base plate 2, there is still material from the side rail 4 below the heating tube 24 and thus between the heating tube 24 and the base plate 2.

- the recess 25 is also provided on the underside of the side rail 4.

- the heating pipe 24 rests on the base plate 2 , rests laterally on the side rail 4 and on the support block 8 and again rests on the side rail 4 on the upper side.

- the height and width of the receiving space formed by the recess 25 have dimensions that correspond to the diameter of the heating tube 24 .

- the heating tube 24 is part of the assembly 19. This means that the relevant tongue device 1 in the same way as in the Figures 1 to 9 shown tongue device 1 is produced, but before the pointing of the support blocks 8, but at the latest before the final attachment of the support blocks 8, the heating tube 24 is inserted into the recess 25, which has previously been milled into the side rail 4.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Baking, Grill, Roasting (AREA)

Claims (16)

- Dispositif d'aiguille (1) du type à lit plat, pour un système d'aiguille, comprenant une plaque de base (2), un rail contre-aiguille (3), un rail secondaire (4) et une plaque de glissement (5) disposée entre le rail contre-aiguille (3) et la plaque supérieure (4) pour la languette (7) d'une lame d'aiguille (6),

caractérisé en ce qu'

entre le rail contre-aiguille (3) et le rail secondaire (4) est disposé une pluralité de cales d'appui (8) séparées par le rail contre-aiguille (3) et le rail secondaire (4), disposées sur la plaque de base (2), la plaque de glissement (5) s'étendant au-dessus de la pluralité des cales d'appui (8) et reposant sur la pluralité des cales d'appui (8). - Dispositif d'aiguille selon la revendication 1, caractérisé en ce que sur le rail secondaire (4) est disposé un gradin (29) sur lequel repose la plaque de glissement (5).

- Dispositif d'aiguille selon la revendication 1 ou 2, caractérisé en ce que le rail contre-aiguille (3) constitué d'un profilé de rail ordinaire en particulier un profilé de rail à gorge, est fabriqué par usinage d'ablation de matière.

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce que des cales d'appui (8) sont disposés et/ou une des cales d'appui (8) s'étendre du rail secondaire (4) au moins essentiellement à angle droit vers le rail contre-aiguille (3).

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce qu'entre deux cales d'appui (8) adjacentes est ménagé un orifice de passage (11), et en ce que, de préférence, l'orifice de passage (11) dont ses zones de bord orientées vers l'élément structural respectif, s'étend au moins essentiellement parallèlement à l'élément structural respectif.

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce qu'une des cales d'appui (8) sur la face frontale (12) orientée vers le rail contre-aiguille (3) comporte au moins un orifice de vissage (13) comportant en particulier un filetage et/ou en ce que dans l'âme (14) du rail contre-aiguille (3) est ménagé au moins un orifice de passage (15) destiné au vissage avec l'une des cales d'appui (8) et/ou en ce qu'au moins un élément de remplissage est disposé entre la face frontale (12) côté rail contre-aiguille et le rail contre-aiguille (3).

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce que le patin (16) du rail contre-aiguille comporte dans la zone d'une des cales d'appui (8) associée au moins un évidement.

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce que le rail secondaire (4) est associée à un dispositif de chauffage (23) et en ce que, de préférence, le dispositif de chauffage (23) est associé à un dispositif de commande, de préférence avec au moins une sonde de température, destinée à commander et/ou à régler le fonctionnement du dispositif de chauffage (23).

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce que le dispositif de chauffage comporte au moins un tube chauffant (24) constitué de préférence d'acier, en particulier d'acier inoxydable, s'étendant longitudinalement au rail secondaire (4) et en ce que, de préférence, le tube chauffant repose sur le rail secondaire et/ou sur au moins l'une des cales d'appui (8), la cale d'appui reposant sur le rail contre-aiguille (3).

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce que le tube chauffant (24) s'étend sur toute la longueur du rail secondaire (4) et/ou en ce que dans le rail secondaire est ménagé un évidement (25) s'étendant longitudinalement au rail secondaire (4), destiné à loger le tube chauffant (24).

- Dispositif d'aiguille selon l'une quelconque des revendications précédentes, caractérisé en ce que l'évidement (25) s'adapte dans la section transversale au moins à certains endroits à la forme du tube chauffant (24) de manière à ce que le tube chauffant (24) disposé dans l'évidement (25) repose à plat au moins à certains endroits sur le rail secondaire (4) et/ou que l'évidement (25) soit ménagé sur la face inférieure et/ou sur la face du rail secondaire (4) orientée vers le rail contre-aiguille (3) et/ou que le tube chauffant (24) repose au moins à certains endroits sur la plaque de base (2).

- Procédé de fabrication d'un dispositif d'aiguille (1) selon l'une quelconque des revendications précédentes, en particulier un dispositif d'aiguille pour rail à gorge, la plaque de glissement (5) étant disposée entre le rail contre-aiguille (3) et le rail secondaire (4), entre le rail contre-aiguille (3) et le rail secondaire (4) est disposée la pluralité de cales d'appui (8) séparées par le rail contre-aiguille (3) et le rail secondaire (4), reposant sur la plaque de base (2), la plaque de glissement (5) s'étendant au-dessus de la pluralité des cales d'appui (8) et sur la pluralité de cales d'appui (8), caractérisé en ce qu'en premier lieu la plaque de base (2), au moins une des cales d'appui (8), le rail secondaire (4) et la plaque de glissement (5) sont soudées ensemble au module (19).

- Procédé selon la revendication 12, caractérisé en ce que la plaque de glissement (5) est redressée avant la liaison du module (19) au rail contre-aiguille (3).

- Procédé selon la revendication 12 ou 13, caractérisé en ce que le rail contre-aiguille (3) constituée en profilé de rail ordinaire est fabriqué par usinage d'ablation de matière.

- Procédé selon l'une des revendications 12 à 14, caractérisé en ce que le rail contre-aiguille (3) doté de la plaque de base (2) du module (19) est soudé à un ensemble (20) et en ce que, de préférence, le rail contre-aiguille (3) est précontraint pour le soudage.

- Procédé selon la revendication 12, caractérisé en ce que le rail contre-aiguille (3) avant le soudage à la plaque de base (2) est vissé à au moins l'une des cales d'appui (8) et en ce que, de préférence, entre la cale d'appui (8) et le rail contre-aiguille (3) est inséré au moins un élément de remplissage pour respecter l'ornière.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016001631.0A DE102016001631A1 (de) | 2016-02-15 | 2016-02-15 | Zungenvorrichtung, insbesondere Rillenschienen-Zungenvorrichtung und Verfahren zur Herstellung einer Zungenvorrichtung |

| DE202016002305.6U DE202016002305U1 (de) | 2016-02-15 | 2016-04-12 | Zungenvorrichtung, insbesondere Rillenschienen-Zungenvorrichtung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3205770A1 EP3205770A1 (fr) | 2017-08-16 |

| EP3205770B1 EP3205770B1 (fr) | 2018-08-22 |

| EP3205770B2 true EP3205770B2 (fr) | 2023-03-08 |

Family

ID=56133134

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17000227.3A Active EP3205770B2 (fr) | 2016-02-15 | 2017-02-14 | Aiguillage et procédé de fabrication d'un tel aiguillage |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3205770B2 (fr) |

| DE (2) | DE102016001631A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3062402B1 (fr) * | 2017-01-30 | 2020-01-31 | Societe D'equipement Industriel. Lietaert - Sei.L | Procede pour fabriquer une cale d'aiguillage. |

| DE102017129825A1 (de) * | 2017-09-19 | 2019-03-21 | Voestalpine Bwg Gmbh | Zungenvorrichtung |

| LU101697B1 (fr) * | 2020-03-17 | 2021-09-17 | Vossloh Cogifer Sa | Ensemble pour appareil de voie |

| DE102020002392A1 (de) | 2020-03-23 | 2021-09-23 | Riecken Maschinenbau Gmbh | Zungenvorrichtung und Verfahren zur Hrstellung einer Zungenvorrichtung |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE469939C (de) † | 1928-12-29 | Both & Tilmann G M B H | Strassenbahnweiche | |

| DE493589C (de) † | 1930-03-08 | Gutehoffnungshuette Oberhausen | Zungenlagerung fuer aus Schienen zusammengebaute Weichen | |

| DE1898454U (de) † | 1964-05-02 | 1964-08-13 | Schreck Mieves K G | Zungenvorrichtung fuer im pflaster liegende weichen. |

| DE4447926B4 (de) † | 1994-10-27 | 2006-08-31 | Bwg Gmbh & Co. Kg | Oberbau-Zungenvorrichtung |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE552276C (fr) * | ||||

| DE835010C (de) | 1950-12-28 | 1952-03-27 | Stahlwerk Osnabrueck A G | Zungenvorrichtung fuer Strassenbahnweichen |

| DE3343239C1 (de) * | 1983-11-30 | 1985-05-30 | Elektro-Thermit Gmbh, 1000 Berlin | Zungenvorrichtung fuer Rillenschienenweichen |

| DE3904026A1 (de) | 1989-02-10 | 1990-08-16 | Magna Holding Anstalt | Gleiteinlage fuer geschlossene zungenvorrichtungen wie auch fuer gleitflaechen fuer bewegliche herzstueckspitzen, sowie verfahren zum befestigen einer derartigen gleiteinlage an dem gleitbett von rillenschienenzungenvorrichtungen |

| ES2068424T3 (es) | 1991-05-25 | 1995-04-16 | Kihn | Cambio de via para carriles con garganta. |

| DE19825792A1 (de) | 1998-06-10 | 1999-12-16 | Schreck Mieves Gmbh | Oberbau-Zungenvorrichtung |

| DE19920858C2 (de) | 1999-01-15 | 2003-02-27 | Schreck Mieves Gmbh | Oberbau-Zungenvorrichtung |

| AT410330B (de) * | 1999-04-27 | 2003-03-25 | Vae Ag | Zungenkasten für rillenschienenweichen |

| DE19922211A1 (de) | 1999-05-14 | 2000-11-16 | Butzbacher Weichenbau Gmbh | Abstützung für eine erste Schiene wie Zungenschiene |

| DE102004048751B3 (de) | 2004-08-11 | 2005-12-29 | Schreck-Mieves Gmbh | Zungenvorrichtung |

| FR2952655B1 (fr) | 2009-11-19 | 2012-01-13 | Vossloh Cogifer | Dispositif de fixation d'un rail contre-aiguille a un appareil de voie, tel qu'un bloc de demi-aiguillage compose d'un assemblage de rails |

-

2016

- 2016-02-15 DE DE102016001631.0A patent/DE102016001631A1/de not_active Ceased

- 2016-04-12 DE DE202016002305.6U patent/DE202016002305U1/de active Active

-

2017

- 2017-02-14 EP EP17000227.3A patent/EP3205770B2/fr active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE469939C (de) † | 1928-12-29 | Both & Tilmann G M B H | Strassenbahnweiche | |

| DE493589C (de) † | 1930-03-08 | Gutehoffnungshuette Oberhausen | Zungenlagerung fuer aus Schienen zusammengebaute Weichen | |

| DE1898454U (de) † | 1964-05-02 | 1964-08-13 | Schreck Mieves K G | Zungenvorrichtung fuer im pflaster liegende weichen. |

| DE4447926B4 (de) † | 1994-10-27 | 2006-08-31 | Bwg Gmbh & Co. Kg | Oberbau-Zungenvorrichtung |

Also Published As

| Publication number | Publication date |

|---|---|

| DE202016002305U1 (de) | 2016-06-01 |

| EP3205770B1 (fr) | 2018-08-22 |

| EP3205770A1 (fr) | 2017-08-16 |

| DE102016001631A1 (de) | 2017-08-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3205770B2 (fr) | Aiguillage et procédé de fabrication d'un tel aiguillage | |

| EP1135616A1 (fr) | Assemblage en t de deux barreaux profiles | |

| DE1146238B (de) | Hohle Bautafel aus Kunststoff und Vorrichtung zum Herstellen der Tafel | |

| EP1643049B1 (fr) | Construction avec profilés porteurs | |

| DE2648025A1 (de) | Vorgefertigte isolierende platte sowie anlage fuer deren kontinuierliche herstellung | |

| EP0904463A1 (fr) | Dispositif pour fixer la position de corps moules d'un passage a niveau sur des voies ferrees | |

| DE19920858C2 (de) | Oberbau-Zungenvorrichtung | |

| DE4102565A1 (de) | Plattenartiges metallelement fuer eine elektrische widerstandsgittervorrichtung | |

| EP1346814B1 (fr) | Dispositif de calibration | |

| DE69900609T2 (de) | Wärmedämmender Baublock | |

| WO2007088072A1 (fr) | Liaison entre le cote frontal d'un tube en matiere synthetique et un corps en matiere synthetique | |

| EP1803548A1 (fr) | Plaque chauffante pour presse à plateaux | |

| DE2729938C3 (de) | Doppelbandpresse zum Herstellen von Preßplatten | |

| EP3219895A1 (fr) | Système de porte coulissante et vantail coulissant d'un système de porte coulissant | |

| DE4438393A1 (de) | Verfahren zum Verschweißen je zweier benachbarter Platten eines Plattenwärmeaustauschers sowie nach dem Verfahren hergestellter Plattenwärmeaustauscher | |

| DE102018115382B4 (de) | Verbinden von Blechendabschnitten mittels Umformen | |

| EP3307653B1 (fr) | Grille destinée en particulier à être utilisée en tant que tablette pour des rayonnages à plaques ou des rayonnages pour charges lourdes | |

| DE102015108299B4 (de) | Steckbarer Gitterrost | |

| DE19525135C2 (de) | Dehnungsstoß | |

| DE3123296C2 (de) | Stromentnahmeschiene | |

| DE10223895C1 (de) | Plattenklemmvorrichtung | |

| EP1698736B1 (fr) | Façade et méthode de construction de façade | |

| EP1430973B1 (fr) | Procédé d'emboutissage, outil d'emboutissage et élément profilé | |

| EP1048903B1 (fr) | Raies de fixation pour tubes de chauffage par le sol ansi que procédé et appareil pour manufacturer les raies | |

| DE2720127B2 (de) | Verfahren und Werkzeug zum Herstellen eines Heizkörpers mit mindestens einem profilierten Konvektorblech |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20170829 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HEINRICH KRUG GMBH & CO. KG Owner name: KUENSTLER BAHNTECHNIK GMBH Owner name: RIECKEN MASCHINENBAU GMBH |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E01B 7/02 20060101AFI20180321BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20180430 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1032664 Country of ref document: AT Kind code of ref document: T Effective date: 20180915 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017000115 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180822 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181122 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181123 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181122 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181222 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502017000115 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: VOESTALPINE VAE GMBH Effective date: 20190520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190214 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190228 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190228 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181222 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: VOESTALPINE RAILWAY SYSTEMS GMBH Effective date: 20190520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20170214 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180822 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20230308 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502017000115 Country of ref document: DE |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230613 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20240220 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240220 Year of fee payment: 8 Ref country code: CH Payment date: 20240301 Year of fee payment: 8 |